Why Specify Certified? - Builders Hardware Manufacturers Association

advertisement

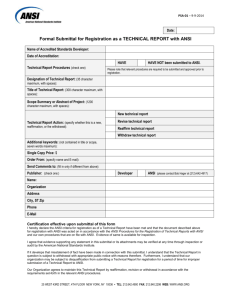

Builders Hardware Manufacturers Association (BHMA) is a Registered Provider with The American Institute of Architects Continuing Education Systems. Credit earned on completion of this program will be reported to CES Records for AIA members. Certificates of Completion for non-AIA members are available on request. This program is registered with the AIA/CES for continuing professional education. As such, it does not include content that may be deemed or construed to be an approval or endorsement by the AIA of any material of construction or any method or manner of handing, studying, distributing or dealing in any material or product. Questions related to specific materials, methods and services will be addressed at the conclusion of this presentation. The Importance of BHMA Certification Builders Hardware Manufacturers Association Presentation Objectives • General Overview of the BHMA Certification Program • The Benefits of Certification Specifying Builders Hardware Because it impacts life safety and security, builders hardware is one of the few categories of functional hardware that are specified. Builders hardware is subject to repeated use and wear, and yet has to remain operational at all times. The security, fire resistance and egress capability of exits and entrances is reliant on the quality of their collective parts, including: • Locksets • Electric strikes • Exit devices • Electromagnetic locks • Door closers Why Specify Certified Products? Standards establish performance requirements for hardware products, and in turn, products that are certified are guaranteed to meet the criteria called for by their standards. Performance assurance is especially important for products that impact: • Life Safety • Security Certified products are: • Tested • Graded • Proven to meet the relevant standard • Assured to do their job What does certification mean? A product that has been certified has been formally tested and shown to meet or exceed the minimum criteria of its standard. Builders hardware that has been certified meets the associated ANSI/BHMA standard for: • Durability • Strength • Performance • Security All BHMA certified hardware is subjected to independent third-party testing. Benefits of Certification • Product Improvement • Quality Control • Enhanced Industry Integrity Steps to Certification 1. Testing: Performed at an independent laboratory or at an in-house lab that has been approved by an independent lab. 2. Statement of Compliance: An independent laboratory’s written statement declaring that the product complies with the standard. 3. Auditing: Regular follow-up factory audits of the product by an independent laboratory. Certification Levels • Self-certification • Affiliated certification (two-party certification) • Third-party Certification Process Finding and Identifying Certified Products • Third-party certification may be labeled “BHMA Certified” and listed in the BHMA Certified Products Directory. • BHMA Certified Products Display the Mark Builders Hardware Standards • BHMA has developed 35 standards for builders hardware, each of which impact safety and security, either directly or indirectly. • The standards include products from hinges to exit alarms. • Each product, when specified and installed properly, can make a significant difference in the event of an emergency. Standards-At-A-Glance BHMA’s Standards-at-a-Glance offer an abbreviated requirement listings and explanations of standards for products that are in the certification program. Performance Grades Within the standards there are grades which indicate the extent to which the product meets or exceeds its standard. • Grades are determined by tests designed to measure a product’s performance capabilities. • They assist the specifier in determining which product is most appropriate for a project. Certified Standards • ANSI/BHMA A156.1 Butts & Hinges • ANSI/BHMA A156.2 Bored & Preassembled Locks & Latches • ANSI/BHMA A156.3 Exit Devices • ANSI/BHMA A156.4 Door Control-Closers • ANSI/BHMA A156.5 Auxiliary Locks • ANSI/BHMA A156.8 Door Controls, Overhead Stops & Holders • ANSI/BHMA A156.9 Cabinet Hardware • ANSI/BHMA A156.11 Cabinet Locks • ANSI/BHMA A156.12 Interconnected Locks & Latches • ANSI/BHMA A156.13 Mortise Locks • ANSI/BHMA A156.15 Release Devices • ANSI/BHMA A156.17 Self-Closing Hinges • ANSI/BHMA A156.18 Materials & Finishes • ANSI/BHMA A156.19 Power Assist & Low Energy Power Operated Doors • ANSI/BHMA A156.21 Thresholds • ANSI/BHMA A156.22 Gaskets • ANSI/BHMA A156.23 Electromagnetic Locks • ANSI/BHMA A156.24 Delayed Egress Locks • ANSI/BHMA A156.25 Electrified Locking Devices • ANSI/BHMA A156.26 Continuous Hinges • ANSI/BHMA A156.29 Exit Locks & Alarms • ANSI/BHMA A156.30 High Security Cylinders • ANSI/BHMA A156.31 Electric Strikes • ANSI/BHMA A156.36 Auxiliary Locks Butts and Hinges ANSI/BHMA 156.1-2006 Butts and Hinges Choosing the appropriate hinge is crucial to ensuring the proper installation and problem-free functioning of doors, including emergency exits. This standard established requirements for lightweight, standard weight and heavy weight hinges. Tests include: • Cycle • Vertical and Lateral Wear • Hinge Pin Rise • Hinge Pin Play High Security Cylinders ANSI/BHMA A156.30-2007 High Security Cylinders High security cylinders must meet two standards, one written specifically for the product type and another written for general cylinders. Cylinders are tested for durability, reliability and strength. Electrical high security cylinders are also tested for their ability to withstand sophisticated break-in attempts. Tests include: • Mechanical Pick Resistance • Electrical Pick Resistance • Magnet Resistance Exit Devices ANSI/BHMA A156.3-2008 Exit Devices Exit devices include panic hardware and fire exit hardware, which provides fire protection when used as part of a fire door assembly. Tests gauge the ability to withstand repeated use and applied force. Tests include: • Cycle • Exit • Outside • Inside Pull • Push • Force to Door Latch • Finish Evaluation A Grade 1 exit device can withstand 500,000 cycles of being opened and closed, while a Grade 3 product is required to withstand 100,000 cycles. Locks and Latches ANSI/BHMA A156.2-2011 Bored & Preassembled Locks & Latches Qualified locks and latches are designed to allow free egress while maintaining security from the outside. Criteria dictated by the standards include amount of torque required to engage and disengage the lock, and the amount of force knobs and levers can withstand. Tests include: • Operational • Strength • Cycle • Material Evaluation • Finish Evaluation Door Gasketing Systems ANSI/BHMA A156.22-2005 Door Gasketing Systems This standard covers the installation and performance of gasketing systems, including intumescents applied to, or mortised to, doors and/or frames. Performance tests are intended to provide installation guidelines, gauge resistance to smoke and air infiltration, and measure the life and durability of gasketing materials. Tests include: • Latching • Adhesion • Smoke/Air Infiltration • Specific tests for Intumescent and Non-Intumescent Gaskets Certify for Life Safety and Security Specify certified for quality products that: • Provide quality assurance • Are assured to do their job again and again • Will perform at or above standard requirements Don’t be Misled CLAIMS of ANSI compliance or statements to the effect that products meet requirements of the standard are NOT THE SAME as BHMA certification. Soft Words • Implication of BHMA Certification • Mistaken use of “soft words”: • Meets ANSI BHMA Standards • Tested to ANSI BHMA Standards • Complies to ANSI BHMA Standards The Difference VS. • The BHMA Member Logo should NOT be used to promote certification • Non-members can participate in the BHMA Certification Program Specify Certified Products Be Safe. Be Secure. Look for the Mark. Thank you for Attending! BHMA 355 Lexington Avenue, 15th Floor New York, NY 10017 (212) 297-2122 www.buildershardware.com