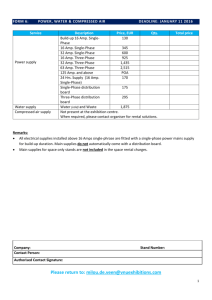

AMP - Order Entry & Fulfill

advertisement

AMP, Inc.: Order Entry and Fulfillment cmpm A00267ppmmJun93B • Background • Business Process Redesign: Process, IT • Key Performance Indicators • Implications: Process, IT -1- AMP: BACKGROUND AMP Is a Leading Global Supplier of Connection Devices to Many Complex Electric/Electronic Markets AMP: • Has $3 billion in annual sales of electric/electronic connectors • Owns an 18% share in an $18 billion market: - Very complex product offering with more than 100,000 SKUs • It is very profitable: 1991 gross income of 33% of sales • Organized into 19 units that serve very diverse end-use markets through direct and distributor channels: - Aerospace/military - Computers/office equipment - Government systems - Industrial/commercial - Consumer good - Government systems - Communications - Transportation/electrical - Advanced cables/ interconnection • Each unit owns from one to five plants, totaling 85 plants in U.S. alone cmpm A00267ppmmJun93B -2- AMP: BACKGROUND AMP Has Experienced Sustained Sales and Income Growth AMP, Inc. Revenues ($ million) 35 00 30 00 Net Income ($ million) 350 300 250 25 00 20 00 200 150 100 15 00 10 00 ’82 ’83 ’84 ’85 ’86 ’87 ’88 ’89 ’90 ’91 ’92 50 0 ’82 ’83 ’84 ’85 ’86 ’87 ’88 ’89 ’90 ’91 ’92 • AMP has grown faster (CAGR revenues = 14%) than the connection device industry (12%) • AMP is considered one of the best-in-class U.S. producers that holds Far East and European producers at bay cmpm A00267ppmmJun93B -3- AMP: BACKGROUND AMP Faces a Very Challenging Business Environment Product/Customers Suppliers • Concentration of suppliers • Threat of forward integration (e.g., DuPont, 3M) AMP Inc. • Over 6,000 customers with more than 100,000 SKUs in over 235 product families • Slowing end-user growth • End-user supplier rationalization efforts • “Commoditization” of product in some markets • Growing emphasis on price and product availability • Growing power of distributors over products Competitors • Extreme price competition: -Eight aggressive players, including DuPont, 3M, and ITT • Competitor initiatives to improve product quality,delivery time and service AMP’s vision is to provide customers with products and services so outstanding that it will become the “Supplier of Choice.” cmpm A00267ppmmJun93B -4- AMP: BUSINESS PROCESS AMP Historical Order Entry and Fulfillment Processes Suffered from Key Weaknesses Order Entry: • No real prioritization of customer requests • High percentage of customer calls blocked (busy) and abandoned • Different procedures across businesses • Inconsistent policies regarding product returns • People scattered across businesses and warehouses—few economies of scale • Paper-intensive process: - For products not available in their warehouse, CSRs took customers’ requests down and called them back later Order fulfillment: • Low productivity • Product obsolescence and error rates • Need to adjust finished goods to reflect physical inventories cmpm A00267ppmmJun93B -5- AMP: BUSINESS PROCESS The “Plan for Excellence” Program Involved a Redesign of AMP’s Business Processes Key Questions • How do we provide superior customer service? • How can we provide superior product delivery and availability? • How can we improve our cost base? • How can order entry and fulfillment improve quality? “Plan for Excellence” (kicked off in 1988/89) • The program built on a dozen independent initiatives conducted in the 1980s: - Productivity improvement - Total quality improvement • It became part of AMP’s vision and enjoyed top management support • Emphasized leadership, communications, training, and improvement: - Introduced objectives measurement systems • Looked for aggressive implementation cmpm A00267ppmmJun93B -6- AMP: BUSINESS PROCESS AMP Redesigned Its Order Entry Process to Respond to Customer Calls Immediately and Completely Focus on Key Customer Needs Order Entry Business Process and IT = + Consolidated Customer Service Activities + cmpm A00267ppmmJun93B • Supported customer profiles and pricing • Migrated key customers to EDI • Provided early warning to key accounts • Installed a hotline for key customers • Placed all order entry under a “logistics” organization • Integrated a few independent businesses— each of which had its own approach—to use identical process and systems • Consolidated most of the order entry in two locations, achieving very high productivity gains • Implemented foolproof order entry protocols • Trained personnel extensively • Developed single return policies across divisions -7- AMP: BUSINESS PROCESS AMP Redesigned Its Order Entry Process to Respond to Customer Calls Immediately and Completely (cont.) Implemented Management Processes Order Entry Business Process and IT (cont.) • Linked offices to back up each other (e.g., Central to cover East Coast if overloaded) • Linked offices and manufacturing sites through systems • Instituted auditing procedures + = Enhanced Invoicing • Derived prices and conditions from customer files • Use EDI for key client invoicing • Make invoice data available online + Installed Enhanced Technology • Expanded phone line and switching capacity • Greatly enhanced order entry: -Provided on-line view of all warehouses and scheduled production runs -Enabled “reserved” material status • Expanded EDI functionality cmpm A00267ppmmJun93B -8- AMP: BUSINESS PROCESS For Example, the Order Entry Process Allows Real-Time Responses to Key Customer Requests Real Time Order Entry Assigned CSR Team (10 CSRs) Customer Calls with Product Request Product in any AMP warehouse? Frequent Caller Not Frequent Caller YES Fulfill order; ship or reserve product Discuss with plant schedulers to expedite NO NO If Loaded, Backup Product being released from plant next week? YES Reserve product Satisfactory answer from scheduling? Suggest delivery date Dialogue with one of 200 production schedulers through E-mail: PF Key YES Promise delivery NO Call Distributor Based on Industry and Product Code Product in production schedule? (8 weeks) YES NO NO Reserve Product cmpm A00267ppmmJun93B Date acceptable to customer? NO Stock at AMP distributor? (on line search) YES Fill from distributor Inventories YES -9- AMP: BUSINESS PROCESS Order Entry Business Process Placed New Demands on IT Connectivity An IT View of Order Entry Order Entry: CSR Manufacturing Plants Access Production Schedules Order Fulfillment Warehouse Share Finished Goods Inventories MRP II Share Finished Goods Inventories Distributor Warehouse Can Access AMP Distributor Inventories Growth of EDI (20% of all volume) and faxes also creates new demands. cmpm A00267ppmmJun93B - 10 - AMP: BUSINESS PROCESS The Redesigned Order Entry Process Translates into Minimal Customer-Call Losses Customer Service Phones Percentage of Calls Blocked (Busy) Percentage of Calls Abandoned After Pick-Up (Hang-Ups) 1 1% 8% 5% 3% 2% 2% 1% 1 98 8 1 98 9 cmpm A00267ppmmJun93B 1 99 0 0% 0% 1 99 1 1 99 2 1 98 9 1 99 0 1 99 1 1 99 2 - 11 - AMP: BUSINESS PROCESS It Results in Fewer Order Entry Errors, Higher Staff Productivity, and Increased Customer Satisfaction Percentage of Key Customers Satisfied on Initial Call Cost of Clerical Errors ($ million) 90 % 1 85 % 0 .8 80 % 0 .6 75 % 0 .4 70 % 0 .2 65 % 0 60 % 1/90 3/90 1/91 3/91 1/92 3/89 1/90 Quarter /Year 3/90 1/91 3/91 1/92 3/92 Quarter /Year Bookings per Customer Service Staff ($ million) 4 .8 5 .0 4 .5 3 .8 4 .0 3 .5 4 .0 4 .2 3 .5 3 .0 3 .0 2 .5 ’88 cmpm A00267ppmmJun93B ’89 ’90 ’91 ’92 ’93 E - 12 - AMP: BUSINESS PROCESS AMP’s New Order Fulfillment Process Seeks to Provide Superior Availability and Delivery of Orders • Implemented a network of master and regional warehouses Consolidated -Closed regional warehouses and stocking points Warehouse -Built an automated distribution center in Schaumburg Network • Asked independent businesses to move to AMP warehouses + Order Fulfillment Business Process and IT = • Made warehouse staff more sensitive to customer needs • Developing interactive training programs (e.g., video Strengthened training) Staffing • Hired or trained logistics professionals to run operations • Rotated personnel throughout warehouse areas: -Creating a career path in logistics + • Increased use of customer forecasts Strengthened • Standardized inventory carrying cost formulas Core Finished • Developed optimization algorithms Product • Defined inventory levels (e.g., minimum lot sizes) to Procedures minimize cost of stockouts + cmpm A00267ppmmJun93B - 13 - AMP: BUSINESS PROCESS AMP’s New Order Fulfillment Process Seeks to Provide Superior Availability and Delivery of Orders (cont.) Enhanced Order Fulfillment Activities + Order Fulfillment Business Process and IT = Enhanced Packaging and Labeling • Developed a real-time system to track materials across warehouses • Implemented effective shipping routines: -For regular orders -For emergencies • Revised policy and procedures for return of goods • Implemented auditing and control procedures • Redesigned packaging: -Developed standard color scheme -Introduced bar-coded labels displaying quantity and part number on all carrying units + Strengthened IT Support to Process cmpm A00267ppmmJun93B • Developed interfaces between computer systems (e.g., tied order entry to plants’ MRP II) • Computerized warehouses -Invested in portable bar-code readers - 14 - AMP: BUSINESS PROCESS AMP Has Strengthened the Training of Its Staff Number of People That Are Certified by APICS 58 55 49 22 Jan ’89 cmpm A00267ppmmJun93B Jan ’90 Jan ’91 Jan ’92 - 15 - AMP: BUSINESS PROCESS The Redesigned Order Fulfillment Process Exhibits Greater Efficiency Warehouse Productivity Inventory Turns per Year (Lbs./Man Year) 10 0 90 2.7 80 3.0 3.4 3.5 ’89 ’90 3.9 4.3 70 60 50 ’87 ’88 ’89 ’90 ’91 ’92 ’93 ’87 ’88 ’91 ’92 Shipping Errors Expenses $300,000 High Range $120,000 Low Range ’90 cmpm A00267ppmmJun93B ’91 ’92 - 16 - AMP: BUSINESS PROCESS AMP Now Provides Best-in-Class Order Fulfillment Percentage of Orders Shipped by Customer Request Dates Independent Survey of Competitors’ a On-Time Delivery Rates (1991) 9 1% 8 7% 7 6% 1 98 8 7 9% 7 8% 1 98 9 1 99 0 1 99 1 8 8% 1 99 2 8 5%8 5% 8 8% 1 99 3 AMP T&B DuPont 8 0% 7 5% 7 5%7 5% Burndy 3M 7 0% R-N Augat 6 5%6 5% ITT Molex LPL When measured against its own promised dates, AMP has achieved a 95% on time delivery. a. Bishop and Associates, December 1991. cmpm A00267ppmmJun93B - 17 - AMP: PERFORMANCE INDICATORS AMP Has Implemented Comprehensive Metrics to Measure Progress Order Entry Percentage of Percentage of Percentage of Percentage of Percentage of Transactions Customers Calls Calls Correctly Satisfied on Transactions Blocked Abandoned “Real Time” Entered First Call Clerical Errors ($) Bookings Per CSR ($) Order Fulfillment Percentage of Percentage of On-Time On-Time Shipments Shipments Number of (to Customer (to AMP Customer Request) Schedule) Disputes cmpm A00267ppmmJun93B Inventory Spillage Turns Percentage Shipping Errors Percentage ($) Repackaged Pounds/ Person Year - 18 - AMP: PERFORMANCE INDICATORS Successful Implementation Has Won AMP High Marketplace Satisfaction AMP Customers’ Overall Satisfaction Level (Percentage That Rated AMP’s Service Excellent or Very Good) 1989 78% 1991 91% At the same time that it increased customer satisfaction, AMP increased order entry and distribution center productivity by 25% to 50%. cmpm A00267ppmmJun93B - 19 - AMP: IMPLICATIONS AMP Learned Some Critical Lessons from their Business Process Redesign • One organization should ultimately be responsible for all order entry and fulfillment activities: - “We put 1,100 people together in a new logistics organization and one person accountable for it” • Need to introduce tracking system • It’s a complex change management project: - “The complexity is overpowering: we had a 35 feet by 20 feet PERT chart” • There is a gut-wrenching organizational and systems change • It requires “out of the box” thinking... - “Complex algorithms to optimize inventories with minimal costs” • . . . And top management support: - “CEO and top managers need to go over numbers at least every month to see progress” cmpm A00267ppmmJun93B - 20 - AMP: IMPLICATIONS AMP Also Learned Some Information Technology Lessons • New business process and IT support had to be implemented concurrently, not sequentially • No “off-the-shelf” package offered the flexibility required by AMP to redesign its processes - Three years of developing systems…and still going • Technology investments were necessary at many levels: - Call management system at switchboards - Interfaces and date exchange across several platforms and applications - Bar-code readers and processors at warehouses AMP spent over $75 million in systems; payback came in only two years. cmpm A00267ppmmJun93B - 21 -