PID CONTROLLER

advertisement

PROJECT 2

PID CONTROLLER

Qin Rong

Yiqi Ju

Ying Shen

2011/4/28

We aim to learn how to use PID controller to ensure a robot car run a specified degree with

PID controller. And the inbuilt PID controller is disabled.

Objectives

1. Build a robotic car

2. Understand PID control design for robots

3. Design a PID controller. Tune a PID controller

Equipment

1.

LEGOS NXT Robotic kit

2.

PC to NXT USB cable

3.

Computer with RobotC installed

Background

The car robot we are using is a differential drive car robot as it has two motorized wheels that

provide drive and steering functions. There are some basic problems with this program. The car

may not go straight as the two motors may not have the same speed even though we have

commanded both of them to be at a specified power. This can be due to the different construction

of the two motors as well as different outside environment for the two wheels. One motor my

rotate faster than the other causing the car to drift. To counter these effects, we can use

ROBOTC’s inbuilt PID control function or we can build our own PID controller to ensure the car

will run a specified degree.

Theory

A proportional–integral–derivative controller (PID controller) is a generic control loop

feedback mechanism (controller) widely used in industrial control systems – a PID is the most

commonly used feedback controller. A PID controller calculates an "error" value as the difference

between a measured process variable and a desired setpoint. The controller attempts to minimize

the error by adjusting the process control inputs.

Figure 1: PID control for general system

The PID controller calculation (algorithm) involves three separate constant parameters, and is

accordingly sometimes called three-term control: the proportional, the integral and derivative

values, denoted P, I, and D. Heuristically, these values can be interpreted in terms of time: P

depends on the present error, I on the accumulation of past errors, and D is a prediction of future

errors, based on current rate of change. The weighted sum of these three actions is used to adjust

the process via a control element such as the position of a control valve or the power supply of a

heating element.

In the absence of knowledge of the underlying process, a PID controller is the best controller.

By tuning the three parameters in the PID controller algorithm, the controller can provide control

action designed for specific process requirements. The response of the controller can be described

in terms of the responsiveness of the controller to an error, the degree to which the

controller overshoots the setpoint and the degree of system oscillation. Note that the use of the

PID algorithm for control does not guarantee optimal control of the system or system stability.

As for LEGO NXT, the motors have rotation sensors, and therefore can measure the speed. A

speed rating 100 corresponds to the power of 100%. The max speed of the motor in ideal

conditions is 1000 degrees per second.

The closed loop PID control algorithm uses feedback from the motor encoder to adjust the

raw power to provide consistent speed. Closed loop control continuously adjusts the motor raw

power to maintain a motor speed relative to the maximum regulated speed.

To set the maximum regulated speed we use the command nMaxRegulatedSpeedNxt, which

is the max regulated speed level in degrees per second. We can use any value lower than 1000.

Usually, the batteries may not be 100% charged, so we will not be able to get the max speed and

therefore a lower value is recommended. Here we set the max speed as 500.

We will use nMotorPIDSpeedCtrl[motorB] = mtrNoReg and nSyncedMotors = synchNone to

disable the inbuilt PID controller. And we will write our own PID controller.

PID tuning

Tuning a control loop is the adjustment of its control parameters (gain/proportional band,

integral gain/reset, derivative gain/rate) to the optimum values for the desired control response.

Stability (bounded oscillation) is a basic requirement, but beyond that, different systems have

different behavior, different applications have different requirements, and requirements may

conflict with one another.

PID tuning is a difficult problem, even though there are only three parameters and in

principle is simple to describe, because it must satisfy complex criteria within the limitations of

PID control. There are accordingly various methods for loop tuning, and more sophisticated

techniques are the subject of patents.

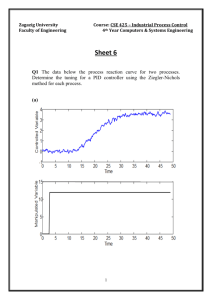

Ziegler–Nichols method

This method was developed by John G. Ziegler and Nathaniel B. Nichols in the 1940’s. Here

we will discuss the Z-M method for those systems that can become unstable by using proportional

control only. The basic steps in Z-M method are

1. Set K I and K D equal to zero.

2. Slowly increase K p to a value K u at which we see sustained oscillations (constant

amplitude and periodic).

3. Note the period of oscillation. We will denote it by Tu .

4. Use the following values as the initial tuning constants

Z-M model

Kp

KI

KD

P controller

0.5 K u

0

0

PI controller

0.455 K u

0.833 Tu

0

PID controller

0.588 K u

0.5 Tu

0.125 Tu

Table 1: Z-M table for PID tuning

Task

1. Build a LEGO NXT Robot car. Instructions are provided in the LEGO MINDSTORM’s

instruction manual. For testing, keep the robotic car upside down for design. Keep the

robot fully charged, as design solution may change if the battery power changes.

Position

Output

set point

NXT Servo

Motor

∑

+

-

Figure 2: PID control for NXT position control

position

2. In ROBOTC, write a code for the PID controller. Define the error signal as the actual

angle of the encoder and angle set point (target angle). The angle set point is 500 degrees.

The motor should run for 10s.

a.

It is important to disable all inbuilt ROBOTC PID control functions. This can be

done using the commands shown below. Do not use any inbuilt ROBOTC PID

control function.

nMotorPIDSpeedCtrl[motorA] = mtrNoReg;//disable NXT inbuilt PID

nMotorPIDSpeedCtrl[motorB] = mtrNoReg;//disable NXT inbuilt PID

nSyncedMotors = synchNone;//disable NXT inbuilt PID

b. Provide a soft copy (.c) of the code as well as put in the project report. The code

should not be unnecessary complex and should be well commented explaining

the functioning of the program.

3. Tune the PID controller by following the steps below

a.

Use the Ziegler–Nichols (Z-N) method to find K u and Tu . Draw a plot

showing sustained oscillations and period of the oscillations. An example plot is

shown in figure 3.5. Provide the values of K u and Tu

b. Using the values of K u and Tu , show the initial tuned performance of the PID

controller. Provide the rise time, percentage overshoot and settling time (± 5%)

c.

Tune the PID values further for a maximum percent overshoot Mp < 6% , settling

time < 1.2 sec (2% scenario) and steady state error of < 1.3 %.

4. Design a PID controller for speed control using the set point speed to 250 degrees per

second. Tune the PID values for a percent overshoot < 7%, settling time < 1.5 s (5%

scenario) and steady state error of < 10%.

Model

Figure 3: Robot Car Model based on LEGO NXT

Code

#define Kp 0.05292 // Kp

#define Ki 0.0000000075 // Ki

#define Kd 0.0375 //Kd

task main()

{

nMaxRegulatedSpeedNxt=500; // set the max speed as 500

nMotorEncoder[motorB]=0; // initialize encoder of motor B

nMotorEncoder[motorC]=0; // initialize encoder of motor C

nMotorPIDSpeedCtrl[motorB] = mtrNoReg;//disable NXT inbuilt PID

nMotorPIDSpeedCtrl[motorC] = mtrNoReg;//disable NXT inbuilt PID

nSyncedMotors = synchNone;//disable NXT inbuilt PID

motor[motorB] = 50;//set speed to 500/2=250 degrees per second

motor[motorC] = 50;//set speed to 500/2=250 degrees per second

int setPoint=500; // target degrees

// initialize all variables for both motor B and motor C

int actualDegreesB=0;

int actualDegreesC=0;

int errorB=0;

int errorC=0;

int pre_errB=0;

int pre_errC=0;

int IB=0;

int IC=0;

int DB=0;

int DC=0;

float outputB=0;

float outputC=0;

time1[T1]=0;

while(time1[T1]<10000)

{

// motor B

actualDegreesB = nMotorEncoder[motorB]; // find actual degrees of motor B

errorB=setPoint-actualDegreesB; // find error of motor B

IB=IB+errorB; // find value of integral

DB=errorB-pre_errB; // find value of derivative

outputB=Kp*errorB+Ki*IB+Kd*DB; // pid contorl for motor B

pre_errB=errorB; // store the error

motor[motorB]=50+outputB*50;

// motor C

actualDegreesC = nMotorEncoder[motorC]; // find actual degrees of motor C

errorC=setPoint-actualDegreesC; // find error of motor B

IC=IC+errorC; // find value of integral

DC=errorC-pre_errC; // find value of derivative

outputC=Kp*errorC+Ki*IC+Kd*DC; // pid contorl for motor C

pre_errC=errorC; // store the error

motor[motorC]=50+outputC*50;

// record the value of actual degree of motor C for further research.

AddToDatalog(1, actualDegreesC);

// wait for 50 ms

wait1Msec(50);

}

// store all data into a file.

SaveNxtDatalog();

}

Solution

When we set Ku as 0.09, the robot starts to oscillate:

Figure 4: PID tuning. Z-N oscillations

Figure 5: Zoom in the plot of PID tuning. Z-N oscillations

Tu is easily to be found as 0.3s. So when we set Kp=0.588*Ku=0.05292, Ki=0.5*Tu=0.15,

Kd=0.125*Tu=0.0375. We find it still oscillates. The plot diagram is shown as below:

Figure 6: A test example PID response

We can find the Ki is too big from this example. So we low Ki until the PID response is

proper. When we try about 70 times, we find when Ki is equal to 0.0000000075 the response is

very good. The plot diagram is shown below:

Figure 7: A good PID response

Though we want to let the robot run only 500 degrees, the steady state we get is 519.

The steady state error is

(519-500)/519*100%=3.8%

Figure 8: Zoom in for the good PID response

We don’t know why there is such a tolerance. But when we try different target degrees, like

480, 400, and 300, we get the plot diagram below:

Figure 9: An example PID response for target degree as 480

Figure 10: An example PID response for target degree as 400

Figure 11: An example PID response for target degree as 300

If the tolerance is generated by algorithm, the tolerance should be changed proportionally to

the target degree. But we found the steady states are always 20 bigger than the target states. So we

believe the tolerance may be generated by the robot itself, not algorithm.

Overshoot is when a signal or function exceeds its target. It arises especially in the step

response of bandlimited systems such as low-pass filters.

Figure 12: The highest value the system reached

So the overshot in this plot diagram is

(526-519)/519*100%=1.349%

Rise time refers to the time required for a signal to change from a specified low value to a

specified high value. Typically, these values are 10% and 90% of the step height.

Since the steady degree is 519, the rise time is the time that values rise from 10% to 90% of

the step height, which is about 51.9-467.1.

Figure 13: The trend line for the rise part

We use the rise part of the plot to determine the formula for that part. The formula is

y=0.2842x2+36x-57.622

Since we know the formula and values, we can find the rise time easily.

If y=51.9, which means 51.9=0.2842x2+36x-57.622

x=2.97252

If y=467.1, which means 467.1=0.2842x2+36x-57.622

X=13.20007

So the rise time is

13.2007-2.97252)/200*10=0.511s

The settling time of an amplifier or other output device is the time elapsed from the

application of an ideal instantaneous step input to the time at which the amplifier output has

entered and remained within a specified error band, usually symmetrical about the final value.

Figure 14: The lowest value after highest value

After the system reaches the highest value, the lowest value is 513.

When the specified error band is ± 5%, the error band will be about 493.05-544.95. Since the

highest value is 526, so we just find when the system reaches 493.05.

If y=493.05, which means 493.05=0.2842x2+36x-57.622

X=13.79427

So the settling time is

13.79427/200*10=0.6897s

When the specified error band is ± 2%, the error band will be about 508.62-529.38. Since the

highest value is 526, so we just find when the system reaches 493.05.

If y=508.62, which means 508.62=0.2842x2+36x-57.622

X=14.14861

So the settling time is

14.14861/200*10=0.7074s

Conclusion

There exists a tolerance generated by the system itself, not my program. All values we got are

very good. The plot diagram we got looks beautiful.

From this project, we know how to use ROBOTC. And we know more about PID controller,

especially why we need PID controller.

Reference

Wikipedia. (2011, April 30). PID controller. Retrieved from

http://en.wikipedia.org/wiki/PID_controller

Wikipedia. (2011, April 29). Rise time. Retrieved from http://en.wikipedia.org/wiki/Rise_time

Wikipedia. (2011, April 28). Settling time. Retrieved from

http://en.wikipedia.org/wiki/Settling_time

Wikipedia. (2011, April 29). Ziegler–Nichols method. Retrieved from

http://en.wikipedia.org/wiki/Ziegler%E2%80%93Nichols_method

Wikipedia. (2011, April 28). Overshoot_(signal). Retrieved from

http://en.wikipedia.org/wiki/Overshoot_(signal)