or SAP Best Practices for

advertisement

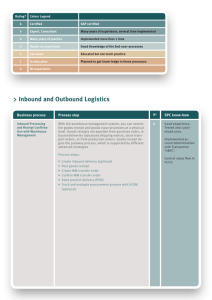

Warehouse and DC Management (Lean WM) SAP Best Practices for Retail (US) SAP Best Practices Scenario Overview 1 Purpose and Benefits: Purpose This scenario describes the processing of merchandise in the distribution center with inventory management done at the level of storage location – Lean Warehouse Management. Benefits Since storage procedures depend on space limitations, organization and the type of merchandise being stored, this scenario should be seen as one example of an implementation. However, this example can be easily adjusted to fit the warehouse of SAP customer. Key process flows covered Goods Receipt Processing Return Deliveries Goods Issue Processing Warehouse Physical Inventory Tools and Workbenches Scenario Overview 2 SAP Applications Required: Required SAP EHP3 for SAP ERP 6.0 Company roles involved in process flows Retail Warehouse Clerk Retail Sales Person Retail Warehouse Manager Retail Sales Person Retail Warehouse Clerk Process Flow Diagram 3.3.1 Create Purchase Order 3.3.2 Create Inbound Delivery 3.4.1 Posting Rough Goods Receipt 3.4.3 Goods Receipt with Reference to Rough Goods Receipt Document Flow in the Warehouse PO Inb. Delivery Rough GR GOODS RECEIPT PUTAWAY TRANSFER ORDER There is no stock keeping in Lean-WM, but just recording of movements using transfer orders. FIXED STORAGE BIN Outb. Del. GOODS ISSUE PICKING TRANSFER ORDER Inventory Management - IM vs. WM Inventory Management on article level Site Storage Location Whose number Storage type Fixed storage bin can be maintained in the article master (text field) No additional level of stock keeping below IM. Warehouse number and type are just used for the recording of stock movements using the transfer order, but no stock posting is triggered when moving merchandise at this level. Using Lean WM When you implement Lean WM, inventory management takes place solely at storage location level. The system does not update the stock data at storage bin level using the quants like the Warehouse-Management-System (WMS) . You use Lean WM solely for processing goods receipts and goods issues. Using Lean WM, you process the warehouse movements in basically the same way as if using the Warehouse Management System: you work with deliveries, and you create transfer orders for these deliveries. These transfer orders serve as pick lists. The use of transfer orders in Lean WM provides the following advantages: You can reprint transfer orders at any time. You can split transfer orders and thus distribute the workload better among the staff in your warehouse. You can use mass processing functions based on the transfer order (for example wave picks). Mass Processing of Deliveries Manual creation in the outbound delivery monitor using selection by: Delivery Delivery Delivery Delivery Delivery Shipping point Picking date Route, carrier ... Free selection Delivery Delivery Automatic generation using selection by: Picking date / time Additional filter by several criteria (e.g. route, shipping point, ship-to-party ...) Considering capacity restrictions: Group of Outbound Deliveries or Wave Pick Weight, volume Maximum items on the picking list Working time ... Mass Processing of Deliveries Delivery Delivery Delivery Delivery Delivery Delivery Delivery Collective Follow-On-Processing: Group of Outbound Deliveries or Wave Pick Create transfer order Confirm transfer order Post goods issue Rough Workload Estimate Planned Goods Issue Delivery Delivery Delivery Delivery Calculation of workload using: Estimated Workload in: Logistics Load Category Unit of Measure Whse no. / storage type Warehouse process Quantity Weight Volume Execution time Delivery Information on: needed manpower needed transport capacity Processes Goods Receipt and Return Deliveries Processes Picking and Goods Issue Process Physical Inventory