Team 2 SDR Presentation

advertisement

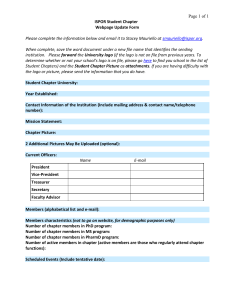

Company LOGO System Definition Review Akshay Ashok, Nithin Kolencherry, Steve Skare, Michael McPeake, Muhammad Azmi, Richard Wang, Mintae Kim, Dodiet Wiraatmaja, Nixon Lange www.company.com Company LOGO • • • • • • • • • Outline Re-cap Market Forecasts Key Design Goals Progress Update Constraint Analysis Concept development process and result Advanced Technology Concepts Cabin Layout Sizing Studies Overview of Concept – Walk around chart • Conclusion www.company.com Company LOGO Opportunity Description Create a supersonic transport aircraft that meets the following characteristics: • Mach 1.6-1.8 Cruise Speed • 4000 nm Design range • 35-70 Passengers (Mixed Class) • 3 Pax-mi/lb Fuel Efficiency • Takeoff Field Length < 10000 ft www.company.com Company LOGO Mission A cost-effective, advanced, high-speed commercial air transport that connects major worldwide hubs Key Design Goals: • Supersonic flights over land (Overpressure < 0.3psf) • IOC in 2020 • Manufacturing capabilities exist • 60 passengers • 4000nm ground range www.company.com Company LOGO Market Summary • Three regions of focus • Design Mission – Trans-Atlantic – Trans-continental – Inter-Asia • Worldwide Hubs – – – – – Los Angeles (LAX) New York (JFK) London (LHR) Dubai (DXB) Beijing (PEK) • Hub and Spoke Structure www.company.com Company LOGO www.company.com Company LOGO CONSTRAINT ANALYSIS www.company.com Company LOGO Constraint Analysis • Performance Constraints – 1-g steady flight • M=1.8, H=50000ft, VS=100fpm – Subsonic 2-g maneuver • V=250Kts, H=10000ft – Takeoff and Landing operations from JFK and DXB • Short runway length at JFK • Hot climate at DXB – 2nd segment climb • 3% with 4 engines Key Assumptions Cd0 0.016 Thrust Lapse Rate 0.35 Maximum fuselage diameter 13 ft Oswald efficiency factor 0.8 CLmax subsonic flight 1 ΔT 25 / 43 R CLmax land 2 eTO 0.6 CLmax TO 1.5 Number of engines 3 Ewd 1.9 Cruise climb capability 100 fpm www.company.com Company LOGO Constraint Analysis constraint diagram 0.8 0.6 0.4 Tsl/W0 0.2 0 40 60 80 100 120 140 160 -0.2 -0.4 -0.6 -0.8 W0/S 1g steady, level flight, M =1.8 @ h=50000ft subsonic 2g manuever, V =422ft/s @ h=10000ft takeoff ground roll 10000ft @ h = 34ft,43° hot day[DXB] landing ground roll 4374ft @ h = 34ft,43° hot day[DXB] second segment climb gradient of 2.7% 3 above 34ft,43° hot day takeoff ground roll 8000ft @ h = 13ft,25° hot day[JFK] landing ground roll 2800ft @ h = 13ft,25° hot day[JFK] www.company.com Company LOGO CONCEPT SELECTION www.company.com Company LOGO BRAINSTORMING PUGH’s MATRIX (1ST RUN) 3 BASELINE CONCEPTS SELECTED HYBRID CONCEPTS GENERATED FURTHER RESEARCH PUGH’s MATRIX (2ND RUN) FINAL DESIGN www.company.com Company LOGO Brainstorming Concepts 7 1 8 6 2 5 3 4 www.company.com Company LOGO Pugh’s Matrix 1st run 2 3 4 5 6 7 8 SONIC BOOM + + s + + s + + SUBSONIC NOISE s s s s + + s + TURN AROUND TIME s s s s s + + s AIRPORT COMPATIBLE s - - s - - - - s s s s + s s + + + - + + + - s CABIN VOLUME + + s s s s s + COST + + - + s + - s MOVING PARTS + - - + + + - - AESTHETICS s - - s s s - s + 5 4 0 4 5 5 2 4 - 0 3 5 0 1 1 5 2 s 5 3 4 5 4 4 3 4 EASE OF MANUFACTURE D A T U M 1 SAFETY CONCORDE www.company.com Company LOGO Hybrid Concept 1 Engine Location: - Under wing Wing: - Delta - Mid fuselage (height) - Anhedral Control surface: - on wing Sonic boom mitigation: - Hybrid nose design (weak compression waves) www.company.com Hybrid Concept 2 Company LOGO Engine Location: - Over wing Wing: - Delta -Mid Fuselage - No dihedral/ anhedral Control surface: - Canards - Upper fuselage - Dihedral Sonic boom mitigation: - Nose shaping (F-5 shaped sonic boom demostrator) www.company.com Hybrid Concept 3 Company LOGO Engine Location: - Under wing inlet - Over wing outlet (similar to YF-23) Wing: - Delta - Bottom fuselage - Dihedral Control surface: - Canards - Top fuselage - Anhedral Sonic boom mitigation: - Gulfstream / NASA Quiet Spike™ www.company.com Company LOGO Aft Arrow Wing Concept Engine Location: - Under wing inlet - Over wing outlet (similar to YF-23) Wing: - Delta - Bottom fuselage - Dihedral Control surface: - Canards - Mid fuselage Sonic boom mitigation: - aircraft geometry APPLICATION OF SONIC-BOOM MINIMIZATION CONCEPTS IN SUPERSONIC TRANSPORT DESIGN by Harry W, Carlson, Rdymond L. Barger, and Robert J. Muck, Lungley Research Center, Hdmptolz, Vd. 23665 NATIONAL AERONAUTICS AND SPACE ADMINISTRATION WASHINGTON, D. C. JUNE 1973 www.company.com Pugh’s Matrix : 2nd Run 2nd run SONIC BOOM SUBSONIC NOISE CONTROL SURFACES TURN AROUND TIME AIRPORT COMPATIBLE SAFETY EASE OF MANUFACTURE EMPTY WEIGHT COST AFT ARROW WING CONCEPT HYBRID CONCEPT 1 HYBRID CONCEPT 2 HYBRID CONCEPT 3 D A T U M Company LOGO + s s s + s + - + s + + + s + - s s + s - 2 4 3 5 2 2 1 5 2 www.company.com Company LOGO Detailed Considerations DESIGN CRITERIA DETAILED DESCRIPTION aspect ratio frontal area induced drag control surface effects location of control airport sufaces compatibility complexity size of control surfaces weight stability debris preflight SONIC BOOM geometry altitude weight wetted area SUBSONIC NOISE engine placement noise mitigation type of engine CONTROL SURFACES types of control surfaces static stability number TURN AROUND TIME # of passenger doors # of service doors preflight checks AIRPORT COMPATIBLE location of control sufaces location of doors geometry fuel bay location engine placement SAFETY engine placement fuel bay location landing gear vertical stabilizer osciallations emergency exits EASE OF MANUFACTURE moving parts materials used geometry costs EMPTY WEIGHT # of engines materials used # of landing gear wing size # of moving parts COST procurement operation manufacture maintenance crew www.company.com Company LOGO www.company.com Company LOGO Supersonix Concept Further Work: - Engine placement (over/ under wing) - Vertical tail selection - Dihedral/ Anhedral effects (wing/ canard) - Location of doors www.company.com Company LOGO ADVANCED TECHNOLOGY CONCEPTS www.company.com Company LOGO Boom Shaping : Dihedral • Increase Effective Length – Multi-plane lifting surface – Mitigates Boom overpressure • Potential Issues – Wash out • subsonic lateral instabilities – Low planform area • Lift is reduced – Structural Considerations www.company.com Company LOGO Boom Shaping : Effective Area Distribution • Smooth area distribution – Gradual lift development • Long chord of wing root – Fuselage diameter morphing – Aircraft length • Engine Nacelle Placement – Area rule • Canards – High dihedral www.company.com Company LOGO Boom Shaping : Nose Design • Blunt nose – Create strong bow shock • Mitigate subsequent shocks, overpressure – Supersonic Area rule – High wave drag • Nose keel – Alternate option – Unverified results – Material Problems www.company.com Company LOGO Efficient Supersonic Cruise • Wing Characteristics – High AR, low sweep for efficient supersonic • Laminar flow supersonic wing – Low AR, high sweep for shock mitigation – Need to achieve acceptable trade-off • Active flow management – Attached flow on wing – “Phantom Body” • Artificial area www.company.com Company LOGO Engines T/Wen vs. Manufactured Year 8 Samara NK-25 7 GE F136 6 P&W F135 5 Aviadvigatel D-30F6 Samara NK-321 4 T/We GE F101-102 P&W 1000G 3 2 1 0 1975 1980 1985 1990 1995 2000 2005 2010 2015 www.company.com Company LOGO Engines Engines – 107724 lb thrust is needed – Samara NK-321 • Produced by Kuznetsov Design Bureau • Entered service in 1987 • Used on Tupolev Tu-144LL • Noise problem www.company.com Company LOGO Engine Noise : Solutions – Adaptive Cycle Engine (ACE) • extra bypass duct on the outside of the engine • quiet on take off and landing • Significant improvement in subsonic flight – Eccentric Exhaust Configuration • Decrease the effective perceived noise by 10.5 dB www.company.com Company LOGO CABIN LAYOUT CONFIGURATION www.company.com Company LOGO Cabin Layout / Fuselage Design • 7 rows of 2 first class seats, 15 rows of 3 coach class seats • Passenger total: 59 • Crew: 4 (Captain, First Officer, 2 Attendants). www.company.com Company LOGO Cabin Layout / Fuselage Design • 7 rows First Class x 40” Seat Pitch = 280” 15 rows Coach x 36” Seat Pitch = 540” 2 Galleys/Restrooms (exits) x 104” = 208” 1028”(~90 ft) 90 ft 170 ft www.company.com Company LOGO Cabin Layout / Fuselage Design • Cabin Diameter: 9 feet, Aisle Height: 78” • “Jump seats” for attendants • 4 exits: 2 between FC and coach, 2 overwing Exits Exits Crew Seats Cockpit www.company.com Company LOGO SIZING STUDIES www.company.com Company LOGO Design Mission www.company.com Company LOGO Sizing Process www.company.com Company LOGO Attributes Values W0 Design 284000 lb We Design 124000 lb Wf Design 143000 lb Tsl Required 108000 lbf Wing Area 3340 ft2 Design Range 4700 nm AR 2.1 W0/S 85 lbf/ft2 Tsl/W0 0.38 Cruise Mach # 1.8 Maximum Mach # 2.0 SFC cruise 0.94 1/hr Supersonic (L/D)max 9.2 Supersonic (L/D)cruise 7.9 Subsonic (L/D)max 10 Subsonic (L/D)loiter 10 www.company.com Company LOGO Component Weights • Used database of 16 existing commercial aircraft • Some differences between our aircraft and those in the database – Horizontal Tail – Delta Wing • Average mass fraction values were corrected based on these differences www.company.com Company LOGO Component Weights www.company.com Company LOGO Average Component Weights For 16 Commercial Aircraft www.company.com Company LOGO Calculated Component Weights (Corrected) www.company.com Company LOGO Center of Gravity • Utilized Derived Component Weights • Includes All Major Component Weights, Most Minor Weights – Includes: Fuel, Wing, Tail, Canard, Engines, Fuselage, Furnishings, Passengers, etc. – Does Not Include: Baggage, Air Conditioning, Anti-Icing System • Placement was not accurate enough at this stage www.company.com Company LOGO • Center of Gravity Location (at MTOW) ≈ 97 ft – Roughly 57% of the total length of the aircraft – Estimation includes 87% of the take off gross weight of the aircraft • Likely to change, but not significantly www.company.com Company LOGO AIRCRAFT SUMMARY www.company.com CompanyBlunt Nose LOGO Aerodynamically Contoured Skin Arrow-wing Design Top-mounted Canards Area-ruled fuselage for minimum wave drag Dihedral Wing Rear mounted Engines www.company.com Company LOGO Compliance Matrix Requirements Target Threshold Revised on 3/3 Requirement Units Take off field length 8400 10000 8000 ft Landing field length 8400 10000 2800 ft Door height above ground 8 10 ft Turnaround time 0.5 1 hr Still air range 5000 4000 4000 nm Number of passenger 60 50 59 people Cruise Mach number 2 1.6 1.8 Mach Cabin volume per pax 65 50 43.13033982 pax/[ft^3/pax] Operating cost Cruise Altitude $/ASM 50000 Cruise Efficiency 40000 50000 ft 0.3 0.6 lb fuel/pax mi 0.8 lb/ft^2 Sonic boom overpressure 0.3 0.3 Cumulative certification noise 60 80 dB Stall Speed kts COTs 80 50 Second Segment climb gradient 2.6 2.4 % 3 % www.company.com Company LOGO • • • • • • • • • • • • References http://www.nasa.gov/vision/earth/improvingflight/supersonic_jousting.html Carlson, H.W, Muck, J.R, APPLICATION OF SONIC-BOOM MINIMIZATION CONCEPTS IN SUPERSONIC TRANSPORT DESIGN, June 1973 F-5 Shaped Sonic Boom Demonstrator’s Persistence of Boom Shaping Reduction through Turbulence John M. Morgenstern*, Alan Arslan†, Victor Lyman‡ and Joseph Vadyak§ Lockheed Martin Aeronautics Company, Palmdale, CA 93599 AIAA-2005-0012; 43rd AIAA Aerospace Sciences Meeting and Exhibit - Reno, NV http://www.enemyforces.net/aircraft/mig31.htm http://www.fighter-planes.com/info/mig31_foxhound.htm http://www.jet-engine.net/ Papamoschou, D. Debiasi, M. Conceptual Development of Quiet Turbofan Engines for Supersonic Aircraft, April 2003 www.company.com Company LOGO QUESTIONS www.company.com