mRocket Systems Modeling Effort November 18, 2002

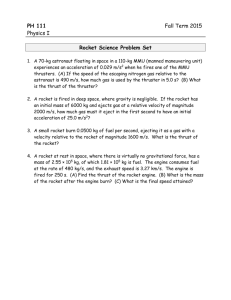

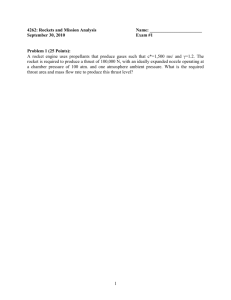

advertisement

GOING TO MARS WITH NUCLEAR THERMAL PROPULSION Daniel Robert Kirk Assistant Professor Mechanical and Aerospace Engineering Department Florida Institute of Technology October 22, 2004 Department of Physics and Space Sciences Colloquium 1 GOING TO MARS WITH NUCLEAR THERMAL ROCKET PROPULSION • Comments from President Bush (January 2004) – “Our third goal is to return to the Moon by 2020, as the launching point for missions beyond.” – “With the experience and knowledge gained on the Moon, we will then be ready to take next steps of space exploration: Human missions to Mars and to worlds beyond.” • A human mission to Mars implies need to move large payloads as rapidly as possible, in an efficient and cost-effective manner • Renewed interest in break-through deep space science/exploration missions – Project Prometheus and Jupiter Icy Moon Orbiter (JIMO) 2 OVERVIEW • Rocket Overview – Categorization of various types of Rockets – Rocket Mission Selection Guide – Rocket Performance Parameters • Nuclear Thermal Propulsion – Historical Overview – Hot Hydrogen Properties – Fluid Mechanic and Heat Transfer Modeling – Simulation Results • Future Work – What can we do at FIT? – How to Simulate Nuclear Reactors for Space Applications – New Experimental Facility – Analytical and Computational Efforts 3 WHY ROCKET PROPULSION? • Rockets provide means to: – Insert payloads into space (satellites, experiments, defense applications, etc.) – Space exploration (Atmospheric, solar system) – Precise, continuous or pulsed, momentum change (station keeping) – Weapons (wide range of missiles: cruise 1st stage boost, ICBM) – Rapid change in momentum devices (retro-rockets, JATO, car air bags) • Rockets vs. other propulsion devices – Advantages: orbital insertion, deep space travel, etc. – Disadvantages: carry all propellant, small payload fraction (STS ~ 0.01) – Area of vigorous research and development • Rocket propulsion is an exact, but not a fundamental subject – No basic scientific laws of nature peculiar to propulsion 4 ROCKET CLASSIFICATION • Rockets may be classified in many ways – Depending on energy source (chemical, electrical, nuclear, etc.) – Depending on gas acceleration mechanism / force on vehicle mechanism – Basic function (booster, sustainer, station keeping) – Type of vehicle (missile, aircraft, spaceship) – Based on performance measures (T, T/W, Isp, h) and/or propellant types – By number of stages • Primary distinction between Chemical (thermal) and Electrical systems – Only types of rockets in operation today – However, a future human mission to Mars will likely utilize a NEW version of an OLD concept: Nuclear Thermal Propulsion 5 CHEMICAL (THERMAL) ROCKETS: ENERGY LIMITED 6 Chemical Energy HOW A CHEMICAL ROCKET WORKS F Rocket Propulsion (class of jet propulsion) Thermal Energy Kinetic Energy F m eVe Pe Pa Ae F m eVe that produces thrust by ejecting stored matter • Propellants are combined in a combustion chamber where chemically react to form high T&P gases • Gases accelerated and ejected at high velocity through nozzle, imparting momentum to engine • Thrust force of rocket motor is reaction experienced by structure • Same phenomenon which pushes a garden hose backward as water flows from nozzle QUESTION: Could a jet or rocket engine exert thrust while discharging into a vacuum (with not atmosphere to “push against”)? 7 ELECTRIC ROCKETS: POWER LIMITED 8 NUCLEAR PROPULSION: PROJECT ORION • • 1955 (classified paper) release atomic bombs behind a spacecraft Bombs would explode, creating a hot plasma, which would them push against a spacecraft pusher plate, propelling it forward • Interstellar version: called for a 40-million-ton spacecraft to be powered by the sequential release of ten million bombs, each designed to explode roughly 60 m to vehicle's rear • Nuclear test-ban treaty: explosion of nuclear devices illegal “This is the first time in modern history that a major expansion of human technology has been suppressed for political reasons." 9 ADVANCED PROPULSION TECHNOLOGIES • • • • • • • • • • • Solar sailing is a method of converting light energy from the sun into a source of propulsion for spacecraft Obtain propulsive power directly from Sun No Engine → No Need to Carry Fuel Photons are reflected off giant, mirror-like sails made of thin, lightweight, reflective material Continuous pressure exerted by photons provide thrust Very high Isp Open up new regions of solar system for exploration, with no environmental impact on Earth Leading candidate for missions that require spacecraft to hold position in space, rather than orbit Earth or Sun May also extend duration of other missions Light Sails Do NOT harvest the solar wind for their propulsion (solar wind < 0.1% due to that of light pressure) Do not convert to electricity like solar cells 10 FUTURE OF SPACE PROPULSION (?) 11 MOMENTUM EXCHANGE TETHERS • Momentum-eXchange/Electrodynamic-Reboost (MXER) tether is combination of technologies designed to help propel satellites and spacecraft • Long, strong cable rotating in an elliptical orbit around Earth • Like a catapult, one end of tether catches payloads in LEO, accelerates them to higher velocities, and then throws them into higher-energy orbits • Momentum to payload restored using ED forces to push against Earth’s B field • Solar power drives ionospheric current, tether reboost without using propellant 12 WHAT IS ENERGY LIMIT? “The basic secret of space travel and extending human presence throughout heliocentric space is energy, immense quantities of energy” 13 ANTIMATTER PROPULSION = 1/10th gram antimatter • Propulsion by annihilation of matter and antimatter is under investigation • Mixture of matter/antimatter provides highest energy density of any propellant • Most efficient chemical reactions produce about 1 x 107 J/kg, nuclear fission 8 x 1013 J/kg, and nuclear fusion 3 x 1014 J/kg, complete annihilation of matter and antimatter, E = mc2, yields 9 x 1016 J/kg • Matter-antimatter annihilation releases about ten billion times more energy than H2/LOX mixture that powers SSME and 300 times more than fusion reactions at Sun's core • Antimatter must be manufactured • 1 gram of antimatter ~ $62.5 trillion • Isp ~ 10,000,000 s • Mars in 2 hours 14 EVERYTHING YOU NEED TO KNOW TO BE A ROCKET SCIENTIST 1. Thrust, [N] – – – “How much Force?” T/W is key metric for launch vehicles Less important with space exploration applications 2. Specific Impulse, [sec] – – – – – “How Efficient?” High thrust (chemical) have low specific impulse High specific impulse (electric) rockets usually have low thrust Increasingly important for space exploration applications Increases with increasing temperature and decreasing molecular weight 3. Ideal Rocket Equation, [m/s] (1 form of many) M initial V Ve ln M final – “When and How Fast? Can a rocket travel to a speed faster than speed at which exhaust leaves rocket? 15 PERFORMANCE COMPARISON 16 OUTLINE • Rocket Overview – Categorization of various types of Rockets – Rocket Mission Selection Guide – Rocket Performance Parameters • Nuclear Thermal Propulsion – Historical Overview – Hot Hydrogen Properties – Fluid Mechanic and Heat Transfer Modeling – Simulation Results • Future Work – What can we do at FIT? – How to Simulate Nuclear Reactors for Space Applications – New Experimental Facility – Analytical and Computational Efforts 17 WHY NUCLEAR THERMAL PROPULSION? • • • • • NTP improvement: 100-400 percent over best conventional rocket motors Large gain in DV, Isp possible with NTP rockets Operate for short time ~ 1-3 HRS to achieve desired DV Highly reduced mission times (12-14 months vs. 2-3 years to Mars) Combination of temperature and low molecular weight: Isp ~ 900 s (2 x SSME) 18 • • • • • • Rover/NERVA, GE-710, ANL (1955-1973) Soviet Union (195?-1986) SDI (1983-1988) SEI (1989-1993) INSPI (UF) /LUTCH (1993-1997) INSPI (1992-Present) RD-0410 Nuclear Thermal Engine BACKGROUND: REVIEW OF PROGRAMS (1955-PRESENT) 19 ROVER/NERVA HISTORY • Main objective of Rover/NERVA (Nuclear Engine for Rocket Vehicle Application) was to develop a flight-rated thermodynamic nuclear rocket engine – Initially program and engine designed for missile applications – 1958: NASA use in advanced, long-term space missions • Reactor Tests: – Kiwi-A, Kiwi-B, Phoebus, Pewee, and the Nuclear Furnace, all conducted by Los Alamos to prove concepts and test advanced ideas • Rocket Engine Tests: – Aerojet and Westinghouse tests: NRX-A2 (NERVA Reactor Experiment), A3, EST (Engine System Test), A5, A6, and XE-Prime (Experimental Engine). • Conducted at Nuclear Rocket Development Station at AEC's Nevada Test Site • Late 1960's and early 1970's, Nixon Administration cut NASA and NERVA funding cut dramatically and ultimately project ended in 1973 20 COMPARISON OF REACTORS TESTED IN ROVER/NERVA PROGRAM 21 PICTURES FROM ROVER/NERVA TESTING 22 NTP BASIC OPERATION • NTP rockets utilize fission energy to heat a reactor core to high temperatures • Monopropellant H2 coolant/propellant flowing through core becomes superheated and exits engine at very high exhaust velocities 23 CORE DETAILS AND MAJOR COMPONENTS 24 MORE CORE DETAILS: KIWI 4B 25 NTP BASIC OPERATION 26 NUCLEAR-FUEL MATERIALS • Uranium – “The mother of all nuclear fuels” – Uranium ‘found’ in 1727, ‘discovered’ as a unique, half-metal in 1789 – Concept of nuclear fission first introduced in 1939 – U3O8: U234, U235, U238 – Pu239 (may also be formed from U238) – Th232 (→ U233) Note: BLUE: fissionable fuel, RED: source material – Fuel is highly enriched (90-99% U235 present) • Most important properties: Nuclear properties (cross sections, particle behavior, burn up), physical, thermal, mechanical, chemical (hot H2) effects) • About 10 billion nuclear fuel atoms undergoing fission / cm3-sec in reactor core – May be varied to control Temperature very acutely • Fission process is independent of propellant/coolant flow 600,000 pounds of chemical fuel = 1 pound of nuclear fuel 27 THERMAL GENERATION MECHANISM: NUCLEAR FISSION Various coolants may be used: H2O, Ar, He, liquid metals, H2 U n 1 2 2.5n radiation Total Radiation Exposure Mission to Mars: NTP < Chemical Rocket 28 IF NTP SO GOOD, WHY HASN’T IT HAPPENED? “Sounds too much like Buck Rogers!”, President Eisenhower (1958) “The day is not far off when nuclear rockets will prove feasible for space flight.” (1965) • “Chicken and egg syndrome" – “It takes longer to develop a NTP system than to develop a space mission. Project managers cannot include NTP systems in mission planning until system has been developed and tested.” – “If only reactors could be developed, users would emerge to claim them.” – “NTP ready for flight tests and yet no users have come forward in ensuing decades.” • “Cutbacks were made in response to a lack of public interest in human space flight, end of space race, and growing use of low-cost unmanned, robotic space probes.” "Post Vietnam Congresses appear more concerned with perceived excesses of science and technology, hence their abolishment of [NTP] and space committees.” “Cynical maneuvering, vicious attacks and double dealing that led to its closing after years of toil to prove the successful development of then Project Rover/NERVA in 1973.” “They pushed NASA hard because it was dominated by people who built there lives around chemical rockets they didn't want to see [nukes] come in cause they feared it.” • • • 29 IF IT’S NOT NEW… WHAT IS THERE TO DO? • Fuel sets upper limit of NTP performance – – – – “No fuel geometry or material ever totally solved NERVA fuel degradation problem.” “Mass loss limits life by causing significant perturbation to core neutronics.” “Crack development in fuel element coating was never completely eliminated.” “Non-nuclear testing of coated elements revealed relationship between diffusion and temperature. For every 205 K increase, mass loss increased by factor of ten.” • Limited experimental data at temperature, temperature ratio, heat flux, L/D for H2 – “Correlations have not been verified experimentally at heat flux levels present in coolant channels and accuracy and applicability of these equations is in question.” – “Even though Re, Pr, L/D within stated range of accuracy for existing correlations, Tw/Tbulk ratio exceeds range of database if heat flux is high enough.” "One overriding lesson from NERVA program is fuel and core development should not be tied simply to a series of engine tests which require expensive nuclear operation. Definitive techniques for fuel evaluation in loops or in non-nuclear heated devices should be developed early and used throughout program..." 30 RESEARCH CONTEXT A well thought out and carefully designed NTP roadmap is needed • NTP is well investigated technology, but development / improvement remains – Heat transfer relations, geometries, materials, etc. • Fuel development and evaluation essential component of NTP program – Testing at max temperatures, heat fluxes, transients, duration, re-start, etc. • Preliminary Research Programs are Beginning to Form – Non-Nuclear development to gain knowledge base – Design of experiment, data acquisition and analysis • Partnering to facilitate development – Confluence of NASA, industry (P&W), and academia • Hot H2 NTP experiments at MSFC – Support / design / build-up from academia 31 APPROACH • Non-nuclear testing in hot H2 environment key to engine development – T=300-3200 K – Realistic mass flow rates (0.8-1.5 g/s per) and inlet pressures (500 psi) – Modular test section: investigate NERVA, particle bed, pebble bed, etc. – Materials characterization and assessment of performance/stability in hot H2 – Safety, instrumentation, diagnostics, etc. “The Rover/NERVA engine is to be used as a “reference,” against which other concepts… will be compared.” - Dr. Stanley K. Borowski “Solid core has plenty of growth potential. Just because it's 1960's era technology doesn't mean it's obsolete. Object of a new program should be to build on this.” “If you had kept on working [NERVA] you would now have a 4th generation system. It would have Isp's over 1000, power densities 3000 MW, and maybe 30 hours of engine lifetime with 180 stop & starts.” - Dr. James Dewar, AEC 32 RANGE OF NTP INPUT DATA Reactor Power (MW) Thrust (N) Maximum Propellant Temperature (K) Specific Impulse (s) Ideal Exhaust Veloctiy, (m/s) Chamber Pressure (psi) Chamber Pressure (Mpa) Total Mass Flow Rate (kg/s) Number of Fuel Element Number of Cooling Holes / Fuel Element Power / Fuel Element (MW) Power / Cooling Hole (W) Mass Flow / Cooling Hole (g/s) Cooling Hole Diameter (cm) Coolant / Propellant Preliminary Simulation Reactor Material PHOEBUS 2A 5000 1113 2528 820 8036 550 3.79 138.4 4789 19 1.0441 54950 1.52 0.28 H2 Graphite, G10 NERVA 1570 334 2361 825 8085 450 3.10 41.3 1584 19 0.9912 52166 1.37 0.28 H2 Graphite, G10 Summary: Baseline Case Values Power / Fuel Element ~ 1MW / Element for each case Flow Rates ~ 1.5 g/s H2 Chamber Pressure ~ 3.5 MPa (~ 500 PSI) Maximum Propellant Temperature ~ 2500 K CERMET 2000 445 2507 930 9114 600 4.14 48.8 1600 19 1.2500 65789 1.61 0.28 H2 Tungsten 33 REACTOR TEMPERATURE DISTRIBUTION MODEL Model: Single H2 cooling passage within single element Test sub-section to replicate various portions of cooling path Match power input, H2 temperature and wall temperature at various x/D, r/D locations Cooling Hole ID: 0.1-0.125 inches / Cooling Holes OD: 0.183 inches L/D ~ 500 for NERVA elements 34 H2 COOLANT / PROPELLANT COMMENTS • Range of interest – T=300-3000 K, P=14.7-1000 psi • Important to model H2 properties accurately – Up to ~ 1500 K, pressure has little effect on Cp, g, m, k – For T > 1500 K, must include pressure effect on thermal transport properties • References: NASA SP [King],[Kubin and Presley],[Weber], [McCarty], [Patch] • Dissociation with P at constant T – P=1 ATM, T=3000 K, NH=15 % vs. P=40 ATM, T=3000 K, NH=2.6 % – Isp improvement with dissociation, but no impact on cf • Ionization: not relevant at these temperatures – P=1 ATM, T=3000 K, NH+ ~ O(10-11) vs. P=40 ATM, T=3000 K, NH+ ~ O(10-12) • Compressibility: small effect – P=1 ATM, T=3000 K, Z=8.2 % vs. P=40 ATM, T=3000 K, Z=1.3 % 35 H2 DATABASE: IMPORTANT TO CAPTURE T & P 36 H2 COMMENTS: UNIQUE BEHAVIOR P=1 ATM, T=2600 K NH=3.9 %, NH+=1.3x10-13 P=40 ATM, T=2600 K NH=0.6 %, NH+=8.8x10-15 Effects of dissociation and ionization on cp, k are dramatic Higher pressures dissociation suppressed NTP “nominal” range of operation T < 3500 K and P ~ 20-40 ATM 37 H2 COMMENTS: VACUUM SPECIFIC IMPULSE Phoebus 2A, Ispvac~918 s Vacuum Isp equation corrected for dissociation Isp based on channel exit temperature, not mixed-out temperature Mixed-out temperature (model) ~ 100-300 K lower than exit temperature, 10% Isp 38 H2 COMMENTS: DISSOCIATION AND ISP,VAC As Pch , mass flow , Thrust (T/W) System optimization for required T/W vs. Isp, future work consideration Max material (U,Zr,Nb)C temperature ~ 3300 K (1hr): Max Tmelt (TaC, HfC) ~ 4200 K 39 HYDRODYNAMIC CONSIDERATIONS/MODELING • Laminar and Turbulent Regions, critical Reynolds numbers – ReD ~ 2,300 onset of turbulence – ReD ~ 10,000 for fully turbulent conditions – ReD ~ 70,000 for Phoebus/NERVA • Entrance and fully developed region – No satisfactory general expression for entry length in turbulent flow – Fully-developed turbulent flow for x/D > 20 (approx. independent of ReD) • Pressure drop and inlet/exit boundary conditions • Total pressure decrease due to constant volume heat addition (~7 %) • Thermal choking: Only 1/3rd of total DTt,max/Tt capacity • H2 attack on core / degradation – Corrodes/erodes away channel wall and protective coatings, “Scouring” action – Radial pressure drops (channel to channel) which shakes core modules – Mass loss and cracking of elements 40 REACTOR POWER DISTRIBUTION 41 REACTOR TEMPERATURE DISTRIBUTION 42 TEMPERATURE DISTRIBUTION: COMMENTS • Note that Tbulk maximum at L=100% • Maximum inner and centerline wall temperatures at L ~ 80% • For metals, Re, Ta, W, TCL and TID close ~ 50 K – For actual NTP materials, TCL and TID exhibit larger DT ~ 100-500 K – For actual NTP materials, TCL and TID not at same axial location • Location of maximum Twall-Tbulk, Axial Twall, Axial Tbulk all located in midband region • Mid-band region of max corrosion from NERVA reports: – "Corrosion most pronounced in mid-range region, about a third of distance from cold end” – “Fuel operating temperatures lower here than fabrication temperatures, hence thermal stresses higher than at hot end. Also, neutron flux highest in this region..." • Flow time ~ 6 ms, Velocities ~ 1000 m/s at exit, but M ~ 0.2 • 55 kW to single cooling channel for H2 simulation 43 HEAT TRANSFER COEFFICIENT: VARIOUS FORMS Nu D hg D k A Re 4D 5 Pr B RCF ACF C D • Various heat transfer correlations may be applicable within operational range – Differ by up to 20% (not to mention H2 data uncertainty) – Correlations at such elevated conditions, “that do exist have not been verified experimentally at the heat flux levels present in coolant channels and accuracy and applicability of these equations is in question.” Equation Set Reference Nusselt Number A1 Given and Anghaie, Eq.8, [Error! Reference source not found.] Nu D , iso Re D 1000 P r f 2 12 1.07 12.7 P r 2 3 1 f 2 B2 Incropera and De Witt, Eq. 8.60, [Error! Reference source not found.] NuD 0.027 Re 4D 5 Pr n C3 Incropera and De Witt, Eq. 8.62, [Error! Reference source not found.] Nu D nheating Twall Tbulk 0.4 f 8Re D Pr 12 1.07 12 .7 f 8 Pr 2 3 1 ncooling Twall Tbulk 0.3 Fanning Friction Factor6 Radial Correction7 1 f 0.0014 Re D0.32 8 T Nu D Nu D ,iso wall Tbulk T n log 10 wall Tbulk Axial Correction Range of Validity n f 1.82 log10 Re D 1.64 2 Non-Applicable Incropera and De Witt, 8.61, [Error! Reference source not found.] 14 0 .3 x 0 . 7 T 0 .7 Nu D x Nu D 1 wa ll D Tb u lk 0.5 < Pr < 2000 2300 < ReD < 5x106 m Nu D 0.027 Re 4D 5 Pr1 3 m wall Nu D f 8Re D 1000 Pr 12 1 12 .7 f 8 Pr 2 3 1 f 0 .079 ln Re D 1 .64 None Provided None Provided None Provided None Provided 0.5 < Pr < 2000 104 < ReD < 5x106 0.5 < Pr < 2000 2300 < ReD < 5x106 0.14 None Provided 0.7 < Pr < 160 ReD > 10,000 L/D > 10 D4 Incropera and De Witt, Eq. 8.63, [Error! Reference source not found.] 0.7 < Pr < 16,700 ReD > 10,000 L/D > 10 E5 Bartz Heat Flux Formula Nu D 0.026 Re 0D.8 Pr 2 T Nu D 0.026 Re 0D.8 Pr T avg w 0 .6 0. 8 0 .2 w 44 HEAT TRANSFER COEFFICIENTS 45 HEAT TRANSFER EXPERIMENTAL SCALING 0.026 0.8 0.2 T hg 0.2 ru c p m T D avg • • • • • 0.68 Convective coefficient scales with diameter as hg~1/D0.2 – Doubling tube diameter will decrease hg by 13% – Smaller diameters lead to larger heat fluxes (from Reynolds dependence on Cf) Heat flux almost linear with pressure, scales as hg~r0.8~p0.8 – Halving inlet pressure will reduce coefficient by 57% Lighter gases lead to higher heat fluxes, hg~1/M0.6 – Ratio of molecular weights of Ar:H2 ~ 20, heat flux for Ar:H2 ~ 16% Evaluation of viscosity term is also important both at wall and fluid temperatures – Accounts for differences in gas temperature within boundary layer and bulk flow – Exponent less than unity, acts as enhancement of heat transfer coefficient Careful evaluation of cp, m, k 46 SAMPLE MODEL OUTPUTS: FLOW VARIABLES VS. AXIAL LOCATION 47 OVERVIEW • Rocket Overview – Categorization of various types of Rockets – Rocket Mission Selection Guide – Rocket Performance Parameters • Nuclear Thermal Propulsion – Historical Overview – Hot Hydrogen Properties – Fluid Mechanic and Heat Transfer Modeling – Simulation Results • Future Work – What can we do at FIT? – How to Simulate Nuclear Reactors for Space Applications – New Experimental Facility – Analytical and Computational Efforts 48 BUILD-UP OF EXPERIMENT • Surrogate test gases to build-up experiment in less-complex, cost effective way – H2 and hot H2 logistics and safety precautions – Reduced power requirements • Development with bench-top 12.5 kW induction system – Verification of experimental set-up, diagnostics, heat transfer correlations – Reduced cost elements (Ta) vs. materials ~ 100% dense to H2 (Re) • Make use of surrogate test gases, such as He, N2, and Ar – Investigate cooling channel using 12.5 kW power supply – Using Ar, test entire elements (19 cooling channels) at PRL using 100 kW • Using surrogate test gases, match: – Non-dimensional and actual temperatures – Heat fluxes – Heat transfer coefficients • Scale power input, mass flow, gas type, etc. 49 SURROGATE TEST GASES: He, N2, Ar H2 He N2 Ar 50 PRELIMINARY TEST MATRIX • Test Series 1: Cold Flow Tests Using He, N2 or Ar – Objectives: Verify design, instrumentation, sealing, operation, etc., T~ 800 K – Materials: Stainless Steel ($80/tube) • Test Series 2: Hot Flow Tests Using He, N2 or Ar – Inductive heating of test specimen to T~3000 K – Verify power/temperature distribution of test specimen – Heat flux correlations – Materials: Tantalum ($800/tube) • Test Series 3 at MSFC: Cold Flow H2 – H2 safety check-out, sealing, test emergency shut-down • Test Series 4 at MSFC: Hot Flow H2, Full Cooling Channel Simulation – Inductive heating of test specimen – Material assessment, H2 corrosion, impact on heat transfer correlations, etc. – Materials: Rhenium ($8,000/tube), make use of actual non-enriched elements/material 51 PRELIMINARY EXPERIMENTAL CONFIGURATION • • • Initial Test Chamber – 77.6 inch (Full scale test article: L=55 inches), 8.25 inch OD Chamber – 16 ports already in place, D=1.38 inches • 12 located near ends, 4 located near center • Induction in and out feeds, vacuum, pyrometer access, instrumentation, etc. – Chamber modifications • Vacuum ready, outer cooling jacket, ports to capture mid-band and peak • 1 inch bellows fittings to relieve thermal expansion of material – Re, Ta, W, expect 0.5-0.75 inches thermal expansion at max T – Radiation loss modeling • Loss estimate ~ 10-20 kW for 12.5 kW, need GRAFOIL insulator Induction Heating – Heating material with alternating EM field, 150 < f < 350 kHz vs. d penetration – Coil design for sinusoidal power distribution ~ 1/r2 – Design for test coupon, tubular (prismatic) and particle bed reactor type Test Duration – H2 11 min/bottle, 4 hour H2: 23, He: 12, N2: 2, Ar: 2 52 SUPPORT ANALYSES IN PROGRESS • • • • • • Reactor Power Profile Optimization – “From a nuclear rocket design standpoint, a flat power profile may not be best configuration and that an optimum power profile probably exists that gives that lowest fuel temperatures for a given core and operating condition.” Mixing Model – Mixed out flow temperature for a given radial profile and number of elements – Compound flow, vorticity generation, mixing time scale, void support structure – Sample result: Tmix ~ 300 K lower than (Texit)max, 10% Isp Optimization of T/W vs. Isp for low pressure operation NTP Materials: Behavior of UyZr1-yC1-x (Fuel) and ZrC1-x (Coating) Plug Nozzle vs. Traditional Bell – “Some of the things that have been rejected in the chemical engines, such as expansion-deflection nozzles, spike nozzles, and plug nozzles, all become candidates for reexamination to see what would be the optimum way to design a thrust chamber/nozzle for hydrogen recombination.” Potential for tailoring of flow path cross-sectional area – Minimum area located at maximum heat transfer locations – Minimize potential heat transfer hot-spots 53 SUMMARY • NTP is well investigated technology, but development / improvement remains – Heat transfer relations, geometries, materials, etc. • Fuel development and evaluation essential component of NTP program – Testing at max temperatures, heat fluxes, transients, duration, re-start, etc. • Preliminary Research Programs are Beginning to Form – Non-Nuclear development to gain knowledge base – Design of experiment, data acquisition and analysis – Various expertise essential (materials, diagnostics, hot H2, etc.) • Partnering to facilitate development – Confluence of NASA, industry (P&W), and academia (FIT, UF) • Hot H2 NTP experiment at MSFC – Support / design / build-up from academia 54 “BREAKTHROUGH” IDEA #1 ? • Significant gains possible with high T + low P operation → H2 dissociation – However, low P implies low mass flow → low thrust – Dissociation driven by static temperature – Heat transfer driven by total temperature • Current channels, constant cross sectional area • Introduce converging-diverging geometry within channel – Choke mass flow to desired value upstream, retain high thrust – Large Dp downstream, continuously heat, integrated nozzle/channel – Recombination in final expansion portion → double benefit ! • Approach: 1-D finite differencing of full influence coefficients (Mach parameter) – Variable cp and W – Area ratio optimization, geometric confinement and friction 55 SCHEMATIC REPRESENTATION Traditional: Constant Area Only dissociation possible with high static T, Mach ~ 0.2 New: ‘Supersonic Core’ Retain high total temperatures for heat transfer Static pressure drop for dissociation Potential DIsp ~ 150 seconds Integrated nozzle 56 “BREAKTHROUGH” IDEA #2 ? • Chemical rocket propulsion system benefit from scaling – T~A, W~V, T/W~1/L • Does not appear NTP scalable due to critical mass • Examine use of radioisotope as heat source – Used on prior space missions, but for electrical – Trade of half-life vs. specific power • Candidates Po210, Pu238, Cm242, 244 – Examine scalability – Deep space missions, Isp ~ 700-800 s (H2) – Metal foil bonding technique (W, Re possible) • White paper design in progress with LLNL 57 SUPPLEMENTAL SLIDES 58 TYPES OF ROCKETS LAUNCHERS SPACECRAFT SPACE STATIONS Atlas (USA) Mercury (USA) Skylab (USA) Delta (USA) Gemini (USA) Salyut (USSR) Titan (USA) Apollo (USA) Mir (Russia) Pegasus (USA) Shuttle Orbiter (USA) ISS Saturn (USA) Vostok (USSR) Space Shuttle (USA) Soyuz (Russia) A-Vehicle (Russia) Proton (Russia) Long March (China) 59 ROCKETS: ENERGY VS. POWER LIMITED • • Chemical Rockets are Energy Limited Unit of Energy: JOULE, Energy=F*Displacement =[kg m/s2]*[m]==[kg m2/s2] – Quantity of energy (per unit mass of propellant) that can be released during combustion is limited by fundamental chemical behavior of propellant – Low Isp: high thrust, launch, high thrust escape at perigee • • Electrical Rockets are Power Limited Unit of Power: WATT (J/s), Power= F*V=[kg m/s2]*[m/s]==[kg m2/s3] – Usually a separate energy source is used (nuclear or solar) and much higher propellant energy is possible – However, rate of conversion of nuclear or solar energy to electrical energy and thence to propellant kinetic energy is limited by mass of conversion equipment required. Since mass is large portion of total mass of vehicle, electrical rocket is essentially power limited 60 CHEMICAL: LIQUID VS. SOLID ROCKETS Liquid Rockets, Shuttle Main Engines Fuels: Liquid hydrogen and liquid oxygen Advantages – High Thrust, throttle, shutdown Disadvantages – Highly complex (plumbing, cooling, steerting, throttle, structures, etc.) Liquid-Propellant Rocket Engine 11D33 Solid Rockets, Shuttle SRB Fuel: Aluminum and Nitrate Advantages – Simple, low cost, safe Disadvantages – Thrust cannot be controlled, no shut down 61 EXAMPLE: ATLAS / CENTAUR • • • Independently developed by USAF as first ICBM, cold war mission to deter nuclear attack Part of Project Mercury. Mission goal to put a human into orbit, accomplished Feb. 20, 1962. Used today to launch payloads into orbit ATLAS CENTAUR FAMILY RECORD • First launch: 8-May-1962 • Number launched: 97 to end-1995 • Launch sites: Cape Canaveral pads 36A/B; Vandenberg AFB SLC-3E from 1998 • Vehicle success rate: 86.60% to end-1995 • Success rate, past 20 launches: 100% to end-1995 For more on Atlas / Centaur Rockets: http://users.commkey.net/Braeunig/space/specs.htm 62 EXAMPLE: ATLAS IIAS • • • • • • • 47 m tall, 3-4 m diameter, 234,000 kg Lockheed-Martin 2-stage liquid propellant (LOXRP1) booster $95-105M per launch First stage booster section – 2 Rocketdyne engines – 1.84 MN thrust, Isp=263 seconds – runs about 3 minutes Second stage is “sustainer section” – 1 Rocketdyne engine – 269 KN thrust, Isp=220 seconds – 5 minutes burn with booster Strap-on solid rockets – Four Thiokol Castor IVA SRMs – 433 KN thrust, Isp=229 seconds – 9 m tall, 1 m diameter, 12K kg – Burn about 56 seconds Uses a Centaur upper stage – 2 Pratt & Whitney engines – LOX-LH2 – 185 KN thrust, Isp=449 seconds – 1st engine runs about 5 minutes – 2nd engine runs about 1-2 minutes 63 EXAMPLE: DELTA • • • In use since 1960, Delta launched successfully over 250 times Scientific satellites placed into orbit by a Delta rocket include IUE, COBE, ROSAT, EUVE, WIND, RXTE, Iridium, Navstar GPS Manufactured for USAF and NASA by Boeing DELTA FAMILY RECORD • First launch: 13-May-1960 • Number launched: 230 to end-1995 • Launch sites: Cape Canaveral pads 17A/B; Vandenberg AFB SLC-2W • Vehicle success rate: 94.8% • Success rate, past 25 launches: 100% For more Delta Rockets: http://users.commkey.net/Braeunig/space/specs.htm 64 EXAMPLE: TITAN • • • • • • Titan is a family of expendable rockets. Most Titan’s are derivatives of Titan II ICBM. Titan III is stretched Titan II with optional solid rocket boosters. Used to launch NASA scientific probes such as the Voyagers. Titan IV is stretched Titan III with non-optional solid rocket boosters. Used to launch US Military payloads, NASA's Galileo and Cassini probes to Jupiter and Saturn. Titan IV is a horrendously expensive launch vehicle. Currently, three Titan IVBs remain to be launched, no more ordered. Current owners of Titan line (Lockheed-Martin) decided to extend Atlas family instead of Titans. By 2005 the Titans will likely be extinct. For more on Titan Rockets: http://users.commkey.net/Braeunig/space/specs.htm 65 EXAMPLE: STS • • • • Space Shuttle developed by NASA. NASA coordinates and manages, oversees launch and space flight requirements for civilian and commercial use. STS consists of four primary elements: orbiter spacecraft, two Solid Rocket Boosters (SRB), an external tank for three Shuttle main engines Shuttle will transport cargo into near Earth orbit 100 to 217 nautical miles (115 to 250 statute miles) above the Earth. Payload is carried in bay 15 feet in diameter, 60 ft long. 1st Launch: April 12, 1981, 7:00:03 a.m, EST. QUESTION: How many rockets systems on STS? For more on STS: http://users.commkey.net/Braeunig/space/specs.htm 66 EXAMPLE: A-VEHICLE (RUSSIA) • • • A-class Soviet launch vehicles are based on Soviet SS-6 ICBM Vehicles in this class are Vostok, Soyuz and Molniya launchers Three vehicles all use same core stage and four strap-on boosters (liquid oxygen and kerosene propellant) QUESTION: Why does this rocket have many primary engines (20 in picture) instead of 1 or 2 primary engines? Note: Saturn V was powered by 5 F-1 engines. Why not just use 1 big one? For more on A-Vehicles: http://users.commkey.net/Braeunig/space/specs.htm 67 EXAMPLE: PROTON (RUSSIA) • • • • Proton medium-lift launch vehicle 1965 First Russian launcher not based on a ballistic missile prototype. Proton used in 3 and 4-stage versions, with 3stage version used for many of Mir support missions. 4-stage Proton used primarily for geostationary satellite missions. First stage incorporates 6 strap-on boosters, provides over 2 million pounds of thrust. 3-stage Proton launch vehicle can place over 44,000 pounds into LEO, will be used for largest of ISS components that are launched by RSA. For more on Proton Rockets: http://users.commkey.net/Braeunig/space/specs.htm 68 ROCKET CLASSIFICATION 2 • • • Another way to classify rocket engines depends on propellant (gas) acceleration mechanism or the force on the vehicle mechanism – Thermal • Gas pushes directly on walls by pressure forces • Nozzle accelerates gas by pressure forces • Most large rockets, chemical, nuclear, some electric (arcjet, resistojet) – Electrostatic • Ions accelerated by E field • Electrostatic force (push) on electrodes (Ion Engines) • Force (push) on magnetic coils through j (Hall Thrusters) – Electromagnetic • Gas accelerated by j x B body forces • Force (push) on coils or conductors (magnetoplasmadynamic (MPD)) Distinction between Chemical and Electrical – Energy vs. Power Limited Other types – Nuclear, Pulse Detonation, Air-Breathing (Hybrids), vehicle caries only fuel and takes oxidizer from air, Photon (ejection), Solar Sail (radiation pressure via absorption) 69 ROCKETS IN USE TODAY 2 Primary Classes: Chemical and Electrical • Liquid Rockets (Chemical: Energy Limited) – Gas feed or turbopump supplied – Liquid propellants, mix and burn in combustion chamber – Almost all launch vehicles for space are liquid rocket engines – More thrust per pound (T/W) than solid rockets • Solid Rockets (Chemical: Energy Limited) – Solid propellant inside pressure tube, no separate combustion chamber, entire rocket burning on inside, fuel and oxidizer mixed together (fireworks). – Several ways to burn. From end up (like a cigarette), or from center outward. Grain may be circular or star-shaped. – Once started cannot be shut off until they burn-out – Solid rocket motors can be stored for months or years without leaking or degrading. Missiles have to sit for years, then used quickly and without delay. – Strap-on rockets of shuttle and other launch vehicles are solid rocket motors China 800-1200 AD, War of 1812, ‘…rockets red glare’ National Anthem 70 ROCKETS IN USE TODAY • Ion (Electrical, Electrostatic: Power Limited) – Electricity to accelerate a small amount of gas VERY fast, O(1000 km/s) – Strip off electron, accelerate gas very fast, neutralize and eject. Typical gas is Xenon (heavy, inert, non-radioactive gas) – Electrical source: solar to high powered nuclear sources (such as radiographic thermal generators (RTG)). – Extremely high specific impulse, lowest thrust. • Useless in atmosphere and as a launch vehicle. Highly useful in space. – Used today as final thruster to higher orbit, adjusting orbits, station keeping • Arc Jet (Electrical, Electrothermal: Power Limited) – Short low power thrusters (station keeping). Non-flammable propellant is heated by electrical heat source (coil). Expanded and expelled at high speed. – Propellant expelled is not combusted, just heated (typically changing phase from liquid to gas) so that it is under pressure. – Systems are low thrust, very reliable, may use electrical power from solar sails or batteries 71 FUTURE LAUNCH VEHICLES? Linear Aerospike Engine Taurus Minotaur More Information: http://www.spaceandtech.com/spacedata/rlvs/venturestar_sum.shtml http://www.orbital.com/LaunchVehicle/SpaceLaunchVehicles/index.html http://www.aerospaceweb.org/design/aerospike/main.shtml Pegasus 72 EXAMPLE: AUTOMOBILE AIRBAG Airbags have been clocked at 300 MPH. Most airbags deploy at 200-300 mph. Side airbags deploy at 3 times speed of frontal airbags • • • Airbag inflators are a spin-off of military and rocket industries Equivalent of solid rocket booster Major suppliers of inflators is rocket fuel manufacturer, Morton Thiokol (also make space shuttle boosters). Why Rocket-type? How does it work? • To ignite, 12 volt input from airbag control computer, heats a resistive wire element initiating exothermic chemical reaction which decomposes sodium azide (NaN3) in a three step process. Chemical deflagration includes potassium nitrate (KNO3) and silicon dioxide (SiO2). • Sodium azide (NaN3) and potassium nitrate (KNO3) react very quickly to produce a large pulse of hot nitrogen gas 73 EXAMPLE: ELECTRIC AND ION THRUSTERS • Designer: Rocketdyne. • Developed in: 1999. Propellants: Electric/Xenon Thrust (vac): 0.001 N • Isp: 3,500 s • Satellite orbit raising and station-keeping applications. Thrust created accelerating positive ions through gridded electrodes, more than 3,000 tiny beams of thrust. Ions ejected travel in an invisible stream at a speed of 30 kilometers per second (62,900 miles per hour), nearly 10 times that of its chemical counterpart. Ion thrusters operate at lower force levels, attitude disturbances during thruster operation are reduced, further simplifying the stationkeeping task. For more on Electric Propulsion: http://hpcc.engin.umich.edu/CFD/research/NGPD/ElectricP ropulsion/ http://www.marsacademy.com/propul/propul7.htm http://richard.hofer.com/electric_propulsion.html http://www.stanford.edu/group/pdl/EP/EP.html No Combustion 74 EXAMPLE: ELECTRIC AND ION THRUSTERS • Designer: Rocketdyne. • Developed in: 1999. Propellants: Electric/Xenon Thrust (vac): 0.001 N • Isp: 3,500 s • Satellite orbit raising and station-keeping applications. Thrust created accelerating positive ions through gridded electrodes, more than 3,000 tiny beams of thrust. Ions ejected travel in an invisible stream at a speed of 30 kilometers per second (62,900 miles per hour), nearly 10 times that of its chemical counterpart. Ion thrusters operate at lower force levels, attitude disturbances during thruster operation are reduced, further simplifying the stationkeeping task. For more on Electric Propulsion: http://hpcc.engin.umich.edu/CFD/research/NGPD/ElectricP ropulsion/ http://www.marsacademy.com/propul/propul7.htm http://richard.hofer.com/electric_propulsion.html http://www.stanford.edu/group/pdl/EP/EP.html No Combustion 75 EXAMPLE: NUCLEAR POWER • Project Prometheus will develop the means to efficiently increase power for spacecraft, thereby fundamentally increasing our capability for Solar System exploration. • Space fission power can be used as the power source to provide large amounts of electricity for electric propulsion systems (Nuclear Electric Propulsion) • The heat generated by the fission process can be used directly to create thrust (Nuclear Thermal Propulsion) Increased power for spacecraft means not only traveling farther or faster, but it also means exploring more efficiently with enormously greater scientific return. High levels of sustained power would permit a new era of Solar System missions designed for agility, longevity, flexibility, and comprehensive scientific exploration Today, only nuclear power can enable scientifically vital, but incredibly challenging missions • • • 76 EXAMPLES OF NUCLEAR PROPULSION No Combustion In These Devices 77 ROCKET SELECTION GUIDE MISSION REQUIREMENT ROCKET TYPE 1. Non-Space Missions – Atmospheric / Ionospheric Sounding – Tactical Missiles – Medium-Long Range Missiles Solid Propellant, 1-4 stages Solid Propellant, 1-2 stages Solid or Liquid Propellant, 2-3 stages (very high acceleration) 2. Launch to Space 3. Impulsive DV in Space • Time critical maneuvers • Energy change from elliptic orbits, plane change from elliptic orbits • Non-fuel limited situations 4. Low Thrust DV in Space • Mass-limited missions • Non-time critical missions • Small, continuous orbit corrections, near circular orbits Solid, liquid or combination, 2-4 stages (2-4g), Possible: hybrid, 2-4 stages Small solid propellant (apogee kick, etc.) Bi-propellant (storable), liquids, monopropellant (storable) liquids. Future: nuclear thermal Solar-electric systems: Arcjet (a bit faster, less Isp), Hall, Ion (slower, higher Isp), PPT (precision maneuvers), Nuclear-electric systems, direct solar-thermal 78 PERFORMANCE MEASURES: THRUST • • • • • Thrust, (T, F), Thrust to Weight Ratio, (T/W, F/W) Thrust is the force that propels a rocket or spacecraft and is measured in pounds (lbf), kilograms (kgf) or Newtons (kg m/s2) – Result of pressure force which is exerted on wall of combustion chamber – Existence of pressure force results in a momentum flux Weight is measured in pounds (lbf), kilograms (kgf) or Newtons (kg m/s2) T/W is a non-dimensional metric Some Example Numbers – Very Large: 20-100, Chemical Rockets – Medium: 5-20, Nuclear – Very Low: O(10-3), Solar, Electric Propulsion, Power Limited) – Typical payload ration ~ 0.02 (mass of payload/mass of entire rocket) – Engines ~ 2 x payload – Combustion Temp ~ 2500-4500 K, Ve ~ 1500-4500 m/s 79 PERFORMANCE MEASURES: THRUST • For our simple rocket we had (Pe=Pa): eVe F m • For a given exit momentum flux relative to rocket, thrust is independent of flight speed of vehicle. Could a rocket vehicle be propelled to a speed much higher than the speed at which the jet leaves the rocket nozzle? How about for an airplane? 80 PERFORMANCE MEASURES: SPECIFIC IMPULSE • • Specific Impulse, Isp, (measured in seconds) Specific impulse is the amount of thrust you get for the fuel weight flow rate F Isp m e g earth Isp • • • F m e g earth kg m N s 2 s kg m kg m 2 s s s s 2 m eVe V e m e g earth g earth ge is measured on the earth’s surface, ge=9.8 m/s2 Some Example Numbers – Chemical rocket range: 200-500 s (500 is just about the limit) – Shuttle Main Engine: 455 s (T=1670 kN each), SRB: 250 s (T=14700 kN each) – Nuclear Thermal: 800-1200 s – Trade-off vs. mass for EP, 500-6000 s – Nuclear Electric Rocket: 20,000 s (T/W=0.0001) Specific impulse improves with LOW molecular weight, LOW specific heat ratio, and HIGH temperature 81 Isp ROCKET VS. TURBOJET ISP Mach Number 82 NUCLEAR THERMAL ROCKET APPLCIATIONS • • • “This gigantic (nuclear) missile would dwarf the V-2. Even though a practical design might reduce considerably the amount of propellant required, nuclear powered rockets seem remote.” (1946) Limitations of Nuclear Propulsion for Earth to Orbit. (2001 NASA Study) – Only very best… reactors might be applicable for earth-to-orbit However, in terms of high mass, space travel, NTP is among the best – Proven concept – Marriage of two well proven technologies 1. Liquid, chemical rocket development 2. Solid-fuel nuclear reactors 83 KIWI-A PRIME ATOMIC REACTOR • Kiwi-A Prime is one of a series of atomic reactors for studying the feasibility of nuclear rocket propulsion, in Los Alamos, New Mexico. Developed by the Los Alamos Scientific Laboratory for the U.S. Atomic Energy Commission, the reactor underwent a highly successful full-power run on July 8, 1960, at Nevada Test Site in Jackass Flats, Nevada. Kiwi was a project under the National Nuclear Rocket development program, sponsored jointly by Atomic Energy Commission and NASA as part of project Rover/NERVA (Nuclear Engine for Rocket Vehicle Application). 84 XECF • The first ground experimental nuclear rocket engine (XE) assembly, in a "cold flow" configuration, is shown being installed in Engine Test Stand No. 1 at the Nuclear Rocket Development Station in Jackass Flats, Nevada. Cold flow experiments are conducted using an assembly identical to the design used in power tests except that the cold assembly does not contain any fissionable material nor produce a nuclear reaction. Therefore, no fission power is generated. Functionally, the XECF (Experimental Engine Cold Flow) is similar to the breadboard nuclear engine system (NERVA Reactor Experiment/Engine System Test or NRX/EST) tested in 1966, except that the experimental engine more closely resembles flight configuration. In addition to the nozzle-reactor assembly, the XCEF has two major subassemblies: an "upper thrust module" (attached to test stand) and a "lower thrust module" containing propellant feed system components. This arrangement is used to facilitate remote removal and replacement of major subassemblies in the event of a malfunction. The cold flow experiential engine underwent a series of tests designed to verify that the initial test stand was ready for "hot" engine testing, as well as to investigate engine start up under simulated altitude conditions, and to check operating procedures not previously demonstrated. The XECF engine was part of project Rover/NERVA. 85 JFK VISIT • President John F. Kennedy departs from the Nuclear Rocket Development Station, after a brief inspection visit on December 8, 1962. At the President's left are: Dr. Glenn T. Seaborg, Chairman of the U.S. Atomic Energy Commission; Senator Howard Cannon, (DNV); Harold B. Finger, Manager of the Space Nuclear Propulsion Office; and Dr. Alvin C. Graves, Director of test activities for the Los Alamos Scientific 86 PERFORMANCE COMPARISON 87 TYPES OF ROCKETS LAUNCHERS SPACECRAFT SPACE STATIONS Atlas (USA) Mercury (USA) Skylab (USA) Delta (USA) Gemini (USA) Salyut (USSR) Titan (USA) Apollo (USA) Mir (Russia) Pegasus (USA) Shuttle Orbiter (USA) ISS Saturn (USA) Vostok (USSR) Space Shuttle (USA) Soyuz (Russia) A-Vehicle (Russia) Proton (Russia) Long March (China) 88 MOMENTUM EXCHANGE TETHERS 89 H2 COMMENTS: VARIATION IN DATA SETS NASA SP Reports Kubin and Presley McCarty Patch Incropera and De Witt Curve Fits Hill and Peterson CHEMKIN 90 • • • • H2 COMMENTS: H2 ATTACK ON CORE H2 rapid increase in temperature (300 3000 K) and velocity (100 2000 m/s) Under such conditions GH2 takes on aggressive characteristics and attacks core – Chemically • Corrodes/erodes away channel wall and protective coatings, “Scouring” action – “Small hard pebble swirling around inside of a soft channel matrix” – Greater flow rate, more scouring, enhanced by higher temperatures • Penetrates into fuel-matrix structure and weakens core – Mechanically: • Radial pressure drops (channel to channel) which shakes core modules Resistance to core attack depends on core type and specific design of protective coating – TiC, ZrC, and NbC are potential coatings which are H2 resistant Experiment should be able to study these affects over a range of core types (starting with simple tubular/prismatic structure), materials and coatings 91 RADIATION DOSSAGE (rem) rem=absorbed radiation dose x quality factor 92 NUCLEAR SHIELDING / REFLECTOR MATERIALS • • • Goal is to reflect neutrons back into system, attenuate radiation The principal absorber is the core itself – 85% go into fission fragments and are recovered as heat – 5% go into birth of new neutrons – 10% goes into the ejection of b and g rays, most of which can be recovered in form of auxiliary heating and preheating of propellant – Loose about 3-5% of the fission energy through escaping radiation Common reflector materials – Beryllium, graphite, Zirconium Carbide, Tungsten, Titanium, Aluminum 93 NUCLEAR FUEL COMPOUNDS • Physical properties are key: most important metric is melting temperature • Uranium has poor melting point (1405 K), but very high compounding stability • Binary Compounds: Uranium + 1 other material – Intermetallic • Aluminum, beryllium, bismuth, copper, molybdenum, nickel, titanium – Ceramic (5 > UBe13) • UC, UC2, US, UN, UO2 • Ternary Compounds: Uranium + 2 other materials (Tmelt ~ 3560 K) – U-Ta-C – U-Nb-C – U-Zr-C 94 FISSION CONTROL 95 NEW NASA MESSAGES “A well thought and carefully designed NTP roadmap is needed” – Prof. Anghaie • NTP is well investigated technology, but development / improvement remains – Heat transfer relations, geometries, materials, etc. • Fuel development and evaluation essential component of NTP program – Testing at maximum temperatures, heat fluxes, transients, duration, re-start, etc. • Preliminary Research Programs are Beginning to Form – Non-Nuclear development to gain knowledge base – Design of experiment, data acquisition and analysis – Handling H2 levels required for simulation at engine conditions – Various expertise essential (materials, diagnostics, hot H2, etc.) • Partnering to facilitate development – Confluence of NASA, industry (P&W), and academia • Hot H2 NTP experiments – Support / design / build-up from academia 96 RADIATION • • • • Radiation is of two forms (and emanate on two time scales) – Beta Rays: • Mass and charge of an electron • Do not escape from core – Gamma Rays: • Non-charged particles without mass • Tend to escape from core Both types of radiation have prompt and delayed components – Prompt radiations emanate instantly with fission – Delayed radiations emanate over varying periods of time REM=absorbed radiation dose x quality factor Examples: – Natural radioactive material in bones: 0.034 rem/year – Chest x-ray: 0.01 rem – 90-day space station mission: 16 rem – Properly shielded nuclear reactor: 10 rem/year Total Radiation Exposure Mission to Mars: NTP < Chemical Rocket 97 REACTOR COOLANTS • Over 100 types of reactor coolants can be used – Ordinary gases, Water, organic liquids, liquid metals, molten metals, liquefied salts, fluidized dusts, etc. • For NTP: Reactor coolant becomes propellant – Space-based applications, hydrogen is best for Isp – Space-based reactors looking to operate just below melting point of materials – In deep space-based system radioactive exhaust jettisoned from rocket • H2 stored in liquid form and then converted to gas • H2 is one of best moderating materials for slowing down neutrons and can also serve as pre-core moderator/reflector and shield • H2 does not participate in fission reaction nor does it have any direct contact with fission fragments Remember: Only one propellant needed – system complexity is greatly reduced 98 APPROACH • Non-nuclear testing in hot H2 environment key to engine development – T=300-3200 K – Realistic mass flow rates (0.8-1.5 g/s per cooling channel) – Realistic inlet pressures (500 psi) – Modular test section: investigate NERVA, particle bed, pebble bed, etc. – Materials characterization and assessment of performance/stability in hot H2 – Safety, instrumentation, diagnostics, etc. • Technological Archeology – Many texts, reports, data sets, workshop reviews, etc. – What other hardware and test apparatus available? • ANL Nuclear Rocket Program, H2 test loops • LUTCH (Russia), hot H2 test facility • PET (Prototypical Element Tester) Grumman / Sverdrup ($3.5 M) • Who should be involved? 99 ANALYSIS APPROACH FOR EXPERIMENTAL DESIGN “The Rover/NERVA engine is to be used as a “reference,” against which other concepts… will be compared.” - Dr. Stanley K. Borowski, Nuclear Thermal Rocket Workshop (1990) “Solid core has plenty of growth potential. Just because it's 1960's era technology doesn't mean it's obsolete. Object of a new program should be to build on this and get it flying.” “If you had kept on working [NERVA] you would now have a 4th generation system. It would have Isp's over 1000, power densities 3000 MW, and maybe 30 hours of engine lifetime with 180 stop & starts.” - Dr. James Dewar, AEC • “Reference” Cases Considered: – PHOEBUS-2A • 5 GW Reactor: “Most powerful nuclear rocket reactor ever built” – NERVA • UC2/graphite, composite carbide/graphite, (U, Zr)C, UO2/T-111, UO2/W-Re, UN/W-Re – CERMET Type • W matrix material 100 H2 SAFETY AND WORST CASE SCENARIOS • Test Cell Safety – Worst case scenario: All H2 leaks into room and ignition source (overhead light is turned on)? • Room size: 50’ x 50’ x 30’ • H2 will diffuse to ceiling of room • Chamber / Test Apparatus – Worst case scenario 1: Optical window breaks completely (1 inch hole), at the same time, tube shatters and H2 is filling into the chamber at 1.5 g/s • Chamber initially at vacuum and ambient air begins to fill • Detonation limit with air ~ 6 psi, so have time for emergency shut-off • Flammability limit ~ 0.1 psi, so might have time for emergency shut-off • At equilibrium, H2/Air ratio ~ 2 % at 1 ATM, non-flammable – Worst case scenario 2: Optical window small crack, such that ideal ratio of H2/Air enters chamber • 20 < H2/Air < 60 and above 6 psi, detonation region 101 ANALYSES IN PROGRESS • • Transient Analysis: Experiment Start-Up – Ensure that coolant gas is flowing prior to heating – Emergency Shut-Off System: Cuts Heating Cuts H2 Purge Flow Perturbation – Step change 50% reduction in mass flow for Dt 0.5 ms Simulate: Cracked element, blockage, back-flow response time, turbo-pump transients, etc. 102 INDUCTIVE HEATING • Induction heating is a method of heating conductive material by subjecting it to an alternating electromagnetic field – MSFC: Power 12.5 kW (currently in lab) 100 kW also available, 150 < f < 350 kHz • Basic Operation – Magnetic field induces eddy currents in piece, and electrical resistance of piece to flow of current causes piece to heat up – Depth at which current flows is dependant on frequency of magnetic field • Higher frequencies: shallow depth, lower frequencies: deeper depth – Depth of heating is function of electrical frequency applied, heating time and power density applied to component being heated – Coil ID ~ 1.5 inches • Depends on internal configuration of power supply 103 ANALYSES IN PROGRESS • Inductive Coil Design – Working with Dr. Dahake (Ameritherm) and Dr. Rudnev (Inductoheat Group) – Example: Heating a Titanium Rod to 1200 K, 13 turn coil over 5 inches • NTP Materials: Behavior of UyZr1-yC1-x (Fuel) and ZrC1-x (Coating) – Considered as fuel and coating in several designs of NTP reactors (Tmelt ~ 3693 K) – Vaporization rate and melting point prediction in presence of flowing hot H2 – If flowing H2 changes C content – Change in Tmelt with presence of U (~400 K per 10%) – Major influences: component vapor pressure, diffusion constants of C and U, equilibrium pressure of various hydrocarbon reaction products, degree to which equilibrium with various gases is achieved – Question: Based on mass loss rate and degradation, is there an optimum mass flow rate, i.e., is it better to have more small channels or fewer larger ones? • Question can be answered from a flow physics point of view also • Optimization of T/W vs. Isp for low pressure operation 104 EXPERIMENTAL DESIGN CONSIDERATIONS • Test Duration – Preliminary tests • H2 ~ 11 min/bottle – For a 4 hour duration test at 1.5 g/s using 2400 psi (11 inch x 61 inch) bottles (BOC): • H2: 23, He: 12, N2: 2, Ar: 2 bottles required • Measurement of mass loss, volume change, grain growth, etc. • Preliminary Materials Selection / Specimen Quotes – Tantalum: • Metal Technology, Inc. – $747/piece, OD: 0.165 inch, ID: 0.125 inch, 6 ft. long – Seamless, as drawn condition, un-annealed, ASTM B521 • The Rembar Company, Inc. – $810/piece, OD: 0.187 inch, ID: 0.202 inch, 4 ft. long – Seamless, annealed – Rhenium • ULTRAMET – $ 6,172/piece, OD: 0.155 inch, ID: 0.125 inch, 4.5 ft. long – CVD deposited on graphite mandrel, ID roughness 0.0005-0.001 inch 105 FUTURE WORK: ANALYSES • • • Low Pressure Operation – Radial Out-Flow Core (Maximize Flow) – “One of the advantages of low pressure is that the heat flux is greatly reduced. It is about a factor of 50:1 less than the high pressure NERVA engine.” Plug Nozzle – “A nozzle concept already exists which, philosophically in retrospect, appears as though it were predestined for nuclear rockets.” Crouch, 252 – “Some of the things that have been rejected in the chemical engines, such as expansion-deflection nozzles, spike nozzles, and plug nozzles, all become candidates for reexamination to see what would be the optimum way to design a thrust chamber/nozzle for hydrogen recombination.” (Ramsthaler, 127-150). Potential for tailoring of flow path cross-sectional area – Minimum area located at maximum heat transfer locations – Minimize potential heat transfer hot-spots 106 ANALYSES IN PROGRESS • • • Reactor Power Profile Optimization – “From a nuclear rocket design standpoint, a flat power profile may not be best configuration and that an optimum power profile probably exists that gives that lowest fuel temperatures for a given core and operating condition.” – Constrained to half-cosine function • Maximum propellant exit temperature exists when zero at each end point – Constrained to half-cosine function, but allow for skew – Exponential power distribution • Determine exponential shape factor for maximization of coolant exit temperature for a given reactor length • Given a maximum allowable reactor length, determine shape profile to maximize coolant exit temperature Mixing Model – Mixed out flow temperature for a given radial profile and number of elements – Compound flow, baroclinic vorticity generation, mixing time scale – Include “void flow” for support structures – Sample result: Tmix ~ 300 K lower than (Texit)max, 10% Isp Optimization of T/W vs. Isp for low pressure operation 107 FUTURE WORK: EXPERIMENTAL DEVELOPMENT • • • • • • • How to vent H2 exhaust gas – 43 lb/hr of H2 without burn-stack run at MSFC • (43 lb/hr)*(1 kg/2.2 lb)*(1 hr/3600 s)=0.00543 kg/s=5.43 g/s • Proposed NTP experiment H2 mass flow ~ 1-2 g/s Burst calculation for tube samples at pressure and T – Ductility of sample probably increases with T – Hydrostatic validation test (calculation suggests OK with SF of 5) Upgrade thermal H2 model to contain NTP carbide fuel mass loss mechanisms – Carbon loss by H2 corrosion (T~1500 K) – Corrosion inhibited by hydrocarbon in gas stream (T~2800 K) – Mass loss by vaporization (T~3000 K) Model axially segmented core sections, with differing power distributions – May mitigate mid-band issues resulting from fabrication technique How does Acs change with time due to H2 erosion, what is impact on hg Surface roughness for pressure loss management, friction flow factor “Investigate laminar flow instability at NERVA maximum and minimum core inlet temperature during cooldown.”, P.116 [low pressure applications] 108