PowerPoint Presentation - Moving to High Performance

advertisement

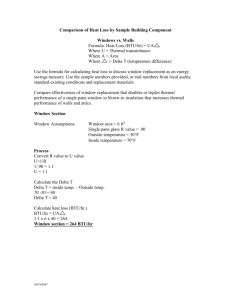

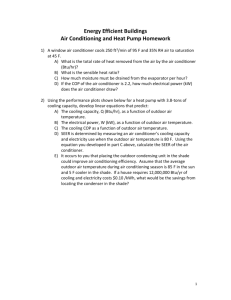

Building Science, Durability & Energy Efficiency BCT 206 Lecture 4-5 Jan 29 Feb 5, 2008 Today’s Objectives Learn basic concepts of Building Science – – Weatherization strategies – – Heat Flow Energy and Moisture Transport in buildings Flashing, Drainage Planes Vapor Barriers vs. Vapor Retarders Energy Efficiency – – – Wall Systems Windows HVAC Building Pollutants Occupants Comfort Moisture Heat loss Operating cost Fire safety Mechanical Systems Environment Heat/Energy Transfer Movement of Thermal Energy: Heat Flow Three methods – – – Conduction Convection Radiant Most heat transfer has some combination of all three occurring at the same time Heat Goes to Cold Conduction Affected by: – Insulation Installation practices – Windows – Framing techniques Photo © Kevin Kennefick 2001 Conduction The transfer of thermal energy from one solid object to another through direct contact. An object does not have to be warm or hot for heat transfer through conduction to occur, only a difference of temperature between the two solid objects, or across a solid object. Air Moves Under Pressure Convection Temperature Wind Exhaust/Mechanicals Temperature is typically the dominant effect Convection The transfer of thermal energy from a fluid flowing over a solid object- [Air is a fluid!] But, air is a relatively poor conductor of heat – – – A solid object = dense arrangement of molecules Liquid = less dense arrangement Gas = least dense arrangement of molecules Transferring heat using a gas is inefficient – Must pass a lot of molecules over an object to equal the carrying capacity of a denser material. Positive pressure (relative to outdoors) Negative pressure (relative to outdoors) Stack Effect Hot Surfaces Warm You Up Radiation – – You feel heat through space, even if the air is cold You feel cold surfaces the same way-but heat energy is flowing from you Function of temperature difference, area Radiant Heat Transfer The transfer of thermal energy or heat that is in direct line of sight of the object being heated. – – Heat from the sun comes to the earth this way We feel heat from a camp fire the same way Once the solid materials in a room have heated up to a desired setpoint temperature, they act as radiant heating surfaces too Comfort is determined by the balance of colder and warmer surfaces surrounding the body Heating with Air Uses a poor conductor (air) to carry heat and transfer energy to the objects we wish to heat (the house and contents) – Then, the human body manages heat by evaporating liquid from the skin, which then is carried away by air moving across its surface. Using airflow across a human body is effective for cooling it To heat a person that way, we have to increase the temperature of that air to counteract the “chill factor” The “Chill Factor” The Chill Factor can be a direct cause of discomfort A lesser noticed effect of unbalanced forced air systems is inducing increased infiltration – Due to pressure imbalances and duct leaks Heating the air in a room does a relatively poor job of heating solid objects – Those objects in the room at a temperature lower than one’s body act to rob the body of heat (through radiation), requiring higher room temperatures to offset that effect Mean Radiant Temp 72°F 70°F 25°F 68°F 59°F 64°F Mean Radiant Temperature: = 67 °F Cold Surfaces 72°F 70°F 25°F 59°F 59°F 64°F Mean Radiant Temperature: = 63 °F How can Energy loss be reduced? Reduce conductive heat losses – – R-value Thermal bridging Reduce air infiltration – convective heat losses Air Leakage/Infiltration Energy movement through convection (air flow) – – Heat energy enters or escapes a building enclosure through the process This happens at transition points, where two materials meet. Air Leaks 30% of heat loss in “typical” home Transport moisture Reduce comfort Increase indoor pollution Largest cause of ice dams Air leaks move moisture vapor into walls and attics Air leaks are largest cause of ice dams …and pipe freezing problems Where Does Air Leak? At transitions between building surfaces – – – Where one material meets another Where walls/floors/roof lines meet Where empty spaces are hidden by drywall Knee Wall Knee Wall Solution Wind baffle Permeable material to prevent wind washing Blocking R- Value R-value is a measure of apparent thermal conductivity, and thus describes the rate that heat energy is transferred through a material or assembly, regardless of its original source. Performance of a material is a function of it’s R-value, but is also dependent on the temperature difference on either side of the material. – R value is able to be added when layering bulk materials, example: If the plywood sheathing is R-0.5, the wall cavity is R21, and the drywall is R-0.5, the entire assembly is R-22 Thermal Bridging Heat Conduction through framing members Wood is approximately R-1 per inch – Framing is a weak link in the thermal boundary of the building shell. Advanced Framing Reduce framing members (24 o.c. framing) Increase insulation space Wall make up – – – – 18% Wood (R5.5) 82% Insulation (R21) R17.7 Perfect installation R14.2 Probable installation 4% - 6% R-value improvement Air leakage still an issue Advanced Framing Developed by NAHB Saves lumber, money & energy Staggered Studs 2 Rows: 2x4 16” OC offset Blown-in blanket Better total wall Rvalue No thermal bridging Insulation Types Batts Blown-in blanket Spider Spray foam Hybrid Rigid exterior Blown Cellulose Insulation Wet-spray cellulose Damp spray cellulose Spray-in cellulose insulation Recycled content Cellulose insulation made from recycled newsprint Blow-in-Blanket (BIBS) Fiberglass Spider Foam + batts Some Alternative Wall Systems SIPS – Structural Insulated Panels ICF – Insulated Concrete Forms Composite blocks systems Structural Insulated Panels Insulated Concrete Forms – Alternative Materials Rastra block Durisol block Windows “Insulating Glass” This name is commonly applied to double glazing – Approximately R-2 > 3 times the heat loss as the worst wall anyone is likely to build today (R-11) Basic Glazing Types Single Pane – not legal to produce Double Pane – Common today Triple Pane – Rare but available Additional features added to windows Low-e – coated Gas fills (argon, krypton) Heat mirror (extra low-e films) U- Value Basic Frame Types Aluminum Wood Vinyl – hollow or insulated Fiberglass – hollow or insulated Window enhancing components Warm Edge spacers Inert Gas fills –Argon/Krypton Metallic coatings (Low E) Warm Edge Spacers Thermally improved edge spaces isolate panes of glass the appropriate distance apart. Accommodate stress induced by thermal expansion and pressure differences Overall U-Value is improved by reduced heat loss at glass pane edges Provide gas tight seals Argon or Krypton Gas Fill Thermal resistance is increase with gas fills, reducing winter heat loss and summer heat gain through conduction Higher temperatures in winter on interior glass surface contribute to greater comfort and less condensation Visual transmittance is not effected Low E coatings Long-wave radiant heat is reflected, giving an improved U-factor and reduced winter heat loss Higher temperatures on interior glass surface increase comfort and reduce condensation Slight affect in visible transmittance Coatings can allow solar transmittance or reflection U-Value and SHGC U-Value gives the amount of heat that transmits through a square foot of building cross section, the lower the value, the less heat transfer. SHGC measures the amount of Solar Heat Gain a material or assembly of materials allows through. HVAC Ventilation - Improving Indoor Air Quality Eliminate pollution sources Minimize unavoidable pollution sources Separate pollutants from occupants Ventilate: – – Exhaust known pollutants at their source Supply fresh (cleaner) air to dilute remaining pollutants Mechanical Air Exchange Reliable Occupant control of when, where, and how much Outdoor air can be treated as it enters the house (heat, cool, filter) Allows houses to be built tighter by providing fresh air and controlling moisture in winter Central Exhaust Fan Bath Quiet Bath Exhaust Fans Return Duct Fresh Air Return Supply Supply Motorized damper Fresh air inlet hood Timer/ controller Furnace/ air handler 6" insulated air inlet duct Heating Equipment Energy Sources – – Natural Gas, Oil #2 or Bio Diesel, Propane Grid Source electricity – Coal and natural gas generated electricity, wind or other renewable Heating and Cooling Systems Furnace –Heats air that is delivered to building by an electric blower Sealed combustion, separate from house air Supply Air Exhaust Gases Heat Exchanger Combustion Air Inlet Combustion Chamber Return Air Exterior Wall Heating Cont. Boiler- Heats fluids, usually water, that are then circulated to distribution point, can be circulated as a liquid or a gas (steam) – – – Radiators Convectors – Baseboard or convection radiators Mass (radiant floors) Hydro-air System Heating Cont. Water heaters, used for space heat – Same system as boiler but lower water temperatures, not used for steam. Preferably high efficiency Condensing Water Heater Provides heat and hot water Hydronic heat or hydroair Sealed combustion Stainless tank High Efficiency Tankless Water Heater Heating and Cooling Geo-thermal Heat Pumps – – Use air or hydronic distribution High efficiency rates Air Source Heat Pumps – – Also use air distribution Electrically fueled BTU’s Btu is the measurement of heat energyBritish Thermal Unit’s 1 Btu of heat energy is about equivalent to a kitchen match The number of Btus a piece of equipment is rated for is the maximum capacity that equipment is capable of burning per hour – Example: 100,000 btu/h furnace can burn 100,000 btu’s of energy in an hour BTU and Heat Heat is measured in Btus 1 Btu is the amount of energy required to raise a pound of water by 1°F The number of Btus of heat, a pound of any material absorbs or releases for each degree of temperature change is called it’s specific heat. Specific Heat Specific heat is measured in BTUs per pound per degree Fahrenheit (Btu/lb./°F) The specific heat of water is 1, because it requires 1 Btu to raise a pound of water by 1°F It takes 0.2 Btu to raise a pound of aluminum by 1°F, so aluminum has a specific heat of 0.2 Btu/lb./°F Heating of Buildings Heating Loads in buildings are expressed in Btus. The typical method of expressing loads of a building is in Btu/Hour. This is the number of Btus need to maintain a particular temperature in the building at a given Temperature Difference (Delta T) between indoors and outdoors during one hour. Calculating Loads to Size Equipment Heating load is used to determine the size (power) of the heating equipment in Btuh or Btu/hour, to determine this we use a formula: Btuh = U x A x ∆T (Corrected! Incorrectly this was originally posted as UA x A x ∆T the extra A was a typo) U = heat transmission A = Area ∆T = Temperature Change between Indoors/Outdoors U – Value and Area U- Value is the amount heat transmittance through a square foot of building cross section (A combination of multiple materials) U is expressed as Btus . ft2 ∙ hr ∙ °F U is the inverse or R-Value U=1/R and R=1/U When R=1 then U=1 When R=2 then U=0.50 The Area of the building is simply the shell area expressed in square feet. Finding the ∆T Design Temperature. For heating, this is the temperature equaled or exceeded 97.5% of the time, during the three coldest months, Dec. Jan. Feb. To standardize the sizing of loads we use a standard desired interior temperature during heating season of 68°, combining the desired interior temp and our design temp gives us the Delta T of the indoors and outdoors In Portland, OR the design for heating temperature is 27°F Interior Temp 68° - Design Temp 27° = ∆T 41° Calculating Heat Load We do this to select enough power (heating equipment size) Too small a system will not provide enough heat during the coldest days, too big a system will waste substantial energy (not sustainable) BTU’s & Efficiency Although a heating system may be capable of burning 100,000 btu/hr, the amount of that heat energy available for distribution to the space depends on the efficiency of the system. We usually see this expressed as a percentage. The input of the equipment is the btu/hr of energy entering the equipment (potential energy of fuel), the output of the system is the heat energy available to distribute once the losses are accounted for (what goes up the chimney) A 100,000 btu/hr furnace has an input of 100,000 btu/hr and if it is 80% efficient has an output of 80,000 btu/hr of heat energy available for distribution Common Equipment Efficiency’s AFUE -Furnaces and Boilers COP, HSPF, SEER –Air Source Heat Pumps & Geo-thermal Heat Pumps EF -Water Heaters AFUE Annual Fuel Utilization Efficiency- tells us how much of the potential energy in the fuel makes it into the heating distribution system. – – AFUE accounts for fuel burning losses, chimney losses, cycling loss, and heat losses through the heaters cabinet. If a Furnace is rated at 100,000 btus, and has an AFUE of 80%, this means on 80% of the total rating is available to heat the space- in this case, 80,000 btus COP The oldest and most common way to measure heat pump efficiency is the COP (Coefficient of Performance) This tells us how many times more efficient a particular heat pump is compared to electric resistance heat (100% efficient). COP 1.6 means for every 1 kW hours of electric input, 1.6 kW hours of heat is delivered. Geo-thermal heat pumps are rated this way as well as air source heat pumps COP range from 1.6 to as high as 5 (That’s 500% more efficient than standard electric heaters) HSPF Heat Seasonal Performance Factor – – This account for the addition of electric resistance heat during heat pump operation. In some climates when the air temperature is too cold to extract usable heat, back-up electric heat engages. This less efficient heat is factored into the overall performance and a seasonal efficiency is assigned. SEER Seasonal Energy Efficiency Ratio measures the ratio of btu of cooling provided, divided by the electrical energy input. SEER ratings from 9 to about 19 currently exist although the standard for all newly manufactured air conditioning equipment is now 13 SEER 13 SEER is 30% more efficient than 9 SEER 1-(9/13)=30 EF Energy Factor describes the fraction of the water heaters energy that actually remains in the water leaving the unit. Factors range from .50 - .93, current federal minimum is .59EF Energy Factor takes into account: – – – – Use- assumes 64 gallons a day is used Energy loss during heating Pilot light loss (if gas) Thermal loss through the tank Ducts-Distribution We worry about ducts, because they leak! With Hydronic systems leaks are very apparent, air systems tend to leak unnoticed. Avoid locating ducts in the attic or crawlspace for this reason Why Seal Duct Leaks? Leaks reduce heating system efficiency – Increase or magnify house air leakage – When they leak into unconditioned spaces 30-300% while blower is running Reduce comfort for occupants – – drafts unbalanced air delivery Impact of Duct Leakage Duct Leakage in typical homes 12% % of Sample 10% 8% 6% 4% 2% 0% 5% 15% 25% 35% 45% 55% 65% 75% >80% CFM 25 / Nominal Airflow 1210 homes, Duct Blaster® at 25 pa. (0.10”WC) Source: CheckMe!® database, PEG Courtesy of Proctor Engineering Group Worst duct leakage areas Swivel elbows Branch takeoffs from trunk ducts Other finger jointed connections Folded corners of boots and other fittings Filter racks, other plenum connections Sealing only the connections between duct sections will result in a leaky system! Missing pieces! Duct testing Testing for duct leakage – Total Leakage Test- Measures the total system leakage and does not differentiate from indoor or outdoor leakage – Most common in New Construction – Will be an optional code requirement in OR after April 2008 Leakage to Outside Test Measures only the outdoor leakage by counter pressurizing indoor leakage with a blower door Duct Sealing Essentials Use Mastic not tape – UL181A or UL 181B type mastic Use mastic over mesh tape for larger gaps Seal the inner duct material, not the vinyl or insulation wraps No tapes (including butyl tape or “mastic tape”) and never use duct tape on ducts!