p 1

advertisement

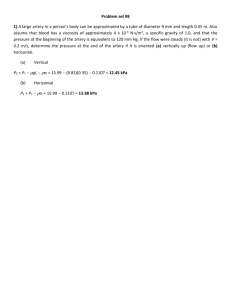

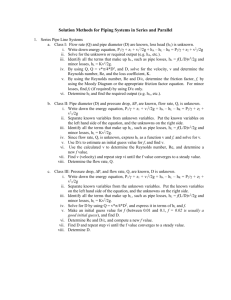

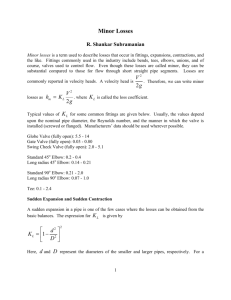

TL2101 Mekanika Fluida I Benno Rahardyan Pertemuan Mg 1 Topik Sub Topik Tujuan Instruksional (TIK) Pengantar Definisi dan sifat-sifat fluida, berbagai jenis fluida yang berhubungan dengan bidang TL Memahami berbagai kegunaan mekflu dalam bidang TL Pengaruh tekanan Tekanan dalam fluida, tekanan hidrostatik Mengerti prinsip-2 tekanan statitka Pengenalan jenis aliran fluida Aliran laminar dan turbulen, pengembangan persamaan untuk penentuan jenis aliran: bilangan reynolds, freud, dll Mengerti, dapat menghitung dan menggunakan prinsip dasar aliran staedy state Idem Idem Idem 3 Prinsip kekekalan energi dalam aliran Prinsip kontinuitas aliran, komponen energi dalam aliran fluida, penerapan persamaan Bernoulli dalam perpipaan Mengerti, dapat menggunakan dan menghitung sistem prinsi hukum kontinuitas 4 Idem Idem + gaya pada bidang terendam Idem 5 Aplikasi kekekalan energi Aplikasi kekekalan energi dalam Latihan menggunakan aplikasi di bidang TL prinsip kekekalan eneri khususnya dalam bidang air minum 2 Pipes are Everywhere! Owner: City of Hammond, IN Project: Water Main Relocation Pipe Size: 54" Pipes are Everywhere! Drainage Pipes Pipes Pipes are Everywhere! Water Mains Types of Engineering Problems How big does the pipe have to be to carry a flow of x m3/s? What will the pressure in the water distribution system be when a fire hydrant is open? FLUID DYNAMICS THE BERNOULLI EQUATION The laws of Statics that we have learned cannot solve Dynamic Problems. There is no way to solve for the flow rate, or Q. Therefore, we need a new dynamic approach to Fluid Mechanics. The Bernoulli Equation By assuming that fluid motion is governed only by pressure and gravity forces, applying Newton’s second law, F = ma, leads us to the Bernoulli Equation. P/g + V2/2g + z = constant along a streamline (P=pressure g =specific weight V=velocity g=gravity z=elevation) A streamline is the path of one particle of water. Therefore, at any two points along a streamline, the Bernoulli equation can be applied and, using a set of engineering assumptions, unknown flows and pressures can easily be solved for. Free Jets The velocity of a jet of water is clearly related to the depth of water above the hole. The greater the depth, the higher the velocity. Similar behavior can be seen as water flows at a very high velocity from the reservoir behind the Glen Canyon Dam in Colorado Closed Conduit Flow Energy equation EGL and HGL Head loss – major losses – minor losses Non circular conduits The Energy Line and the Hydraulic Grade Line Looking at the Bernoulli equation again: P/γ + V2/2g + z = constant on a streamline This constant is called the total head (energy), H Because energy is assumed to be conserved, at any point along the streamline, the total head is always constant Each term in the Bernoulli equation is a type of head. P/γ = Pressure Head V2/2g = Velocity Head Z = elevation head These three heads, summed together, will always equal H Next we will look at this graphically… V12 p2 V22 1 z1 h p 2 z2 ht hL g 2g g 2g p1 Conservation of Energy Kinetic, potential, and thermal energy hp = head supplied by a pump ht = head given to a turbine hL = mechanical energy converted to thermal downstream from cross section 1! Cross section 2 is ____________ irreversible Point to point or control volume? V is average velocity, kinetic energy V 2 Why ? _____________________________________ Energy Equation Assumptions hydrostatic Pressure is _________ in both cross sections – pressure changes are due to elevation only p gh section is drawn perpendicular to the streamlines (otherwise the _______ kinetic energy term is incorrect) Constant ________at the cross section density Steady flow _______ V12 p2 V22 1 z1 h p 2 z 2 ht hL g 2g g 2g p1 EGL (or TEL) and HGL EGL pressure head (w.r.t. reference pressure) p g V2 2g z velocity head elevation head (w.r.t. datum) p HGL z γ downward (in The energy grade line must always slope ___________ direction of flow) unless energy is added (pump) The decrease in total energy represents the head loss or energy dissipation per unit weight EGL and HGL are coincident and lie at the free surface for water at rest (reservoir) If the HGL falls below the point in the system for which it lower than pressure is plotted, the local pressures are _____ ____reference __________ ______ Energy equation velocity head static head Why is static head important? Energy Grade Line Hydraulic G L V2 2g p pressure g head z elevation pump z=0 datum p1 V p V 1 z1 h p 2 2 z2 ht hL g 2g g 2g 2 1 2 2 The Energy Line and the Hydraulic Grade Line Lets first understand this drawing: Measures the Static Pressure Measures the Total Head 12 12 V2/2g EL HGL 1: Static Pressure Tap Measures the sum of the elevation head and the pressure Head. 2: Pilot Tube Measures the Total Head EL : Energy Line Q P/γ Total Head along a system HGL : Hydraulic Grade line Z Sum of the elevation and the pressure heads along a system The Energy Line and the Hydraulic Grade Line Understanding the graphical approach of Energy Line and the Hydraulic Grade line is key to understanding what forces are supplying the energy that water holds. V2/2g EL Q P/γ V2/2g HGL 2 P/γ Z 1 Z Point 1: Majority of energy stored in the water is in the Pressure Head Point 2: Majority of energy stored in the water is in the elevation head If the tube was symmetrical, then the velocity would be constant, and the HGL would be level Bernoulli Equation Assumption Frictionless _________ (viscosity can’t be a significant parameter!) Along a streamline __________ Steady flow ______ Constant density ________ No pumps, turbines, or head loss z V 2 2g p g const Why no ? ____________ point velocity no Does direction matter? ____ Useful when head loss is small Pipe Flow: Review We have the control volume energy equation for pipe flow. We need to be able to predict the relationship between head loss and flow. How do we get this relationship? __________analysis _______. dimensional V12 p2 V22 1 z1 hp 2 z2 ht hL g 2g g 2g p1 Example Pipe Flow Problem cs1 Find the discharge, Q. 100 m D=20 cm L=500 m valve cs2 Describe the process in terms of energy! V12 p2 V22 1 z1 H p 2 z2 Ht hl g 2g g 2g p1 V22 z1 z2 hl 2g a V2 2 g z1 z2 hl f Flow Profile for Delaware Aqueduct Rondout Reservoir (EL. 256 m) 70.5 km West Branch Reservoir (EL. 153.4 m) V12 p2 V22 1 z1 H p 2 z2 H t hl g 2g g 2g p1 Sea Level (Designed for 39 m3/s) hl z1 z2 Need a relationship between flow rate and head loss Ratio of Forces Create ratios of the various forces The magnitude of the ratio will tell us which forces are most important and which forces could be ignored Which force shall we use to create the ratios? Inertia as our Reference Force F f ra F=ma F ra Fluids problems (except for statics) include a velocity (V), a dimension of flow (l), and a density (r) Substitute V, l, r for the dimensions MLT M rl M f 2 2 LT 3 Ll T l V Substitute for the dimensions of specific force V2 fi r l Dimensionless Parameters Reynolds Number Froude Number Weber Number V2 fi r l r Vl Re = m V Fr = gl W V 2 lr fu V l2 fg r g f 2 l r c2 Mach Number f Ev = V l M c (Dp + r g Dz ) Pressure/Drag Coefficients 2 p C 2Drag d Cp 2 2 r V A rV – (dependent parameters that we measure experimentally) Problem solving approach 1. 2. 3. 4. 5. 6. Identify relevant forces and any other relevant parameters If inertia is a relevant force, than the non dimensional Re, Fr, W, M, Cp numbers can be used If inertia isn’t relevant than create new non dimensional force numbers using the relevant forces Create additional non dimensional terms based on geometry, velocity, or density if there are repeating parameters If the problem uses different repeating variables then substitute (for example wd instead of V) Write the functional relationship Friction Factor : Major losses Laminar flow – Hagen-Poiseuille Turbulent (Smooth, Transition, Rough) – Colebrook Formula – Moody diagram – Swamee-Jain Laminar Flow Friction Factor gD 2 hl V 32 L hl Hagen-Poiseuille 32LV rgD 2 LV2 hl f D 2g 32LV LV2 f 2 D 2g rgD 64 64 f rVD R Darcy-Weisbach Pipe Flow: Dimensional Analysis What are the important forces? pressure Therefore Inertial ______,viscous ______,________. ________number and _______________ Pressure coefficient . Reynolds What are the important geometric length, roughness height parameters? diameter, _________________________ – Create dimensionless geometric groups ______, ______ l/D /D Other repeating parameters? Write the functional relationship l C p f Re, , D D Cp 2p rV 2 l C p f , , Re D D Dimensional Analysis How will the results of dimensional analysis guide our experiments to determine the relationships that govern pipe flow? If we hold the other two dimensionless parameters constant and increase the length to diameter ratio, how will Cp change? D C 2p Cp proportional to l C p f , Re p 2 D f C p f , Re l D l D f is friction factor rV Laminar Flow Friction Factor g D 2 hl V 32 L 32 LV hf r gD 2 L V2 hf f D 2g 32 LV L V2 f 2 r gD D 2g 64 64 f rVD Re Hagen-Poiseuille hf 128LQ r gD 4 Darcy-Weisbach -1 on log-log plot Slope of ___ Viscous Flow in Pipes Viscous Flow: Dimensional Analysis D Cp l f ,R D Where rVD R Two important parameters! R - Laminar or Turbulent /D - Rough or Smooth and 2p Cp rV 2 Laminar and Turbulent Flows Reynolds apparatus rVD inertia R damping Transition at R of 2000 Boundary layer growth: Transition length What does the water near the pipeline wall experience? Drag or shear _________________________ Why does the water in the center of the pipeline speed Conservation of mass up? _________________________ Pipe Entrance v v Non-Uniform Flow Need equation for entrance length here v Images - Laminar/Turbulent Flows Laser - induced florescence image of an incompressible turbulent boundary layer Laminar flow (Blood Flow) Simulation of turbulent flow coming out of a tailpipe Turbulent flow Laminar flow http://www.engineering.uiowa.edu/~cfd/gallery/lim-turb.html Laminar, Incompressible, Steady, Uniform Flow Between Parallel Plates Through circular tubes Hagen-Poiseuille Equation Approach – Because it is laminar flow the shear forces can be quantified – Velocity profiles can be determined from a force balance Laminar Flow through Circular Tubes Different geometry, same equation development (see Streeter, et al. p 268) Apply equation of motion to cylindrical sleeve (use cylindrical coordinates) Laminar Flow through Circular Tubes: Equations a2 r 2 d u p gh 4 dl umax a2 d p gh 4 dl a is radius of the tube Max velocity when r = 0 a2 d V p gh 8 dl Velocity distribution is paraboloid of average velocity revolution therefore _____________ (V) is 1/2 umax _____________ a 4 d Q p gh 8 dl Q = VA = Vpa2 Laminar Flow through Circular Tubes: Diagram a2 r 2 d u p gh 4 dl du dr r d 2 dl du dr p gh r d Velocity Shear p gh 2 dl ghl True for Laminar or r 2l Turbulent flow Laminar flow Shear at the wall 0 ghl d 4l Laminar flow Continue Momentum is Mass*velocity (m*v) Momentum per unit volume is r*vz Rate of flow of momentum is r*vz*dQ dQ=vz2πrdr but vz = constant at a fixed value of r rv z (v2rdr) z rv z (v2rdr) z dz 0 Laminar flow Laminar flow Continue 2r zr r dz 2 (r dr) zr r dr dz p z 2rdr p z dz 2rdr rg2rdrdz 0 dvz dr Q R 0 p pz 0 pz L rgL R 4 p 2vz dr 8 L Hagen-Poiseuille The Hagen-Poiseuille Equation V12 p2 V22 z1 1 Hp z2 2 Ht hl cv pipe flow g1 2g g2 2g p1 p1 g1 z1 p2 g2 Constant cross section h or z z 2 hl p p hl 1 z1 2 z 2 g1 g2 p hl h g Laminar pipe flow equations a 4 d Q p gh 8 dl gD 4 hl Q 128 L gD 4 d p Q h 128 dl g gD 2 hl V 32 L hl dp h dl g L Prof. Dr. Ir. Bambang Triatmodjo, CES-UGM : Hidraulika I, Beta Ofset Yogyakarta, 1993 Hidraulika II, Beta Ofset Yogyakarta, 1993 Soal-Penyelesaian Hidraulika I, 1994 Soal-Penyelesaian Hidraulika II, 1995 Air mengalir melalui pipa berdiameter 150 mm dan kecepatan 5,5 m/det.Kekentalan kinematik air adalah 1,3 x 10-4 m2/det. Selidiki tipe aliran Bilangan reynolds : VD 5,5 x0,15 5 6 , 35 x 10 v 1,3 x10 6 Karena Re 4000 berarti aliran turbulen Re Minyak di pompa melalui pipa sepanjang 4000 m dan diameter 30 cm dari titik A ke titik B. Titik B terbuka ke udara luar. Elevasi titik B adalah 50 di atas titik A. Debit 40 l/det. Debit aliran 40 l/det. Rapat relatif S=0,9 dan kekentalan kinematik 2,1 x 10-4 m2/det. Hitung tekanan di titik A. Diameter pipa : D 30 cm Panjang pipa : L 4000 m Debit aliran : Q 0,04 m 3 / dtk 4 Kekentalan kinematik : v 2,1x10 m / dtk 2 Rapat relatif : S 0,9 r 900 kg / m 3 Elevasi ujung atas pipa ( B) terhadap ujung bawah ( A) : Z B Z A 50m Kecepatn aliran : Kehilangan tenaga 32vVL 32 x 2,1x10 4 x0,566,4000 hf 17,23 m 2 2 gD 9,82 x0,3 pA 2 Q 0,04 V 0,566 m / dtk A x0,32 4 Bilangan reynolds : pA 0 0 50 17,23 pA 67,23m VD 0,566 x0,3 808,6 4 v 2,1x10 Karena Re 2000 berarti aliran La min er p A 67,23 x900 x9,81 Re 2 V p V A z A B B z B hf g 2g g 2g VA VB g g p A 593,574 N / m 2 p A 593,574kPa Minyak dipompa melalui pipa berdiameter 25 cm dan panjang 10 km dengan debit aliran 0,02 m3/dtk. Pipa terletak miring dengan kemiringan 1:200. Rapat minyak S=0,9 dan keketnalan kinematik v=2,1x 10-4 m2/det. Apabila tekanan pada ujung atas adalah p=10 kPA ditanyakan tekanan di ujung bawah. Diameter pipa : D 25 cm Kehilangan tenaga Panjang pipa : L 10.000 m Debit aliran : Q 0,02 m 3 / dtk 32vVL 32 x 2,1x10 4 x0,4074 x10000 hf gD 2 9,82 x0,252 44,65 m Kekentalan kinematik : v 2,1x10 4 m 2 / dtk Selisih elevasi kedua ujung : Rapat relatif : S 0,9 r 900 kg / m 3 1 x10.000 50m 200 2 2 p A VA pB VB zA z B hf g 2g g 2g VA VB Kemiringan pipa : 1 : 200 Tekanan di B : pB 10kPa 10.000 Nm 2 Kecepatn aliran : Q 0,02 0,4074 m / dtk A x0,252 4 Bilangan reynolds : V VD 0,4074 x0,25 Re 485 v 2,1x10 4 Karena Re 2000 berarti aliran La min er z pA 0 pA 95,78m g g 10.000 50 44,65 900 x9,81 p A 95,78 x900 x9,81 p A 845,642 N / m 2 p A 845,642kPa Turbulent Pipe and Channel Flow: Overview Velocity distributions Energy Losses Steady Incompressible Flow through Simple Pipes Steady Uniform Flow in Open Channels Turbulence A characteristic of the flow. How can we characterize turbulence? – intensity of the velocity fluctuations – size of the fluctuations (length scale) u u u u instantaneous velocity mean velocity velocity fluctuation u t Turbulent flow When fluid flow at higher flowrates, the streamlines are not steady and straight and the flow is not laminar. Generally, the flow field will vary in both space and time with fluctuations that comprise "turbulence For this case almost all terms in the Navier-Stokes equations are important and there is no simple solution uz úz Uz average ur úr Ur average p P = P (D, , r, L, U,) p average P’ Time Turbulent flow All previous parameters involved three fundamental dimensions, Mass, length, and time From these parameters, three dimensionless groups can be build P L ) 2 f (Re, rU D rUD inertia Re Viscous forces Turbulence: Size of the Fluctuations or Eddies Eddies must be smaller than the physical dimension of the flow Generally the largest eddies are of similar size to the smallest dimension of the flow Examples of turbulence length scales depth (R = 500) – rivers: ________________ – pipes: _________________ diameter (R = 2000) – lakes: ____________________ depth to thermocline Actually a spectrum of eddy sizes Turbulence: Flow Instability In turbulent flow (high Reynolds number) the force viscosity leading to stability (_________) is small relative to inertia the force leading to instability (_______). Any disturbance in the flow results in large scale motions superimposed on the mean flow. Some of the kinetic energy of the flow is transferred to these large scale motions (eddies). Large scale instabilities gradually lose kinetic energy to smaller scale motions. The kinetic energy of the smallest eddies is dissipated by viscous resistance and turned into heat. head loss (=___________) Velocity Distributions Turbulence causes transfer of momentum from center of pipe to fluid closer to the pipe wall. Mixing of fluid (transfer of momentum) causes the central region of the pipe to have relatively constant _______velocity (compared to laminar flow) Close to the pipe wall eddies are smaller (size proportional to distance to the boundary) Turbulent Flow Velocity Profile du dy du h = eddy viscosity dy rlI u I u I lI du dy rl 2 I Turbulent shear is from momentum transfer du dy Length scale and velocity of “large” eddies Dimensional analysis y Turbulent Flow Velocity Profile du rl lI y r y 2 du k = 0.4 (from experiments) dy du r y dy 2 2 du y dy r du dy increases as we Size of the eddies __________ move further from the wall. dy 2 2 I 2 Log Law for Turbulent, Established Flow, Velocity Profiles du y dy r u u* 1 u* ln yu* 0 r 5.5 Integration and empirical results Shear velocity Laminar Turbulent y u* u I x Pipe Flow: The Problem We have the control volume energy equation for pipe flow We need to be able to predict the head loss term. We will use the results we obtained using dimensional analysis Friction Factor : Major losses Laminar flow – Hagen-Poiseuille Turbulent (Smooth, Transition, Rough) – Colebrook Formula – Moody diagram – Swamee-Jain Turbulent Pipe Flow Head Loss L V2 Proportional ___________ to the length of the pipe hf f D 2g square of the velocity Proportional to the _______ (almost) Increases ________ with surface roughness Is a function of density and viscosity independent of pressure Is __________ Smooth, Transition, Rough LV h f Turbulent Flow D 2g 2 f Hydraulically smooth pipe law (von Karman, 1930) Rough pipe law (von Karman, 1930) Transition function for both smooth and 1 rough pipe laws f (Colebrook) Re f 1 2 log f 2.51 1 3.7 D 2 log f 2.51 D 2 log Re f 3.7 (used to draw the Moody diagram) Pipe Flow Energy Losses V12 p2 V22 1 z1 hp 2 z2 ht hl g 2g g 2g p1 hl p g D f C p f , R D L 2 ghl 2p Cp Cp 2 rV V2 2 ghl D f 2 V L LV2 hl f D 2g Horizontal pipe Dimensional Analysis Darcy-Weisbach equation Turbulent Pipe Flow Head Loss Proportional to the length of the pipe ___________ Proportional to the square of the ___________ velocity (almost) Inversely ________ with the diameter (almost) ________ Increase with surface roughness Is a function of density and viscosity Is independent __________ of pressure Surface Roughness Additional dimensionless group /D need to be characterize Thus more than one curve on friction factorReynolds number plot Fanning diagram or Moody diagram Depending on the laminar region. If, at the lowest Reynolds numbers, the laminar portion corresponds to f =16/Re Fanning Chart or f = 64/Re Moody chart Friction Factor for Smooth, Transition, and Rough Turbulent flow P D f L 2 rU 2 1 4.0 * log Re* f Smooth pipe, Re>3000 f 0.4 f 0.079Re 0.25 Rough pipe, [ (D/)/(Re√ƒ) <0.01] Transition function for both smooth and rough pipe 1 D 4.0 * log 2.28 f 1 D D/ 4.0 * log 2.28 4.0 * log4.67 1 f Re f Smooth, Transition, Rough LV h f Turbulent Flow D 2g 2 f Hydraulically smooth pipe law (von Karman, 1930) Rough pipe law (von Karman, 1930) Transition function for both smooth and 1 rough pipe laws f (Colebrook) Re f 2 log 2.51 f 1 3.7 D 2 log f 1 D 2.51 2 log 3.7 Re f (used to draw the Moody diagram) Moody Diagram 0.10 0.08 D f Cp l 0.06 0.05 0.04 0.03 friction factor 0.05 0.02 0.015 0.04 0.01 0.008 0.006 0.004 0.03 laminar 0.002 0.02 0.001 0.0008 0.0004 0.0002 0.0001 0.00005 0.01 1E+03 smooth 1E+04 1E+05 R 1E+06 1E+07 1E+08 D Fanning Diagram 1 D D/ 4.0 * log 2.28 4.0 * log4.67 1 f Re f f =16/Re 1 D 4.0 * log 2.28 f Swamee-Jain 1976 limitations f 0.25 5.74 log 3.7 D Re0.9 /D < 2 x 10-2 – Re >3 x 103 – less than 3% deviation from results obtained 5/ 2 Q 2.22 D with Moody diagram ghf L easy to program for computer or calculator use hf 2 no f ghf 1.78 log L ghf 3.7 D 3/ 2 D L 1.25 LQ D 0.66 ghf 2 4.75 5.2 0.04 L Q ghf 9.4 Each equation has two terms. Why? Colebrook Solution for Q 1 2.51 D 2 log 3.7 f Re f 8 LQ 2 hf f 2 g D5 1 2.51 D 4 log f 3.7 Re f 2 1 1 8 LQ f hf 2 g D 5 4Q Re D 4Q Re f D hf 2 g D5 8 LQ 2 1 2 ghf D 3 Re f L hf g 8 f 2 5 D LQ 2 2 Colebrook Solution for Q 2 1 8 LQ 2 4 log 2 5 hf g D 3.7 D 1 2.51 2 ghf D 3 L log 3.7 D 1 2.51 2 ghf D 3 L 2 L Q ghf D 5 / 2 Q D5 / 2 2 ghf log 2.51 L 3.7 D L 3 2 ghf D Swamee D? 1.25 Q Q D 0.66 g g 8 LQ 2 hf f 2 g D5 1/ 5 Q D 0.66 g 2 2 1/ 4 5/ 4 Q g 2 1/ 5 0.04 Q Q 2 5 2 Q g g 1/ 4 1/ 5 1/ 25 Q 2 Q g 1/ 5 1/ 5 2 2 1/ 4 2 1/ 5 Q Q 5/ 4 Q D Q g g 8 g 1/ 5 1/ 4 1/ 5 64 5/ 4 Q 2 Q2 f 2 Q g g 2 8 Q D5 f 2 g 64 Q 2 D f 2 8g 5 1/ 5 Q 64 D f 2 8 g 2 5 2 1 5/ 4 Q f 4 4 g 2 2 1/ 4 1/ 5 1/ 5 Q 2 Q g Pipe roughness pipe material glass, drawn brass, copper commercial steel or wrought iron asphalted cast iron galvanized iron cast iron concrete rivet steel corrugated metal PVC pipe roughness (mm) 0.0015 0.045 0.12 d Must be 0.15 dimensionless! 0.26 0.18-0.6 0.9-9.0 45 0.12 Solution Techniques find head loss given (D, type of pipe, Q) 0.25 2 8 LQ f 4Q 2 hf f 2 Re 5 5.74 g D D log 3.7 D Re0.9 find flow rate given (head, D, L, type of pipe) Q D5 / 2 2 find ghf log 2.51 L 3.7 D L 3 2 ghf D pipe size given (head, type of pipe,L, Q) 2 LQ 1.25 D 0.66 gh f 4.75 5.2 0.04 L Q ghf 9.4 Exponential Friction Formulas RLQ n and hf = m D Commonly used in commercial industrial settings data Only applicable over range _____of__ ____ collected Hazen-Williams exponential friction formula 4.727 USC units Cn R 10.675 SI units n C 1.852 10.675L æQ ö hf = 4.8704 èC ø D SI units C = Hazen-Williams coefficient Head loss: Hazen-Williams Coefficient C 150 140 130 120 110 100 95 60-80 Condition PVC Extremely smooth, straight pipes; asbestos cement Very smooth pipes; concrete; new cast iron Wood stave; new welded steel Vitrified clay; new riveted steel Cast iron after years of use Riveted steel after years of use Old pipes in bad condition Hazen-Williams vs Darcy-Weisbach 1.852 10.675L Q hf 4.8704 D C SI units 8 LQ 2 hf f 2 g D5 Both equations are empirical Darcy-Weisbach is dimensionally correct, andpreferred ________. Hazen-Williams can be considered valid only over the range of gathered data. Hazen-Williams can’t be extended to other fluids without further experimentation. Non-Circular Conduits: Hydraulic Radius Concept A is cross sectional area P is wetted perimeter Rh is the “Hydraulic Radius” (Area/Perimeter) Don’tp confuse with radius! D2 A 4 D Rh = = = P pD 4 For a pipe D = 4 Rh LV2 hf = f D 2g L V2 hf = f 4 Rh 2 g We can use Moody diagram or Swamee-Jain with D = 4Rh! Pipe Flow Summary (1) Shear increases linearly _________ with distance from the center of the pipe (for both laminar and turbulent flow) Laminar flow losses and velocity distributions can be derived based on momentum and energy conservation Turbulent flow losses and velocity distributions requireexperimental ___________ results Pipe Flow Summary (2) Energy equation left us with the elusive head loss term Dimensional analysis gave us the form of the head loss term (pressure coefficient) Experiments gave us the relationship between the pressure coefficient and the geometric parameters and the Reynolds number (results summarized on Moody diagram) Questions Can the Darcy-Weisbach equation and Moody Diagram be used for fluids other than water? Yes _____ What No about the Hazen-Williams equation? ___ Does a perfectly smooth pipe have head loss? Yes _____ Is it possible to decrease the head loss in a Yes pipe by installing a smooth liner? ______ Darcy Weisbach Major and Minor Losses Major Losses: Hmaj = f x (L/D)(V2/2g) f = friction factor L = pipe length D = pipe diameter V = Velocity g = gravity Minor Losses: Hmin = KL(V2/2g) Kl = sum of loss coefficients V = Velocity g = gravity When solving problems, the loss terms are added to the system at the second point P1/γ + V12/2g + z1 = P2/γ + V22/2g + z2 + Hmaj + Hmin Hitung kehilangan tenaga karena gesekan di dalam pipa sepanjang 1500 m dan diameter 20 cm, apabila air mengalir dengan kecepatan 2 m/det. Koefisien gesekan f=0,02 Kehilangan tenaga Penyelesaian : L V2 hf f Panjang pipa : L = 1500 m D 2g Diameter pipa : D = 20 cm = 0,2 m 1500 x 2 2 0,02 0,2 x 2 x9,81 Kecepatan aliran : V = 2 m/dtk 30,58 m Koefisien gesekan f = 0,02 Air melalui pipa sepanjang 1000 m dan diameternya 150 mm dengan debit 50 l/det. Hitung kehilangan tenaga karenagesekan apabila koefisien gesekan f = 0,02 Penyelesaian : Panjang pipa : L = 1000 m Diameter pipa : D = 0,15 m Debit aliran : Q = 50 liter/detik Koefisien gesekan f = 0,02 Kehilangan tenaga 8L 5 hf f Q g 2 D 5 8 x0,02 x1000 0,02 9,81x 2 x(0,015) 2 54,4 m Hitung kehilangan tenaga karena gesekan di dalam pipa sepanjang 1500 m dan diameter 20 cm, apabila air mengalir dengan kecepatan 2 m/det. Koefisien gesekan f=0,02 Kehilangan tenaga Penyelesaian : L V2 hf f Panjang pipa : L = 1500 m D 2g Diameter pipa : D = 20 cm = 0,2 m 1500 x 2 2 0,02 0,2 x 2 x9,81 Kecepatan aliran : V = 2 m/dtk 30,58 m Koefisien gesekan f = 0,02 Air melalui pipa sepanjang 1000 m dan diameternya 150 mm dengan debit 50 l/det. Hitung kehilangan tenaga karenagesekan apabila koefisien gesekan f = 0,02 Penyelesaian : Panjang pipa : L = 1000 m Diameter pipa : D = 0,15 m Debit aliran : Q = 50 liter/detik Koefisien gesekan f = 0,02 Kehilangan tenaga hf f 8L 5 Q g 2 D 5 8 x0,055 x1000 0,02 9,81x 2 x(0,015) 5 54,4 m Example Solve for the Pressure Head, Velocity Head, and Elevation Head at each point, and then plot the Energy Line and the Hydraulic Grade Line Assumptions and Hints: P1 and P4 = 0 --- V3 = V4 same diameter tube We must work backwards to solve this problem 1 γH2O= 62.4 lbs/ft3 R = .5’ 4’ 2 R = .25’ 3 4 1’ Point 1: Pressure Head : Only atmospheric P1/γ = 0 Velocity Head : In a large tank, V1 = 0 V12/2g = 0 Elevation Head : Z1 = 4’ 1 γH2O= 62.4 lbs/ft3 4’ R = .5’ 2 R = .25’ 3 4 1’ Point 4: Apply the Bernoulli equation between 1 and 4 0 + 0 + 4 = 0 + V42/2(32.2) + 1 V4 = 13.9 ft/s Pressure Head : Only atmospheric P4/γ = 0 Velocity Head : V42/2g = 3’ Elevation Head : Z4 = 1’ 1 γH2O= 62.4 lbs/ft3 4’ R = .5’ 2 R = .25’ 3 4 1’ Point 3: Apply the Bernoulli equation between 3 and 4 (V3=V4) P3/62.4 + 3 + 1 = 0 + 3 + 1 P3 = 0 Pressure Head : P3/γ = 0 Velocity Head : V32/2g = 3’ Elevation Head : Z3 = 1’ 1 γH2O= 62.4 lbs/ft3 4’ R = .5’ 2 R = .25’ 3 4 1’ Point 2: Apply the Bernoulli equation between 2 and 3 P2/62.4 + V22/2(32.2) + 1 = 0 + 3 + 1 Apply the Continuity Equation (Π.52)V2 = (Π.252)x13.9 V2 = 3.475 ft/s P2/62.4 + 3.4752/2(32.2) + 1 = 4 P2 = 175.5 lbs/ft2 Pressure Head : P2/γ = 2.81’ 1 γH2O= 62.4 lbs/ft3 4’ R = .5’ 2 Velocity Head : V22/2g = .19’ R = .25’ 3 4 1’ Elevation Head : Z2 = 1’ Plotting the EL and HGL Energy Line = Sum of the Pressure, Velocity and Elevation heads Hydraulic Grade Line = Sum of the Pressure and Velocity heads V2/2g=.19’ EL P/γ =2.81’ V2/2g=3’ V2/2g=3’ Z=4’ HGL Z=1’ Z=1’ Z=1’ Pipe Flow and the Energy Equation For pipe flow, the Bernoulli equation alone is not sufficient. Friction loss along the pipe, and momentum loss through diameter changes and corners take head (energy) out of a system that theoretically conserves energy. Therefore, to correctly calculate the flow and pressures in pipe systems, the Bernoulli Equation must be modified. P1/γ + V12/2g + z1 = P2/γ + V22/2g + z2 + Hmaj + Hmin Major losses: Hmaj Major losses occur over the entire pipe, as the friction of the fluid over the pipe walls removes energy from the system. Each type of pipe as a friction factor, f, associated with it. Energy line with no losses Hmaj Energy line with major losses 1 2 Pipe Flow and the Energy Equation Minor Losses : Hmin Momentum losses in Pipe diameter changes and in pipe bends are called minor losses. Unlike major losses, minor losses do not occur over the length of the pipe, but only at points of momentum loss. Since Minor losses occur at unique points along a pipe, to find the total minor loss throughout a pipe, sum all of the minor losses along the pipe. Each type of bend, or narrowing has a loss coefficient, KL to go with it. Minor Losses Minor Losses We previously obtained losses through an expansion using conservation of energy, momentum, and mass Most minor losses can not be obtained analytically, so they must be measured Minor losses are often expressed as a loss coefficient, K, times the velocity head. hK High R C p f geometry , R 2p Cp rV 2 Cp 2 ghl V2 hl C p V 2 2g V2 2g Head Loss: Minor Losses Head loss due to outlet, inlet, bends, elbows, valves, pipe size changes Flow expansions have high losses – Kinetic energy decreases across expansion potential thermal energy – Kinetic energy ________ and _________ Hydraulic jump drag – Examples – Vehicle ________________________________ Minor losses! __________________________________________ Vena contracta Losses can be minimized by gradual transitions Minor Losses Most minor losses can not be obtained analytically, so they must be measured Minor losses are often expressed as a loss coefficient, K, times the velocity head. High Re C p = f (geometry, Re) Cp 2 ghl V2 hl C p V2 2g V2 hl = K 2g Head Loss due to Gradual Expansion (Diffusor) 2 V1 V2 hE K E 2g 2 2 V2 A2 hE K E 1 2 g A1 KE 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 0 20 40 60 80 diffusor angle ( ) Sudden Contraction 2 1 V2 hc 1 2 C 2g c V1 V2 flow separation Ac losses are reduced with a gradual contraction Cc A2 Sudden Contraction 1 0.95 0.9 0.85 Cc 0.8 0.75 0.7 0.65 0.6 0 F 1 I V h G 1J HC K2 g 2 c c 2 2 0.2 0.4 0.6 A2/A1 Qorifice CAorifice 2 gh 0.8 1 Entrance Losses Losses can be K e 1.0 reduced by accelerating the flow gradually and K 0.5 e eliminating the vena contracta K e 0.04 he K e V2 2g Head Loss in Bends High pressure Head loss is a function of the ratio Possible separation of the bend radius to from wall R the pipe diameter (R/D) D Velocity distribution Low pressure returns to normal V2 hb K b several pipe 2g diameters K varies from 0.6 - 0.9 b Head Loss in Valves Function of valve type and valve position The complex flow path through valves can result in high head loss (of course, one of the purposes of a valve is to create head loss when it is not fully open) hv K v V2 2g Solution Techniques Neglect minor losses Equivalent pipe lengths Iterative Techniques Simultaneous Equations Pipe Network Software Iterative Techniques for D and Q (given total head loss) Assume all head loss is major head loss. Calculate D or Q using Swamee-Jain equations Calculate minor losses Find new major losses by subtracting minor losses from total head loss Solution Technique: Head Loss Can be solved directly hminor K V 2 hminor K 2g Re 4Q D f 8Q 2 g 2 D 4 0.25 5.74 log 3.7 D Re 0.9 hl h f hminor 2 hf f 8 LQ 2 g 2 D 5 Solution Technique: Discharge or Pipe Diameter Re Iterative technique Set up simultaneous equations in Excel 4Q D hminor K f 0.25 5.74 log 0.9 3.7 D Re 8Q 2 g 2 D 4 hl h f hminor 2 hf f 8 LQ 2 g 2 D 5 Use goal seek or Solver to find discharge that makes the calculated head loss equal the given head loss. Example: Minor and Major Losses Find the maximum dependable flow between the reservoirs for a water temperature range of 4ºC to 20ºC. Water 25 m elevation difference in reservoir water levels Reentrant pipes at reservoirs Standard elbows 2500 m of 8” PVC pipe Sudden contraction 1500 m of 6” PVC pipe Gate valve wide open Directions Assume fully turbulent (rough pipe law) – find f from Moody (or from von Karman) Find total head loss Solve for Q using symbols (must include minor losses) (no iteration required) Obtain values for minor losses from notes or text Example (Continued) What are the Reynolds number in the two pipes? Where are we on the Moody Diagram? What value of K would the valve have to produce to reduce the discharge by 50%? What is the effect of temperature? Why is the effect of temperature so small? Example (Continued) Were the minor losses negligible? Accuracy of head loss calculations? What happens if the roughness increases by a factor of 10? If you needed to increase the flow by 30% what could you do? Suppose I changed 6” pipe, what is minimum diameter needed? Pipe Flow Summary (3) Dimensionally correct equations fit to the empirical results can be incorporated into computer or calculator solution techniques Minor losses are obtained from the pressure coefficient based on the fact that the constantat high pressure coefficient is _______ Reynolds numbers Solutions for discharge or pipe diameter often require iterative or computer solutions Loss Coefficients Use this table to find loss coefficients: Expansion: Conservation of Energy 1 2 V12 p2 V22 z1 1 Hp z2 2 H t hl g1 2g g2 2g p1 p1 p2 g hl V22 V12 hl 2g p1 p2 g V12 V22 2g z1 = z2 What is p1 - p2? Head Loss due to Sudden Expansion: Conservation of Momentum A2 A1 x 2 1 M1 M 2 W Fp1 Fp2 Fss Apply in direction of flow M 1x M 2 x Fp1 x Fp2 x M 1x rV12 A1 Neglect surface shear M 2 x rV22 A2 rV12 A1 rV22 A2 p1 A2 p2 A2 p1 p2 g V V 2 2 2 1 g A1 A2 Pressure is applied over all of section 1. Momentum is transferred over area corresponding to upstream pipe diameter. V1 is velocity upstream. Divide by (A2 g) Head Loss due to Sudden Expansion hl Energy p1 p2 g Momentum p1 p2 g hl V22 V12 hl V2 V1 g V1 V2 2 2g V12 V22 A1 V2 Mass A2 V1 2g V V 2 2 A1 A2 g V V 2g 2 1 2 1 2 2 V22 2V1V2 V12 hl 2g V A1 hl 1 2g A2 2 1 2 A1 K 1 A2 2 Contraction EGL V22 hc K c 2g HGL Expansion!!! V1 V2 vena contracta losses are reduced with a gradual contraction Questions: In the rough pipe law region if the flow rate is doubled (be as specific as possible) – What happens to the major head loss? – What happens to the minor head loss? Why do contractions have energy loss? If you wanted to compare the importance of minor vs. major losses for a specific pipeline, what dimensionless terms could you compare? Entrance Losses Losses can be reduced by accelerating the flow gradually and eliminating the vena contracta reentrant Ke 1.0 Ke 0.5 Ke 0.04 V2 he Ke 2g Head Loss in Valves Function of valve type and valve position The complex flow path through valves often results in high head loss What is the maximum value that Kv can have? _____ 2 V hv K v 2g How can K be greater than 1? Questions EGL HGL What is the head loss when a pipe V enters a 2 V reservoir? 2g Draw the EGL and HGL A K 1 1 A2 2 V12 p2 V22 z1 1 Hp z2 2 H t hl g1 2g g2 2g p1 cs1 Example valve 100 m cs 2 D=40 cm D=20 cm L=1000 m L=500 m Find the discharge, Q. What additional information do you need? V22 100m = + hl Apply energy equation 2g Use S-J on small pipe How could you get a quick estimate? _________________ Or spreadsheet solution: find head loss as function of Q. Pipe Flow Example 1 Z1 = ? γoil= 8.82 kN/m3 f = .035 60 m 2 Kout=1 7m r/D = 0 Z2 = 130 m 130 m r/D = 2 If oil flows from the upper to lower reservoir at a velocity of 1.58 m/s in the 15 cm diameter smooth pipe, what is the elevation of the oil surface in the upper reservoir? Include major losses along the pipe, and the minor losses associated with the entrance, the two bends, and the outlet. Pipe Flow Example 1 Z1 = ? γoil= 8.82 kN/m3 f = .035 60 m 2 Kout=1 7m r/D = 0 Z2 = 130 m 130 m r/D = 2 Apply Bernoulli’s equation between points 1 and 2: Assumptions: P1 = P2 = Atmospheric = 0 V1 = V2 = 0 (large tank) 0 + 0 + Z1 = 0 + 0 + 130m + Hmaj + Hmin Hmaj = (fxLxV2)/(Dx2g)=(.035 x 197m x (1.58m/s)2)/(.15 x 2 x 9.8m/s2) Hmaj= 5.85m Pipe Flow Example 1 Z1 = ? γoil= 8.82 kN/m3 f = .035 60 m Z2 = 130 m Kout=1 7m r/D = 0 2 130 m r/D = 2 0 + 0 + Z1 = 0 + 0 + 130m + 5.85m + Hmin Hmin= 2KbendV2/2g + KentV2/2g + KoutV2/2g From Loss Coefficient table: Kbend = 0.19 Kent = 0.5 Hmin = (0.19x2 + 0.5 + 1) x (1.582/2x9.8) Hmin = 0.24 m Kout = 1 Pipe Flow Example 1 Z1 = ? γoil= 8.82 kN/m3 f = .035 60 m 2 Kout=1 7m r/D = 0 Z2 = 130 m 130 m r/D = 2 0 + 0 + Z1 = 0 + 0 + 130m + Hmaj + Hmin 0 + 0 + Z1 = 0 + 0 + 130m + 5.85m + 0.24m Z1 = 136.09 meters Pipa ekivalen Digunakan untuk menyederhanakan sistem yang ditinjau Ciri khasnya adalah memiliki keserupaan hidrolis dengan kondisi nyatanya Q, hf sama Pipa ekivalen dapat dinyatakan melalui ekivalensi l,D,f