Reliability

advertisement

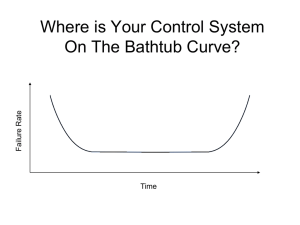

Project & Quality Management Quality Management Reliability Reliability Management Why is it needed? • Reliable operation of critical equipment • Planning of maintenance activities • Improved ‘quality’ of an item Reliability Management Reliability management is concerned with performance and conformance over the expected life of the product “the probability that a product or a piece of equipment performs its intended function for a stated period of time under specified operation conditions’” Definition of Reliability The definition has four important elements: • Probability • Time • Performance • Operating conditions Definition of Reliability Probability • A value between 0 and 1 • Precise meaning e.g. probability of 0.97 means that 97 of 100 items will still be working at stated time under stated conditions Definition of Reliability Performance • Some criterion to define when product has failed e.g. bearing clearances in an engine or amount of emissions from a car Definition of Reliability Operating conditions • These describe the operating conditions that correspond to the stated product life. e.g. for a car engine this might mean → Speed → Loading → Effects of an expected amount of misuse such as over-revving and stalling. Reliability Measurement This is based on the Failure Rate i.e. Items Failed Failure rate Total Operating Time Some products are scrapped when they fail e.g. hairdryer Others are repaired e.g. washing machine. Failure rate over the life of a product The failure rate is expected to vary over the life of a product – ‘Bathtub Curve’ A D C Failure Rate B Time Bathtub Curve A-B Early Failure • ‘Teething’ problems. Caused by design/material flaws B-C Constant Failure • Lower than initial failure rate and more or less constant until end of life C-D End of life failure • Failure rate rises again due to components reaching end of life Calculating Failure Rate Simplifying Assumption • Exponential distribution of failure rate is assumed. This means that the failure rate remains constant over life of product Failure Rate • Bathtub curve becomes a straight line Time Calculating Failure Rate Failure rate Items Failed Total Operating Time usually expressed by the Greek letter lambda () The probability of a product surviving until time (t) is given by the following function: Reliability at time (t) = e is the exponential function e t Procedure To establish reliability of an item: • Conduct a series of tests until a number of them fail. • Calculate failure rate (Lambda). • Calculate reliability for a given time using Reliability at time (t) = e-t Example Trial data shows that 105 items failed during a test with a total operating time of 1 million hours. (For all items i.e. both failed and passed). 105 4 1.05 x10 The failure rate 1000000 Example Find the reliability of the product after 1000 hours i.e. (t) =1000 Reliability at 1000 hours: R(1000) e e (1.05 x104 x1000) t = 0.9 Therefore the item has a 90% chance of surviving for 1000 hours