Applied_Math-Physics_Vapor

advertisement

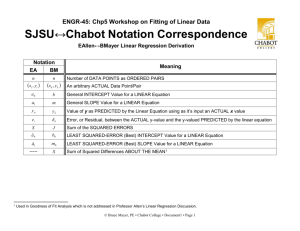

Chabot Engineering Semiconductor Machine-Tool Chemical Delivery Chp3 Bubblers-323 Bruce Mayer, PE Licensed Electrical & Mechanical Engineer BMayer@ChabotCollege.edu Chabot College Engineering 1 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt The Following Presentation Lead to an American Institute of Physics (AIP) Publication in 2001 Chabot College Engineering 2 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt WJ’s Patented Bubbler C. C. Collins, M. A. Richie, F. F. Walker, B. C. Goodrich, L. B. Campbell “Liquid Source Bubbler”, United States Patent 5,078,922 (Jan 1992) Chabot College Engineering 3 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Patent 5 078 922 Chabot College Engineering 4 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt WJ Bubbler Design Schematic diagram of a the WJ chemical vapor generating bubbler system used in CVD applications. Note the use of the dilution MFC to maintain constant mass flow in the output line. An automatic temperature controller sets the electric heater power level Cut-away view of a WJ chemical source vapor bubbler. The bubbler features a total internal volume of 0.95 liters, and a 25 mm thick isothermal mass jacket with an exterior diameter of 180 mm. Chabot College Engineering 5 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt CONCEPTUAL Degree of Saturation vs Liquid Level 110% 100% 90% Degree of Saturation 80% 70% 60% With a 2.2” Liq Level does the WJ bubbler operate HERE? Or HERE? 50% 40% 30% 20% 10% 0% 0 20 40 60 80 100 120 Liquid Level (Arbitrary Units) file = Vap_Prss.xls Chabot College Engineering 6 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Microscopic Transient Behavior: Bubble Vapor Saturation How Well Does the Bubbler “Humidify” the “Dry” Nitrogen Carrier Gas? Does the Liquid LEVEL in the Bubbler Affect this Humidification (degree of Saturation) What other Factors affect the Degree of Saturation, and in What Quantity? What does Bubbling Look like? Flow Visualization – – BT98_VRo.ppt BT_9806c.ppt Chabot College Engineering 7 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt WJ-1999 Bubbler Test; t = 0 Water Surface Bubble 6.35 mm Chabot College Engineering 8 Carrier N2 Flow Rate in slpm Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt WJ-1999 Bubbler Test; vr,f Water Surface 9.7 mm Bubble Bubble t=0 t = 33.3ms 6.35 mm 3.7 mm QN2 = 1 slpm Chabot College Engineering 9 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Bubble Saturation Problem Partition The Bubble Saturation Problem Consists of 3 Loosely Coupled Sub-Processes [2] 1. Bubble Saturation as a Function of Bubble Size and Vapor Diffusivity 2. Bubble Size as Function of Sparger Tube HoleSize, Liquid Density, and Liquid Surface Tension 3. Residence Time of the Bubble in the liquid by integration the bubble rise-velocity over the liquid height [2] B. Mayer, “Liquid Source Bubbler Carrier Gas Vapor-Saturation Transient Analysis”, WJ-SEG Engineering Library Report, file BM961112.doc, 12Nov96 Chabot College Engineering 10 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt IntraBubble Vapor Mass Transport Partial Differential Equation Assume Bubble Diffusion Physics at right Assume Diffusion of vapor obeys the Fick Eqn Cv r , t Fv r , t Dv r – Where o o o o Fv the molar flux in the r-direction in kmol/m2s Dv the (assumed constant) vapor diffusivity in N2 in m2/s Cv the molar concentration of the vapor in kmol/m3 r the radial coordinate in the bubble in m Chabot College Engineering 11 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Bubble Sat PDE cont.-1 Molar Flux INTO the Bubble Control Volume nv ,in Cv Fv ,in ACVsurf ,outside Dv r Molar Flux OUT of the Bubble Control Volume nv ,out Cv 2 Fv ,out Asurf ,inside Dv 4r r r STORAGE Rate of C v 2 n 4 r dr Vapor in the Bubble v , stor t r Control Volume Chabot College Engineering 12 4 r dr r dr 2 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Bubble Sat PDE cont.-2 Setting: Influx − Outflux = Storage Rate 2 Cv Cv 2 Cv 1 2 Cv 1 Cv 2 Dv 2rdr r dr 2 r dr 2 r r r r r t r r r Dv t This is the 1-Dimensional Diffusion Equation in Spherical CoOrdinates Now use Perfect Gas Theory to Convert to Vapor Pressure Formulation 1 2 Pv 1 Pv r 2 r r r Dv t Taylor series expansion in Appendix-A of JVST-A 2001 paper; Perfect Gas conversion in Appendix-B Chabot College Engineering 13 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Bubble Sat PDE cont.-3 1 2 Cv 1 Cv 0 Comments on the PDE 2 r r r r Dv t Linear & Homogeneous 2nd order in r (need two Boundary Conditions) 1st Order in t (need one Initial Condition) BC1: Assume Equilibrium at Bubble Edge Pv ( ro , t ) Pv. sat BC2: By Symmetry have No diffusion at r = 0 Pv r 0 for all time r 0 Chabot College Engineering 14 for all time Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Bubble Sat PDE cont.-4 IC: At t=0 bubble is 0% Saturated (trivial IC) Pv ( r,0) 0 NonDimensionalize r ro for all r Dv t r 2 o P v Pv Pv , sat Define the Degree of NonSaturation (a.k.a. Complementary Degree of Sat) Pc Pv , sat Pv , sat Pv Pv Pc 1 Pv Pv , sat Pv , sat Pv , sat Chabot College Engineering 15 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Bubble Sat PDE cont.-4 PDE Summary Parameter Problem Formulation Pv(r,t) Pv(,) Pc(,) 1 2 Pv 1 Pv r r 2 r r Dv t 1 2 P v P v 2 1 2 Pc Pc 2 BC-1 Pv ( ro , t ) Pv .sat Pv (1, ) 1 Pc (1, ) 0 BC-2.1 Pv ( r , t ) finite P v ( , ) finite P c ( , ) finite Pv 0 r r0 Pv 0 0 Pc 0 0 Pv ( r ,0) 0 P v ( ,0) 0 Pc ( ,0) 1 PDE BC-2.2 IC Chabot College Engineering 16 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Bubble Sat PDE Solution Non-Dim Solution for Pc P c , 2 1 n 1 n 1 P v r, t 1 2 1 n 1 2 n 1 sin n r ro n e n r ro 2 2 Dv t ro2 See next Slide for Graphical Representation of This (really cool) Solution Chabot College Engineering 17 2 Dimensional Solution for Pv sin n n e n Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Liquid Source Vapor Bubble Saturation Transient 1.0 • Bubble Diameter = 5 mm • D for TEOS in N2 = 0.05 cm2/s Vapor Saturation Fraction, P v 0.8 Increasing Time Pv(r,t) (t=0.01 s) Pv(r,t) (t=0.04 s) Pv(r,t) (t=0.10 s) Pv(r,t) (t=0.15 s) Pv(r,t) (t=0.25 s) Pv(r,t) (t=0.35 s) Pv(r,t) (t=0.50 s) 0.6 0.4 0.2 Pv r , t 1 2 1 n1 n1 sin n r ro n2 2 Dt ro2 e n r ro 1st 100 Terms of Summation 0.0 0.0 0.3 0.5 0.8 1.0 1.3 1.5 1.8 2.0 Radial Position Inside Bubble, r (mm) Chabot College Engineering 18 2.3 2.5 file = BubPv(t)1.xls Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Bubble Size Determination Perform Force Balance as shown below Bubble Breaks free when Buoyant Force just barely exceeds the Surface Tension Force Chabot College Engineering 19 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Bubble Size Determination cont.-1 The Buoyant Force FB 4 3r g l g 4 3g r 3 o – 3 l o Where FB the the buoyant force in newtons g the acceleration of gravity, 9.8 m/s2 l the density of the liquid in kg/m3 (936 kg/m3 for TEOS) g the density of the carrier gas in kg/m3 (1.01 kg/m3 for N2 at 65 °C) o ro The outside radius of the bubble in m o o o o Chabot College Engineering 20 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Bubble Size Determination cont.-2 The Surface Tension Force Fs Dhs – Where o Fs the surface tension force in newtons o Dh the diameter of the vent hole in the sparger tube in meters (0.508 mm, or 0.02”, from WJ bubbler dwg 986595) o s the liquid surface tension in N/m (0.022 N/m, the value of ethanol at 30 °C) Thus the Bubble Radius Equation 3Dhs ro 4 g l Chabot College Engineering 21 13 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Rising-Bubble Liquid Residence Time Assume rough Equivalence for Fluid-Mechanical Drag between: light bubble rising through a liquid heavy sphere falling through the same liquid Position-varying drag forces determine the velocity of a bubble rising in a liquid Chabot College Engineering 22 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Bubble Residence Time, r cont.-1 The Drag Force FD C D r 2 o – v 2 l 2 r Where o FD the drag force in newtons o CD the the coefficient of drag, a dimensionless number o vr the rise velocity of the bubble in m/s Apply Newton’s Law of Motion to Rising Bubble dvr Fy FB FD mB ar mB dt Chabot College Engineering 23 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Bubble Residence Time, r cont.-2 – Where o Fy the sum of the forces, in the y-direction, acting on the bubble in newtons o ar the rise acceleration of the bubble in m2/s o mB the “mass” of bubble in kg Effective Bubble Mass is the Liquid Displaced mB 4 3r l g 4 3r l 3 o 3 o Thus the Expression for Bubble Acceleration dvr dvr dy dvr 3C D vr2 ar vr g dt dy dt dy 8ro Chabot College Engineering 24 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Bubble Residence Time, r cont.-3 Comments on Acceleration Equation Ordinary Differential Equation (ODE) for vr in terms of y or t – – NONlinear & NONhomogeneous 1st order in y or t (need one BC or IC) BC/IC: Assume velocity is ZERO at the instant the bubble breaks away from the tube BC/IC: y = t = 0 vr = 0 Note: the Bubble Reaches Terminal Velocity vr,f when: ar = dvr/dt = dvr/dy = 0 Chabot College Engineering 25 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Bubble Residence Time, r cont.-4 r Solution Strategy (see JVST-A paper) If we know vr(t) at every instant in time, then simply integrate vr over liquid height H. H dy vr dy H vr dt 0 dt 0 r Implicitly evaluate vr(t) at any arbitrary time, tA using ODE vr t A 0 tA 0 0 dvr vr (t A ) ar dt Chabot College Engineering 26 tA 3CD vr2 t g dt 8ro Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Bubble Residence Time, r cont.-4 Using the “H” and “vr(tA)” Equations H r dy H 0 0 t 0 A 3v r2 t C D dt dt A g 8ro Almost Done. Find CD in Idelchik Text Ref. 23.99 4.565 0.491 23.99 4.565 0.491 CD 3 13 12 Re Re Re v r 2ro v r 2ro v r 2ro Chabot College Engineering 27 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Bubble Residence Time, r cont.-5 Collapse constant expressions into “K” Terms r H dy H 0 0 t 0 A 0.375K1v r K 2 v r5 3 K 3v r3 2 g dt dt A ro This eqn can be solved numerically as described in JVST ppr, eqns 2529 Table on the next slide shows a typical result The 2mm diameter bubble reaches a terminal velocity of 0.214 m/s (0.48 mph) – This is consistent with the literature Bubble rises the WJ std 2.2” liq Height in 280 ms Chabot College Engineering 28 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Bubble Residence Time, r cont.-6 Example Calc: ro = 1 mm, = 7.4x10-7 m2/s Time Step, n a (m/sq-s) Re del-v (m/s) v (m/s) del-y (m) H (m) 1 9.8 n/a 0.0098 0.0098 9.8E-06 9.8E-06 1 2 9.715655 26.48649 0.009716 0.019516 1.95E-05 2.93E-05 2 3 9.570822 52.74501 0.009571 0.029086 2.91E-05 5.84E-05 3 4 9.382618 78.6121 0.009383 0.038469 3.85E-05 9.69E-05 4 5 9.159834 103.9705 0.00916 0.047629 4.76E-05 0.000145 5 6 8.909038 128.7268 0.008909 0.056538 5.65E-05 0.000201 6 7 8.635705 152.8053 0.008636 0.065174 6.52E-05 0.000266 7 276 1.55E-08 579.3578 1.55E-11 0.214362 0.000214 0.055772 276 277 1.44E-08 579.3578 1.44E-11 0.214362 0.000214 0.055986 277 2.2” = 0.0559m Chabot College Engineering 29 Time (ms) Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Degree of Saturation We (finally) have all the tools to determine the degree of saturation, Sv, for the rising bubble S v ( ro ) P v r, r dr ro ro 0 0 Conceptually Note n 1 sin n r ro n 1 2 1 e n r ro n 1 2 2 Dv r ro2 dr Sv Sv ( Dv , Dh ,s , l , H , ) Dh and H are DESIGN-controlled Well known liquid properties = l Poorly Characterized Liquid properties = Dv, s, Chabot College Engineering 30 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Degree of Saturation cont.-1 Estimate Properties for TEOS, Etc. Chemical Temperature (K) Mw (kg/kmol) l (kg/m3) Dv (m2/s) s (N/m) (m2/s) TEOS 338 (65 °C) 208.3 936 7.27x10-6 0.0240 5.11x10-7 TMB 297 (24 °C) 103.92 915 7.87x10-6 0.0226 6.58x10-7 TMPi 297 (24 °C) 124.08 1005 8.42x10-6 0.0259 19.3x10-7 Ethanol 303 (30 °C) 47.06 789 13.7x10-6 0.0220 12.7x10-7 Water 298 (25 °C) 18.01 998 23.9x10-6 0.073 9.13x10-7 Saturation Safety Factor, N Chemical Temperature (K) ro (mm) vr,f (m/s) r,99 (ms) r,tot (ms) N TEOS 338 (65 °C) 0.9996 0.233 67 257 3.8 TMB 297 (24 °C) 0.9873 0.220 60 273 4.6 TMPi 297 (24 °C) 1.001 0.169 57 343 6.0 Chabot College Engineering 31 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Degree of Saturation cont.-2 Validation Testing Performed in Jun98 by MSWalton, B. Mayer, C. Koehler Water used as Benign Surrogate – See next slide Calculated ro = 1.45 mm vr,f = 0.274 m/s (0.61 mph) Min Saturation height = 6-7mm (0.25”) Chabot College Engineering 32 Actual ro = 1.5-2 mm vr,f = 9.7mm/33.3ms = 0.29 m/s (0.65 mph) Fully Humidified Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Validation Testing Chabot College Engineering 33 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt TEOS Liquid Source Vapor Bubble Saturation v. Liquid Height 100% 150 99% Saturation after 67 ms, or 0.46" 120 60% 90 Linear portion of r curve indicates terminal velocity of ~0.23 m/s 40% 60 20% 30 • Bubble Diameter = 1.999 mm 2 • Dv for TEOS in N2 = 0.0727 cm /s Integrated Saturation (%) • Kinematic viscosity,, = 0.00511 cm2/s Rise Time (ms) 0% 0 0.0 0.2 0.4 0.6 0.8 Liquid Level Inside Bubbler, y (inch) Chabot College Engineering 34 Bubble Rise Time, r (ms) Integrated Bubble Saturation, S v 80% 1.0 file = Sv(t)_01.xls Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt Degree of Saturation - Conclusions The standard WJ bubbler liquid level of 2.2” more than assures 100% saturation of the N2 carrier gas with the source chemical vapor. The 2.2” liquid height results in saturation time factors of safety of 3.8 for all source chemicals. The liquid level can drop about 1.5” (to 0.7” above the sparger tube) before non-saturation becomes a potential problem The 1.5” depth equates to a 460 ml working volume for post-dep fill applications Chabot College Engineering 35 Bruce Mayer, PE BMayer@ChabotCollege.edu • Applied_Math-Physics_Vapor-Gen_Transient_Behavior.ppt