1st New Design- Flying Eagle

advertisement

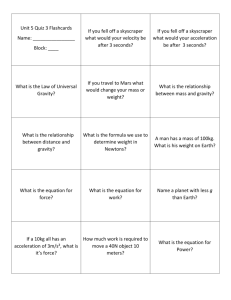

The Central Project Central University – A/E/C Engineering Building ARCHITECTURE ENGINEERING CONSTRUCTION OWNER Joy Liu, Cal-Berkeley Norm Faris, Stanford Tim Kolaya, Georgia Tech Alex Barron, Stanford Site Context Central University Engineering School Location: Los Angeles Metropolitan Area Busy urban location / heavy traffic Seismic Concerns – San Andreas Fault (8 km) Warm Climate High Ground Water Level Site Plan Designs & Decision Matrix New Design1: Flying Eagle A 1) Steel SMRF w/ E composite deck C 2) Shearwall w/ Flat E Plate Gravity C 3) Concrete MRF w/ E Flat Plate Gravity C Pros Cons Interesting progression Less resonable space layout Steel effective in seismic region Biaxial Bending in Frame Efficient construction method Auditorium contruction Difficult Combination of gravity and lateral Detailing Shearwalls for Penetrations Shotest construction time " More outside viewing space Integrating Wallfle slab w/ the Concrete Mom. frame Economic 1st Fl.design " 2nd Fl. 3rd Fl. New Design 2: Pouring Stream Pros Cons A Great potential for poetic space Limited space use 1) Steel EBF w/ E Excellent performance for Region Cost of Repair in Major Event Composite Deck C Cost Efficient Atrium poses uncertainty in construction 2) Steel SMRF& shearwall E Versatile system Cantilever gravity Scheme @core w/ Composite Deck C Cost Efficient Atrium poses uncertainty in construction 3) Concrete MRF& Shearwall E Consistent integration of build. MaterialInteract.of Waffle slab over Auditorium Mom. frame w/ Flat Plate Gravity C Cost Efficient Over Budget 2nd Fl. 3rd Fl. 1st Fl. Architect Vision of 2015 • Awareness in Green Design for Sustainable Architecture • Better and cheaper materials ex. low-e glass Design Focus • • • • Roof design Poetic experience in space Privacy measure Green Design development Pouring Stream- 1st Floor N Pouring Stream- 2nd Floor N Pouring Stream- 3rd Floor N Evaluation Roof Design Keep Rain out Revised Roof Ceiling Fans Air ventilation Old Roof N • • Average Wind Breeze between 10-15 miles per hour (direction N or W) Average Seasonal Rain Fall 14.77 inches Sections Section B A B B Section A A Material Choice Photovoltaic (PV) cells Traffic Concrete (Aerated) Traffic 3D Model STRUCTURAL MODEL DUAL LATERAL SYSTEM: COMPOSITE GRAVITY SYSTEM: SHEARWALLS AND PERIMETER STEEL SMRF CONCRETE SLAB w/ STEEL BEAMS ANALYSIS – DESIGN & LOADING DESIGN USING UBC ’97 CRITERIA SHEARWALL AND STEEL SMRF DESIGN: 100% BASE SHEAR TO WALLS 25% TO FRAMES (BACK-UP) DYNAMIC NONLINEAR LATERAL ANALYSIS - VERIFICATION (ETABS) TORSIONAL - ’97 RESPONSE SPECTRA EFFECTS LOADING CRITERIA •BASE SHEAR: V = 510 KIPS •NEAR SOURCE EFFECTS •DUAL SYSTEM: R = 8.5 •DL (TYPICAL) = 70PSF •DL (AUDITORIUM) = 90PSF •LL (CLASSROOM) = 50PSF •LL (CORRIDORS) = 80PSF 100% V + TORSIONAL RESISTANCE 13% V 13% V V TORSIONAL RESISTANCE GRAVITY PATH DESIGN CRITERIA: - 5 KSF BEARING - SANDY SOIL - WATER DEPTH = 15FT FOUNDATION MAT FOUNDATION @ UTILITY 12” 8” 3’-0” X 3’-0” @ MRF MRF FTGS: 7’-6” X 7’-6” GRAVITY SPREAD FTGS: 6’-0” X 6’-0” 2’-6” X 6’-0” CONT. FTG. WITH 3’-6”SHEAR KEY 1st FLOOR S.O.G. – 4” w/ #4 @18” O.C. AUDITORIUM S.O.G – 6” w/ #4 @ 12 O.C. 1ST FLOOR (ARCHITECTURAL CONTEXT) LAB & LARGE CLASSROOM RESTROOMS AND ‘WET WALL’ AUDITORIUM w/ PRECAST RISERS JOINING 2ND FLOOR. SMRF COLUMNS: W14 X 61 SMRF BEAMS: W21 X 62 SMALL CLASSROOMS SHEARWALLS: 8” W/ BOUNDARY ZONES TYPICAL GRAVITY COLUMN: W8X31 2ND FLOOR (ARCHITECTURAL CONTEXT) RESTROOMS AND ‘WET WALL’ LABS SMRF BEAMS: W18 X 60 STUDENT OFFICES COMPUTER ROOM SEMINAR 3RD FLOOR (ARCHITECTURAL CONTEXT) RESTROOMS AND ‘WET WALL’ LONG SPAN PRE-FAB TRUSSES LOUNGE TS 6X6 FACULITY OFFICES ATRIUM CHAIR OFFICE EXTERIOR CANTILEVER STAIR DESIGN STIFFENER PLATES IN COLUMN – TYPICAL. EMBEDDED PLATE W/ SHEAR STUDS AND DOWEL ANCHORS INTO WALL W14 WELD TS10X6 TO COLUMN FLANGE WELD TS10 X 6 TO EMBEDDED PLATE 2” SLAB ON 3” DECK OVER C6X13, STUD WELDED TS 10 X 6 CANTILEVER 6’ X 8’ LANDING C10 BEAM w/ BENT RISERS FILLED w/ 2” CONCRETE CENTRAL TEAM – ITERATIONS A-E-C EXTERIOR STAIR SYSTEM A A – STAIRS THAT PROVIDE EXPRESSION TO THE STRUCTURE. E – DESIGN TO BE INTEGRAL WITH MAIN STRUCTURE. E C C – DIFFICULTY IN ERECTION AND STABILITY DURING CONSTRUCTION. A – STAIRS TO HAVE CLADDING. E – DESIGN. C – COST. A – HEADROOM CONSTRAINTS. C – COST AND ERECTION PROCEDURES – POSSIBLE IMPLICATIONS. E – MENTOR ADVISE TO SEPARATE STAIR FROM MAIN SYSTEM. A – ISSUES w/ CLADDING. ATRIUM – CONSTRAINTS AND DESIGN (4) #5 IN ADDITION TO #4 BARS TO ATTAIN RIGID DIAPHRAGM ACTION. TYPICAL BEAMS – W10 X 26 IN COMPOSITE ACTION. 3/8” BENT PLATE w/ ½” D.B.A. @ 18” O.C., WELD PLATE TO CENTER BEAM 12” CL BEAM TO EDGE (3) #5 CENTERED OVER BEAM IN SLAB. SLAB EDGE DETAIL 20’ X 44’ OPENING W14 BOLTED TO PLATE AT TOP OF COLUMN. CAN TILEVER W14 Adjusted Budget - $3,500,000 Budget & Cost Initial Estimate - $3,200,000 DIVISION 5 - METALS Item Quantity Code Number 05100 - STRUCTURAL METAL FRAMING W 12X26, Gravity Bm. 4152 05120-640-1500 W 12X50, Gravity Clmn. 612.5 05120-640-1560 W 14X120, MF Clmn. 468.75 05120-640-2500 W 21X62, MF Bm. 756 05120-640-4500 T 6X6X1/4 0 05120-440-0725 Structural Steel Truss 30 05120-680-3100 05300 - METAL DECKING Steel Decking - Open Type 31400 05310-300-2200 05400 - COLD FORMED METAL FRAMING Door and Window Framing 4100 05410-300-0200 Stud Wall Framing 8750 05410-400-5110 05500 - METAL FABRICATIONS Steel Stair Railing 400 05520-700-0640 Aluminum Stair Tread 80 05550-700-0010 Unit Daily Output Duration Crew Bare Costs Labor Equipment Total Total Incl. O&P Total Cost Final Project Cost - $3,378,000 LF LF LF LF LF TON 880 750 720 1036 28 13 SF 4900 6.40816 E-4 4.71818 E-2 0.81667 E-2 0.65104 E-2 0.72973 E-2 General 0 E-3 2.30769 E-5 15.9 1.95 30 2.29 69 2.39 37 2.41 Requirements 5.18 27.3 1675 192 1.16 1.36 1.42 1.07 2.94 85 19.01 33.65 72.81 40.48 35.42 1952 22 38.5 82 46.5 60 2275 $91,344 $23,581 $38,438 $35,154 $0 $68,250 0.7 0.21 0.02 0.93 1.18 $37,052 3.12 5.1 Site Construction Concrete LF LF 220 18.6364 2 Carp 77 113.636 2 Carp 2.05 5.85 5.17 10.95 6.65 14.8 $27,265 $129,500 LF Ea 137 2.91971 E-4 23 7.5 24 3.33333 1 Sswk 25 10.55 Woods & Plastics 0.61 31.11 35.55 40 47 TOTAL DIV. 5 $16,000 $3,760 $379,000 Metals DIVISION 6 - WOOD & PLASTICS Item Quantity Code Number 06100 - ROUGH CARPENTRY Blocking to Steel Const. 0.875 06110-100-2740 Ceilings Framing 1 06110-510-6400 06200 - FINISH CARPENTRY Base Moldings 8750 06220-200-0561 Ceilings Molding 8750 06220-450-0600 Trim Molding 8750 06220-700-3800 Door Molding 78 06220-800-3150 Window Molding 150 06220-800-5910 Wood Shelving 500 06270-200-0100 06400 - ARCHITECTURAL WOODWORK Material Unit Daily Output MBF MBF 0.14 0.5 LF LF LF Opng. Opng. LF 240 270 270 5.9 13 110 Thermal & Moisture Protection Duration Crew Material Labor Doors Windows 6.25 1 Carp Total Cost 1600 900 2190 1510 3175 2100 $2,778 $2,100 36.4583 1 Carp 0.76 0.94 Specialties 32.4074 1 Carp 0.6 0.83 32.4074 1 Carp 0.98 0.83 Conveying 13.2203 1 Carp Systems 12.7 38 11.5385 1 Carp 15.3 17.3 4.54545 2.31 2.05 MEP 1 Carp 1.7 1.43 1.81 50.7 32.6 4.36 2.32 1.97 2.39 74 44.5 5.75 $20,300 $17,238 $20,913 $5,772 $6,675 $2,875 Finishes 2 2 Carp 590 610 Bare Costs Equipment Total Total Incl. O&P 9/29/15 Construction Schedule 3/7/16 Building Closed In Building Finished – 9 Months Contract Completed – 11 Months 6/17/16 8/8/16 Substantial Completion Project Finished Construction Sequencing Equipment Selection 150 Ton Crawler Hydraulic Hammer Backhoe Loader / Front-end Loader Welding Machines Hydraulic Excavator Cement Mixers / Dump Trucks / various others… MEP SCHEMATIC (BACK) VERTICAL DISTRIBUTION THRU ‘WET WALLS’ DEMANDS: • COOLING CAPACITY - 90 TONS • AIR VOLUME – 35,000 CFM • MAIN AIR DUCTS – 20 FT2 • FRESH AIR LOUVERS – 80 FT2 • EXHAUST AIR LOUVERS – 70 FT2 2ND & 3RD DISTRIBUTION THRU LONG SPAN TRUSSES. 3RD FLOOR DISTRIBUTION 2ND FLOOR DISTRIBUTION 1ST FLOOR DISTRIBUTION MAIN UNITS BELOW AUDITORIUM RISERS UTILITY BASEMENT – PUMPS, MAIN SERVICES, COMMUNICATION, 8’ X 8’ HYDRAULIC ELEVATOR w/ 6’ ELEVATOR MOTOR, OUTFLOW. MECHANICAL PIT FOR SERVICE. CENTRAL TEAM – ITERATIONS A-E-C MEP SYSTEMS – LOCATION & DISTRIBUTION INITIALLY LOCATE ALL SYSTEMS IN BASEMENT. C – LARGE COSTS FOR EXCAVATION – DIFFICULT AXCESS. A – UTILIZE SPACE BELOW RISERS IN AUDITORIUM. C – EASY REPLACEMENT/AXCESS FIRE SYSTEMS EASILY INTEGRATED. E – DESIGN OF SPACE TO ENSURE ALL MACHINARY WILL FIT. E – FRESH AIR AND EXHAUST LOUVERS – LESS IMPLICATION ON STRUCTURE. A – ISSUES WITH SOUND – USE OF INSULATION AND SOUND PROOFING. C – COST OF SOUND PROOFING MATERIAL VS. EXCAVATION. DISTRIBUTION OF VERTICAL AND HORIZONTAL DUCTS TO ROOMS VERSUS HEADROOM . A – MAXIMIZE HEADROOM – REDUCED RESTROOM SIZE AND PROVIDED ‘WET WALLS’ E – MINIMIZE PENETRATION IN BEAMS AND SHEARWALLS. A – PLACE DUCTS PERPENDICULAR TO BEAMS ALONG WALLS AND THOSE PARALLEL TO BEAMS BETWEEN THE SPANS.. C – INPUT ON COST FOR BEAM PENETRATIONS AND WALL BLOCK-OUTS. CENTRAL TEAM - INTERACTION MSN MESSENGER PBL DISCUSSION FORUM • GROUP MEETINGS NETMEETING • DOCUMENT / STORE • ‘QUICK QUESTIONS’ • SHARING PROGRAMS • SET – UP MEETINGS • ‘INSTANT’ •A & E COMMUNICATION • POST QUESTIONS CENTRAL TEAM - PROCESS • A – INITIATED MAIN DESIGN CONCEPTS – VERY EFFECTIVE IN COMMUNICATING CHANGES AND IDEAS. • E – DEVELOPED MOST QUESTIONS & ISSUES IN THE DESIGNS. • C – PROVIDED DIRECTION IN MEETINGS & ON STEPS TO TAKE. • A – ABILITY TO CONCEPTUALIZE ‘E & C’ REQUIREMENTS. • E – ATTEMPT TO MAINTAIN ARCHITECTURAL CONCEPT IN STRUCTURAL LAYOUT & EFFECTIVELY MINIMIZE COST AND ERECTION DIFFICULTIES. • C – CONSISTENTLY EXPRESSED SCHEDULE & COST IMPLICATIONS FOR ALL ITERATIONS AND PHASES OF DESIGN. CENTRAL TEAM – WHAT WE LEARNED? • •E C • A• • BETTER BETTERUNDERSTANDING INVOLVEMENT WITH OF THE THEREQUIREMENTS ARCHITECT AND OF ENGINEER THEUNDERSTANDING ARCHITECT ON THE FRONT-END AND ABOUT CONSTRUCTION OF ENGINEER THE PROJECT MANAGER. DESIGN • BOTH BETTER AND AND DEVELOPMENT PROCESS. • ACCOMPLISHED GOAL OF BEING ABLE TO GET INVOLVED CONSTRUCTION MANAGER’S CONSTRAINT AND ABLE • WITH MORE THE CONSISTENT ARCHITECT EARLY IN THE OF DESIGN TEAM PHASE. MEMBERS OF TO INTEGRATE INTONOTIFICATION THE DESIGN PROCESS PROGRESS ON THE PROJECT AND NEEDS • • MORE INNOTIFICATION THE USE OF TECHNOLOGOICAL MOREEFFICIENT FREQUENT TO THE FROM TEAM OTHERS. • TOOLS TECHNOLOGY AS A ABOUT MEANS CANTHE OF BECOMMUNICATION. A HUGE BARRIER IF YOU FAIL TO MEMBERS PROCESS AND QUESTIONS. TAKE ADVANTAGE OF IT AND A TREMENDOUS AIDE IF YOU MAKE EFFECTIVE USE OF IT! CENTRAL TEAM THANK YOU WE WOULD LIKE TO EXTEND OUR GREATEST APPRECIATION TO THE FOLLOWING PEOPLE: MR. GREG LUTH – KL&A BROOK BARRET - DPR PAUL CHINOWSKY – GEORGIA TECH. PROF. MIKE MARTIN –BERKELEY HUMBERTO CAVALLI- BERKEELY DAVID BENDET-MBT PROF. BOB TATUM - STANFORD PROF. HELMUT KRAWINKLER - STANFORD RENATE FRUCHTER …. AND OF COURSE FELLOW STUDENTS. The Central Project QUESTIONS? CENTRAL TEAM – WHAT WE LEARNED? •E • BETTER UNDERSTANDING OF THE REQUIREMENTS OF BOTH THE ARCHITECT AND CONSTRUCTION MANAGER. • ACCOMPLISHED GOAL OF BEING ABLE TO GET INVOLVED WITH THE ARCHITECT EARLY IN THE DESIGN PHASE. • MORE EFFICIENT IN THE USE OF TECHNOLOGOICAL TOOLS AS A MEANS OF COMMUNICATION. CENTRAL TEAM – WHAT WE LEARNED? • C • BETTER INVOLVEMENT WITH THE ARCHITECT AND ENGINEER ON THE FRONT-END OF THE PROJECT DESIGN AND DEVELOPMENT PROCESS. • MORE CONSISTENT NOTIFICATION OF TEAM MEMBERS OF PROGRESS ON THE PROJECT AND NEEDS FROM OTHERS. • TECHNOLOGY CAN BE A HUGE BARRIER IF YOU FAIL TO TAKE ADVANTAGE OF IT AND A TREMENDOUS AIDE IF YOU MAKE EFFECTIVE USE OF IT!