HVAC Final Demonstration

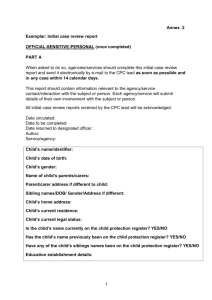

advertisement

ISE3 - HVAC Project Development of ISE Interoperability Modules Final Demonstration Washington, D.C. October 21, 2004 1 Agenda • ISE Project Overview • Interoperability and Integration • Common Parts Catalog (CPC) • Navy Vision • Highlights of ISE2 Demo - April 10, 2003 • Overview of TWR841 Test Ship • ISE3 - HVAC Demo • Return on Investment 2 ISE3 Team Participants Gulf Coast Region University of Maritime Technology Center New Orleans 3 Other Team Members from ISE2 Project • American Bureau of Shipping (ABS) • Altarum • Anteon Corporation (Proteus) • Marine Machinery Association (MMA) • Naptheon • Northrop Grumman Ship Systems Avondale Operations • Northrop Grumman Newport News • University of Connecticut 4 ISE Builds tools to Support 2nd Generation IPDE First Generation Integrated Product Development Environment (IPDE) Digital Virtual Product & Process Collaborative Design-Build MOCKUP 3D Design Electronic DRAWING • Data Config. Mgmt. • 3D • 3D Visualization Wireframe/Solids (Polygonal) • Computer-Aided • Rudimentary Data Drafting Mgmt • Desktop Visualization • Business Process Modeling • Interactive Walkthrough • Integrated Design/Build Process • Anthropomorphic Modeling • Sophisticated Eng.Analysis Digital Ship Design Process Evolution • Enhanced Product Model • Lean Design • Rule Based Design • Internet Technologies • Remote Collaboration • Intensive Simulations • High-end Integrated Analysis • Simulation Based Design 2nd Generation IPDE 5 ISE Background • First NSRP major systems technology • project Phase 1: Requirements definition and architecture for shipbuilding systems interoperability »March 1999 to December 1999 • Phase 2: Deployment for Structure & Piping »March 2000 to December 2003 • Phase 3: Deployment for HVAC & CPC Interfaces »October 2003 to October 2004 6 ISE Project Approach • Develop and demonstrate tools that are low cost – can be selectively used by shipyards to support interoperability – capitalize on XML and related Internet technologies • Flexibility is critical – allow shipyards to transform their data to/from common information model • Drive development of shipbuilding product data standards (e.g. STEP, PLIB) – Construct a single Shipbuilding Information Model – Demonstrate and educate U.S. shipbuilding community 7 ISE Architecture ISE architecture represents an innovative, practical solution to the information interoperability challenge • Accessible to large and small shipyards – Only system dependency is Web infrastructure – Utilizes open standards • Innovative integration of STEP and XML technologies – Supports sharing of geometric & geometric product models • Permissive (mediation) architecture – Lets each enterprise choose its own tool set • Incorporated into CAD platforms used by U.S. shipbuilders 8 Levels of Interoperability Inter-business system domain Shipyard A Shipyard B ERP/CAM ERP/CAM Intercomponent Intercomponent PDM/CAD PDM/CAD Inter-System Inter-System Parts Library Parts Library IDE INTOP IDE 9 Collaboration among Shipyards is Required in Today’s Environment • Almost every major recent U.S. Navy ship design and/or construction contract has involved collaboration among multiple shipyards – For example: • • • • CVNX (NGNN & EB) DDX (NGSS - Ingalls & Bath) Initial LPD Award (NGSS - Avondale & Bath) VIRGINIA (EB & NGNN) • This trend will continue • Navy views system interoperability as enabling multiple yards to be viewed as “One Shipyard” 10 11 NAVSEA Vision of “One Shipyard” 11 11 Goals of Integration • Better analysis through simulation • Re-use of data instead of redundant data – increased accuracy – eliminates unnecessary checking – speed of data entry (already entered) • Facilitates partnering with other firms • Reduce overhead costs 12 Integration Strategy • STEP (Standard for Exchange of Product Model Data) – Is a good common language for CAD Product Models • XML (Extensible Markup Language) – Is good for CAE applications • Therefore, combine the two, and embed small strings of STEP into XML, based on industry agreements, such as ISE 13 XML + STEP = Ideal Combo • XML brings: – Accepted format/schema method – Web-enabled • STEP brings: – Standards for data expression – Standards for geometric exchange Leverages development of interfaces 14 XML and STEP Transactions of Data Packaged in Standards Company A Virtual Ship part(s) XML = Industry Standard Container for Data STEP = ISO Standard Language for Data* Standards Company B Data XSLT - map data to another XML schema 15 Product Configuration : AP203 Shipbuilder Parts : PLIB Structural Analysis: AP209 : AP209 Structural Analysis HVAC : AP227 Cable harness design ed.2 : AP212 Ship Arrangement :: AP AP215 ShipArrangement Ship Forms: AP : AP216 ShipMoulded MouldedForms Ship ShipStructures Structures :: AP218 AP Ship Machinery: AP227 Ship Machinery: AP ed.2 Process ProcessPlant PlantPiping: Piping:AP227 AP Technical Data Package : AP232 System Engineering : AP233 Shipbuilding Product Data in STEP and System Product Definition Analysis / Simulation Results Delivery 16 DONXML • The Department of Navy (DON) vision for Extensible Markup Language (XML) is to fully exploit XML as an enabling technology to achieve interoperability in support of maritime superiority • For cataloging product data in XML format, the DONXML working group has agreed to allow the STEP Schemas developed under the ISE Project to be registered in the DONXML repository 17 Endorsement from Northrop Grumman "The development and testing of international standards for product data is important to the Shipbuilding industry for interoperablility and data archiving which will enable NAVSEA's "One Shipyard" Concept." Dave Whiddon VP Research, Development & Design Northrop Grumman Ship Systems 18 Endorsement from Electric Boat "Electric Boat endorses the development of interoperability tools and the use of international standards for product model exchange in the shipbuilding industry. We feel that these efforts (undertaken under the NSRP ASE Program) will enhance collaboration among U.S. shipyards and foster the Navy's goal of "One Shipyard". Millard Firebaugh VP-Innovation and Chief Engineer Electric Boat Corporation 19 The Navy and Shipbuilders Are Using Product Model Data Technology Product Model Data = 3-D CAD + definitions + other documentation Continued investment is key indication of value 20 ISE Tools • Tools developed by the ISE Project are made available on the Web at: www.isetools.org • These include: – Formal information requirements published • • • • Ship Piping Ship Structures Ship HVAC CPC Interfaces – Translator generators for custom representations – XML schema generators • ISO 10303-28 ed 2 – Automated test frameworks for conformance testing 21 NAVY Ships are a Highly Complex Product SSBN 12,000,000 HRS 1,000,000 PARTS 18,750 TONS SSN BOEING 777 FIGHTER AIRCRAFT LAND VEHICLE 8,000,000 HRS 950,000 PARTS 6,900 TONS 50,000 HRS 103,000 PARTS 254 TONS MISSILE 5,500 HRS 14,000 PARTS 65 TONS 1,700 HRS 5,000 PARTS 1.6 TONS AUTOMOBILES 57,000 HRS 30,000 PARTS 10 TONS INCREASING COMPLEXITY 23 HRS 3,000 PARTS 1.9 TONS Labor Hours 0 10 20 30 40 50 60 Parts Weight 70 80 MANUFACTURING TIME (MONTHS) 22 Roadmap - Past Ship Product Model Data Exchange ISO TC 184/SC 4/WG 3 AP 233 Systems Engineering Data Representation AP 239 Product Life-cycle Support Ship Structural Envelope Distribution Systems Piping Ship Arrangement ISO AP 215:2004 (Plant Spatial Configuration) Ship Moulded Forms ISO AP 216:2003 (Plant Spatial Configuration) Ship Structures ISO AP 218:2004 (Plant Spatial Configuration) ISO AP 227:2001 HVAC ISO AP 227 Edition 2 Equipment/Subsystems Parts Library ISO 13584 Finite Element Analysis ISO AP 209:2001 Reference Data Libraries ISO 15926 Computational Fluid Dynamics ISO AP 237 Cable Trays Logistics/Spares ISO AP 232:2002 ISO AP 227 Edition 2 Mechanical Systems (Plant Spatial Configuration) ISO AP 227 Edition 2 Electrical (Electrotechnical Design & Install) ISO AP 212:2001 Miscellaneous •Ship Structural Envelope (hull form, arrangements, structure) •Distributed Systems (piping, electrical, HVAC, cable trays, mechanical) •Equipment/Subsystems Automotive ISO AP 214:2001 23 Roadmap - Present Ship Product Model Data Exchange ISO TC 184/SC 4/WG 3 AP 233 Systems Engineering Data Representation AP 239 Product Life-cycle Support Ship Structural Envelope Distribution Systems Piping Ship Arrangement ISO AP 215:2004 (Plant Spatial Configuration) Ship Moulded Forms ISO AP 216:2003 (Plant Spatial Configuration) Ship Structures ISO AP 218:2004 (Plant Spatial Configuration) ISO AP 227:2001 HVAC ISO AP 227 Edition 2 Equipment/Subsystems Parts Library ISO 13584 Finite Element Analysis ISO AP 209:2001 Reference Data Libraries ISO 15926 Computational Fluid Dynamics ISO AP 237 Cable Trays Logistics/Spares ISO AP 232:2002 ISO AP 227 Edition 2 Mechanical Systems (Plant Spatial Configuration) ISO AP 227 Edition 2 Electrical (Electrotechnical Design & Install) ISO AP 212:2001 Miscellaneous •Ship Structural Envelope (hull form, arrangements, structure) •Distributed Systems (piping, electrical, HVAC, cable trays, mechanical) •Equipment/Subsystems Automotive ISO AP 214:2001 24 Roadmap - Future Ship Product Model Data Exchange ISO TC 184/SC 4/WG 3 AP 233 Systems Engineering Data Representation AP 239 Product Life-cycle Support Ship Structural Envelope Distribution Systems Piping Ship Arrangement ISO AP 215:2004 (Plant Spatial Configuration) Ship Moulded Forms ISO AP 216:2003 (Plant Spatial Configuration) Ship Structures ISO AP 218:2004 (Plant Spatial Configuration) ISO AP 227:2001 HVAC ISO AP 227 Edition 2 Equipment/Subsystems Parts Library ISO 13584 Finite Element Analysis ISO AP 209:2001 Reference Data Libraries ISO 15926 Computational Fluid Dynamics ISO AP 237 Cable Trays Logistics/Spares ISO AP 232:2002 ISO AP 227 Edition 2 Mechanical Systems (Plant Spatial Configuration) ISO AP 227 Edition 2 Electrical (Electrotechnical Design & Install) ISO AP 212:2001 Miscellaneous •Ship Structural Envelope (hull form, arrangements, structure) •Distributed Systems (piping, electrical, HVAC, cable trays, mechanical) •Equipment/Subsystems Automotive ISO AP 214:2001 25 ISE2 Demo Storyboard April 10, 2003 FlagShip SafeHull 7b 7a 2 1 IntelliShip 5 3 LEAPS Foran 6 4 CAE 9 CAM Database Deliverables ST-Viewer Pipe Stress Tribon Tribon SIMSMART Parts Lib CATIA CATIA Supplier CAM (IPT) AutoCAD 26 ISE Process - Detail Piping Design Demonstration on April 10, 2003 CATIA V5 ISE Tribon M2 27 ISE Process for Feeding Analysis Programs from Structural Design Atlantec TRIBON Intergraph ISDP Intergraph IntelliShip 28 Common Parts Catalog (CPC) Interfaces • Developed formal information for – CPC parts data – CPC documents • Basis for sharing parts data outside the CPC community • Specification of parts information requirements between Navy and shipbuilders – DONXML repository (in progress) 29 Integrated Shipbuilding Environment HVAC Demonstration Washington DC • October 21, 2004 Simsmart 30 The ISE Test Ship - TWR 841 This ship is used to locate and retrieve torpedoes and missile drones. It has a maximum payload capacity of 42 long tons which includes the deck cargo plus full liquids, full complement, and normal stores. 21 Oct. ‘04 This ship was selected because it is in-service, has a complete set of drawings available for distribution, and is: Approved for Public Release: Distribution Unlimited. 31 3 TWR Walkthrough myShipVi Selective HVAC STEP Export TWR IDE • Utilize ship CAD geometry data where possible • Access ship data in multiple systems • Technology leverages ISE XML schemas • Technology will be deployed on LPD 17-20 32 Business Case Concept Design Analysis Initial Design Parts Contract Design Teaming Shipyard Detailed Design Manufacturing 33 ISE3 Demo Overview Parts (CPC) Analysis (Simsmart ™) Teaming Shipyard Detailed Design (FORAN) Order Material Legend demonstrated discussed Initial HVAC Design (ISDP) Detailed Design Tool 1 (TRIBON) Parts (CPC) Parts (CPC) Analysis Detailed Design Tool 2 (CATIA) Manufacturing (EB Sheet Metal) Parts Catalog Analysis Tool CAD Tool Manufacturing 34 Initial Design – Part 1 Parts CPC (CPC) Analysis (Simsmart ™) Teaming Shipyard Shipyard Detailed Design (FORAN) OrderMaterial Material Order Legend demonstrated discussed Initial Initial HVAC Design (ISDP) Detailed Design Tool 1 (TRIBON) Parts CPC (CPC) Parts CPC (CPC) Analysis Detailed Design Tool 2 (CATIA) Manufacturing Manufacturing (EB Sheet Metal) Parts Catalog Analysis Tool CAD Tool Manufacturing 35 Initial Design - Part 1 ISDP Selective HVAC STEP Export STEP file ISDP ISE HVAC Translator ISE XML Analysis (Simsmart ™) 36 Initial Design Analysis Parts (CPC) Analysis (Simsmart ™) Teaming Shipyard Detailed Design (FORAN) Order Material Legend demonstrated discussed Initial HVAC Design (ISDP) Detailed Design Tool 1 (TRIBON) Parts (CPC) Parts (CPC) Analysis Detailed Design Tool 2 (CATIA) Manufacturing (EB Sheet Metal) Parts Catalog Analysis Tool CAD Tool Manufacturing 37 HVAC Design & Performance Analysis 38 Common Parts Catalog Parts (CPC) Analysis (Simsmart ™) Teaming Shipyard Detailed Design (FORAN) Order Material Legend demonstrated discussed Initial HVAC Design (ISDP) Detailed Design Tool 1 (TRIBON) Parts (CPC) Parts (CPC) Analysis Detailed Design Tool 2 (CATIA) Manufacturing (EB Sheet Metal) Parts Catalog Analysis Tool CAD Tool Manufacturing 39 Common Parts Catalog 40 Initial Design – Part 2 Parts (CPC) Analysis (Simsmart ™) Teaming Shipyard Detailed Design (FORAN) Order Material Legend demonstrated discussed Initial HVAC Design (ISDP) Detailed Design Tool 1 (TRIBON) Parts (CPC) Parts (CPC) Analysis Detailed Design Tool 2 (CATIA) Manufacturing (EB Sheet Metal) Parts Catalog Analysis Tool CAD Tool Manufacturing 41 Initial Design - Part 2 ISDP Selective HVAC STEP Export STEP file Updated Plenum ISDP ISE HVAC Translator ISE XML Detailed Design (TRIBON) 42 Importing into Tribon (Atlantec) Parts (CPC) Analysis (Simsmart ™) Detailed Design Tool 1 (TRIBON) Teaming Shipyard Detailed Design (FORAN) Order Material Legend demonstrated discussed Initial HVAC Design (ISDP) Parts (CPC) Parts (CPC) Analysis Detailed Design Tool 2 (CATIA) Manufacturing (EB Sheet Metal) Parts Catalog Analysis Tool CAD Tool Manufacturing 43 Export to Foran (Atlantec) Parts (CPC) Analysis (Simsmart ™) Detailed Design Tool 1 (TRIBON) Teaming Shipyard Detailed Design (FORAN) Order Material Legend demonstrated discussed Initial HVAC Design (ISDP) Parts (CPC) Parts (CPC) Analysis Detailed Design Tool 2 (CATIA) Manufacturing (EB Sheet Metal) Parts Catalog Analysis Tool CAD Tool Manufacturing 44 Teaming Yard Detailed Design Parts (CPC) Analysis (Simsmart ™) Teaming Shipyard Detailed Design (FORAN) Order Material Legend demonstrated discussed Initial HVAC Design (ISDP) Detailed Design Tool 1 (TRIBON) Parts (CPC) Parts (CPC) Analysis Detailed Design Tool 2 (CATIA) Manufacturing (EB Sheet Metal) Parts Catalog Analysis Tool CAD Tool Manufacturing 45 Teaming Shipyard Returns Part FORAN FORAN TWR’s Preliminary Design (ISE2) FORAN TWR’s Structural Detailed Design (ISE2) TWR’s HVAC Detailed Design Selective HVAC STEP Export ISE3 FORAN HVAC STEP Export Translator ISE3 P21 STEP file OUTPUT 46 Teaming Shipyard Returns Part FORAN Database FORAN HVAC STEP Import Translator ISE3 P21 STEP file INPUT FORAN HVAC STEP Export Translator ISE3 OUTPUT P21 STEP file 47 Import into Tribon Parts (CPC) Analysis (Simsmart ™) Detailed Design Tool 1 (TRIBON) Teaming Shipyard Detailed Design (FORAN) Order Material Legend demonstrated discussed Initial HVAC Design (ISDP) Parts (CPC) Parts (CPC) Analysis Detailed Design Tool 2 (CATIA) Manufacturing (EB Sheet Metal) Parts Catalog Analysis Tool CAD Tool Manufacturing 48 Transfer to Manufacturing Parts (CPC) Analysis (Simsmart ™) Teaming Shipyard Detailed Design (FORAN) Order Material Legend demonstrated discussed Initial HVAC Design (ISDP) Detailed Design Tool 1 (TRIBON) Parts (CPC) Parts (CPC) Analysis Detailed Detailed Design Tool 2 (CATIA) Manufacturing (EB Sheet Metal) Parts Catalog Analysis Tool CAD Tool Manufacturing 49 Manufacturing Parts (CPC) Analysis (Simsmart ™) Teaming Shipyard Detailed Design (FORAN) Order Material Legend demonstrated discussed Initial HVAC Design (ISDP) Detailed Design Tool 1 (TRIBON) Parts (CPC) Parts (CPC) Analysis Detailed Design Tool 2 (CATIA) Manufacturing (EB Sheet Metal) Parts Catalog Analysis Tool CAD Tool Manufacturing 50 Electric Boat HVAC Demo Scenario CATIA V5 STEP FILE Generate Manufacturing Parameters Common Parts Catalog CATIA V4 / CDM Manufacturing Process Manufacture Part 51 EB Manufactures Test Case 4 ELBOW H = 4” W = 6” Rin = 4” Rout = 12” DUCT H = 4” W = 6” L = 86”” TRANSITION H1 = 4” W 1 = 6” H2 = 3” W 2 = 12” L = 12” Revised Duct for Demo H = 4” W = 6” L =12” 52 Return on Investment (ROI) • Professor Alley Butler of the Gulf Coast Region Maritime Technology Center (GCRMTC) and the University of New Orleans is conducting a Return on Investment Analysis as part of the ISE3 Project • Although his study has not yet been completed, the following slides give some early results from his analysis 53 HVAC Data Exchange ROI • Current estimates point to substantial savings in engineering manhours by employing the AP 227 neutral format for porting information to Simsmart • Estimates are incomplete, but analysis is in progress – Part 1 : Flow Analysis – Part 2 : Manufacturing • Additional cost savings are anticipated from manufacturing implementation 54 Estimating Savings from an ISE-3 Implementation • The ISE-3 deliverables for HVAC permit porting of information from most commonly used CAD systems to the Simsmart analysis tool – This capability should save manhours of engineering and designer time – It avoids re-entering data to create the Simsmart models • Time is money. So, how much time and money is saved? 55 HVAC Data Exchange ROI • The Cruiser/Destroyer/Frigate Case – Potential Savings are estimated to be • 6,903 manhours • $414,162 for one ship design 56 HVAC Data Exchange ROI • This preliminary analysis can be extended to: – Other classes of ships (e.g. submarines, carriers) – Additional systems • i.e. for auxiliary systems that are not specifically HVAC, such as engine/generator uptakes • Additional exchange scenarios (such as Manufacturing) should also be included in calculating ROI 57 NIST: Economic Impact Assessment - Product Data Sharing - • The Shipbuilding Industry has the opportunity to realize $147.1M in annual benefits by sharing product data : - $76.4M in cost avoidance ◦ ◦ ◦ ◦ Elimination of redundant design, analysis, and manufacturing systems Training IT support Productivity loss - $70.7M in risk mitigation ◦ Model rework ◦ Manual data re-entry ◦ Delays • Currently, the Shipbuilding Industry is only realizing $25.7M in annual benefits. Source : Planning Report 02-05 December 2002 58 Goal : Implement in Production • • • The ISE Project has developed tools and demonstrated interoperability between shipyards in the areas of: – – – – Structure Piping HVAC Common Parts Catalog Interfaces The goal of current and future efforts is to make these techniques and tools available in production and to all U.S. shipyards – STEP Shipbuilding Translators – XML Tools – Common Parts Catalog Interfaces A Website has been established to contain the relevant software tools, schemas, etc. as provided by the ISE Project – www.isetools.org 59 Summary • ISE3 has successfully demonstrated the potential of standards based data exchange to LEAN design and construction processes for HVAC as ISE1 and ISE2 had done for molded forms, structures and piping. • Two major challenges lie ahead of us: – Commercialization of this technology – Continuing to prototype standards based data exchange in other application areas such as ships arrangements, ships electrical systems, and system engineering 60 Conclusions • In order to increase the availability and lower the price of production ready tools: – The ship owner / operator needs to insist that data be delivered in a system neutral format – The shipbuilder needs to insist that STEP functionality be an integral part of product • The next challenge is to move this technology into the mainstream and that the technology is mature enough to transition into commercial CAD and Product Modeling products 61 Endorsements • The technology works and it is supported by upper management in major U.S. shipyards – "The development and testing of international standards for product data is important to the Shipbuilding industry for interoperablility and data archiving which will enable NAVSEA's "One Shipyard" Concept.” Dave Whiddon VP Research, Development & Design Northrop Grumman Ship Systems – "Electric Boat endorses the development of interoperability tools and the use of international standards for product model exchange in the shipbuilding industry. We feel that these efforts (undertaken under the NSRP ASE Program) will enhance collaboration among U.S. shipyards and foster the Navy's goal of "One Shipyard". Millard Firebaugh VP-Innovation and Chief Engineer Electric Boat Corporation 62