ME 492 CAPSTONE DESIGN PROJECT

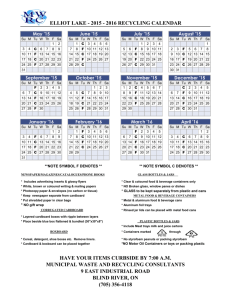

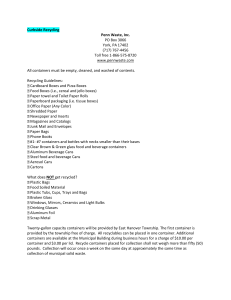

advertisement

ME 492 CAPSTONE DESIGN PROJECT GROUP MEMBERS Ben Samms Travis Ellis Mark Goss Abdulkareem Al-Yami Introduction Background • Bulking Process The paint consolidated into 55 gal. drums (bulking) entails the following process: – The paint cans collected are sorted in metal wire cages (dimensions vary). – Cages are positioned into the bulking room for processing. – Staff No. 1 removes the cans; opens the cans (1 gallon cans with an opener, 5 gallon cans by prying) and passes the cans on to Staff No. 2. – Staff No. 2 pours off liquid into the two provided drums and passes it on to Staff No. 3. – Staff No. 3 loads the cans into a hydraulic crusher and crushes the cans and separates solid material from the cans. Once crushed the cans are removed and disposed off. Introduction Problems • • • & Issues Ergonomic Issues: Several staff members have experienced repetitive motion injury and stain induced injury due to this process. The current process leaves the staff vulnerable to potential injuries due to heavy loads being lifted, pushed, and without proper ergonomic considerations. Close proximity of the staff members, congestion of the process, and the volatility of the chemicals require that the process allow for the expedient evacuation of all personnel in the event of an incident. Design Brief Our objective is to re-design the benchmark process to minimize the potential for injury and also increase the flow of the process minimize staff risk for exposure to hazardous chemicals and potential fire. We intend to look at the present layout and design with the main focus on ergonomic issues, load handling, and limited space utilization. In our design we must account for the exposure of any equipment to hazardous chemicals, explosive environment, as well as varying load sizes of cans and containers (worst environment possible). The project gives room for the use of hydraulic and pneumatic equipment, however, it is recommended that we try to avoid incorporating electricity in the operation of our design due to the volatility of the chemicals. Since the scope of the bulking room problems is too large to fulfill in only two quarters, our team will focus its attention on the transportation of the containers from the cages to placing them in the hydraulic crusher. Bulking Process 5 Gallon Bucket Cage Handling 5 Gallon Containers Carrying 5 Gallon Containers Lid Removal of 5 Gallon Containers Opening 1 Gallon Containers Pouring the Liquid Off Loading Crusher Bulking Room Entrance Product Design Specifications (PDS) Performance: Capable of lifting full five-gallon containers (up to 200 lb.) from ground level. Requires free 2-dimensional movement (x-y axis) as well as z-displacement (lift) with minimum zdisplacement of crusher door height from ground. Product should be compact and easily storable for convenience and optimal space saving. Product is required to roll across floor grating (if not permanently mounted). Product should clear all floor gradients in facility (if not permanently mounted). Final product should be usable in current operating environment as well as future expanded operation as applicable. Minimal design should lift and move cans while optimum design would allow pouring off of liquids between lifting and loading. Also desirable but not required is the ability to incorporate use with 1 gallon containers into design. Product should be operable by one person. Load area is 36.5 in. x 19 in. (crusher door) . Lift speed should be comparable to human processing speed. Though not required, it is desirable to incorporate a mechanism to open or puncture the container to allow pouring of the 5 gal. Containers Benchmark Air manipulator (Unidex): Requires spark resistant modification for controls Roll Handler (Alum-a-Lift Inc.): requires compatible storage cage/modified wheels to roll on grating/inclines Analysis of Customer Survey Since this product is primarily a special one-time application, the customer we concerned ourselves with was the Metro operation. The future may yield more customers in similar facilities but at present, these operators are the only resource for this specialized need. 1) On Friday, January 14th, the contact engineer (Dawit Solomon) and site supervisor (Kim Liebich) met with the design team to narrow the scope of the project. The team was presented with the problem statement divided into appropriate sized sub-problems for the team to focus on. The areas were as follows: – I) Move 5 gal. bucket from loaded cages, pass to (II) – II) Receive 5 gal. bucket, remove lid, pour-off liquid contents, load into crusher – III) crushing action (w/ associated problems), and material removal (difficult) As per meeting on 1/14/00, the group (along with Metro contacts) decided to address issues I and II in order to achieve the greatest immediate benefit to Metro employees. It was agreed that lid removal is a secondary problem and was not required. Analysis of Customer Survey (Cont.) 2) An open ended survey among current employees yielded the following key elements in the design of the new bulking process: – Lifting/moving of five gallon containers is too difficult* – turning motion in pouring/hand-off is causing injury* – crush plate on crusher has periodic alignment issues – grating on crusher becomes too packed with viscous materials (hinders operation) – pulling material stuck in grating is difficult – cages provide awkward lifting angles and distances* – removing lids from 5 gal. containers is difficult/time consuming* * This corresponds to the desires of the customer’s main concerns when operators were asked to prioritize the problems. The decision made in part 1 is based on this survey. QFD 1 1 1 1 9 10 13 11 9 12 1 3 13 4 11 12 5 4 2 1 12 13 6 9 8 2 6 3 5 4 1 2 9 6 7 8 5 10 8 9 7 11 7 10 3 3 9 9 3 9 3 9 3 9 3 9 3 3 3 3 9 3 1 3 1 3 3 1 3 9 3 3 3 3 3 Warner Air lift AO60 Aluma-Lift Current system 3 Number of controls Lid puncturing ability Explosion proof option Maximum lift height(in) Total vertical range of motion (in) Maximum extended length (Ft) Rotation range of end effector (degrees) Rotation Range of Arm(Degrees) Range of can diameters that can be gripped. (in) Lift speed (in/s) Lift Capacity (lbs.) Gripper closing force (lbs) Engineering Management Waste Handler Functional performance Durable Explosion Proof Fit Present Facility Pour Liquids Off Of Solids Promotes Recycling Handle 5-Gallon Cans Human Factors Safe To Use Easy To Clean Large Control surfaces Limited Operator Lifting Simple Control Structure Reduced operator Movements 1 The required number of people to process a can. 3 3 1 5 5 5 5 1 3 3 3 5 5 5 4 5 4 5 5 5 1 5 1 5 1 3 2 4 5 3 3 4 4 4 5 4 4 5 3 4 Interface With Crusher Works With Crusher Current Method Aluma-Lift Warner Ail lift AO60 Target 3 n/a n/a n/a ? 45 250 200 200 3 18 high 2 6 9--24 0 90 2 6 9--24 180 180 5 6 6--13 180 270 9 9 48 60 60 60 48 Y 0 72 yes no 2 72 yes no 2 60 yes yes 3 3 2 2 1 Project Plan Team Members And Expertise Ben Samms -Ten Years Working with SEH-America Mechanical Engineer at Technician. Mark Goss -Four Years with Edward Consulting Consulting Engineers Travis Ellis - Interned at Stanley Hydraulics Where he held the position of Engineering Credence System Inc . Abdulkareem Al-Yami -Summer Intern for OSM -Lab Testing Technician PSU Project Time Line Identification of Tasks Tasks: Come up with a design product that satisfies the ergonomic needs of the operators with regards to lifting as well as space constraints. Robustness should be a key feature in our design due to the environment of operation. In designing the lifting apparatus, we must account for the fact that the cans/containers are to be unloaded from steel cages that may or may not need to be modified to fit our specific needs. Our design must also comply with safety codes and not obstruct emergency evacuation paths at any time. All elements of the project should be null spark due to the volatility of the environment. The lifting device must incorporate the position of the hydraulic crusher as well as its dimensions and loading features. We should keep in mind the possibility of incorporating the function of emptying a can during the lifting operation before it is placed in the hydraulic crusher. The staff members must be able to operate our piece of equipment while wearing protective gear that does not allow them a high level of dexterity. Economic Analysis Currently the Metro facility has placed no spending limit on this project. This is in part due to the substantial safety concerns that are associated with it. Current intention is for Metro to review the suggestions and recommendations that our group provides and to determine the feasibility of those suggestions, if the suggestions are good and sound, Metro intends to manufacture and/or install the proposed equipment. Metro has provided the following information based on OSHA reports and information from the current management staff. Statistics from OSHA 200 report for both hazardous waste facilities: Location Emp. class 1998 Metro South Metro South Metro Central 1999 Metro South Metro Central R = regular T = temp # of Incidents Days Lost Days restricted R T R 4 1 1 0 0 17 18 0 7 R R 5 2 0 0 0 0 Economic Analysis (Cont.) Extrapolated figures from the above two years suggest the following. Total as a result of lost days: $ 2,942.31 Temp replacement: $52,415.57 Average per year $27,678.94 Also, note that in these cases Metro is continuing to pay the regular employee their wages for performing duties other than they were hired for. These figures also do not include the medical costs that are incurred. Therefore, the average per year can be substantially higher, depending on the number, types, and severity of incidents.