CaribooMuleDeerExperience2Reduced

advertisement

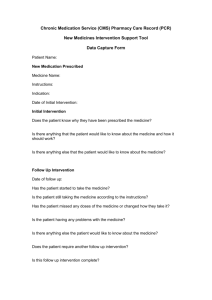

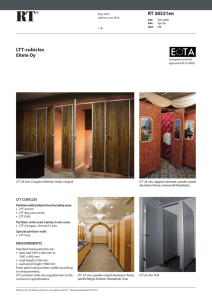

Lessons Learned On the Second Entry in a Cariboo Mule Deer Winter Range Alex Fraser Research Forest Ken Day, Manager SISCO Winter Workshop, February 10, 2015 | Kamloops, BC 1 EP903 – Coordination of Timber and Mule Deer Management Acknowledgements 2 Three Cutblocks As established 1984 Paired blocks with controls Remeasured cruise plots harvest and control Re-established track transects and remeasured pre-harvest 17.9 ha IDFdk3 38.2 ha IDFxm 38.4 ha IDFxm 3 Mule Deer Winter Range Cariboo Style History Guidance GAR Order 4 Basic Tenets 5 Silvicultural Approach Management Objective: Continuous supply of large, wide crowned Douglas-fir Strategy Clumpy Single Tree Selection BDq regulation Regeneration gaps up to 1 tree length in diameter Retain clumpy structure 6 Target and Prescribed Stand Structure 250 CB 222 Existing, Long Term Target (LTT) and Prescribed Stand Structure (PRSC) SPH 200 150 Fdi 100 LTT Dc = deciduous Marking Rule: Cut 1/3 50 PRSC 0 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 Diameter class (cm) 7 Mark to Cut 8 Map Existing and Planned Skid Trails Area of trails is limited in GAR Order Also map Wildlife and Danger Trees, No-work zones, Non-merch areas Digital map to logger 9 Logging Contractor Nilsson Select Contracting Williams Lake Harvester and Forwarder Cut to length at the stump Marking was critical to making his time efficient 10 End Result Compared to Plan 250 Inital, Long Term Target (LTT), Prescribed (PRSC) and Final Stand Structure from Cruise Data Initial Population 200 Long Term Target Prescribed Stand 150 SPH Final Stand 100 50 0 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 Diameter class (cm) 11 End Result Compared to Plan 6.0 Inital, Long Term Target (LTT), Prescribed (PRSC) and Final Stand Structure from Cruise Data Initial Population 5.0 Long Term Target Prescribed Stand 4.0 BA Final Stand 3.0 2.0 1.0 0.0 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 Diameter class (cm) 12 Value and Costs $70 Avg Value $/m3 $60 Mark+Production $/m3 $40 $30 $20 $10 1800 $- 1600 L50032-222 L50032-229 L50032-232 Pulp Veneer 1400 Saw 1200 Volume (m3) $/m3 $50 1000 800 600 400 200 0 L50032-222 L50032-229 13 L50032-232 Costs and Productivity Brokerage 3% Stumpage 0% Marking 11% Harvesting 42% Trucking 17% Loading 6% Fall & Skid OS 2% Forwarding 19% $30.00 CB 222 Cost ($/m3) $25.00 $20.00 CB 229 CB 232 $15.00 $10.00 $5.00 $0.00 14 Managing Costs and Productivity 15 Summary High Habitat MDWR cruising, layout, planning & supervision Harvester/Forwarder is the right method Less expensive to make decisions in your boots, than in the cab of a machine Pulpwood market $0.25/m3 stumpage Presented costs do not include Though marking is expensive, it needs to be done On this trial we broke even By regulation the harvest opportunity is limited Much of the growing stock is poorer than sawlog High accounts for 1/3 of the MDWR in the Cariboo IDF Every pulp log we made cost us money But those trees need to be cut to release the growing space These treatments will improve G&Y and contribute to long term habitat objectives 16 Questions? 17 Costs and Productivity Ken Byrne, Preliminary Results FPInnovations 2014 • Time and motion study for one shift • Elements will be applied to shift-level data and actual production at the block level Productivity Harvester Forwarder Tree Marking * Total * Assumed labour rate of 2 x $30/Hour. Productivity (m3/PMH) 12.2 42.4 60.7 Cost ($/m3) 17.47 5.03 1.01 23.51 Peter commented that stand/harvesting conditions were as good as it gets so calculated costs would be on the low side. 18