Document

advertisement

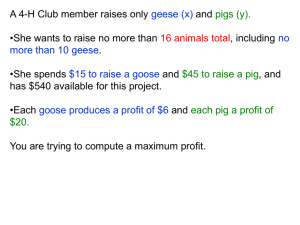

Slides prepared by John Loucks ã 2002 South-Western/Thomson Learning TM 11 Chapter 8 Strategic Allocation of Resources 2 Overview Introduction Recognizing Linear Programming (LP) Problems Formulating LP Problems Solving LP Problems Real LP Problems Interpreting Computer Solutions of LP Problems Wrap-Up: What World-Class Companies Do 3 Introduction Today many of the resources needed as inputs to operations are in limited supply. Operations managers must understand the impact of this situation on meeting their objectives. Linear programming (LP) is one way that operations managers can determine how best to allocate their scarce resources. 4 Linear Programming (LP) in OM There are five common types of decisions in which LP may play a role Product mix Ingredient mix Transportation Production plan Assignment 5 LP Problems in OM: Product Mix Objective To select the mix of products or services that results in maximum profits for the planning period Decision Variables How much to produce and market of each product or service for the planning period Constraints Maximum amount of each product or service demanded; Minimum amount of product or service policy will allow; Maximum amount of resources available 6 LP Problems in OM: Ingredient Mix Objective To select the mix of ingredients going into products that results in minimum operating costs for the planning period Decision Variables How much of each ingredient to use in the planning period Constraints Amount of products demanded; Relationship between ingredients and products; Maximum amount of ingredients and production capacity available 7 LP Problems in OM: Transportation Objective To select the distribution plan from sources to destinations that results in minimum shipping costs for the planning period Decision Variables How much product to ship from each source to each destination for the planning period Constraints Minimum or exact amount of products needed at each destination; Maximum or exact amount of products available at each source 8 LP Problems in OM: Production Plan Objective To select the mix of products or services that results in maximum profits for the planning period Decision Variables How much to produce on straight-time labor and overtime labor during each month of the year Constraints Amount of products demanded in each month; Maximum labor and machine capacity available in each month; Maximum inventory space available in each month 9 LP Problems in OM: Assignment Objective To assign projects to teams so that the total cost for all projects is minimized during the planning period Decision Variables To which team is each project assigned Constraints Each project must be assigned to a team; Each team must be assigned a project 10 Recognizing LP Problems Characteristics of LP Problems in OM A well-defined single objective must be stated. There must be alternative courses of action. The total achievement of the objective must be constrained by scarce resources or other restraints. The objective and each of the constraints must be expressed as linear mathematical functions. 11 Steps in Formulating LP Problems 1. 2. 3. 4. 5. 6. 7. 8. Define the objective. Define the decision variables. Write the mathematical function for the objective. Write a 1- or 2-word description of each constraint. Write the right-hand side (RHS) of each constraint. Write <, =, or > for each constraint. Write the decision variables on LHS of each constraint. Write the coefficient for each decision variable in each constraint. 12 Example: LP Formulation Cycle Trends is introducing two new lightweight bicycle frames, the Deluxe and the Professional, to be made from aluminum and steel alloys. The anticipated unit profits are $10 for the Deluxe and $15 for the Professional. The number of pounds of each alloy needed per frame is summarized on the next slide. A supplier delivers 100 pounds of the aluminum alloy and 80 pounds of the steel alloy weekly. How many Deluxe and Professional frames should Cycle Trends produce each week? 13 Example: LP Formulation Deluxe Professional Aluminum Alloy 2 4 Steel Alloy 3 2 14 Example: LP Formulation Define the objective Maximize total weekly profit Define the decision variables x1 = number of Deluxe frames produced weekly x2 = number of Professional frames produced weekly Write the mathematical objective function Max Z = 10x1 + 15x2 15 Example: LP Formulation Write a one- or two-word description of each constraint Aluminum available Steel available Write the right-hand side of each constraint 100 80 Write <, =, > for each constraint < 100 < 80 16 Example: LP Formulation Write all the decision variables on the left-hand side of each constraint x1 x2 < 100 x1 x2 < 80 Write the coefficient for each decision in each constraint + 2x1 + 4x2 < 100 + 3x1 + 2x2 < 80 17 LP Problems in General Units of each term in a constraint must be the same as the RHS Units of each term in the objective function must be the same as Z Units between constraints do not have to be the same LP problem can have a mixture of constraint types 18 Solving LP Problems Graphical Solution Approach - used mainly as a teaching tool Simplex Method - most common analytic tool Transportation Method - one of the earliest methods Assignment Method - occasionally used in OM 19 Graphical Solution Approach 1. Formulate the objective and constraint functions. 2. Draw the graph with one variable on the horizontal axis and one on the vertical axis. 3. Plot each of the constraints as if they were lines or equalities. 4. Outline the feasible solution space. . . . more 20 Graphic Solution Approach 5. Circle the potential solution points -- intersections on the inner (minimization) or outer (maximization) perimeter of the feasible solution space. 6. Substitute each of the potential solution point values of the two decision variables into the objective function and solve for Z. 7. Select the solution point that optimizes Z. 21 Example: Graphical Solution Approach x2 3x1 + 2x2 < 80 (Steel) Potential Solution Point x1 = 0, x2 = 25, Z = $375.00 40 35 Optimal Solution Point x1 = 15, x2 = 17.5, Z = $412.50 30 25 2x1 + 4x2 < 100 (Aluminum) 20 15 10 Feasible Solution Space MAX 10x1 + 15x2 (Profit) Potential Solution Point x1 = 26.67, x2 = 0, Z = $266.67 5 5 10 15 20 25 30 35 40 45 50 x1 22 Simplex Method Examples of standard LP computer programs that use the simplex method are: IBM’s Optimization Solutions Library POM Software Library GAMS MPL for Windows Solver -- available within spreadsheet packages such as MicrosoftExcel, Lotus 1-2-3, and Quattro Pro What’s Best! and Premium Solver -- add-ons to common spreadsheet packages 23 Example: Excel/Solver Solution Partial Spreadsheet Showing Problem Data A 1 2 Material 3 Aluminum 4 Steel 5 Profit/Bike B C Material Requirements Deluxe Profess. 2 4 3 2 10 15 D Amount Available 100 80 24 Example: Excel/Solver Solution Partial Spreadsheet Showing Formulas A B C Decision Variables Deluxe Professional D 6 7 8 Bikes Made 9 10 =B5*C10+C5*D10 Maximized Total Profit 11 12 Constraints Amount Used Amount Avail. 13 Aluminum =B3*B8+C3*C8 <= 100 14 Steel =B4*B8+C4*C8 <= 80 25 Example: Excel/Solver Solution Partial Spreadsheet Showing Solution A 6 7 8 9 10 11 12 13 14 Bikes Made B C Decision Variables Deluxe Professional 15 17.500 Maximized Total Profit Constraints Aluminum Steel Amount Used 100 80 D 412.500 <= <= Amount Avail. 100 80 26 Transportation Method This method can solve a special form of LP problem, including the classical transportation problem, with these typical characteristics: m sources and n destinations number of variables is m x n number of constraints is m + n (constraints are for source capacity and destination demand) costs appear only in objective function (objective is to minimize total cost of shipping) coefficients of decision variables in the constraints are either 0 or 1 27 Example: Transportation LP National Packaging has plants in Tulsa, Memphis, and Detroit that ship to the firm’s warehouses in San Diego, Norfolk, and Pensacola. The three warehouses require at least 4,000, 2,500, and 2,500 pounds of cardboard per week, respectively. The plants each have 3,000 pounds of cardboard per week available for shipment. The shipping cost per pound from each plant to each warehouse is shown on the next slide. Formulate and solve an LP to determine the shipping arrangements (source, destination, and quantity) that will minimize the total weekly shipping cost. 28 Example: Transportation LP Source Tulsa Memphis Detroit Destination San Diego Norfolk Pensacola $12 20 30 $6 11 26 $5 9 28 29 Example: Transportation LP Define the objective Minimize the total weekly shipping cost Define the decision variables There are m x n = 3 x 3 = 9 decision variables. xij represents the number of pounds of cardboard to be shipped from plant i to warehouse j. Tulsa Memphis Detroit San Diego Norfolk Pensacola x11 x12 x13 x21 x22 x23 x31 x32 x33 30 Example: Transportation LP Write the mathematical function for the objective Min Z = 12x11 + 6x12 + 5x13 + 20x21 + 11x22 + 9x23 + 30x31 + 26x32 + 28x33 31 Example: Transportation LP Write the constraints (1) x11 + x12 + x13 < 3000 (2) x21 + x22 + x23 < 3000 (3) x31 + x32 + x33 < 3000 (4) x11 + x21 + x31 > 4000 (5) x12 + x22 + x32 > 2500 (6) x13 + x23 + x33 > 2500 (Plant 1 capacity in pounds) (Plant 2 capacity in pounds) (Plant 3 capacity in pounds) (Wareh. 1 demand in pounds) (Wareh. 2 demand in pounds) (Wareh. 3 demand in pounds) 32 Assignment Method This method can solve a special form of LP problem, including the classical assignment problem, with these typical characteristics: is a special case of a transportation problem the right-hand sides of constraints are all 1 the signs of the constraints are = rather than < or > the value of all decision variables is either 0 or 1 33 Example: Assignment LP A sprinkler system installation company has three residential projects to complete and three work teams available and capable of completing the projects. The work teams are not equally efficient at completing a particular project. Shown on the next slide are the estimated laborhours required for each team to complete each project. How should the work teams be assigned in order to minimize total labor-hours? 34 Example: Assignment LP Work Team Alice, Ted Gary, Marv Tina, Sam Projects A B C 28 30 18 35 32 20 25 25 14 35 Real LP Problems Real-world LP problems often involve: Hundreds or thousands of constraints Large quantities of data Many products and/or services Many time periods Numerous decision alternatives … and other complications 36 Computer Solutions of LP Problems Computer output typically contains: Original-problem formulation Basis variables (variables in the final solution) and their values Slack-variable values -- slack represents the amount of a scarce resource that is not used by the decision variables Shadow prices -- which indicate the impact on Z if the constraints’ right-hand sides are changed … more 37 Computer Solutions of LP Problems Computer output typically contains: Ranges of right-hand side values for which the shadow prices are valid For each nonbasic variable: amount Z is reduced (in a MAX problem) or increased (in a MIN problem) for one unit of x in the solution 38 Wrap-Up: World-Class Practice Managers at all levels use LP to solve complex problems and aid in decision making Some companies establish formal operations research, management science, or operations analysis departments Other companies employ consultants LP is applied to long, medium, and short range decision making 39 End of Chapter 8 40