ST_MON_AM_1135_Schnier

advertisement

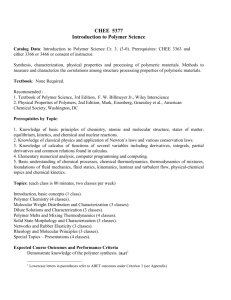

Are You Getting Your Money’s Worth? Dividends of Performance-Based Polymer Procurement Keller Schnier, PE November 2015 Acknowledgements Maggie Macomber, PE – Charlotte Water Jackie Jarrell, PE – Charlotte Water David Wagoner, PE – CDM Smith Presentation Take Aways Key steps in the polymer selection program Importance of: Proper polymer selection Planning the process Qualified participation Maintaining control of the process Polymer selection determination Lowest cost polymer = best value? Relationship between performance and overall cost 3 Importance of Proper Polymer Selection Cost Control Equipment Operations Polymer - type Biosolids - end use/disposal Quantity Dewatering performance Quality Handling Odors 4 Polymer Selection Goal Produce the best biosolids product for the lowest cost Best product fits your program needs Lowest Cost Polymer cost (selection and usage based) Operations and maintenance cost (operator and equipment) Reuse/disposal cost (performance based) 5 Polymer Selection – Step-Wise Approach Step 1 – Consider 3rd party Project/program manager Step 2 – Develop Customized Approach Baseline criteria development Establish ground rules and polymer selection criteria Testing plan and schedule Vendor Solicitation/selection Step 3 - Conduct Testing Selected vendors Bench-scale testing Full-scale testing Performance data development/handling Step 4 - Bid document/Polymer Selection 6 Step 1 – 3rd Party Project Manager Administers Polymer Trial program Time – coordination - responsiveness Manage the process and the vendors Single point of contact Multiple plants create challenges Uniformity and consistency Control of all data 7 Step 2 – Customized Approach Baseline criteria development Historical performance Equipment capacities Establish ground rules and polymer selection criteria Detailed testing plan and schedule Vendor selection 8 Advertise details Request submission of Notification of Interest Pre-submission meeting Selection of vendors for Trials Establishing Baseline Criteria Goal - Set boundaries/criteria for equipment operation, polymer use and required performance System review - conditions and limitations Polymer mixing Feed concentrations Feed capacity/ranges Dewatering system performance and information Capacity of dewatering equipment Historic performance data Special concerns Odors Fecal coliform reactivation or regrowth 9 Plant Information and Data Summary Sheets Facility Name Polymer storage/mix/feed Type of Device NSF Standard 60 Certification required Make/Model - Attach Specification Dedicated to thickening or combined with dewatering Number of units operational Polymer delivery - drum, tote, bulk Dewatering Feed, gpm Combined Bulk Polymer mixing system type - batch, continuous Batch, DW/TK Combo Current Daily average flow rate per unit Operating Range Min/Max per unit 320 Batch tank mixer type 250 / 390 Mix tank volume & batches per day Dewatering Feed Solids, % solids 4500 g X 3/13 M-F & 1.5 S-S Average 2.7 Make-up water source; plant or potable Minimum 2.3 Polymer feed system type Prog. Cavity Pump Maximum 3.3 Feed capacity range, gpm 10-35 gpm Desired 22 Dewatered Solids, % Solids Maximum polymer feed concentration Historical Lower Limit 18.5 Active polymer content, % Potable 1.00% 41 Neat Polymer Usage per day / year (gal) 310 / 80,600 18 Neat Polymer per batch (gal) Filtrate/ Centrate/Supernatant Solids, mg/L TSS Desired 100 Historical 150 Upper Limit 500 Operating schedule days of the week hours/day Number of units normally operated 10 No 5 24 1 Current Polymer mix feed conc, % 0.70% Polymer feed rate, gpm Current Average 30 Design Min/Max 0 / 35 Maximum Polymer dosage to achieve cake solids and centrate/filtrate/supernatant specified, lb total polymer/dry ton solids 60 SUBJECT: SOLICITATION OF INTEREST FOR POLYMER SUPPLY CONTRACT To Whom It May Concern: The ________is currently contacting polymer manufacturers that may be interested in supplying polymer for a twelve (12) month period. The polymer will be used in the sludge thickening and dewatering processes at the following facilities ______. Prequalification testing of polymer products will begin in _______. Interested Manufacturers are required to provide a Notification of Interest to: Notifications will be accepted until ___________. All information listed in the Applicant Qualification must be submitted in the Notification. Incomplete or partial submittal of information will not be accepted. A prequalification testing protocol, containing manufacturer qualifications, existing feed equipment description, polymer type specification, sludge characteristics, and evaluation criteria, is attached to this letter for reference. Please read the prequalification testing protocols very carefully. The polymer supplied shall be suitable as a conditioner for: anaerobically digested sludge prior to centrifuge or belt filter press dewatering, water treatment plant alum sludge prior to gravity thickening followed by belt filter press dewatering and secondary sludge centrifuge and gravity belt thickening prior to anaerobic digestion. The polymer supplied by the manufacturer shall be an anionic or cationic emulsion type. No gel, dry or liquid polymers will be accepted. The polymer shall be compatible with the City's existing equipment and treatment scheme and cause no impacts to effluent quality. The prequalification testing process includes: Bench-scale Laboratory Jar Testing: All manufacturers who express an interest will be given an appointment between ______________ to perform jar tests to screen their polymers. Each manufacturer may prequalify more than one product, but only one polymer will be chosen for full scale testing. Designated plant staff (or the city's representative) will be available to assist with jar testing in accordance with the polymer testing protocol. Full-scale Performance Testing: Manufacturers submitting products for full-scale testing will be given eight (8) to ten (10) hour appointments to demonstrate performance. Full-scale testing will be conducted during the months of ________________________. Manufacturers shall provide sufficient quantity of polymer to perform the full-scale tests using plant polymer feed systems on the designated thickening and/or dewatering equipment at no cost to the City. Minimum acceptable performance conditions are provided in the attached information. 11 Manufacturers whose polymers have proven to be effective and acceptable based on achieving the minimum acceptable performance requirements during the full-scale performance tests will be invited to offer a sealed bid. Control the Number of Vendors Seek Strong Technical Experience 1. The manufacturer must be the manufacturer of the polymer(s) and owner of the equipment used in the manufacturing of polymer(s) from component ingredients. Proof of manufacturing and ownership of the equipment must be submitted. 2. The manufacturer must provide current listing of ISO certifications such as 9001 and 14001 and other relative certifications such as designation from the American Chemistry Council as a Responsible Care® industry to demonstrate its dedication to quality control and environmental stewardship. 3. The performance testing shall be conducted under the direction of a designated technical representative (TR) provided by the manufacturer at no cost to the City. Manufacturer shall list the name, address and contact information for the proposed TR. Upon award of contract, the designated TR must be responsible to quickly address the needs of CMU regarding polymer supply and quality, and provide polymer use technical assistance. Accordingly, the residence of the TR must be within a 50 mile radius of _____. 4. Manufacturers shall certify that they have sufficient (existing) manufacturing capacity for the polymer products offered to the City. A detailed list, describing manufacturing capacity and location and a list of existing commitments shall be provided. This information will be used by the City to determine the capability of the prospective polymer manufacturer to supply polymer products in quantities adequate to meet processing requirements of the City. 5. Manufacturers shall include a list of at least three (3) municipal customers, with current contact information, that are currently using or have used the proposed polymer product(s) within the last three (3) years. This information will be provided to CMU and its representative using the form provided in Exhibit 1. 6. Qualified manufacturers while on plant sites with polymers shall maintain product information for all polymers that will be considered for the bench-scale and full-scale tests. At a minimum, product information shall include polymer name, product number, a current material safety data sheet (MSDS) and product specification indicating % active polymer content. 12 Other Key Items in the Solicitation Full-Scale testing and sampling details Procedural approaches Performance data development Polymer Performance Evaluation Calculations Calculations to be used Full transparency Avoid questions/contested conditions later 13 Full-Scale Test and Sampling Details 1. Full-scale testing will be allowed by appointment only. 2. A meeting will be held individually with each manufacturer before initiation of full-scale testing to review the goals, conditions, and responsibilities for the testing. 3. A maximum of two (2) people from the polymer manufacturer will be allowed on-site during the test. 4. A minimum of eight (8) hours, and a maximum of ten (10) hours per day of testing. Under no circumstances shall tests be continued past 5:30 P.M. 5. Minimum of five (5) acceptable polymer dosages with at least 30 minutes of run time per dosage. 6. Maximum of eight (8) acceptable polymer dosages with at least 30 minutes of run time per dosage. 7. Five (5) defined doses (minimum requirements) to be run as close as possible to: a. Lowest possible dosage (lbs/dry ton) to achieve performance goals, the next higher integer dosage (lbs/dry ton), and three (3) more dosages in 2 to 5 lbs/dry ton increments (total of 5 dosages); b. Each of the defined doses will be run twice for a maximum of ten (10) sample sets, and a maximum of sixteen (16) sample sets. 8. Average of the five (5) best acceptable sample sets will be used for evaluation 9. Plant personnel will collect and composite samples for the 30 min run period for each dosage. a. The first sample shall be collected 10 minutes after thickening/dewatering device startup; b. Thereafter samples shall be collected every 10 minutes (3 samples in 30 minutes). 10. Plant personnel will analyze samples and split samples will be analyzed by CMUs state certified laboratory. 14 Polymer Performance Evaluation Criteria Solids Feed Rate, SF, (lb/d) SF = 8.34 x QF x CF Where: QF = sludge feed rate (gpm) CF = sludge feed concentration (mg/L) Polymer Usage, PU, (lb polymer/dry ton) PU = SP / (SF/2,000) Polymer Feed Rate, SP, (lb/d) Sp = 8.34 x QP x CP Solids Recovery, R (%) Where: R =100 x C x (F-B)/(F x (C-B)) QP = polymer feed rate (gpm) CP = polymer feed concentration (mg/L) Polymer Feed Concentration (Neat), CP, (mg/L) CP = 120,090 x M / (VP+ VW) Where: M =Mass of neat polymer per test batch (lbs) VP =Volume of polymer per test batch (gallon) VW = Volume of water per test batch (gallon) 15 Where: C =Total cake solids (%) F =Sludge feed solids (%) B =Centrate solids (%) Example Polymer Performance Calculation Biosolids Production (avg): Land Application Costs: Polymer Dose (avg): Polymer cost: Dewatered Cake Solids (avg): % recovery (avg): 10 dry ton/day $15/wet ton 20 lb/dry ton $1.00/lb 20% solids 98% (from polymer trials) (current contract rate) (from polymer trials) (from polymer bid) (from polymer trials) (from polymer trials) Polymer cost per day = 5 dt/d x 20 lb/dt x $1.00/lb / 0.98 recovery = $102.04/day Land Application Costs = 5 dt/d x $15/wt / 0.20 % solids = $375/day Total Cost = $102.04 + $375 = $477.04/day 16 Selection of Qualified Vendors Pre-submittal meeting with interested Vendors Receive and review Letters of Interest Select 3 to 4 most qualified vendors 17 Step 3 – Conduct Testing Facility tours with Vendors Equipment review polymer measurement, mixing, and feed rate/control arrangements Q&A Refine Testing Schedule Bench-Scale Testing Full-Scale Testing 18 Bench-Scale Testing Conducted at plant site - lab setting Vendor conducts, Owner/PM observes One vendor at a time Sludge samples provided by Owner Owner keeps samples of polymers being considered for fullscale trials Vendor chooses polymer to advance to full-scale trial Projects and presents dosage rates for full-scale testing lb polymer/dry ton of solids Must fall within acceptable dosage range criteria 19 Full-Scale Testing Set dewatering machine operating conditions based on equipment operation ranges ~ mid range test all polymers under same conditions – level playing field Sample collection, control and testing - by Owner Microwave % solids analyzer Data management by Project Manager Performance criteria – pass/fail and range limitations Maximum allowed polymer dosage minimum solids capture % or max TSS levels minimum/maximum cake solids Performance data finalization 20 Step 4 – Vender Bid Price Submittal and Polymer Selection Facility: WWTP Address: ITB 269-0131-010 Manufacturer A B C D 21 Product NC 101 K290FLX 8846FS SE 757 Price Per Pound $ 0.96 $ 1.185 $ 1.11 $ 0.84 Vendor A Polymer Data Polymer Sp Gr Polymer lb/gal Vendor X Product input Polymer Feed Mix % (total), Ferric, $ per gallon Ferric, lb/gal Sludge disposal, $ per wt ton Polymer Bid Price, $/lb Sludge feed Poly Feed Rate, gpm Rate, gpm 251 251 251 251 251 251 251 251 251 251 20.5 22.0 23.5 24.5 24.5 23.5 22 20.5 20.0 19.5 22 Sludge Feed Cake Solids, % Solids, % 2.36 2.31 2.27 2.31 2.34 2.34 2.30 2.28 2.28 2.35 18 min 18.57 19.97 20.25 20.44 21.30 21.77 20.08 19.54 18.46 17.26 Centrate Solids, % .05 max 0.0163 0.0168 0.0154 0.0147 0.0198 0.0105 0.0198 0.0175 0.0194 0.0160 Centrate solids, lb/hr 20.47 21.10 19.34 18.46 24.87 13.19 24.87 21.98 24.37 20.10 Feed Solids, lb/hr 2964 2901 2851 2901 2939 2939 2889 2864 2864 2952 Feed Solids, DT/hr 1.482 1.451 1.426 1.451 1.470 1.470 1.444 1.432 1.432 1.476 input input input input Polymer Feed, lb/hr 79.71 85.54 91.37 95.26 95.26 91.37 85.54 79.71 77.76 75.82 1.04 8.67 0.78% $0.79 11.2 $15.00 $0.96 Polymer batch mix Polymer, gal Water, gal 33.82 4500 Polymer lb/DT feed solids 60 max 53.78 58.96 64.09 65.66 64.82 62.18 59.22 55.67 54.31 51.37 Capture 1=100% Solids Lost lb/hr 0.994 0.994 0.994 0.994 0.992 0.996 0.992 0.993 0.993 0.994 17.89 18.68 17.19 16.39 22.16 11.78 22.04 19.43 21.38 17.38 Net Polymer solids, lb/DT produced,net solids DT/hr produced 1.473 1.441 1.417 1.442 1.458 1.464 1.433 1.422 1.421 1.467 54.11 59.35 64.48 66.04 65.31 62.43 59.68 56.05 54.72 51.68 Ferric Feed lb per lb polymer 0.169 0.157 0.147 0.141 0.141 0.147 0.157 0.169 0.173 0.177 Polymer Cost per DT net solids $51.94 $56.97 $61.90 $63.40 $62.70 $59.93 $57.29 $53.80 $52.53 $49.61 Ferric cost per DT solids Cake Disposal Cost per DT $38.61 $80.78 $39.46 $75.11 $40.14 $74.07 $39.43 $73.39 $39.00 $70.42 $38.86 $68.90 $39.68 $74.70 $40.00 $76.77 $40.02 $81.26 $38.77 $86.91 Avg cost lowest 5 = Total Cost per DT $171.33 $171.55 $176.12 $176.21 $172.12 $167.69 $171.67 $170.57 $173.81 $175.29 $171.78 Vendor D Polymer Data Polymer Sp Gr Polymer lb/gal Vendor Y Product input Polymer Feed Mix % (total), Ferric, $ per gallon Ferric, lb/gal Sludge disposal, $ per wt ton Polymer Bid Price, $/lb Sludge feed Rate, gpm 250 250 250 250 250 250 250 250 250 250 Poly Feed Sludge Feed Rate, gpm Solids, % 26.5 25 23 21 20 20.5 21 21.5 22 22.5 23 2.27 2.35 2.29 2.24 2.3 2.42 2.34 2.36 2.28 2.35 Feed Cake Centrate Centrate Solids, Solids, % Solids, % solids, lb/hr lb/hr 18 min 19.6 19.43 19.42 18.17 17.1 18.11 18.47 18.97 18.6 19.02 .05 max 0.0162 0.0125 0.013 0.014 0.0423 0.0125 0.0168 0.0158 0.0119 0.0119 20.27 15.64 16.26 17.51 52.92 15.64 21.02 19.77 14.89 14.89 2840 2940 2865 2802 2877 3027 2927 2952 2852 2940 Feed Solids, DT/hr 1.420 1.470 1.432 1.401 1.439 1.514 1.464 1.476 1.426 1.470 input input input input Polymer Feed, lb/hr 102.04 96.27 88.57 80.86 77.01 78.94 80.86 82.79 84.71 86.64 1.03 8.59 0.770% $0.79 11.2 $15.00 $0.840 Polymer batch mix Polymer, gal Water, gal 33.82 4500 Polymer lb/DT feed solids Capture 1=100% Solids lost lb/hr 60 max 71.87 65.49 61.83 57.71 53.53 52.15 55.25 56.08 59.40 58.94 0.994 0.995 0.995 0.995 0.984 0.996 0.994 0.994 0.995 0.996 17.93 13.76 14.35 15.37 45.92 13.56 18.37 17.32 13.07 13.06 Net Polymer solids, lb/DT produced,net solids DT/hr produced 1.411 1.463 1.425 1.393 1.416 1.507 1.454 1.468 1.420 1.463 72.32 65.80 62.14 58.03 54.40 52.38 55.60 56.41 59.67 59.20 Ferric Feed lb per lb polymer 7.9 8.4 9.1 10.0 10.5 10.2 10.0 9.7 9.5 9.3 Polymer Cost per DT net solids $60.75 $55.27 $52.20 $48.75 $45.70 $44.00 $46.70 $47.39 $50.13 $49.73 Ferric cost per DT solids Cake Disposal Cost per DT $40.31 $76.53 $38.88 $77.20 $39.91 $77.24 $40.82 $82.55 $40.18 $87.62 $37.75 $82.83 $39.11 $81.21 $38.76 $79.07 $40.07 $80.65 $38.87 $78.86 Avg cost lowest 5 = Total Cost per DT $177.60 $171.35 $169.35 $172.12 $173.49 $164.58 $167.02 $165.22 $170.84 $167.46 $167.02 Performance Conditions + Polymer Price = Lowest Cost Outcome Cake Polymer Solids, % lb/DT Vendor A Vendor D 19.3 18.6 Polymer Bid, $/lb 56.4 $ 56.4 $ Polymer Cost, $/DT 0.96 $ 0.84 $ Cake Polymer + Disposal Disposal $/DT $/DT 54.51 $ 47.59 $ 77.72 $ 80.52 $ 132.23 128.11 Based on performance conditions, Vendor A could have won the contract with a bid of $0.875/lb Performance data provides documentation of the expected performance….once selected polymer is used 24 Summary All polymer is not created equal purchase polymer based on $/lb polymer alone - risky Polymer Trials can provide competitive, performance based polymer selection Qualify polymer vendors with technical expertise Set clear instructions and guidelines Control the process Trials protocol, sampling, testing, selection criteria Develop performance data for each polymer consistent testing conditions for all Apply bid price to performance conditions for lowest cost outcome 25 Questions schnierkw@cdmsmith.com