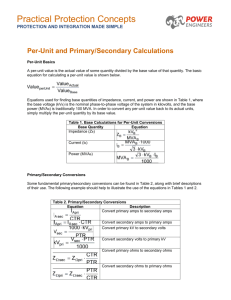

Contemporary Manufacturing Final PowerPoint

By James, Derek, Charles, Hassan

http://www.youtube.com/watch?v=04KKbfL

GI7g

Enjoy!

A company’s decision to “make” or “buy” is essential to the growth of the business as a whole. Companies have to make sure that their decision does not restrict them in the future

To “Make” a product means that a company would need to keep its manufacturing process’s in house, rather than outsource.

To “Buy” would mean a company does the exact opposite. A company would need to purchase its products from outside sources/suppliers.

There are some key numbers you’ll need to analyze when deciding to “make” or “buy” a product

Volume

Fixed cost of manufacturing

Per-Unit direct cost when buying

Per-Unit direct cost when making

Two Fundamental formulas utilize these numbers, cost to buy (CTB) and CTM)

CTB=Volume *Per-Unit cost when buying

CTM=Fixed costs +(Per-Unit direct cost*Volume)

1) What are the Four

Numbers you need to know when making the

“make or buy” decision?

Volume

Fixed cost of manufacturing

Per-unit direct cost when buying

Per-unit direct cost when making

external environmental factors coupled with triggers help form the decision to “make or buy”. These triggers help pinpoint the specific decision in the make or buy process. Cost reduction, lack of capacity, new products and skill shortages all play a key role in developing the strategy.

Technology and manufacturing make or break the decision when “making or buying”. obsolete technology, inefficient manufacturing processes, poor supply chain management, and poor support systems would lead in the “Buy” direction. The opposite would lead you a company to “make” their own products.

The Process

These steps illustrate the way a company can identify weather they can

“make or buy” a product on a smaller scale. By assembling a team collecting and analyzing data and receiving feedback, a company can determine whether they made an educated decision or not.

1)

In the “Make or

Buy” decision process, what

Follows the

Preparation Phase?

Answer:

Data Collection

Companies choose to keep functions that core in their technological aspects of the business

This keeps the design quality, product/brand identity and the security of the design within the company. The additional benefit of this is that the company remains linked to their customers.

Some Additional reasons for making include but are not limited too…

Cost Concerns

Expansion

Direct Control over the product

Quality Control concerns

Supplier Unreliability

Supplier Competence

Order Volume Too small

Organizational Pride

Lack Of Experience

Supplier Expertise

Cost

Small manageable Volume

Insufficient In House capacity

Strategic partnerships

The volume of products produced plays a major role in the “make or “buy” decision. Companies faced with the tasks of manufacturing high and low volumes can look to adopt a “plant-within-aplant” alternative when aiming to efficiently

“make” their product.

Companies can also look to outsource products with low volume demand.

Leading to a narrowing of the internal span of process.

Trade barriers across much of the world have greatly declined.

In 1990 the average tariff was 7%, or less than 1/5 of that in 1960.

We have seen a range of new markets open in Asia and Eastern Europe, and foreign investments.

Markets that previously favored local production facilities due to high tariff levels can now be supplied by imports.

3. Trade barriers across much of the world have greatly _________?

A. Inclined

Answer: B. Declined

B. Declined

Faced with a decline in demand and associated capacity requirements:

companies are being confronted with the necessity to decrease their span of process of many fronts.

Difficult to align functional objectives

(manufacturing tasks) with business strategies.

Estimates of cost and savings must be realistic.

An effective sourcing strategy has become a strategic issue in determining sustainable competitive advantage for firms.

An effective sourcing strategy has the ability to:

(a) decide between ‘Make’ versus ‘Buy’ decision based on transaction cost theory.

(b) integrate sourcing strategies with company strategies.

(c) convert fixed costs into variable costs.

(d) deliberate reduction of vertical integration .

(e) determine the total cost ownership and purchasing strategy.

(f) develop the process of designing and managing supply networks in line with operational and organizational performance objectives .

(g) plan, evaluate, implement, and control the sourcing decisions.

2. What can a company faced with the task of manufacturing high and low volume products do?

A. Outsource all manufacturing.

B. Adopt a plant-within-a-plant strategy.

C. Outsource products with high volume demand.

Answer: B. Adopt a plant-within-a-plant strategy.

A company may opt for ‘Make’ strategy when external capabilities do not exist outside or even if they do exist, they cannot be traded through markets or across companies.

Also will opt to make when suppliers do not want to trade unique and valuable resources.

To remain competitive, companies need to develop the ability to recombine there internal capabilities into new configurations of capabilities. This clearly indicates its strong association with related product diversification strategy.

Traditionally, organizations opt for ‘Buy’ strategy.

▪ Largely on the basis of obtaining the best price.

Companies nowadays tend to contract out more manufacturing and service activities than they did a decade ago.

▪ This trend has been driven by changes in the business environment and the pursuit of lean operations.

The ‘Buy’ strategic option has enabled companies to secure advantages such as:

▪ Economies of scale (mass production) and scope (specialization), cost reduction, quality, service and delivery improvement, organizational focus, and product flexibility enhancement .

1. Which Strategy did organizations traditionally opt for?

A. Make B. Buy

Answer : Traditionally, organizations opted for

‘Buy’ strategy which was done largely on the basis of obtaining the best price .

A study conducted based on 314 respondents out of a population of 1300 generated several interesting outcomes.

The research is based on the Transaction Cost

Theory, and the Resource Based View (RBV).

Paper proposed the hypothesis that there is a significant difference in the performance of companies that opted for ‘Make’ or ‘Buy’ strategy.

The total numbers of respondents were 314 or 24% from 1300 population

(total number of member of the Federation of Malaysian Manufacturers).

From four major manufacturing sectors in Malaysia. (electrical and electronics, chemicals including petroleum, food and beverages, and fabricated metal).

Out of these, 153 of them exercised the ‘Make’ strategy while 161 opted for the ‘Buy’ strategy.

Questionnaires were mailed specifically to individuals holding senior positions (CEOs, managing directors, and general managers) of organizations that would be able to respond comfortably to the issues studied.

The data for this study was collected between May 2008 and July 2008 using a mail survey approach.

Sourcing strategy instruments were adapted and Twelve questions on various sourcing practices were used such as:

(1) lower prices,

(2) better quality

(3) better delivery performance

(4) better availability

(5) access to advanced technology

(6) better customer service

(7) easy to change product design

(8) enhanced competitive position

(9) helps meet countertrade obligation

(10) easy to resolve problems

(11) better communication

(12) better geographic location.

Respondents were required to determine the degree to which the items are “not important at all” or “extremely important” based on a Likert scale continuum from 1 to 7

(scale 1 = not at all important to scale 7 = extremely important) in their extent of usage so as to be competitive in their respective industry.

Cost and Investments

The level of investment will determine the width of Internal Process to a business and In doing so will have a direct bearing on the levels of cost involved.

Strategic Considerations

Important general considerations help for the basis for strategic action.

The principle areas of cost associated with span-of-process decisions are…

Transaction costs concerned with buying, selling and physically handling materials throughout relevant processes.

The costs associated with improving the coordination between the supply production, and distribution activities.

The costs associated with combining similar overhead activities. Companies can do this when they widen their span of process. (Centralizing activities makes it difficult to achieve the apparent overhead gains when internal span of process is narrowed)

The investment of hardware, controls, procedures, and other relevant, infrastructure requirements.

High Entry Barriers

Industries where a wide span of process bring a set of distinct entrybarrier advantages, increasing the internal span will raise the financial and managerial resources required for a company to enter and compete effectively with existing businesses.

Supply Assurance

The supply of critical materials may well be of such importance to a company that this gain alone would be sufficient justification for the investment involved.

Secured Outlets

Securing outlets can result from integrating forward. Additional advantages also accrue with this move. Improved feedback leads to a position of being more aware of demand changed and provides an opportunity to increase the accuracy of forecasts.

In my source I found…

Suggestions regarding considerations that favor making a part in-house.

Factors that may influence a firm to buy a part externally.

The two most important factors to consider in a make-or-buy decision.

Cost considerations for the “buy” analysis.

In the book World Class Supply Management the authors (David

Bury, Donald Dobler, Stephen Starling) stated a rule of thumb for out-sourcing.

It proposes that a firm should outsource all items that do not fit in one of the following three categories:

(1) The item is critical to the success of the product, including customer perception of important product attributes.

(2) The item requires specialized design and manufacturing skills or equipment, and the number of capable and reliable suppliers is extremely limited.

(3) The item fits well within the firm's core competencies, or within those the firm must develop to fulfill future plans. Items that fit under one of these three categories are considered strategic in nature and should be produced internally if at all possible.

What are 2 factors that may influence firms to buy a part externally?

Answer:

1. Lack of Expertise

2. Limited production facilities or insufficient capacity.

The Goal:

During Rogo’s Plant crisis, he was initially faced with two bottlenecks, the NCX-10 & the

”Heat and Treat” machine.

To help solve this problem some of the “Heat and Treat” parts were outsourced to local vendors to increase capacity

-Noted on Page 190

The “Make” or “Buy” decision is a complex process, which consists of preparation, data collection, Data Analysis, and feedback.

These process’s are governed buy different technologies, costs, support systems, and logistics.

Globalization of world trade has changed the way countries traditionally did business.

Places which normally made there own products turned to outsourcing them to save costs

High entry volumes, supplied assurance, and secured markets are some of the strategic considerations that business’s need to consider prior to making the decision to

“make or buy”

![[ click here to type the document title ]](http://s3.studylib.net/store/data/009269825_1-199747c33aba7cc3b331506b68efaf59-300x300.png)