4.3.3 Supply chain management 3M

advertisement

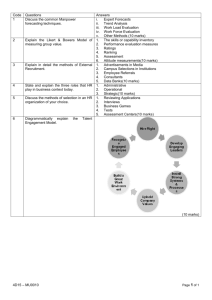

CUSTOMER_CODE SMUDE DIVISION_CODE SMUDE EVENT_CODE SMUAPR15 ASSESSMENT_CODE MB0044_SMUAPR15 QUESTION_TYPE DESCRIPTIVE_QUESTION QUESTION_ID 9054 QUESTION_TEXT Explain the needs and objectives of Supply Chain Management. SCHEME OF EVALUATION SCM is required by an enterprise as a tool to enhance management effectiveness with the following organisational objectives: a.Reduction of inventory b.Enhancement of participation level and empowerment level (3 Marks) c.Increase in functional effectiveness of existing systems like Enterprise Resource Planning (ERP), Accounting Software, and Documentation such as Financial reports/ Statements/ISO 9000 Documents d.Effective integration of multiple systems like ERP, communication systems, documentation system and security (5 Marks) e.Design / Research & Development (R&D) systems f.Better utilisation of resources like men, material, equipment, and money g.Optimization of money flow cycle within the organisation as well as from external agencies h.Enhancement of value of products, operations, and services. These enhancements will consequently enhance the profitability of organisation (7 Marks) i.Enhancement of satisfaction level of customers and clients, supporting institutions, statutory control agencies, suppliers and vendors, employees and executives j.Enhancement of flexibility in the organisation to help in easy implementation of schemes involving modernization, expansion and diversification – even divestments, mergers and acquisitions k.Enhancement of coverage and accuracy of management information systems(10 Marks) QUESTION_TYPE DESCRIPTIVE_QUESTION QUESTION_ID 125790 QUESTION_TEXT What are the principles of a SCM? SCHEME OF EVALUATION Seven principles of SCM are: 1.Group customer by needs: Effective SCM groups customers by distinct service needs, regardless of industry and then tailors services to those particular segments. (1 mark) 2.Customise the logistics network: In designing their logistics network, companies need to focus on the service requirement and profit potential of the customer segments identified. (1 mark) 3.Listen to signals of market demand and plan accordingly: Sales and operations planners must monitor the entire supply chain to detect early warning signals of changing customer demand and needs. (2 marks) 4.Differentiate the product closer to the customer: Companies today no longer can afford to stockpile inventory to compensate for possible forecasting errors. (2 marks) 5.Strategically manage the sources of supply: By working closely with organisation’s key suppliers to reduce the overall costs of owning materials and services, SCM maximises profit margins both for organisations and their suppliers. (1 mark) 6.Develop a supply chain wide technology strategy: As one of the cornerstones of successful SCM, information technology must be able to support multiple levels of decision making. (1 mark) 7.Adopt channel spanning performance measures: Excellent supply chain performance measurement systems do more than just monitor internal functions. (2 marks) QUESTION_TYPE DESCRIPTIVE_QUESTION QUESTION_ID 125794 Explain the phases of Operational strategy? QUESTION_TEXT SCHEME OF EVALUATION Phases of operational strategy: 1. Quality: Quality is the driving factor for any organization. When buying a product, a customer will always think about the value of the money he or she is investing. Even if the price of the product is high, the quality of the product will provoke the customer to buy it. Typical examples of companies focusing on quality are Amway, Coco–cola, Pepsi, Tupperware, Sony, BMW, etc. Many Indian companies coming under Tata group and automotive products manufactures like Maruti Suzuki, Rane (Madras) have won awards for providing high quality products. 2. Time: Time aspect considers that deliveries are made on time to meet the customers’ expectations. Time taken to develop and market new products is becoming very critical in the global environment. To seek more business, organizations should reduce the time taken for each factor during operations. The organizations mainly focus on reducing the time for the elements. 3. Flexibility: Flexibility enables a firm to meet the changing demands of the customers in order to develop new processes and materials and to make the organizations more agile in its manufacture. For example, Photon Inc, a European computer component manufacture, produces components which are not fixed to particular configurations. QUESTION_TYPE DESCRIPTIVE_QUESTION QUESTION_ID 125798 QUESTION_TEXT What is PERT? Explain the steps involved in PERT planning process. A PERT chart is a project management tool. It is used to schedule, organize and co-ordinate tasks within a project. ( 1 mark) SCHEME OF EVALUATION 1. Identify the specific activities & mile stone (1.5 each ) 2. Determine the proper sequence of activity (1.5 each ) 3. Construct a network diagram (1.5 each ) 4. Estimate the term required for each activity(1.5 each ) 5. Determine the critical path (1.5 each ) 6. Update the PORT chart as the project process(1.5each ) QUESTION_TYPE DESCRIPTIVE_QUESTION QUESTION_ID 125799 What is the strategic importance of forecasting? What are the key QUESTION_TEXT activities that are influenced by forecasting? Human resources SCHEME OF EVALUATION 4M Typically, the number of persons required is a function of the production output which, in turn, depends on demand forecasting. Hence hiring, training, and laying off workers, all depend on the anticipated demand. When fresh workers are hired anticipating a rise in the demand, it is expected that they can quickly get into the required job. However, training is required apart from developing good relations with the existing workers. Similarly, if workers are removed, it sets a demoralising atmosphere. Further, the removed workers will spread the news, and the industry will suffer due to bad reputation and poor image. 4.3.2 Capacity 3M Capacity refers to the ability to meet the demand in terms of resources and the preparedness on the part of the company. When the demand pattern is well recognised and indicates a rise, the capacity build up happens and ensures that there are no lost sales for want of product. On the other hand, if the demand is showing a decline, it signals a decrease in capacity. Thus, unnecessary investments are not made. Both for capacity-lead and capacity-lag decisions, demand forecasting is vital. 4.3.3 Supply chain management 3M Supply chain management refers to all the activities that enable the right product at the right place at the right price. Hence, demand forecasting has to be done with utmost care to help identifying the vendors, pricing choices, and material options. When the demand is properly forecasted, it is easy to plan for the suppliers, logistics, and other intermediaries to ensure the delivery of the product at the right time. QUESTION_TYPE DESCRIPTIVE_QUESTION QUESTION_ID 159607 QUESTION_TEXT Under operations management, explain the steps in implementation of operations. Estimating – Estimating gives the quantities to be made at each workstation depending on the sales forecast, provision for buffer stock, quantities bought out, services outsourced, likely shortfalls, and others. It is made on the basis of capacity. SCHEME OF EVALUATION Routing – Routing determines the sequence of operations and the machines that do them, so that work flow, as determined by the processes, is smooth resulting in minimum inventory. Scheduling – Scheduling is mainly concerned with allocating time slots for different jobs. It specifies as to when the jobs start and end at particular workstations. The purpose is to prevent the imbalances among work centres and to utilise the labour hours in such a way that established lead times are maintained. Dispatching – Dispatching is concerned with moving of the materials with tools, jigs, and fixtures to specific machines along with the drawings and ensuring inspections at specific nodes, so that the materials move in the supply chain. Expediting – Expediting ensures that all the above are being done properly. Reports are generated and any bottleneck that gets created is removed. (2 Marks each)