Jason Terry Microeconomics 2010 Professor Wilson PRODUCT

advertisement

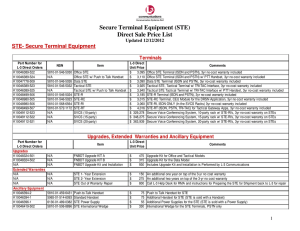

Jason Terry Microeconomics 2010 Professor Wilson PRODUCT MANUFACTURING Manufacturing plays a huge role in in the United States, influencing employment, GDP and economic freedom directly. There are thousands of different manufacturing plants around the country and each is manufacturing and producing different products, anything from chocolate candies to ships and missiles. Each production plant is faced with decisions of what to produce and how much to produce. Each business or corporation is producing these goods because they are looking to make economic profits. Most successful manufacturers and corporations today started as something small, an idea or creation by individuals who are looking to make a profit. When the satisfaction of the specific product is greater than the cost to the consumer, then demand for the product will rise. The profits and incentives to produce more due to the increase in demand are what created these worldwide corporations. “KFC was founded by Harland Sanders, a colorful figure who began selling fried chicken from his roadside restaurant in Corbin, Kentucky, during the Great Depression.” (wikipedia) Even at a time when unemployment was at a record high, people were still willing to come purchase fried chicken at his roadside restaurant. Now you can find KFC all over the country and around the world. There were a lot of factors that took the small town chicken to worldwide fame, demand and consumer preferences are at the top of that list. You could have the best entrepreneur in the world, but it won’t get you anywhere if you have a product that people are not willing to pay for. Mars, Incorporated is another great example of this, started by a 19-year old boy who learned to hand dip candy from his mother. It is now the third largest privately held company in the United States. Even today they are expanding tremendously. “A river of chocolate will begin flowing soon from a new Mars Chocolate plant in Topeka, 30,000 gallons of daily deliciousness on the prairie. When that sweet torrent finishes “enrobing” little bars of chewy nougat and roasted Georgia peanuts, the huge plant each day will produce 14 million individually wrapped miniand “fun-size” Snickers and 31 million peanut M&Ms.” (mars) When this article was written, the facility was not even built yet. How do they already know the exact numbers of each product they will be producing? They are adjusting products, quantities, land, labor, and entrepreneurial skills to the point where the marginal cost equals the marginal benefit. The Total Revenue will be at its peak, and the company can avoid wasted labor, or other resources that it does not need. Factors may change, such as consumer preference and income, and this can play a huge role in the quantity demanded and what the plant will then produce. “L-3 Communications Holdings, Inc. is an American company that supplies command and control, communications, intelligence, surveillance and reconnaissance (C3ISR) systems and products, avionics, ocean products, training devices and services, instrumentation, space, and navigation products.” (L3) L-3 Communications could be considered a monopolistic competition market model, competing with other government defense companies such as Lockheed Martin and Boeing in differentiated products. I have worked for L-3 Communications-CS West for 3 years and I got to be a part of the company transitioning from low volume, (huge complex builds) to a high volume production facility. I am in operations as the Lead Production Planner on the highest volume product that L3 has ever built. When I first started at L3 as a production planner, my product would be moving between 2 different buildings and several different labs. One area would kit all the parts needed for each build, the next area would assemble, a separate building would test, then it would come back for inspection, and assembly of the next “operation”. It was a complete waste of time because the product would sit on an outrack waiting to be moved to the next operation and then when it made it there it would have to wait in line as the workers would only work off of a dispatch list, first in-first out. The jobs all had a time standard but as the jobs sat on shelves, the expected completion date would come and go as product waited on the floor. This would result in myself and other planners “pushing product” by talking to teamleads and managers to get jobs pushed to the front of the line, competing with other programs and product within the company. L3 then received a government contract for over 1,000 of these units, followed immediately by another 1,100. We had to figure out a better way if we expected to complete them all contractually on time. That is when L3 decided to build a Volume Production Facility, a giant lab where we could centrally locate every department that takes part in the build. Assembly, Test, Inspection, Quality, Manufacturing Engineering, Production Control, and right across the hallway from Shipping and Final Acceptance. At first the change resulted in no time wasted on outracks, as the person would move it directly to the next “operation” when they were complete. But everyone was still working off a dispatch and jobs were still sitting on racks waiting to be worked, because they were completing operations at different times. The different departments were very close now, but still not really working together. Work would come into the lab as soon as the parts had come in from the vendors and there were no shortages. Some days they would get 5 jobs, other days they would get 40. We had work that was piling up in specific areas and workers sitting idle in others. Over time, they removed desks and installed assembly lines with touch screen computers above a “track system” that the jobs would just go from one operation to the next on wheels. The inspector would sit right next to the assembler, who sat right next to another assembler, who did the next portion of the build. Then the assembly line would end in test. The simple change in production, used the same amount of labor but jobs were completing 10% faster, then 25% faster. Pretty soon builds that took upwards of 4 weeks were completing in 2 days. Then they started to limit what came into the lab by creating a capacity schedule of which assembly line would be doing what product. My job was to choose quantities that we would be able to build looking at material and shipment schedules, and when we would be able to start those builds. The lab manager would then create a schedule for his people and as soon as the jobs were ready at 9am Monday morning, there was an entire crew to build the product. We went from building less than 100 to our record goal of over 400 units shipped in one month. Our AVC was decreasing as we used these simple techniques, and the profit therefore was increasing for every unit. Just this last month we have converted over to SAP, and using other new improvements such as Grouping, Pegging, and Distribution. Instead of every program ordering the part they need separately, they group them in to one large order, which brings the total cost down dramatically. The parts are then assigned and once received they are distributed to the different programs. This new change will eventually lower our AVC dramatically. They are now working on a set of cameras that visually inspects each product, as well as recording serial numbers and identification tags. There are always ways to improve in manufacturing, and as technological advances hit the manufacturing industry we will see many changes to the way things are produced. But basic economic principles will still be used to find equilibrium, where supply and demand meet, where marginal benefits equals marginal costs, and profit is maximized. Works Cited (wikipedia) “KFC.” Wikipedia. July 29, 2013. Accessed August 3, 2013. http://en.wikipedia.org/wiki/KFC (mars) Collison, Kevin. “Topeka’s New Mars Chocolate Plant Will Produce Millions of Snickers, M&Ms daily.” The Kansas City Star. July 4, 2013. Accessed on August 3, 2013. http://www.kansascity.com/2013/07/04/4330487/a-sweet-deal-in-topekanew-mars.html (L3) “L-3 Communications.” Wikipedia. April 5, 2013. Accessed August 3, 2013. http://en.wikipedia.org/wiki/L-3_Communications