Some Examples

advertisement

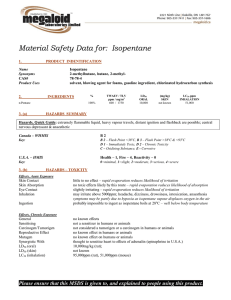

Some Examples Example: daily auto accidents in Saskatchewan to 1984 to 1992 Data collected: 1. Date 2. Number of Accidents Factors we want to consider: 1. Trend 2. Yearly Cyclical Effect 3. Day of the week effect 4. Holiday effects Trend This will be modeled by a Linear function : Y = b0 +b1 X (more generally a polynomial) Y = b0 +b1 X +b2 X2 + b3 X3 + …. Yearly Cyclical Trend This will be modeled by a Trig Polynomial – Sin and Cos functions with differing frequencies(periods) : Y = d1 sin(2pf1X) + g1 cos(2pf2X) + d1 sin(2pf2X) + g2 cos(2pf2X) + … Day of the week effect: This will be modeled using “dummy”variables : a1 D1 + a2 D2 + a3 D3 + a4 D4 + a5 D5 + a6 D6 Di = (1 if day of week = i, 0 otherwise) Holiday Effects Also will be modeled using “dummy”variables : Independent variables X = day,D1,D2,D3,D4,D5,D6,S1,S2,S3,S4,S5, S6,C1,C2,C3,C4,C5,C6,NYE,HW,V1,V2,cd,T1, T2. Si=sin(0.017202423838959*i*day). Ci=cos(0.017202423838959*i*day). Dependent variable Y = daily accident frequency Independent variables ANALYSIS OF VARIANCE REGRESSION RESIDUAL SUM OF SQUARES 976292.38 1547102.1 DF 18 3269 MEAN SQUARE 54238.46 473.2646 F RATIO 114.60 VARIABLES IN EQUATION FOR PACC STD. ERROR COEFFICIENT OF COEFF 60.48909 ) 0.11107E-02 0.4017E-03 4.99945 1.4272 9.86107 1.4200 9.43565 1.4195 13.84377 1.4195 28.69194 1.4185 21.63193 1.4202 -7.89293 0.5413 -3.41996 0.5385 -3.56763 0.5386 15.40978 0.5384 7.53336 0.5397 -3.67034 0.5399 -1.40299 0.5392 -1.36866 0.5393 32.46759 7.3664 35.95494 7.3516 -18.38942 7.4039 VARIABLE (Y-INTERCEPT day 1 D1 9 D2 10 D3 11 D4 12 D5 13 D6 14 S1 15 S2 16 S4 18 C1 21 C2 22 C3 23 C4 24 C5 25 NYE 27 HW 28 T2 33 ***** F LEVELS( 4.000, . STD REG COEFF TOLERANCE F TO REMOVE 0.038 0.063 0.124 0.119 0.175 0.363 0.273 -0.201 -0.087 -0.091 0.393 0.192 -0.094 -0.036 -0.035 0.061 0.068 -0.035 0.99005 0.57785 0.58367 0.58311 0.58304 0.58284 0.58352 0.98285 0.99306 0.99276 0.99279 0.98816 0.98722 0.98999 0.98955 0.97171 0.97565 0.96191 7.64 12.27 48.22 44.19 95.11 409.11 232.00 212.65 40.34 43.88 819.12 194.85 46.21 6.77 6.44 19.43 23.92 6.17 . LEVEL. . 1 . 1 . 1 . 1 . 1 . 1 . 1 . 1 . 1 . 1 . 1 . 1 . 1 . 1 . 1 . 1 . 1 . 1 . 3.900) OR TOLERANCE INSUFFICIENT FOR FURTHER STEPPING VARIABLES NOT IN EQUATION VARIABLE IACC Dths S3 S5 S6 C6 V1 V2 cd T1 7 8 17 19 20 26 29 30 31 32 PARTIAL CORR. TOLERANCE 0.49837 0.04788 -0.02761 -0.01625 -0.00489 -0.02856 -0.01331 -0.02555 0.00555 0.00000 0.78647 0.93491 0.99511 0.99348 0.99539 0.98788 0.96168 0.96088 0.97172 0.00000 F TO ENTER 1079.91 7.51 2.49 0.86 0.08 2.67 0.58 2.13 0.10 0.00 LEVEL 0 0 1 1 1 1 1 1 1 1 Day of the week effects D1 4.99945 D2 9.86107 D3 9.43565 D4 13.84377 D5 28.69194 D6 21.63193 Day of Week Effect 100.0 80.0 60.0 40.0 20.0 0.0 Mon Tue Wed Thu Fri Sat Sun Holiday Effects NYE HW T2 32.46759 35.95494 -18.38942 Cyclical Effects S1 S2 S4 C1 C2 C3 C4 C5 -7.89293 -3.41996 -3.56763 15.40978 7.53336 -3.67034 -1.40299 -1.36866 40 30 20 10 0 0 -10 -20 -30 30 60 90 120 150 180 210 240 270 300 330 360 Example 2 • Data on the reaction rate of the catalytic isomerization of л-pentane to isopentane versus the partial pressures of hydrogen, лpentane, and isopentane are reproduced in the Table on the following slide Table: Partial Pressure (psai) Reaction Hydrogen Isopentane n-Pentane Rate(hr-1) (x1) (x2) (x3) (y) 205.8 404.8 209.7 401.6 224.9 402.6 212.7 406.2 133.3 470.9 300.0 301.6 297.3 314.0 305.7 300.1 305.4 305.2 300.1 106.6 417.2 251.0 250.3 145.1 37.1 36.3 49.4 44.9 116.3 128.9 134.4 134.9 87.6 86.9 81.7 101.7 10.5 157.1 86.0 90.2 87.4 87.0 66.4 33.0 32.9 41.5 14.7 50.2 90.9 92.9 174.9 187.2 92.7 102.2 186.9 192.6 140.8 144.2 68.3 214.6 142.2 146.7 142.0 143.7 141.1 141.5 83.0 209.6 83.9 294.4 148.0 291.0 3.541 2.397 6.694 4.722 0.593 0.268 2.797 2.451 3.196 2.021 0.896 5.084 5.686 1.193 2.648 3.303 3.054 3.302 1.271 11.648 2.002 9.604 7.754 11.590 Isomerization is a chemical process in which a complex chemical is converted into more simple units, called isomers: catalytic isomerization employs catalysts to speed the reaction. The reaction rate depends on various factors, such as partial pressures of the products and the concentration of the catalyst. The differential reaction rate was expressed as grams of isopentane produced per gram of catalyst per hour (hr-1), and the instantaneous partial pressure of a component was calculated as the mole fraction of the component times the total pressure, in pounds per square inch absolute (psia). A common form of model for the reaction rate is the Hougen-Watson model: x3 13 x2 1.632 y f x1 , x2 , x3 ; 1 , 2 , 3 , 4 1 + 2 x1 + 3 x2 + 4 x3 Fit this model