Draft Presentation

advertisement

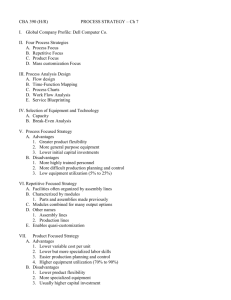

A Configurational Approach to Mass Customization and Its Implications for Work Design Gensheng (Jason) Liu Ph.D. Candidate Operations and Management Science Department Carlson School of Management University of Minnesota August 6, 2005 OM Division PhD Consortium Annual Meeting of AoM, Hawaii 3/16/2016 1 Dissertation Title On Mass Customization: Configurational and Contingency perspectives Dissertation Committee Roger Schroeder (Advisor, OMS) Rachna Shah (Advisor, OMS ) Susan Meyer Goldstein (OMS) Christopher Bingham (Statistics) Stage: Will defend proposal in two months 3/16/2016 2 Dissertation Research questions Are there different patterns in manufacturers’ achievement on mass customization capabilities? Does work design has any impact on manufacturers’ achievement on mass customization capabilities? When is mass customization the most appropriate strategy for a manufacturer? What are the cultural and structural factors that facilitate the achievement of a manufacturer’s mass customization capabilities? Primary research methodology: Cross-sectional survey Unit of observation: Plant Practical contribution: Better understanding of implementation conditions and facilitating factors of mass customization. Academic contribution: Empirically investigate conceptually stated principles about mass customization. 3/16/2016 3 Dissertation Research Essay 1 A Configurational Approach to Mass Customization and Its Implications for Work Design 3/16/2016 4 Outline Research Motivation Propositions and Hypotheses Methods Results Discussion Summary and Conclusion 3/16/2016 5 Research Motivation Mass Customization: A New Production Paradigm Key drivers Increasing customer demand for product variety and customization Shortening life cycle of products Technology development Definition The ability of a firm to quickly produce customized products on a large scale at a cost comparable to non-customized products (Tu et al. 2001). Research Da Silveira et al. (2001): “Literature on mass customization implementation is still incipient. Most claims are drawn from limited case examples or based on educated guesses from authors rather than from hard evidence obtained through exhaustive research.” 3/16/2016 6 Research Motivation Achievement of Mass Customization Capabilities Mass customization strategy is only appropriate for certain market situations (Hart 1995, Salvador et al. 2002) Not all companies that pursue mass customization strategy actually succeed (Pine et al. 1993, Zipkin 2001) Human resource management has an impact on mass customization (Lau 1995, Kakati 2002) 3/16/2016 7 Research Motivation Research Questions Are there different patterns in manufacturers’ achievement on mass customization capabilities? Does work design has any impact on manufacturers’ achievement on mass customization capabilities? 3/16/2016 8 Propositions & Hypotheses Proposition 1: Manufacturers can be classified into distinct groups based on their achievement on various mass customization capabilities. A configurational approach toward mass customization (taxonomy) An extant typology of mass customizers (Duray et al. 2000) Degree of customer involvement in product design Degree of product modularity 3/16/2016 9 Propositions & Hypotheses Sociotechnical systems perspective on work design Fit between social subsystem and technical subsystem within an organization Nine principles (Cherns 1978 & 1987) Applications in OM Cellular manufacturing (Huber & Brown 1991) Lean production (Niepce & Molleman 1998) 3/16/2016 10 Propositions & Hypotheses Hypotheses 1a-j: In work design, compared to other manufacturers, mass customizers use more of the following factors. STS Principles Measures Hypothesis Compatibility; Minimal critical specifications Employee empowerment 1a Variance control; Information flow Feedback to shopfloor employees 1b Autonomous maintenance 1c Multifunctionality; Boundary location Multifunctional employees 1d Management breadth of experience 1e Cellular manufacturing setup 1f Shopfloor assistance to employees 1g Task-related training for employees 1h Human values Human goodness 1i Incompletion Continuous improvement and learning 1j Support congruence 3/16/2016 11 Methods Sample and data collection “High Performance Manufacturing” project 6 countries: U.S., Germany, Finland, Sweden, Japan, and Korea 3 industries: machinery, electronic, and automotive 189 plants Measurement 7-point Likert scales Mass customization capabilities scale based on Tu et al. (2001) Data analysis Cluster analysis for proposition 1 ANOVA for hypotheses 1a-j 3/16/2016 12 Methods Mass customization capabilities scale MC1: We are highly capable of large scale product customization. MC2: We can easily add significant product variety without increasing cost. MC3: Our setup costs, changing from one product to another, are very low. MC4: We can customize products while maintaining high volume. MC5: We can add product variety without sacrificing quality. MC6: Our capability for responding quickly to customization requirements is very high. 3/16/2016 13 Results I: Empirical Taxonomy Derivation of the cluster solution Outlier detection – 172 plants retained Two-stage cluster analysis Hierarchical cluster analysis – 3 cluster solution most viable K-means cluster analysis Final cluster centroids Variable MC1 MC2 MC3 MC4 MC5 MC6 n Group 1 4.849 3.818 3.989 4.302 4.791 4.851 74 Group 2 5.898 4.263 3.789 5.471 5.404 5.822 57 Group 3 5.768 5.297 5.435 5.841 5.898 5.862 41 Group 1: non-customizers; Group 2: inefficient customizers; Group 3: mass customizers 3/16/2016 14 Results I: Empirical Taxonomy Validation of the cluster solution Replication A second nonhierarchical analysis: 95.3% overlap Split sample replication: 91.0% and 76.2% overlap ANOVA on cluster variate Only 3 out of 18 comparisons not significant, but all as expected Discriminant analysis Both discriminant functions significant. Cross-validation: Jack-knifing procedure results misclassification rate of 4.1%. 3/16/2016 15 Results I: Empirical Taxonomy Validation of the cluster solution Predictive validity Manufacturing flexibility: mix flexibility and volume flexibility Product modularity (Duray et al. 2000) Time-based manufacturing practices (Tu et al. 2001) All variables are significantly different between the three groups as predicted by theories or extant research Contextual factors of mass customization Country effect: Germany has more inefficient customizers and Japan has more non-customizers. No industry, plant size, or plant age effect 3/16/2016 16 Results I: Empirical Taxonomy Proposition 1 Proposition 1 supported: Manufacturers have different patterns in terms of their achievement on various mass customization capabilities 3/16/2016 17 Results II: Work Design For Mass Customization Group 1 Group 2 Group 3 Non-Customizers Inefficient Customizers Mass Customizers F-value n = 74 n = 57 n = 41 (sig.) EMPOWER -0.253 (2) 0.184 (1) 0.182 4.05 (.019) FEEDBACK -0.167 (3) -0.203 (3) 0.359 (1,2) 4.76 (.010) AUTOMAIN -0.388 (2,3) 0.084 (1) 0.421 (1) 9.90 (.000) MULTIEMP -0.375 (3) -0.009 0.411 (1) 9.67 (.000) MGTEXP -0.097 (3) -0.266 (3) 0.405 (1,2) 6.17 (.003) CELLULAR -0.287 (3) -0.163 (3) 0.538 (1,2) 10.50 (.000) EMPASSIS -0.306 (3) 0.008 (3) 0.491 (1,2) 9.30 (.000) TRAINING -0.358 (3) -0.001 0.404 (1) 8.66 (.000) GOODNESS -0.368 (2,3) 0.065 (1) 0.486 (1) 11.14 (.000) CIMPROVE -0.291 (3) -0.037 0.286 (1) 4.58 (.012) 3/16/2016 18 Results II: Work Design For Mass Customization Hypotheses 1a-j Hypothesis 1a marginally supported: Mass customizers empower employees marginally more than non-customizers. Hypotheses 1b-j all supported: All these work design factors have significant effect on the achievement of mass customization capabilities. 3/16/2016 19 Discussion Work design has important impact on mass customization. From the sociotechnical systems perspective, to successfully implement mass customization strategy, the social system should fit the technical system. Human resource bundles (MacDuffie 1995, Ichniowski et al. 1996) All work design factors contribute to customization ability. Among the work design factors, assistance to employees, feedback to employees, management breadth of experience, and cellular manufacturing setup also contribute to customization efficiency. Inefficient customizers have even less management breadth of experience and feedback to employees than non-customizers. 3/16/2016 20 Contribution & Limitation Contribution The first empirically based taxonomy of mass customization. Apply sociotechnical systems theory in mass customization research. Empirically investigate the relationship between work design and the achievement of mass customization capabilities, especially identify the work design factors that contribute to efficiency of customization. Limitation Work design factors not complete from the sociotechnical systems perspective (i.e., human values) 3/16/2016 21 Related research A contingency approach toward mass customization: When is mass customization the most appropriate strategy for a manufacturer? Cultural and structural factors that facilitate mass customization 3/16/2016 22 Questions and Comments ? 3/16/2016 23