Apply safety, health and environmental protection procedures

advertisement

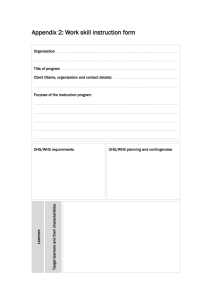

National Certificate in Paper & Pulp Manufacturing NQF Level 3 Apply safety, health and environmental protection procedures Commissioned by PAMSA and German Technical Co-Operation 1 National Certificate in Paper & Pulp Manufacturing NQF Level 3 Apply safety, health and environmental protection procedures Topics Modules Notional Hours P&P3CR TC303 Understanding company’s safety procedures and objectives 24 Safety procedures TC303 Responding to situations which can become unsafe 36 P&P3CR Unsafe situations Total Notional Hours Commissioned by PAMSA and German Technical Co-Operation 60 2 National Certificate in Paper & Pulp Manufacturing NQF Level 3 US: GMET Apply safety, health and environmental protection procedures Critical Cross-field Outcomes TC303 Understanding company’s SHE procedures and objectives Are able to explain and demonstrate emergency procedures Identify and solve problems Work effectively with others Communicate effectively Organise and manage myself and my activities Are able to explain and apply safety procedures in the workplace Collect, analyse, organise and critically evaluate information Understand basic requirements of the regulations related to safety, health and environment to the workplace Use science and technology effectively and critically Understand the company’s safety objectives, standards, policy, regulations and procedures Understand the basic requirements of the OHS Act for the employee and employer Demonstrate an understanding of the world as a set of related systems Use mathematics Learner and societal development Commissioned by PAMSA and German Technical Co-Operation 3 National Certificate in Paper & Pulp Manufacturing NQF Level 3 Topic Specification: TC303 Execute, test and evaluate Analyse, plan and make decisions Collect Information Learning Activities Use Multi media Self Study Plant investigation Media search Understanding company’s safety procedures and objectives Assignment Description W H A T Individual or group training. Do self study to develop key questions. Answers are obtained by discussions with safety experts. HOW Interview experts Attend lectures Group Discussions Sketch Summarise List / Tabulate Develop recommendations Job assignment Make presentation Complete documents Draft a report Do questionnaire / practical test 1. Learners obtain a copy of the OHS Act, local regulations and company policies and procedures 2. Individuals compare the OHS Act and local regulations with company policies and procedures and summarise similarities and differences 3. In a facilitated group discussion, learners comment on their findings and discuss anomalies. Topic assessment criteria The assessor will observe and confirm that learners: • Understand the basic requirements of the OHS Act for the employee and employer • Understand the company’s safety objectives, standards, policy, regulations and procedures • Understand basic requirements of the regulations related to safety, health and environment to the workplace • Are able to explain and apply safety procedures in the workplace • Are able to explain and demonstrate emergency procedures 4. Learners complete a questionnaire to demonstrate understanding of the subject 5. Learners demonstrate in a practical simulation how they would react under certain emergency or unsafe conditions Commissioned by PAMSA Notional Hours 24 and German Technical Co-Operation 4 National Certificate in Paper & Pulp Manufacturing NQF Level 3 US: GMET Apply safety, health and environmental protection procedures Critical Cross-field Outcomes TC303 Responding to situations which can become unsafe Identify and solve problems Work effectively with others Be able remain motivated and encourage others to maintain a safe and healthy working environment Be able to conduct a safety and environment inspection to identify, record and report materials and equipment malfunctions which may result in dangerous or unsafe conditions Be able to recognise and respond to hazards and unsafe acts Know the importance and purpose for cleaning up spillages and leaks Understand the company policy and procedure with regard to safety and environmental inspection Understand the possible effects of the workplace, equipment and materials on myself, my colleagues and the environment Communicate effectively Organise and manage myself and my activities Collect, analyse, organise and critically evaluate information Use science and technology effectively and critically Demonstrate an understanding of the world as a set of related systems Use mathematics Learner and societal development Commissioned by PAMSA and German Technical Co-Operation 5 National Certificate in Paper & Pulp Manufacturing NQF Level 3 Topic Specification: TC303 Execute, test and evaluate Analyse, plan and make decisions Collect Information Learning Activities Use Multi media Self Study Plant investigation Media search Responding to situations which can become unsafe Assignment Description W H A T Expert demonstration Individual or group training. Obtain OHS Act an company safety regulations and procedures. Apply knowledge in a practical safety check. HOW Attend lectures Group Discussions Sketch Summarise Use checklists Develop recommendations Job assignment Make presentation Complete documents Draft a report 1. Learners are supplied with documentation required for safety inspections. 2. Learners obtain or prepare a checklist for a safety inspection 3. A discussion / demonstration of safety inspections is facilitated at the work place 4. Under supervision, learners carry out a safety inspection in the workplace 5. Hazards and unsafe acts must be pointed out, an explanation given and recorded on the appropriate documentation 6. Learners must respond by taking the appropriate action: either react immediately or report and follow-up on implementation of corrective actions Topic assessment criteria The assessor will observe and confirm that learners: • Understand the possible effects of the workplace, equipment and materials on myself, my colleagues and the environment • Understand the company policy and procedure with regard to safety and environmental inspection • Know the importance and purpose for cleaning up spillages and leaks • Are able to recognise and respond to hazards and unsafe acts • Are able to conduct a safety and environment inspection to identify, record and report materials and equipment malfunctions which may result in dangerous or unsafe conditions • Are able remain motivated and encourage others to maintain a safe and healthy working Notional environment Hours Complete checklist 36 Commissioned by PAMSA and German Technical Co-Operation 6