Susterra ® 1,3 Propanediol offers system

advertisement

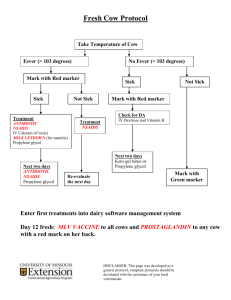

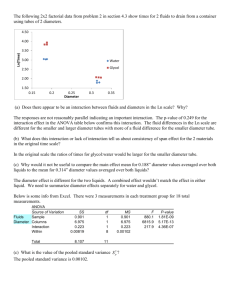

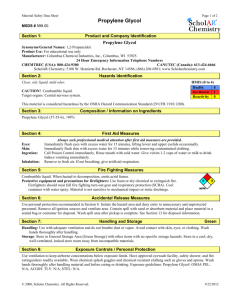

® Susterra 1,3 Propanediol For Brewery Heat Transfer Fluids Susterra® 1,3 Propanediol offers system owners an innovative, bio based glycol alternative for glycol loops 2 3 Glycol Viscosity Comparison Glycol Viscosity Comparison 1600 1400 Viscosity, cps 1200 Propylene Glycol 1000 1,3 Propanediol Ethylene Glycol 800 600 400 200 0 -20 -10 0 10 20 30 o Temp, C Susterra® 1,3 Propanediol exhibits lower viscosity in low-temperature conditions like those in brewery heat transfer loops, improving efficiency of the system. 4 Comparison of Pumping Pressure: Susterra® 1,3 PDO vs PG Properties at -10º C 40.5 wt % PG 40 wt % PDO At -10º C, a 40% PG /60% water solution requires 2.4 times the pumping energy as a 40% Susterra®/ 60% water solution. 5 Freeze Points of Aqueous Glycol Solutions 1,3 Propanediol 60 40 20 EG Vol% PG Vol% PDO Vol% 0 Degrees, F -20 -40 -60 -80 -100 -120 -140 0 10 20 30 40 50 Glycol Volume, % 60 70 80 90 100 Vol, % FP oF FP oC 0 32 0.0 5 29.3 -1.5 10 26.4 -3.1 15 23.2 -4.9 20 19.3 -7.1 25 14.6 -9.7 30 9.4 -12.6 35 3.4 -15.9 40 -4.1 -20.1 45 -11.5 -24.2 50 -20.5 -29.2 55 -33.9 -36.6 60 -49.8 -45.4 65 -65.1 -53.9 70 -82 -63.3 75 -105 -76.1 80 -130 -90.0 85 -125 -87.2 90 -64 -53.3 95 -32.8 -36.0 100 -13.3 -25.2 Susterra® 1,3 Propanediol lowers freeze points in applications like brewery heat transfer loops. 6 6 Glycol Cracking Study Results • • • Glycol cracking occurs as heat transfer fluid sees temperature fluctuations, producing corrosive organic compounds and darkened fluid. This often results in premature replacement of the HTX fluid DTL evaluated the relative stability of three glycols, using the same inhibitor package PG PDO EG After testing, the Susterra®-based fluid exhibited significantly less darkening than the PG and EG fluids 7 Fluid Comparison: Nitrite Levels The sample containing inhibited Susterra® retained significantly more nitrites than the inhibited PG and EG samples 7 8 Fluid Comparison: Glycolate Levels The Susterra®-based fluid produced fewer glycolates than the inhibited PG and EG fluids 8 9 Susterra® Propanediol Achieves NSF International Nonfood Compounds Registration Ingredient for use in Heat Transfer Fluids with Incidental Food Contact (HTX-1) 2010 Press Release: DuPont Tate & Lyle Bio Products is excited to announce that Susterra® propanediol has NSF International Nonfood Compounds Registration. Susterra® is now acceptable as an ingredient for use in heat transfer fluids with incidental food contact (HTX-1) for use in and around food processing areas. Susterra® propanediol offers formulators and suppliers a renewably sourced glycol base that meets the NSF International Registration Guidelines for Proprietary Substances and Nonfood Compounds. Formulators using NSF Registered Ingredients need only identify the Susterra® propanediol name, the NSF Registration No. 141749, and concentration of Susterra® in the finished product of their respective application form. Susterra® is approved as an ingredient for use in HTX with incidental food contact for use in and around food processing areas including breweries. 9 10 Appendix 11 Glycol Comparisons Parameters EG PG Susterra® C2 H6 O 2 C3 H8 O 2 C 3 H8 O 2 107-21-1 57-55-6 504-63-2 Health 2 0 0 Fire 1 1 1 Reactivity 0 0 0 Chemical Formula CAS # HMIS Rating: Molecular Weight 62.07 76.1 76.1 o 1.115 1.038 1.055 o 9.28 8.64 8.78 1.432 1.433 1.439 21 56 52 118(244) 103(217) 129(264) 198(387) 187(369) 214(417) -13(8.6) -60(-76) -24(-11.2) 2.1 2.62 2.5 Explosive Limits: Lower (%) 3.2 2.6 2.6 Upper (%) 15.3 12.5 16.6 399(752) 415(779) 405(761) Vapor Pressure, mmHg (20 C) 0.06 <0.1 0.08 o 48.4 40.1 46.2 0.56 0.59 0.53 0.00062 0.00069 0.00061 Specific Gravity (20/20 C) Weight/gal (US) lbs/20 C o Refractive Index (20 C) o Viscosity, cP (20 C) o o Flash Point, C( F) o o Boiling Point, C( F) o o Freezing Point, C( F) Vapor Density (air = 1) o o Autoignition Temp, C( F) o Surface Tension, dyne/cm (20 C) o o Specific Heat, cal/g/ C (20 C) o o o Coeff of Expansion, per C (10 - 40 C) Heat of Formation (kJ/mol) -480.8 Heat of Vaporization (kJ/mol) 57.9 Heat of Fusion (kJ/mol) 7.1 o Critical Temp ( C) 445 Critical Pressure (mPa) 6.55 12 Thermal Stability: Glycol Cracking Simulation Solar thermal HTX often exceed 200C at elevated pressure during low flow or stagnation events, causing glycol cracking and production of corrosive organic compounds This study was conducted to evaluate relative stability of three glycols, using the same inhibitor package (2.2% of #2792) Concentrated glycols: • 712-132A: 1,2-Propanediol-based fluid (PG) • 712-132B: 1,3-Propanediol-based fluid (PDO) • 712-132C: Ethylene glycol-based fluid (EG) Simulate semi-closed loop solar HTX fluid application; boil samples in a reflux condition for 16 hours and analyze the residual HTX fluid: • Reflux temperature: 362°F to 392°F (183.3°C to 200°C) – Boiling points at 1 ATM: • PG = 371°F (188.3°C) • PDO = 417°F (213.9°C) • EG = 387°F (197.2°C) When paired, the inhibitors and Susterra® exhibited superior thermal stability vs. the PG and EG inhibited glycols 12 13 Enabling a Renewable Economy... From: Molded Parts Oil Refining Chemistry Resins The source is not renewable To: Fibers Crops Biomass Feedstock Metabolic Engineering The source is renewable 13 14 Susterra® Life Cycle Assessment* Comparison From “cradle-to-gate,” the production of Susterra® consumes 40% less energy and reduces greenhouse gas emissions by more than 40% versus petroleumbased 1,3-propanediol and propylene glycol. 6 GHG Emission Non Renewable Energy 103.6 5.0 5 100 3.75 4 80 63.9 3 2.18 2 Green House Gas Emissions - 56% less than Propanediol, - 42% less than Propylene Glycol Non Renewable Energy Use - 42% less than Propanediol, - 38% less than Propylene Glycol 60 40 1 20 0 0 Susterra® Propanediol (PO route) Propylene Glycol Susterra® *Susterra® LCA data based on Loudon process design data; peer reviewed by Five Winds International Propanediol (PO route) Propylene Glycol Non Renewable Energy (MJ/kg) GHG Emissions (kg CO2 equiv / kg) 120 111.0 15 Japan Case Study: HTX for Beverage Processing Susterra® -based fluid is being used in Japan as a heat transfer fluid with low viscosity that is safe for use in food & beverage processing plants