Energy Security, Initiative Few Options.

advertisement

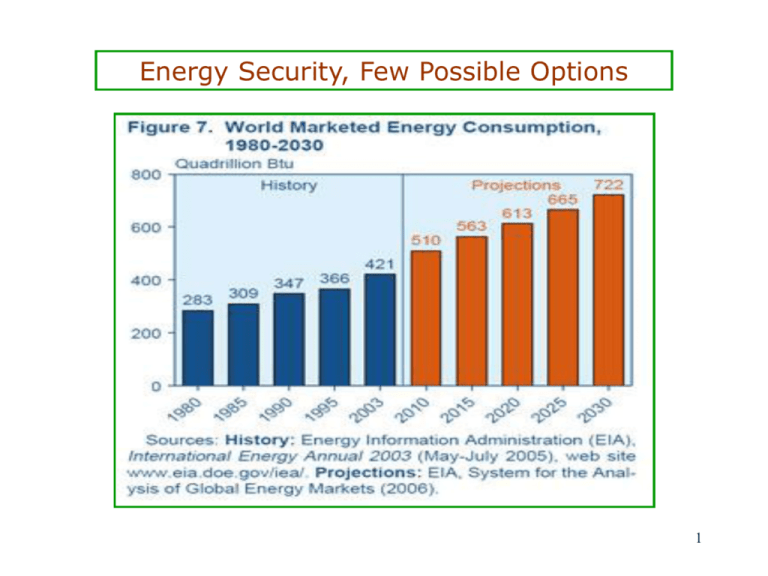

Energy Security, Few Possible Options 1 Energy Security, Few Possible Options 2 Energy Security, Few Possible Options 3 Energy Security, Few Possible Options Global Energy Demand • Global energy demand is projected to grow by 1.6 percent annually, on average, from 2000 and 2030 -- resulting in a 60 percent increase from 2000 to 2030. • Energy demand is projected to grow fastest in the developing world (NonOECD) in the coming decades, accounting for around 80 percent of the global increase. • Global population will grow to approximately 8 billion in 2030 from about 6.5 billion today, with close to 95 percent of the increase occurring in the developing world. • The world's economy is projected to grow at an annual rate of 2.8 percent through 2030, doubling in size from 2000. • Fossil fuels will continue to provide approximately 80 percent of global energy supplies in 2030, according to the U.S. Energy Information Administration and the International Energy Agency. • Total transportation demand for liquids in 2030 is expected to increase by 50 percent from today. 4 Energy Security, Few New Initiatives 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Marginal & Stripper Wells re-vitalization programme in the US. Use of reversible surfactant to improve oil recovery. New technology to produce concentrated CO2 for EOR from green power plants. Transportation of gas from marginal fields as gas hydrates. Power from not-so-hot geothermal. Abundant power from universal geothermal. Tidal turbines. Giant wind turbines. Algae-based fuels. Making Gasoline from Carbon Dioxide. 5 1. Marginal & Stripper Wells Re-vitalization programme (USA) Stripper wells < 10 bpd (o), 60 MCF/d (g). Abandonment results in: Loss of production/reserves. Re-access cost prohibitive USA stripper well position. • • • • • Oil wells : 393,000 0.86 mmbpd (15%) Gas wells : 260,000 1.5 TCF/Y (8%) P&A during 1994-2003 : 142,000 wells Estimated loss, oil revenue - $3.8 billion (at 2004 avg price) oil reserves – 110 million bbls US initiatives to keep stripper wells on production . o o o o Industry driven Stripper Well Consortium (SWC) – 100 members. Projects chosen by industry for improving production & extending reservoir life. Collaboration with Pennsylvania State University. DoE assisted programmes – 30% funding from participants. 6 1 (Contd.) Marginal & Stripper Wells Re-vitalization programme (USA) Few ready-to-use new technologies thru SWC. Gas operated automatic lift pump. • • • • An automatic plunger lift tool to remove fluids from stripper wells. Operates automatically using on-tool pressure activated valve. Needs no external energy. Low maintenance and service requirement. Vortex flow tools. Creates vortex flow regime to accelerate velocity of water and reduces pipe friction. Prevents water build-up in low spots of gas gathering and well flow pipelines, reducing back pressure on well head. Another vortex tool installed at tubing bottom, reduces pressure drop up the tubing string, cutting down gas needed for lifting. • • • Hydraulic Diaphragm Electric Submersible pump. Versatile pump for installation below perforations in sandy wells. Can handle fines, gas/liquid mixtures, variable oil viscosity. Highly efficient with reduced electrical power requirement. • • • Weather bee pump with/without Vacuum & Compressor. Variable capacity compressor/pump for low productivity gas wells. Lower initial and operating costs. Can handle high BTU gas/water. 7 1 (Contd.) Marginal & Stripper Wells Re-vitalization programme (USA) Few ready-to-use new technologies thru SWC Chemical injector for plunger lift gas wells. • • • Plunger conveyed chemical system. Reduces well bore corrosion and maintenance Cost. Simple, economical system that can be installed in 15 minutes without any spl tools. Low cost real-time down hole wireless gauge. • Eliminates cables, clamps, splices inside well bore • • • • Increased reliability, reduced cost and time saved for deployment in wells. Currently monitors pressure and temperature, but additional features can be added. Can be used for build-up tests to optimize production and recovery. Can be used in permanent and service applications. . 8 (2) Reversible surfactant for Improved Oil Recovery (IOR) • Surfactant flooding, a known method of IOR to flush out oil from the reservoir. • Production increase can be as much as 28% when pumped with water into reservoir. • Creates a major problem to separate water coming out as oil-water emulsion. Complicated and expensive, needing other chemicals and heat. • Researchers at Queens University, Ontario, Canada have found an improved surfactant, a type of amidine, which can be switched off and on using CO2 and Air. • Can recover and re-use the surfactant. • At oil prices above $20%, this has now become very attractive. • Surfactant shows promise to work almost in all oil fields, including the oil sands of Canada. • According to Gary Pope, Director, Center for Petroleum Geosystems Engg, Univ of Texas, Austin, surfactant injection is “one of the hottest EOR methods at the moment and increasing exponentially”. 9 (3) CO2 for Enhanced Oil Recovery (EOR) from Green Power Plants. • North sea emerging as a center of development of carbon capture and storage technology. • Oil production slowing down in many fields. • Depleting oil reservoirs offer a place to store from fossil fuel power plants and also to increase oil production - CO2 flooding being an effective EOR option, though not in wide application for want of large quantities of CO2 at affordable price. • Several oil giants like BP, Shell and Statoil recently announced plans to build new power plants to convert North Sea Natural Gas into Hydrogen, burn the Hydrogen to produce electricity, and ship the resulting CO2 to pump into offshore fields. • BP expects to produce extra 40 mmbbls of oil production between 2010 when the plant starts and 2030. • As per recent study, North Sea oil fields can produce an additional 7.3 Billion bbls and at the same time store 10 Billion tonnes of CO2. • Norwegian Company, Sargas is building a coal-fired (also gas, but both at high pressure) power plant in Norway that will produce power and CO2 under pressure. They plan to sell CO2 to offshore fields. Their estimates is CO2 delivered at the platforms at $ 20/tonne and each tonne should yield 2-3 extra bbls of oil. 10 (4) Transportation of gas as Gas Hydrates Large number of small fields globally are not developed for economic reasons as piping costs of gas is prohibitive. Such unutilized gas reserves may be about 40% of world reserves. Mitsui Engineering & Shipbuilding company (MES), in association with Osaka University, is developing technology to convert small volumes of gas to Natural Gas Hydrates (NGH) for transportation. NGH is palletised to increase its stability, storing efficiency, and ship loading/unloading efficiency. A 600 KG/day plant of NGH has been built and tested for continuous operation. In comparison with the conventional Liquefied Natural Gas (LNG) which is produced and stored at extremely low temperature of -162°C , the production cost for NGH is much lower as it needs only -20°C at atmospheric pressure. Though transportation amount per unit energy of NGH is more than that of LNG, the total cost of NGH system including production, storage, transportation and gasification therefore is much cheaper than that of LNG. MES has developed all the components of the value chain, i.e. for NGH manufacture, road and ocean transportation, re-gasification etc. Physical properties of NGH and LNG; NGH LNG Modes of transport & storage Temperature to be maintained Gravity Content of Natural Gas (in 1 M3) Solid -20°C 0.85-0.95 170 NM3 Possible applications; Remote gas/oil fields. Cluster of consumers away from City Gas facility. Peak demands of power plants. Liquid -162°C 0.42-0.47 600NM3 11 (4) NGH System Makes the Development of Small Unutilised Gas Fields Possible (contd.) • There are a lot of small gas fields in the world, which are not presently developed for economical reason, and their associated gas is not almost used either. The total of such unutilised gas resource is estimated about 40% of all natural gas reserve in the world. As a means of developing such unused natural gas reserve, which is no small amount, NGH is expected to play a big role. NGH is also available for small amount transportation of natural gas from large gas field for short distance. Offshore Gas Field Development by NGH-FPSO 12 (4) NGH brings the clean Natural Gas closer to home. (contd.) • NGH can be utilized for other various purposes. The boil-off gas generated during the storage of LNG and/or bio-gas coming out from garbage etc. can be processed into NGH for delivery to the area where the city gas service is not available. Natural gas can be efficiently utilized by a small cargo delivery system of NGH. Overland Transportation of NGH by a Reefer Truck 13 (4) MES Gets a Huge Lead on the Development of NGH Technologies (contd.) MES Gets a Huge Lead on the Development of NGH Technologies. • MES, under the subsidy of the New Energy and Industrial Technology Development Organization (NEDO), has completed a NGH production plant of 600 kg/day capacity and had successful operations of continuous high-speed production of NGH. Besides, MES has built, in collaboration with National Institute of Advanced Industrial Science and Technology and the University of Osaka, a process plant for palletising, transportation, storage and high pressure regasification of NGH in mass as a joint study project with Japan Oil, Gas and Metal National Corporation and successfully achieved a continuous regasification of NGH under high pressure in mass. Those successful achievements have proved that the NGH can be utilized for various business fields of transportation and storage of natural gas. NGH High Pressure Re-gasification Demonstration Plant 14 (4) MES has developed NGH carrier and established Ocean Transport Chain of NGH (contd.) • MES, in collaboration with National Maritime Research Institute and the University of Osaka, has developed NGH carrier. The carrier is supposed to transport NGH from a small overseas gas field at -20°C, and for better performance in handling of cargo, and to enhance preservation effect, NGH is palletised. NGH Carrier 15 Complete NGH System 16 (5) Power from not-so-hot Geothermal • Geothermal power normally derived from sources higher then 300ºF , which are deep underground. • United Technologies Research Center in east Hartford, CT has developed a low-cost system to utilize low-temperature geothermal source. • The modular 200 KW pilot plant has following features: Can convert temperatures as low as 165ºF to electricity. Similar to steam engines. Hot water vaporizes a Hydroflurocarbon refrigerant, which drives a turbine. Refrigerant has lower boiling point than water. New turbine is essentially a refrigerator compressor running backwards. • • Can be used to capture power from hot formation water produced in oil fields. Texas alone produces 12 Billion bbls of hot water, which is discarded by reinjection. • Demonstration plants are planned in Texas and Nevada to try out . The power generated can be used in the oil fields to run pumps for the producing wells. 17 (6) Abundant Power from Universal Geothermal Energy Pioneering studies initiated by Prof. Jefferson Tester of MIT. Geothermal can be much more widespread by making artificial reservoirs to harvest the earth’s heat. There is need to create porosity and permeability, also good connectivity between a set of injection wells and a set of production wells, with the sweep fluid, water. New oil field technologies like deep drilling, stimulation/fracturing, multi- laterals etc can be used for deep heat mining. Prof. Tester calls it “ Universal Geothermal”, energy because reservoir can be located wherever necessary, such as power-hungry cities worldwide. Prof. Tester Estimates: • • • Current world energy consumption 400 Quads (Quadrillion BTU). Potential Geothermal Energy 100 million Quads. If only, 1/10th of 1% comes out, it will be 100,000 Quads (Equiv. to 250 years of current global energy consumption). Minimal impact on environment. Further studies however required but seem doable. • • 18 (7) Tidal Turbines Electric Power Research Institute, Palo Alto, CA an industry R&D consortium in US are upbeat about this possibility. Lessons learnt from wind turbines have helped. First major project with 6 submerged turbines, each of 35 KW, are being installed near New York City to capture energy from East River’s Tidal currents. 3-Bladed Turbines, 5 mtrs in Dia and resemble wind turbines, made by Verdant Power of Arlington, VA. Installation of a farm of 100 turbines is anticipated at the East River site. Federal Energy Regulatory Commission, Washington has issued preliminary permits for 25 sites and another 31 under consideration. Few Tidal Turbines already on operation. 240 MW – LaGrange Barrage in Normandy. 20 MW – Bay Fundy in Nova Scotia, Halifax. 300 KW – Devon, UK. 19 (8) Giant Wind Turbines Huge turbines mounted on floating platforms offshore using composite fibers and alternatives to weighty gear boxes. Can be placed far from shore to avoid objections farms near the shore ( visual pollution ). Use of “tension –leg” platforms and sensor-based technology to quickly angle the blades in response to wind-speed changes is being considered for installation far out in the sea, may be at even 50m Water Depth. GE in a $27 Million partnership with DoE developing 5-7 MW turbines by 2009. – Going up to 10 MW by 2015. Technical Challenges: Mounted to towers 90-95 mtrs high. Rotors – 140 mtrs Dia. Needs higher reliability because of maintenance problem offshore. MIT study reveals large turbines far offshore will be more cost effective than land based and near-offshore turbines, despite extra costs and cabling. GE estimates that 20% of US energy will come from such large wind turbines by the next decade. from residents to large wind 20 (9) Algae Based Fuels Algae makes oil naturally, Raw Algae can be processed to make bio-crude, the renewable equivalent of petroleum. This can be refined to make gasoline, diesel, jet fuel and chemical feed stocks for plastics and drugs. Can be processed in existing oil refineries to make similar bi-products. Algae can be : Grown in open ponds. Grown on marginal lands using water from saline aquifers. Some types can produce oil up to 60% of their weight. Produce far more oil per acre than soyabeans, a source of oil for bio-diesel. Past studies at National Renewable Energy Laboratory (NREL) , USA terminated in 1996 without conclusion mainly because of low oil price. Recent studies initiated in Sandia National Laboratories in Albuquerque, NM. Observations of Kathe Andrews Cramer, lead researcher for bio fuels and bio energy: “ Algae have the potential to produce a huge amount of oil”. “We could replace certainly all of our diesel fuel with algal-derived oils, and possibly replace a lot more than that”. Observations of Lissa M. Jones, CEO of Live Fuel, Menlo Park, CA, “Clearly it (producing fuel from Algae) can be done. The only question is whether we can do it cheaply. And the only way we are going to find out, crank it through, spend some millions on it, and make it happen”. 21 (10) Making Gasoline from Carbon Dioxide Researchers at University of California, San Diego (UCSD) have recently demonstrated that; Light absorbed and converted into electricity by silicon electrode can cause a reaction that converts CO2 into CO and O2. CO is a valuable commodity chemical for making; Plastics, syngas (mixture of CO & H2), methanol and gasoline. Converting CO2 to CO is difficult . Hence the UCSD work is considered interesting and exciting. System shows many promises: Use of CO2 (leading greenhouse gas) as a feedstock and not an end product. Making Plastics from greenhouse gases than making tons of greenhouse gases in the process. UCSD system shows feasibility of using Solar Energy to make CO and then together with H2, can be converted to gasoline. Today CO is made from natural gas and coal. CO2 is more attractive, cheaper and many companies will even pay to get rid of it. Use of catalyst-coated nanoparticles to increase surface area to speed up reactions, may be necessary for large scale application. Prof. Clifford Kubiak, at UCSD says that commercial system may take another 10 years to develop fully. 22 Meeting the Supply-Side Challenges Improved efficiency of energy use. Enhancing fossil fuel reserves & production. Sequestering carbon. Develop emerging fossil fuels like gasification/liquefaction, gas hydrates. CBM, coal Expanding non-fossil sustainability. long term fuel energy for 23 Energy Security, Few Possible Options Two Important Statements from the Emerging Technology Conference at MIT in September 2006 “Global Warming is going to transform the lives of every single person in this room. Within 20 years, if not 5 years, it will become the issue, the only issue. It will require massive redirection of capital”. --- Mr. Joseph Romm Former Assistant Secretary, US Department of Energy and founder of Center for Energy & Climate Solutions “The question has become one of risk management. If we do not cure cancer, the world will stay the same. If we do not cure AIDS, the world will stay the same. But if we do not solve this problem in the next 20 years from a scientific viewpoint, the world is not ever going to be the same”. --- Mr. Nathan S. Lewis Professor of Chemistry California Institute of Technology 24 THANK YOU. 25