ISyE Courses - Data Collection Form2

advertisement

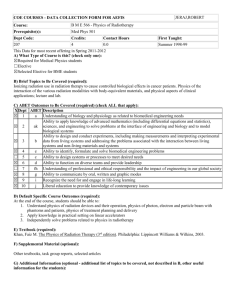

COE Courses - Data Collection Form for AEFIS Course: Prerequisite(s): Dept Code: 490 I SY E 313 - Accounting Analysis for Engineering So st Credits: 5 Contact Hours 3.3 First Taught: Fall 1986-87 This Data for most recent offering in Spring 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required) : Financial accounting principles and cost systems, interpretation and use of accounting reports and supplemental information for engineering economic analyses, consideration of cost-volume-profit analyses, use of discounted cash flow techniques, flexible budgeting, transfer pricing, and capital budgeting. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): Apply a systematic process to making economic decisions. Understand the major capabilities and limitations of discounted cash flow analysis for evaluating investments. Be able to recognize, formulate, and analyze cash flow models. Understand the assumptions underlying these models, and the effects on the modeling process when these assumptions do not hold. Understand how to use Excel to address complex economic decisions. Be able to communicate the results of the modeling process to management and other non-specialist users of engineering analyses. E) Textbook (required): Newnan Lavelle, Eschenbach. Engineering Economic Analysis, Eleventh Edition. Oxford University Press, 2012. F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Economic decision making, cost estimation and cash flows, time value of many, nominal and effective interest, equivalence of cash flows, moment diagrams, present worth analysis, annual worth analysis, rate of return analysis, future worth, estimation and uncertainty, decision trees, depreciation, tax analysis, inflation, cost of capital and public sector analysis, financial planning and investing MANN,TERRY M COE Courses - Data Collection Form for AEFIS Course: Prerequisite(s): I SY E 315 - Industrial Engineering Control Systems Design Comp Sci 302 & Stat 311 Dept Code: 490 Credits: 3 Contact Hours 3.3 First Taught: Fall 1976-77 This Data for most recent offering in Spring 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required) : Techniques and applications of control concepts in the design of inventory, production, quality, and project-planning systems; use of the computer as a component in such systems. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): To gain an understanding and appreciation of the fundamental principles and methodologies relevant to planning, design, operation, and control of World-Class Productive systems. To gain an understanding of the role and importance of productivity in the welfare of society, and learn how to increase productivity and quality for competing in today’s global marketplace. To reinforce analytical skills, and build on these skills to further increase student portfolio of analytical tools. To gain some ability to recognize situations in a production system environment that suggest the use of certain quantitative methods to assist in decision-making. To learn how to think about, approach, analyze, and solve production systems problems using both technology and human skills. To increase knowledge and broaden perspective of the new world in which you contribute your talent and leadership as an Industrial Engineer. E) Textbook (required): Chase, Jacobs, Aquilano. Operations and Supply Management w/Student DVD Rom 12 th Edition. McGraw-Hill Higher Education. F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Operations management, operations and supply strategy, product management, job design and work measurement, M.O.S.T., factor analysis, statistical process control, TQM and six sigma, supply chain strategy, lean manufacturing, aggregate planning, inventory control, material requirements planning, constraint management BIER,VICKI M COE Courses - Data Collection Form for AEFIS Course: Prerequisite(s): Dept Code: 490 I SY E 320 - Simulation and Probabilistic Modeling Stat 311 or equiv Credits: 3 Contact Hours 2.5 First Taught: Spring 1997-98 This Data for most recent offering in Spring 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required) : Analysis of stochastic systems using both analytic methods and computer simulation. Empirical and theoretical models of arrival and service processes. State spaces and state transition probabilities. Simulation of queuing and manufacturing systems. Continuous time Markov analysis of manufacturing systems. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): Understand the stochastic nature of real systems. Learn modeling techniques and tools for stochastic systems. Be able to use simulation software tools to model a system and to estimate performance measures of the system. Be able to present the results of the modeling process to users in a non-technical presentation. E) Textbook (required): Banks, Carson, Nelson, and Nicol. Discrete-Event System Simulation, Fourth Edition (Prentice-Hall, 2005). F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Probability, Random Number Generation, Input Analysis, Poisson Process, Introduction to Queues, Discrete Time Markov Chain, Continuous Time Markov Chain, Queueing Theory, Verification and Validation, Little’s Law, Output Analysis, Comparing Systems, Variance Reduction BIER,VICKI M COE Courses - Data Collection Form for AEFIS Course: Prerequisite(s): Dept Code: 490 I SY E 321 - Simulation Modeling Laboratory Con reg in IE 320 or cons inst Credits: 1 Contact Hours 0.8 First Taught: Spring 1997-98 This Data for most recent offering in Spring 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required) : Computer exercises involving generation and analysis of random variables, spreadsheet models of queuing systems, use of simulation software packages. Project. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): To gain hands-on experience in the use of simulation tools. E) Textbook (required): Simulation with Arena, by W. David Kelton, Rondall, P. Sodowski, & Nancy B. Swets, The McGraw-Hill Companies F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Spreadsheet Fundamentals, Spreadsheet Simulation, Basic Process Modeling, Modeling Basic Operations and Inputs, Decide and Assign Module, Resource Schedules, Set, Output Analysis, Entity Transfers, Small Manufacturing Systems COE Courses - Data Collection Form for AEFIS LINDEROTH,JEFFREY T Course: I SY E 323 - Operations Research Techniques I Prerequisite(s): IE 313, Math 222, and either Math 320 or 340 Dept Code: 490 Credits: 4 Contact Hours 3.3 First Taught: Fall 1976-77 This Data for most recent offering in Spring 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required) : Basic techniques for modeling and optimizing deterministic systems with emphasis on linear programming. Computer solution of optimization problems. Applications to production, logistics, and service systems. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): Write down an algebraic formulation of an optimization model that captures the main decision elements of practical problems. Model a variety of basic problems as optimization models using Excel, and to solve them using Excel Solver. Obtain experience in using an algebraic modeling language to model practical, large-scale problems. Understand the simplex method for linear programming. Understand the relationship between a linear program and its dual, including concepts such as complementary slackness and strong duality. Perform sensitivity analysis to understand how changes in the problem’s input impact the optimal solution output. Understand the importance of networks for modeling many operations research problems. Perform simple network optimization algorithms. Understand how to model advanced logical constraints using integer decision variables. Understand the branch-and-bound algorithm used in discrete optimization. Understand the impact of convexity on an optimization instance’s complexity. E) Textbook (required): Frederick Hillier, Gerald Lieberman. Introduction to Operations Research, Ninth (McGraw-Hill, 2005). F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Linear Programming, Analysis of Linear Programming Solutions, Discrete Models, Nonlinear Programming WIEGMANN,DOUGLAS A COE Courses - Data Collection Form for AEFIS Course: Prerequisite(s): Dept Code: 490 I SY E 349 - Introduction to Human Factors Intro Probability or Statistics Credits: 3 Contact Hours 3.3 First Taught: Fall 1976-77 This Data for most recent offering in Spring 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required) : Design for people-machine interaction, including an introduction to the relevant underlying human sciences. Theory, data, and measurement problems in human information processing, anthropometry, training and industrial safety. Laboratories, discussions, and a design project. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): To understand how people fit into technological systems, recognize the limits of human perceptual-motor capabilities, recognize the limits of human cognitive functioning and why people make errors, be able to assess workstation and task design for ergonomic deficiencies, be able to define safety hazards and general approaches for their control, recognize the human indicators of fatigue and stress, appreciate the importance of organization and job design factors for performance and satisfaction, be able to define the ethical application of human factors in designing products and processes, able to write reports that describe human performance. E) Textbook (required): Wickens, C. D., Lee, J. D., et al. (2004). An Introduction to Human Factors Engineering (2nd ed.). Prentice Hall. Norman, D (2002). The Design of Everyday Things. Basic Books. F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): History of human factors and ergonomics, macro and cognitive ergonomics, physical ergonomics, macroergonomics, and engineering ethics, COE Courses - Data Collection Form for AEFIS Course: Prerequisite(s): I SY E 415 - Introduction to Manufacturing Systems, Design and Analysis Ind Engr 315, 320, 321; or cons inst Dept Code: 490 Credits: 3 Contact Hours 3.3 First Taught: Spring 1990-91 This Data for most recent offering in Spring 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required) : Introduction to the technologies, processes and systems of modern discrete part manufacturing. Emphasis on development of an understanding of the behavior of integrated systems. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): To provide an introduction to the design and analysis of manufacturing systems. The course will develop students’ knowledge in three areas: manufacturing processes and computer-integrated manufacturing systems, manufacturing system design and analysis, and modern manufacturing management strategies. E) Textbook (required): No textbook, reference books and video tapes are kept on reserve in the library F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Introduction to materials and engineering drawing. Steel making. Turning Operations. Milling Operations. Sheet Metal Operations. Casting and Heat Treatment. Plastics. Non-conventional manufacturing processes. Semiconductor manufacturing and circuit board assembly. Evolution of manufacturing systems. Inventory Models. MRP,JIT and Kanban. Flexible manufacturing systems. Assembly line and balancing. Recent Manufacturing strategies. Dynamics of manufacturing systems. Performance evaluation of manufacturing systems. Problems facing traditional accounting systems. Activity-based costing. Justification of manufacturing systems. MONTAGUE,ENID N COE Courses - Data Collection Form for AEFIS Course: Prerequisite(s): Dept Code: 490 I SY E 417 - Health Systems Engineering IE 313, 320, 323 & 349, or cons inst Credits: 3 Contact Hours 3.0 First Taught: Spring 2005-2006 This Data for most recent offering in Spring 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required) : Introduction to the application of industrial engineering methods to the analysis and improvement of health care delivery. Examination of social, regulatory and economic factors unique to health care. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): Analyze the context and components of the health care delivery systems in the US. Select and critically evaluate the utility of key industrial and systems engineering concepts and tools for assessing and modeling health care problems and challenges in health care delivery. Demonstrate the use of ISE techniques in solving selected health care delivery problems. Evaluate the roles of industrial and systems engineers in health care. E) Textbook (required): No required textbook, however readings from: Shi, L and Singh, D (2005). Delivering health care in America: A systems approach. Jones & Bartlett. Reid, P. P., Compton, W. D., Grossman, J. H., and Fanjiang, G. Editors, (2005). Building a Better Delivery System: A New Engineering/Health Care Partnership. Institute of Medicine, National Academy of Sciences. F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Health Systems Engineering, Systems Analysis in Health Care, Health Care from an industrial perspective implications for ISyE, Financing & Payment Systems, Information and Communication Systems, Current Problems and Prognosis in Health Care, Medical Decision Making, Quality in Health Care, Future Health Care, Estimating Demand for Health Services, Acces to Care, Cost-effectiveness & Cost Benefit Analysis COE Courses - Data Collection Form for AEFIS Course: Prerequisite(s): Dept Code: 490 VEERAMANI,DHARMARAJ I SY E 476 - Industrial Engineering Design Ind Engr 320, 321, 349; EPD 397; or cons inst Credits: 3 Contact Hours 2.5 First Taught: Fall 1976-77 This Data for most recent offering in Spring 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required) : Complete design of an industrial engineering system in a real world setting, e.g., manufacturing, hospital, communications, food processing, distribution, transportation, etc. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): To identify a client's problem, define a scope of work, investigate how others have solved similar problems, apply I.E knowledge to formulate a project plan, collect data to address the scope of work, design a problem solution, prepare a final report, present progress and final reports. E) Textbook (required): Not textbook, all required material is on the course webpage F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Problem identification and scope of work development, Investigate how others have solved similar problems and give a progress report to class, Apply I.E knowledge to formulate a scope of work and project plan, Collect data and design a problem solution, Prepare a final report, Submit final report to client and instructor ZHOU,SHIYU COE Courses - Data Collection Form for AEFIS Course: Prerequisite(s): Dept Code: 490 I SY E 510 - Facilities Planning IE 315, 320/321, or cons inst Credits: 3 Contact Hours 3.3 First Taught: Fall 2000-2001 This Data for most recent offering in Fall 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required) : Introduction to plant location theory and analysis of models of plant location; models for determining plant size and time phasing; line balancing models; techniques for investigating conveyor and other material handling problems; and models and optimization of plant layout. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): To gain an understanding and appreciation of the principles and methodologies relevant to the planning and design of "production oriented" facilities. To develop skills and learn modern analytical techniques useful for solving facilities planning problems in such areas as: A. Manufacturing Systems Design; B. Plant Layout; C. Material Handling Systems, Conveyors; D. Cellular Manufacturing Systems. To gain an appreciation of the many qualitative considerations relevant to solving facilities design problems. E) Textbook (required): Tompkins, White, Bozer, and Tanchoco, 2003, "Facilities Planning," 3rd edition, Wiley, New York (reference). F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Introduction to Product Design and Process Planning, Review of Cellular Manufacturing Strategies & Concepts, ComputerAided Layout Planning, Design Considerations for Flexible Machining Cells & Assignment of Project, Detailed Issues in Cell Design, Practical Implementation Issues for Cells, Fundamentals of Assembly Lines, Material Handling System Design: Queuing, Material Handling System Design: Travel Time Model, Material Handling Systems Equipment, Conveyor Systems Design, Systematic Layout Planning (SLP Concepts), P-Q Input Data, Material Flow, Relationship Charts and Diagrams, Space Planning and Considerations, Layout Adjustments and Selection, Project Presentations STEUDEL,HAROLD J COE Courses - Data Collection Form for AEFIS Course: Prerequisite(s): I SY E 515 - Engineering Management of Continuous Process Improvement EPD 397 & Sr or Grad st, or cons inst Dept Code: 490 Credits: 3 Contact Hours 3.0 First Taught: Fall 2000-2001 This Data for most recent offering in Fall 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required): This course addresses the role of the industrial engineer as a 'manager' of continuous improvement in design and production processes. It provides modern tools and techniques for planning and managing team projects, integrating the concepts of total quality, data based decision making, and resource management. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): Understand and describe the role of the industrial engineer as a "manager" of continuous improvement in design and production processes. Implement technical skills and processes in a non-technical workforce. Apply basic problem solving and management/planning tools for effectively defining problems, feasible alternative solutions, and measurable goals in a "real world" environment. Work effectively on a team-based experiential project focused on process design, analysis, and resource management and integrating the concepts of continuous improvement, customer focus, and teamwork. Describe the impact of organizational and cultural influences on the planning and implementation of change. E) Textbook (required): The Memory Jogger Plus +: The Seven Management and Planning Tools by Michael Brassard; 1996 Goal QPC F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): KAIZEN: Concepts & Workshops, Discussion of Class Project, KAIZEN by TQC/TQM, Basic Principles of Problem Solving & PDCA, Management and Planning Tools, Affinity Diagrams (AD) & Workshop, Interrelationship Digraph (ID) & Workshop, Tree Diagram & Workshop COE Courses - Data Collection Form for AEFIS Course: Prerequisite(s): Dept Code: 490 I SY E 516 - Introduction to Decision Analysis Stat 311 or Math 431 or cons inst Credits: 3 Contact Hours 0.0 First Taught: Fall 1990-91 This Data for most recent offering in Summer 2011 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required) : Overview of modeling techniques and mehtods used in decision analysis, including multiattribute utility models, decision trees, and Bayesian models. Psychological components of decision making are discussed. Elicitation techniques for model building are emphasized. Practical applications through real world model building are described and conducted. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): Recognize the types of problems that decision analysis can and can’t address. Identifying the values, objectives, attributes, decisions, uncertainties, consequences, and trade-offs in a real decision problem. Apply the concepts learned in this class (expected value, value of information, risk aversion, and tradeoffs between attributes) to identify good decisions and strategies. Represent a decision problem graphically and/or mathematically. Determine the optimal decision mathematically. Identify which parameters have the most impact on the results of an analysis. Explain the results of a decision analysis to managers and other non-specialists. E) Textbook (required): Robert T. Clemen and Terence Reilly, Making Hard Decisions. John S. Hammond, Ralph L. Keeney, and Howard Raiffa, Smart Choices: A Practical Guide to Making Better Decisions, New York, NY: Broadway Books, 2002. F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Decision trees, multi-stage decision trees, expected value of information, influence diagrams, sensitivity analysis, probability, value functions, one-dimensional utility theory, multi-dimensional utility theory MANN,TERRY M COE Courses - Data Collection Form for AEFIS Course: Prerequisite(s): Dept Code: 490 I SY E 520 - Quality Assurance Systems Sr or Grad st, or cons inst Credits: 3 Contact Hours 2.5 First Taught: Fall 1999-2000 This Data for most recent offering in Spring 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required) : Introduces engineers to applications of total quality concepts and tools to develop, implement, and maintain an effective quality assurance system in a manufacturing or service organization. Emphasis is on documentation development, team-based improvement strategies, and international quality standards. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): Provide students with knowledge and skills in the following areas; basic elements of a Quality Management System (QMS), international standards such as ISO 9000 and ISO 14001, structuring QMS documentation: Quality manual, procedures-work instructions-records, QMS Implementation and Maintenance Approaches, strategic and competitive issues in QMS, computer-based information systems for QMS, role of TQM and statistical methodologies in QMS, quality auditing and management reviews, continuous improvement through corrective and preventive action, integrated quality and environmental management systems. E) Textbook (required): No textbook, class notes available from IIE Student Chapter F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Basic elements of a Quality Assurance (QA) system, Quality standards such as ISO 9001, ISO 14001, and others, Structuring Quality Management System (QMS) documentation: quality manual, procedures, work instructions, records, QMS System Implementation and Maintenance, Strategic and competitive issues in QMS, Computer-based information systems for QMS, Role of TQM and statistical methodologies in QMS, Quality auditing and management reviews, Continuous improvement through corrective and preventive action FERRIS,MICHAEL C COE Courses - Data Collection Form for AEFIS Course: Prerequisite(s): Dept Code: 490 I SY E 525 - Linear Programming Methods Math 443 or 320 or 340 or cons inst Credits: 3 Contact Hours 2.5 First Taught: Fall 2007-2008 This Data for most recent offering in Spring 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required): Real linear algebra over polyhedral cones; theorems of the alternative for matrices. Formulation of linear programs. Duality theory and solvability. The simplex method and related methods for efficient computer solution. Perturbation and sensitivity analysis. Applications and extensions, such as game theory, linear economic models, and quadratic programming. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): To understand the concepts of linear and quadratic programming, focusing on algorithm design and formal mathematical rigor. To solve any linear program at the end of the course, as well as understand and apply duality theory and some facets of numerical analysis. E) Textbook (required): Linear Programming via MATLAB, Michael C. Ferris, O. L. Mangasarian and Stephen J. Wright, SIAM, 2007. F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Linear Algebra: A Constructive Approach, The Simplex Method, Duality, Convexity and Polyhedral Sets, Large Scale Consumption, Sensitivity Analysis, Approximation, Quadratic Programming and Complementarity Problems LEE,JOHN D COE Courses - Data Collection Form for AEFIS I SY E 552 - Human Factors Engineering Design and Evaluation Course: Prerequisite(s): Ind Engr 349 & EPD 397, or cons inst Dept Code: Credits: Contact Hours First Taught: 490 3 2.5 Fall 1994-95 This Data for most recent offering in Spring 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required) : Evaluation, analysis, and design recommendations for improving human performance and productivity in applied settings. Collection of instrument-based and user survey data. Emphasis on ergonomics, human factors and sociotechnical systems engineering approaches and problems. Design project required. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): Develop observation and interview skills to understand customer needs and system interactions. Develop skills to translate observation and interview data into models of customer requirements and system constraints. Develop communication skills to relate model content to the customer and to marketing, engineering, management, and other members of the design team. Translate work models into aesthetically appealing and functional design concepts and prototypes. Evaluate and iterate prototype designs into a system that satisfies customer requirements. E) Textbook (required): Byer, H., & Holtzblatt, K. (1998). Contextual Design: Defining Customer-Centered Systems. San Diego: CA: Academic Press. F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Methods to understand customer needs, contextual inquiry, work model development and interpretation, consolidating work models, communicating customer needs, prototyping and interface structure WIEGMANN,DOUGLAS A COE Courses - Data Collection Form for AEFIS I SY E 555 - Human Performance and Accident Causation Course: Prerequisite(s): IE 349 or Psych 225 or equiv & an intro stats crse or cons inst for Grad students Dept Code: Credits: Contact Hours First Taught: 490 3 2.5 Fall 2000-2001 This Data for most recent offering in Fall 2010-2011 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required): A systems view of accident causation, with emphasis on the human performance limitations important in industrial and other accidents. Models of causation, data collection systems, economic evaluation, and safety programs. Small group projects. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): Understand how human error contributes to accidents. Understand what leads to human error. Ability to evaluate situations where accidents occurred. Apply simple models to examining accidents to define causation. Understand basic interventions and methods for accident control. E) Textbook (required): No textbook required F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Definition of accidents, Theories of accident causation, Human factors aspects of accident causation, Nature of various accidents such as consumer, home, occupational, traffic, air, train, disasters, Accident investigative methodologies, Fitting theory to real life practice, Prevention of accidents. RADWIN,ROBERT G COE Courses - Data Collection Form for AEFIS Course: Prerequisite(s): I SY E 564 - Ergonomics in Manufacturing and Industry Ind Engr 349, Grad st or cons inst Dept Code: 490 Credits: 3 Contact Hours 2.5 First Taught: Spring 1994-95 This Data for most recent offering in Spring 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required) : Introduces engineers how to design manufacturing and industrial operations in which people play a significant role, so that human capabilities are maximized, physical stress is minimized, and workload is optimized. Examples and topics emphasize industrial applications. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): Teaches engineers the basic concepts and design tools needed to consider the physiological basis of human work in the design of industrial operations, equipment and products that are healthful and safe. Understand how to design workspaces for a diverse work population to accommodate the variability of human dimensions. Learn how to determine when loads and forces encountered in manual tasks exceed human strength limits. Understand how to prevent fatigue and enhance performance by designing tasks that account for human energy requirements. Learn how to design work environments that prevent excessive exposure to noise and vibration. Learn how to design physically demanding work for hot and cold environments. Learn how to establish work schedules that prevent adverse effects of shift work. Learn how to design manual material handling tasks that prevent back injuries. Understand how to analyze workstations and tasks for upper limb disorder risk factors. Learn how to institute a plant ergonomics program to control musculoskeletal injuries. E) Textbook (required): Kodak Ergonomics Group. Ergonomic Design for People at Work, Vol. 2. F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Design for Human Variability, Engineering Antropometry, Antropometric Design, Muscular Contraction and Movement, Biomechanical Analysis of Work, Human Strength and Design, Human Performance Measurement, Timed Activity Analysis, Multimedia Video Task Analysis, Energy Demands of Work, Work/Rest Cycles and Fatigue MANN,TERRY M COE Courses - Data Collection Form for AEFIS I SY E 575 - Introduction to Quality Engineering Course: Prerequisite(s): One intro crse in statistical methods, or cons inst Dept Code: Credits: Contact Hours First Taught: 490 3 2.5 Fall 2003-2004 This Data for most recent offering in Fall 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required): Introduction to statistically based quality improvement methods useful in industrial settings; observational methods and design of experiments; experimentation to discover influential factors and to analyze sources of variation; robust products. There will be a one hour discussion section each week. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): Understand how to design experiments and analyze the resulting data in various phases of engineering work, including new product design and development, process development, manufacturing process improvement, and health systems design and improvement. Apply your increased quantitative literacy and new data analysis skills in statistical methodologies, graphical displays, and visual and inferential interpretations to get experimental results faster, easier, and with fewer resources. Work more effectively in a team-based experiential project focused on applying appropriate statistical tools and techniques. Understand and describe the role of the industrial engineer as an innovator and manager of continuous improvement in complex systems composed of people, information, materials, equipment, and financial resources. E) Textbook (required): Statistics for Experimenters, by George E. P. Box, W. G. Hunter, and J. S. Hunter (BH2). Published by John Wiley & Sons, New York, 1978. F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Introduction to Six Sigma & Class Exercise, Six Sigma Methodology, Basic Statistics, Confidence Intervals and Prediction Intervals, Hypothesis Testing of Means, Hypothesis Testing for Differences Between Population Means, Factorial Design of Experiments ZHOU,SHIYU COE Courses - Data Collection Form for AEFIS Course: Prerequisite(s): Dept Code: 490 I SY E 605 - Computer Integrated Manufacturing Ind Engr 315 or cons inst Credits: 3 Contact Hours 3.3 First Taught: Fall 2003-2004 This Data for most recent offering in Fall 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required): An introduction to computer-integrated design and manufacturing with a focus on manufacturing process planning. Emphasis on concurrent engineering principles, manufacturing process engineering, computer-aided process planning, NC programming, and CAD/CAM integration. Course provides experience with CAD/CAM software and NC machines. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): To gain an understanding and appreciation of the principles and methods of computer integrated manufacturing. To develop skills and learn modern analytical and computer techniques useful for solving manufacturing product/process design problems in such areas as: A. product geometry design; B. manufacturing process planning; C. production system planning and scheduling. E) Textbook (required): Tien-Chien Chang, Richard A. Wysk, Hsu-Pin Wang, 2005, Computer-Aided Manufacturing (3rd Edition), Prentice Hall (reference) F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Computer Aided Design, Computer Graphics and Transformations, Geometric Modeling, Numerical Control, NC Programming, Concurrent Process Engineering, Basic Machining Calculations, Process Engineering, Process Planning, Group Technology, Rapid Prototyping, Production Planning and Control, MRP, Production Scheduling COE Courses - Data Collection Form for AEFIS Course: Prerequisite(s): Dept Code: 490 LINDEROTH,JEFFREY T I SY E 635 - Survey of Mathematical Programming Comp Sci/Ind Engr 525 and Con Reg in Math 321 or 521, or Cons Inst Credits: 3 Contact Hours 2.5 First Taught: Spring 1976-77 This Data for most recent offering in Spring 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required) : Formulation and modeling of applications from computer sciences, operations research, business, science and engineering involving optimization and equilibrium models. Survey and appropriate usage of software tools for solving such problems, including modeling language use, automatic differentiation, subroutine libraries and web-based optimization tools and environments. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): The ability to write down an algebraic formulation of an optimization model that captures the main decision elements of practical problems. The ability to categorize optimization models, and understand the implications of modeling on algorithm performance. To understand the tradeoff between model accuracy and tractability and to consider the feasibility of alternative design solutions. The ability to explain, at a non-technical level, how optimization may be applied to decision problems. To become familiar with the operation of state-of-the-art optimization software, including parameters that may significantly affect software performance. Advanced knowledge of the GAMS Modeling System for building and solving practical optimization problems. E) Textbook (required): No required texts F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Linear models, network models, discrete models, uncertain models, nonlinear models KRISHNAMURTHY,ANANTH COE Courses - Data Collection Form for AEFIS I SY E 641 - Design and Analysis of Manufacturing Systems Course: Prerequisite(s): Grads: MSE major or cons inst; Undergrads: IE 315 or 605, & cons inst Dept Code: Credits: Contact Hours First Taught: 490 3 3.8 Spring 1989-90 This Data for most recent offering in Spring 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required) : Covers a broad range of techniques and tools relevent to the design, analysis, development, implementation, operation and control of modern manufacturing systems. A significant portion of the coursework involves a group project with industry. This course also serves as the capstone course for the MSMSE degree. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): Knowledge of key drivers of manufacturing system performance, throughout the manufacturing enterprise (not just shop floor). How lead time reduction can drive improvements throughout the enterprise. Familiarity with common techniques and tools for manufacturing system analysis. How to conduct a manufacturing improvement project (includes: how to set goals and how to get management to sign off on those goals; gathering and analyzing data; using the right tools for analysis; deriving recommendations; presenting the recommendations to management). How to work in a team environment. E) Textbook (required): Quick Response Manufacturing: A Companywide Approach to Lead Time Reduction, R. Suri, Productivity Press, 1998. F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Introduction to modern manufacturing strategy and the importance of Quick Response Manufacturing. Implementing quick response in production. Structured methodology to conduct a manufacturing improvement project. Team Building, conducting meetings. Creating a goals document. Tools for manufacturing system analysis. Impact of lot sizes and capacity planning. MRP in the modern manufacturing context. Supplier and Customer strategies. Quick response in Office Operations. Rapid new product introduction. Management mindset and performance measures. Steps to implementing changes and improvements. CARAYON,PASCALE COE Courses - Data Collection Form for AEFIS Course: Prerequisite(s): I SY E 652 - Sociotechnical Systems Grad st or IE 349 Dept Code: 490 Credits: 3 Contact Hours 3.0 First Taught: Fall 2007-2008 This Data for most recent offering in Fall 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required): Sociotechnical systems theory with applications to the design of organizations and jobs. Open systems and organizational environments. Analysis of the technical and social systems and techniques for 'whole' system consideration. Organizational design strategy. Field site analyses by student teams. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): To know theories and concepts of sociotechnical systems. To understand various methods and approaches for analyzing and redesigning sociotechnical systems. To be able to apply theories and concepts of sociotechnical systems. E) Textbook (required): No required textbook, required readings will be provided. F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Product Development, Production Systems, Routing, Time Study, Single Station, Assembly Line, Dedicated Line, Cellular Manufacturing, Space Requirement, Material Handling and Equipment, Flow Analysis, Systematic Lay outing Planning, Analytical Planning, Computer-Aided Layout Design Methods CARAYON,PASCALE COE Courses - Data Collection Form for AEFIS I SY E 653 - Organization and Job Design Course: Prerequisite(s): Grad st or IE 349 Dept Code: Credits: Contact Hours First Taught: 490 3 2.5 Fall 2007-2008 This Data for most recent offering in Fall 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required): Design of productive organizations and people's roles within them. Issues including boundary location, organizational decision levels, autonomous work groups, implementation and diffusion. Roles of the union. Case studies. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): To be able to conduct a detailed job analysis using a variety of methods. To know theories of job and organization design. To be able to apply theories of job and organization to the analysis and redesign of jobs. E) Textbook (required): No textbook required, course notes required. F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Methods of data collection for job analysis, Theories of job design and organizational management, Features of jobs that affect employee motivation, Job Redesign, Teamwork, Ethical Treatment of Employees VANDERHEIDEN,GREGG C COE Courses - Data Collection Form for AEFIS I SY E 662 - Design and Human Disability and Aging Course: Prerequisite(s): Jr st or cons inst Dept Code: Credits: Contact Hours First Taught: 490 3 3.2 Fall 1990-91 This Data for most recent offering in Spring 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required) : Design of products for persons with physical, sensory or cognitive impairments is covered as well as the design of standard mass market products. Interdisciplinary teams explore specific disabilities, then design a standard mass market product in competition with each other. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): Building a solid understanding of - the different types of disabilities that people experience, - the tools they currently use, and the problems they face due to current design. Developing an understanding of the laws and regulations related to accessible design. Learning the strategies that can be used to build mass market products that: - are attractive, practical, and profitable address as many accessibility issues as is commercially practical - and comply with regulations. Developing skills in putting these strategies into practice. E) Textbook (required): No textbook, handouts in class F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Visual Impairments and Relevant Assistive Technology, Hearing Impairments and Relevant Assistive Technology, Physical Impairments and Interface Assistive Technology, Cognitive and Language Impairments and Relevant Assistive Technology, Interacting with Persons with Disabilities, Governmental Regulations, Reviewing Product Designs for Accessibility, Designing Products to Meet the Needs of Users with Sensory Limitations, Designing Products to Meet the Needs of Users with Physical, Cognitive, and Other Disabilities, Universal Design COE Courses - Data Collection Form for AEFIS Course: Prerequisite(s): VEERAMANI,DHARMARAJ I SY E 671 - E-Business: Technologies, Strategies and Applications Sr or Grad st Dept Code: 490 Credits: 3 Contact Hours 2.5 First Taught: Fall 2007-2008 This Data for most recent offering in Fall 2011-2012 A) What Type of Course is this? (Circle one): Required / Elective / Selected Elective B) Course Description (required): Overview of core concepts of e-commerce and e-business technologies, strategies and applications. Covers business-to-consumer, business-to-business and intra-business models by using real-world examples and cases from various industries. Significant portion of coursework involves interdisciplinary group project with industry. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Dept ABET Description Apply knowledge of math, science, and engineering principles to solve ISYE, social or 1 ak business problems As supervised by faculty use appropriate techniques, skills, and tools to identify, 2 abek formulate, analyze, and solve industrial engineering problems. 3 ce Supervised by faculty, design a system, component or process to meet an identified need Engage in continued learning and demonstrate an appreciation of the benefits of lifelong 4 i learning 5 dg Communicate effectively and work well on class-based project teams Explicitly include consideration of ethical and global/societal issues in course projects 6 cfhj and classes D) Default Specific Course Outcomes (required): Understand key enabling technologies, emerging business models and nontraditional organizational strategies for ecommerce and e-business. Understand and apply knowledge of Business-to-Consumer, Business-to-Business and IntraBusiness interactions in a variety of industries (including manufacturing, retailing and service industries) that illustrate how e-commerce and e-business technologies and practices can lead to significant enhancement in organizational competitiveness and effectiveness. Analyze an organizations current business model and organizational processes from both strategic and operational perspectives. Design and justify a reengineered e-commerce/e-business model and its underlying technological system infrastructure E) Textbook (required): No required textbook F) Supplemental Material (optional): G) Brief Topics to be covered in Addition to B) and any Additional Information (required): E-Commerce and E-Business Evolution, Web Technology Basics, Developing E-Commerce and E-Business Strategy, Overview of Business Models, Business-to-Consumer E-Commerce: Technologies, Strategies