400/230 V

advertisement

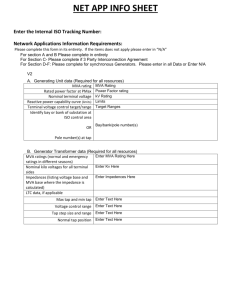

ILC Power Distribution Status Presentation Hamburg, May 2007 J. Pedersen CERN GDE meeting Hamburg May 2007 Global Design Effort 1 Status: Power Distribution • This presentation is an updated version of the one made in Valencia in November 2006. GDE meeting Hamburg May 2007 Global Design Effort 2 Status: Power Distribution • Since Valencia, November 2006 the following has happened: – The power needs of the project seems to stabilize around 230 MVA – The unit loads in certain areas are still to be defined in more detail to allow the Engineering Design to start GDE meeting Hamburg May 2007 Global Design Effort 3 Contents • • • • • Load schedule Network design The area systems Safe power systems Cost Reductions GDE meeting Hamburg May 2007 Global Design Effort 4 Load Schedule, User demands • The users have analysed their load demands and have arrived at an overall load of around 230 MW. • The breakdown of the load is only partially available and the location of the load elements is not developed. Work is needed here to allow the detailed Engineering Design to start • The Need for the integration studies of equipment to be installed in the limited underground space should not be forgotten! GDE meeting Hamburg May 2007 Global Design Effort 5 Load Schedule MW GDE meeting Hamburg May 2007 Global Design Effort 6 Load Schedule ILC top level distribution: 400 kV/36 kV VALENCIA Services links 36 kV 500 3150 5100 11 7 5100 2750 5 26 MW 32.5 MVA 520 A 3 2750 5100 4 2 1.x 41 MW 51 MVA 816 A 32 MW 40 MVA 640 A 5100 6 32 MW 40 MVA 640 A 32 MW 40 MVA 640 A 3 x 300 mm2 Cu: 795 A 15 MW 500 10 26 MW 32.5 MVA 520 A 3 x 240 mm2 Cu: 700 A 3 x 240 mm2 Cu: 700 A RTML 10 MW 3150 3 x 400 mm2 Cu: 915 A Main Linac 75 MW 30 MW 3 x 400 mm2 Cu: 915 A 30 MW 30 MW 3 x 300 mm2 Cu: 795 A Main Linac 75 MW 30 MW Dumps 4 MW Service tunnel 15 RTML 10 MW MW e+ source 20 MW e+ source BDS 12 MW Beam tunnel BDS 12 MW 5 MW 6 MVA Cable current capacity done for: Air, flat formation 90 C screens bonded at both ends e- source 15 25 MW 31 MVA 14 e- Source 5 MW MVA ? Damping ring 25 MW 12 GDE meeting Hamburg May 2007 13 Global Design Effort 7 Network Design • The retained voltage levels are (European site) : – Grid connection: 400 kV – Energy transport to the pits and access areas (Distribution substations): 36 kV – Energy distribution in the areas: 36 kV – 3.6 kV for large motor-compressor sets (> 400 kW; cryogenics?, chillers?) – 3.6 kV for the safe power transport – Local distribution to the general user: 400/230 V • Regional differences will exist. They are considered of limited importance for the design and the cost. GDE meeting Hamburg May 2007 Global Design Effort 8 Network Design • The center of the network will be the main substation, containing (European site): – One bay for the connection to the grid – Four transformer bays: 400/36 kV – Four 36 kV bus-bars, interconnected with bus-ties, allowing operation with one transformer failed. • A simple lay-out of the main sub-station is shown in fig. 1 GDE meeting Hamburg May 2007 Global Design Effort 9 Network Design • Central substation 400/36 kV 400 kV 130 MVA 130 MVA 1 36 kV cable link to point 1 5 36 kV cable link to point 5 7 36 kV cable link to point 7 GDE meeting Hamburg May 2007 130 MVA 3 36 kV cable link to point 3 Global Design Effort 130 MVA 6 36 kV cable link to point 6 2 4 36 kV cable link to point 2 36 kV cable link to point 4 10 Network Design, Power Ratings • The total power, demanded by the users (RDR) is 230 MW • Then the power rating of the transformers would depend on the power factor: • PF = 0.80 => 288 MVA • PF = 0.85 => 270 MVA • PF = 0.90 => 256 MVA GDE meeting Hamburg May 2007 Global Design Effort 11 Network design • Prudence will that the transformer rating is selected at 110 MVA per unit minimum. – (1770 A, well within the limit for standard 36 kV equipment: 2500 A) • This represents a reserve of roughly 20% with respect to the load, at cosphi = 0.85. • It is proposed to invest in a hot spare - kept under voltage, possibly in operation - i.e. four units in total. • 110 MVA units can be easily manufactured and transported as three phase units. Road transport is feasible GDE meeting Hamburg May 2007 Global Design Effort 12 Network design • The main substation will have four 36 kV bus-bars. Each of the three active transformers will feed one of them. • The distribution substations in the access areas will be fed from the main sub-station by 36 kV cable links. • The cables are laid in open loop configuration. This gives added operational flexibility in case of equipment failure in the top level power distribution. GDE meeting Hamburg May 2007 Global Design Effort 13 Network Design • Open loop 36 kV cable links to the central substation Pit n Pit n + m RMU GDE meeting Hamburg May 2007 Global Design Effort 14 Network design • The 36 kV cables will be run in the service tunnel. • They will run on cable ladders, equipped with perforated covers. This will provide mechanical protection. – European version; regional differences may exist here. • In the central area, between pit 2 and 1, up to 8 sets of three single core cables may be routed in the tunnel. • Over the major part of length of the Linac it will be 2 sets plus one, for the emergency supply, running in the service tunnel. GDE meeting Hamburg May 2007 Global Design Effort 15 Available short circuit power •The short circuit power with this solution will vary from around 200 MVA on the 36 kV busbar in the furthest pit to around 675 MVA on the 36 kV busbar in the central substation. •These values can be influenced by the transformer design and the cable cross section. •During the engineering design the voltage drops in the system downstream in the furthest points should be given attention. GDE meeting Hamburg May 2007 Global Design Effort 16 Network design • The distribution substations will comprise two 36 kV switchboards, made up of 36 kV modular switch gear • One for machine supply • One for services • Each switchboard will have voltage monitoring • The two switchboards will be interconnected by a bus-tie. GDE meeting Hamburg May 2007 Global Design Effort 17 Network design • Each feeder will be equipped with the relevant protection equipment, able to perform protection, measurements, logical sequences for interlocks etc. and oscillographic event recording. • The next four figures show single line diagrams of the substations of pits 2, 4 5 and 12. GDE meeting Hamburg May 2007 Global Design Effort 18 Network design 36 kV links to main substation Machine network 36 kV busbar Service network e- tunnel RF2-4 2 MVA 2 MVA 400 V ? Chillers 1560 kVA BDS tunnel 6 MVA Tunnel services, 1.0 and 1.1 to 2 400 V Cryogenics warm building Tunnel services, 2-4 2 MVA 1.25 MVA 400 V Shaft access building Y kV Cryogenics cold buildings Process water 1383.8 kW 2 MVA 8 exhaust fans each 12 kW 400 V Subst. auxiliaries 2 MVA 400 V workshop 2 MVA 400 V Cooling and vent. 2 MVA 2 MVA 1.575 MVA 1.25 MVA Site access e- source. 4 feeders/transformers, 1 feeder/transformer for RF. Surface Underground Office area Office building 400 V Personnel facilities building BDS Service tunnel Pit 1.0, 1.1 Beam tunnel Pit 4 Substation pit 2, Main Linac, e- source GDE meeting Hamburg May 2007 Global Design Effort 19 Network design 36 kV links to main substation Machine network RF 2-4 2 MVA 3 MVA 2 MVA 6 MVA RF 4-6 6 MVA 1.25 MVA Tunnel services, 2 to 4 400 V Dehumidifiers 4x350 kW 400 V? Chillers 2603 kVA 400 V Cryogenics warm building 36 kV busbar Service network Y kV Cryogenics cold buildings Tunnel services, 4 to 6 Y kV Cryogenics cold buildings 2 MVA 400 V Shaft access building Process water 1383.8 kW 2 MVA 8 exhaust fans each 12 kW 400 V Subst. auxiliaries 2 MVA 400 V workshop 2 MVA 400 V Cooling and vent. Office area Site access Office building 400 V Personnel facilities building Surface Underground Service tunnel Pit 2 Pit 6 Beam tunnel Substation pit 4, Main Linac GDE meeting Hamburg May 2007 Global Design Effort 20 Network Design 36 kV links to main substation 3 MVA 2 MVA 400 V Dehumidifiers 4x350 kW 2 MVA 400 V? Chillers 2603 kVA 6 MVA 400 V Cryogenics warm building 36 kV busbar Service network Machine network 6 MVA Y kV Cryogenics cold buildings Y kV Cryogenics cold buildings RF 5-7 RF 3-5 1.25 MVA Tunnel services, 5 to 7 Tunnel services, 3 to 5 2 MVA 400 V Shaft access building Process water 1022.8 kW 2 MVA 4 exhaust fans each 12 kW 2 MVA 2 MVA 2 MVA 2 MVA 400 V Subst. auxiliaries 2 MVA 400 V workshop 2 MVA 400 V Cooling and vent. 2 MVA Office area Site access e+ source, undulator. 2 feeders/transformers for beam part, 3 feeders/transformers for service part, Office building 400 V Personnel facilities building Surface Underground Service tunnel Pit 7 Beam tunnel Pit 3 Substation pit 5, Main Linac, e+ source GDE meeting Hamburg May 2007 Global Design Effort 21 Network Design 36 kV 36 kV damping ring loop 2MVA 400 V 630 kVA 400 V Process water 361 kW, 8 x 12 kW fans M 2 MVA 400 V Power converters, magnets? 2 MVA 400 V Klystron power supplies Surface Underground Damping ring tunnel Pit 13 Pit 3 Substation Pit 12, Damping ring GDE meeting Hamburg May 2007 Global Design Effort 22 Network design • The power distribution in the tunnels will be based on 36 kV cable links, distributing via Ring Main Units and local distribution transformers: 36 / 0.4 kV. The local distribution will be 400/230 V three phase. – European version; regional differences may exist. • The 400/230 V cabling will be five-wire, including neutral and PE, except specific cases where only three phase systems are supplied; f. ex. power converters. – Regional differences may exist, depending on standards. GDE meeting Hamburg May 2007 Global Design Effort 23 Tunnel High Voltage Main Linac 36 kV RF supplies, transformers supplied by RF system 1 RF unit 36 m Conventional supplies 4 RF units 144 m GDE meeting Hamburg May 2007 Global Design Effort 24 Tunnel High Voltage GDE meeting Hamburg May 2007 Global Design Effort 25 Tunnel High Voltage GDE meeting Hamburg May 2007 Global Design Effort 26 Tunnel High Voltage B GDE meeting Hamburg May 2007 Global Design Effort 27 Tunnel High Voltage 25 – 39 MVA GDE meeting Hamburg May 2007 Global Design Effort 28 Tunnel distribution Lay-out of the supply for a 144 m tunnel segment Tunnel floor. Tunnel diameter: 4.5 m 400/230 V distribution switchboards Transformer 36kV/0.4 kV Air-cooled, cast resin. RMU Centerline 800 1460 1550 1050 750 1050 3800 GDE meeting Hamburg May 2007 Global Design Effort 29 Tunnel Distribution An RMU in a 4.5 m tunnel 4.5 m 1050 2000 1100 GDE meeting Hamburg May 2007 Global Design Effort 30 Tunnel distribution • Auxiliary voltage – The equipment in the tunnel will most likely need an auxiliary voltage: 48 V D.C. • This voltage cannot be transported reasonably over large distances; – Voltage drop versus cable section • Alternative: – Produce 48 V at every 144 m, including batteries! Reliability, maintenance (Approximately 170 sources.) • To be looked into during engineering design GDE meeting Hamburg May 2007 Global Design Effort 31 Network design • Each distribution substation will comprise a complete 48 V supply with battery back-up for the safety systems: – The protection equipment of the H.V system – Trip coils and other auxiliaries of the H.V. and L.V. switchgear – Emergency lighting – Emergency stop systems – Power network SCADA system • The 48 V supply will have two battery chargers, two 48 V distribution switchboards with a bus-tie and two batteries, NiCa. These installations shall be backed up by the diesel gen. sets GDE meeting Hamburg May 2007 Global Design Effort 32 Tunnel distribution • Thermal considerations • The switchgear, transformers and cables all dissipate heat in the tunnel. – Typical values: • RMU: RMU • 400 V switchgear: 1 kW per column, rated load • 500 kVA transformer: – No load losses: Po = 2 kW – Load losses: PCu = 6.5 kW • Cables: ? – Per 144 m module: (RMU + 8.5 + 3 + ?)kW GDE meeting Hamburg May 2007 Global Design Effort 33 Network design • Interface to the other systems – Where does the cost and responsibility of the A.C. power distribution stop? • Example, sub-distribution: – The limit of the responsibility of the A.C. distribution is the end of the cable reaching a sub-distribution board installed by another team. The distribution internal to the subdistribution is the responsibility of the relevant team. GDE meeting Hamburg May 2007 Global Design Effort 34 Network design • Example, cooling skid: – The limit of the responsibility of the A.C. distribution is the end of the cable reaching a cooling skid. Any distribution internal to the skid is the responsibility of the cooling team. • Example, cryogenic motor-compressor set: – The limit of the responsibility of the A.C. distribution is the end of the cable reaching the connection points of the motor. Any distribution internal to the compressor set is the responsibility of the cryogenics team. GDE meeting Hamburg May 2007 Global Design Effort 35 Network Design Shaft 5, cooling and vent. Transformer 4-5 2.5 MVA, 36kV/0.4 kV Sump pumps Towers, chilled water 23 kW 12 kW 6 kW 21 kW 10 x 40 A 210 kW 10 x 40 A 10 x 32 A 120 kW 10 x 16 A 60 kW 17 x 60 A 379 kW, Vancouver version GDE meeting Hamburg May 2007 17 x 32 A 204 kW, Global Design Effort 17 x 40 A 357 kW, 17 x 16 A 102 kW, 36 Heater 10 x 100 A Fan pump Cooling tower pump Cooling tower fan Cooling tower spray pump Cooling tower immersion heater Cooling tower immersion heater Cooling tower spray pump 17 x 40 A 357 kW Cooling tower fan Cooling tower spray pump Cooling tower fan Chiller 1560 kVA Heater Cooling tower pump 112 kW 112 kW 150 kW 150 kW 10 x 60 A 224 kW Switchboard type 3 Cooling tower pump Cooling tower pump Chilled water pump, secondary loop Chilled water pump, secondary loop Dehumidifiers Fan pump 17 x 100 A 680 kW Cooling tower immersion heater 4fans, 4 x 32 A 48 kW Cooling tower pump 350 kW 350 kW 350 kW 350 kW Dehumidifiers and fans Cooling tower pump Chilled water pump, primary loop Chilled water pump, secondary loop 3 sump pumps 3 x 100 A 168 kW Transformer 10-5 2.5 MVA, 36kV/0.4 kV Process water Switchboard 3600 A, 400 V type 1 Tower, process water Chilled water 75 kW 75 kW 150kW Switchboard 3600 A, 400 V type 1 Transformer 6-5 2.0 MVA 36kV / 3.6 kV ? Main Linac • The power distribution of the Main Linac consists of three major systems: – The conventional services supply • The services will be supplied from a 36 kV cable link with RMUs inserted every 144 m, or every 4th RF unit. A 500 kVA, 36/0.4 kV transformer and a switchboard will handle all conventional power in a 144 m module. – The RF supply • Only a 36 kV cable link and the RMUs will be provided. – The safe supply • Based on diesel generator sets and, possibly static UPS systems. Still to be defined in detail. GDE meeting Hamburg May 2007 Global Design Effort 37 Main Linac • The conventional services supply – The services will be supplied from a 36 kV cable link with RMUs inserted every 144 m, or every 4th RF unit. A 500 kVA, 36/0.4 kV transformer and a switchboard will handle all conventional power in a 144 m module. • • • • • • The overall non-RF load is approximately 70 MW Applying PF = 0.85 we get 82 MVA. There are 157 modules of 144 m. Per module the non-RF load is thus 520 kVA. A 500 kVA transformer has been foreseen. A bit of fine tuning will be needed. GDE meeting Hamburg May 2007 Global Design Effort 38 Main Linac • Power needs of 144 m Main Linac tunnels, according to criteria sheet • Beam tunnel – Cryogenic module with quad?, (power conv.) – Cryogenic module without quad? – Cryogenic auxiliaries? – Vacuum system? (pumps. f. ex.) – RTML quads? (new) – Socket outlets – Lighting – Water?, HVAC?, Drain and sump? – Other utilities? – Transport? GDE meeting Hamburg May 2007 Global Design Effort 39 Main Linac • Power needs of 144 m Main Linac tunnels, according to criteria sheet • Service tunnel – – – – – – – – – RF racks: 45 kVA Other racks: 45 kVA Socket outlets Lighting Water (process), water (chilled), pumps etc.? Water ( de-mineralised) HVAC? Drain and sump? Transport? Other utilities GDE meeting Hamburg May 2007 Global Design Effort 40 RTML • From the power distribution point of view the 1330 m long RTML areas are like the LINAClike 144 m modules: – 730 m or 5 x 144 m of them with RF – 600 m or 4 x 144 m of them without – The conventional services are considered largely identical • The detailed development of the power distribution of the RTML areas will require a better knowledge of the lay-out, or integration of the equipment. GDE meeting Hamburg May 2007 Global Design Effort 41 RTML • The long low-energy beam lines, part of the RTML have not yet been taken into account by the A.C. distribution. • According to the RTML people, each quad has to be fed from an independent P.C. GDE meeting Hamburg May 2007 Global Design Effort 42 Source e• The power demands for the e- source are rather well defined. – A H.V. distribution is proposed for the area. – The costing based on the criteria sheet was developed for Vancouver, incl. a tentative L.V. distribution. – The e- source installation needs a clear definition of the interface and a lay-out to be able to identify the unit loads and their position GDE meeting Hamburg May 2007 Global Design Effort 43 Source e+ • A preliminary proposal has been made for the e+ source. – A H.V. distribution is proposed for the area. – It covers in some detail the Undulator area. – The power distribution of the rest of the e+ source system has been estimated as place holder – The costing based on the criteria sheet was developed for Vancouver, incl. a tentative L.V. distribution. GDE meeting Hamburg May 2007 Global Design Effort 44 Damping rings • The power distribution in the damping ring tunnel will be based on a 36 kV cable loop. Or two? The loop will be designed to operate open. The loop will allow best possible isolation of faults. • The loop will originate from the Central area surface substation and will be brought to the surface at all damping ring pits. There it will supply, via a 36 kV/0.4 substation, the surface area and the underground installations. GDE meeting Hamburg May 2007 Global Design Effort 45 Damping rings • The low voltage power lines for conventional services will originate from the alcoves. The lines should not be longer than around 600m. Otherwise it becomes difficult to design the lines with a proper protection. • It is not possible to operate with RMU-like systems in the DR tunnel, due to the limited diameter. GDE meeting Hamburg May 2007 Global Design Effort 46 Damping rings Lay-out of an alcove substation. Transformer RMU 400/230 V Distribution switchboards 48 V system GDE meeting Hamburg May 2007 400/230 V Safe supply Global Design Effort 47 Beam Delivery System • BDS Load Breakdown – A number of aspects are becoming clearer, but the power distribution for the BDS is still very much a placeholder. – The reasonably well-defined parts are the H.V. power links and the conventional services. – The machine related parts are still not clear. • Magnet loads ? • Cooling and ventilation? • Cryogenics ? • The integration of this area, most likely with a considerable amount of equipment positioned in the service tunnel, is quite important. GDE meeting Hamburg May 2007 Global Design Effort 48 Detectors • Detector (s) – Power demands unknown. Exists in the costing as place holder. Scaled on CERN experiments. GDE meeting Hamburg May 2007 Global Design Effort 49 Safe power systems • The safe power systems will be based on diesel generator sets (Short break) and static UPS sets (No break). • The dimensions of the project will probably require high voltage generation (3.6 kV) • Long autonomy D.C. systems should be used for critical systems like emergency lighting and network related safety. GDE meeting Hamburg May 2007 Global Design Effort 50 Safe Power Systems Normal supply M 36/3.6 kV X MVA G 3.6 kV 500 m 500 m 500 m 500 m 500 m Local safe loads GDE meeting Hamburg May 2007 Global Design Effort 51 The SCADA system • Supervisory Control And Data Acquisition systems should be purchased from companies with proven expertise in the field! • In order to obtain success with a SCADA system you should use – Existing, proven standard hardware – Standard communication protocols • Can be vendor’s protocol, if he is big enough in the trade: Siemens, ABB, Westinghouse – Equipment that allows for a certain number of hardwired signals to the local control centers GDE meeting Hamburg May 2007 Global Design Effort 52 The SCADA system • Accelerator control specialists believe this to be a mundane activity, that they can handle between breakfast and lunch. • Experience has proven them wrong. • But that does not keep them from trying. • A SCADA system is the main source of information about the state of the grid, the statistics, the consumption ($!) the maintenance etc. It should work as reliable as the network. And that requires professionals. GDE meeting Hamburg May 2007 Global Design Effort 53 Outstanding items • Better specifications of all area systems as electrical consumers. • In that sense development of lay-outs, even simple ones. F. ex in the style of the main linac RF unit. • Specifications of the BDS and the experiment as electrical consumers. GDE meeting Hamburg May 2007 Global Design Effort 54 Outstanding items • Detailed development of a proposal for the safe supply. • Detailed development of a proposal for the 48 V DC supply. • Development of the supply system for the BDS and the Experiments GDE meeting Hamburg May 2007 Global Design Effort 55 Conclusion • The power requirements of the project are stabilizing • Certain area managers should sit down with the future electrical engineer(s) and work out their power and installation requirements in detail • This presentation contains a selection of principles for the construction of the ILC power distribution. It is based on European equipment, experience, standards and requirements. • Good luck with the work leading to the EDR! GDE meeting Hamburg May 2007 Global Design Effort 56