MICROCHNNEL RESONATOR

advertisement

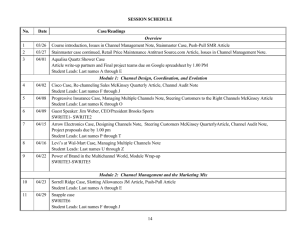

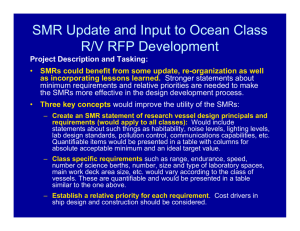

Presentation by Bello Hamza Abdullahi Table of contents Introduction. Suspended microchannel Resonator(SMR). Beam Model. SMR With Integrated Piezoresistive Readout. Fabrication Of SMR. Performance Factors. Advantages. Applications. Introduction There are three commonly used devices in detecting bio-molecules, these are; microcantilever-based biosensor. Surface Plasmon Resonance (SPR) sensor and, Quartz Crystal Microbalance (QCM) sensor. For micro-cantilever-based biosensors, there are two working principles developed for the biodetection, namely, the static mode and the dynamic mode. Suspended Micro-channel Resonator(SMR) SMR is a biosensor that falls under micro-cantilever based dynamic mode biosensor. This is a hollow micro-cantilever that vibrate with a certain resonance frequency. It resonates at a frequency proportional to its total mass⁽²⁾. This works base on the reduction of resonance frequency of the hollow microcantilever induced by molecular adhesion, if an analyte flow through the hollow cantilever. SMR Since SMR is a cantilever it should have the following; Since the tip end, is freely suspended it can easily vibrate. There is low or even no effect of vibration at the fixed end. It resonates at a frequency proportional to its total mass. Therefore change in mass affect the resonance frequency. The vibration intensity reduced as you move from the tip end to the fixed end. SMR Particles are weighed in real-time with the suspended micro-channel resonator (SMR) as they flow through a hollow cantilever. The micro-channel resonant frequency is determined by the difference in mass of the particle with respect to that of the displaced fluid. Thus, the particle's density is determined by measuring its mass in two fluids of different densities. Beam Model Of SMR As the fluid flows inside the SMR, we could study how the relevant properties of the fluid affect its resonant frequency. Derivation of the dynamic theory of the SMR is mainly separated into two parts, namely: A structure element and, fluid element. Beam model of SMR The structural parts depends on the following parameters; The cross sectional area of the internal rectangle tube,(A); young modulus ,(E); Moment of inertia, (I) Mass per unit length of the empty rectangle tube,(m) Longitudinal tension applied on the structure element,(T) Beam Model of SMR Transverse shear force applied on the structure element(Q), Bending moment applied on the structure element(M), shear stress on the internal surface of the rectangle tube(q), Inner perimeter of the rectangle tube(S), Beam Model of SMR For the fluids, depends on: The flow pressure(P), Density(Ƿ), viscosity(μ), Shear stress induced by the viscosity(δ) and, The transverse force per unit length between tube wall and fluid(F). Following the D’Alembert’s principle of dynamic equilibrium⁽¹⁾, the equation of motion for the SMR is given in the next slide. A Sketch of the 1-D beam model. where v(x, t) is the deflection of the beam. U is the average flow velocity. L,B and H is the length, width, and height of the beam, respectively. Beam Model of SMR Beam Model of SMR Then Eq. (2) can be rewritten as The solution of the above equation can be represented by Beam Model of SMR where фn`s are the normal modes of the beam without viscosity (i.e.χ = 0), κ n`s are the expansion coefficients, and ω is the dimensionless circular frequency, where f is the frequency. By orthogonality of ф n(ξ ), one can obtain the following equation from (4) and (5): See next slide. Beam Model of SMR where the coefficient matrices [A] to [E] are defined by Beam Model of SMR To obtain nontrivial solutions, the determinant of coefficient matrix must be zero, i.e., From the above equation, one can determine the resonant frequencies of the SMR as: SMR with Integrated Piezoresistive Readout So far, the frequency measurement of our device has relied on measuring the deflection of a laser beam that is focused onto the tip of the resonator. The optics used in our lab do not scale favorably for large arrays and are not suitable for point of-use applications. On the contrary, Suspended microchannel resonators with integrated (I.e piezoresistive) readout can measure the mass density of solutions with high precision. Basic Operations of piezoresistive SMR Readout of the resistance change is amplified through a Wheatstone bridge. Potentiometers are incorporated in order to balance the amplifier as well as compensate for capacitive coupling of the electrostatic drive signal. Figure 1 shows the frequency response which corresponds to superposition of the signal from the resistor and the drive signal feed through. Measurements of resistance change as the entire device is heated in a convection oven suggest that a reasonable bias voltage of 1V on the bridge will result in biocompatible temperatures of less than 40⁰C. Fabrication of SMR Hard fabrication techniques used to mass-produce silicon portion of device. Usually the material use in this fabrication is silicon. Device is fabricated in two components, then glass frit-bonding is used. Silicon cantilever/functional portion Pyrex capping portion, chosen for transparency . Silicon Fabrication RIE to form channel . b. Structural material, low-stress SixNy, placed then sacrificial layer of poly-Si (LPCVP). Removal of poly-Si performed by chemical-mechanical planarization . c. Another layer of SixNy deposited, and poly-Si dissolved. d. Chromium placed by ion beam deposition (provides reflectivity). e. Chromium and SixNy removed where fluid is in contact with device. f. Bulk micromachining with TMAH. a. Pyrex Fabrication • • • • • • Silicon mask bound to mask and patterned by DRIE. Deep glass etching performed. Mask patterned by DRIE again. Gold film deposited. Gold film patterned. Glass fritting printed onto Pyrex. Performance factors Selectivity Sensitivity Accuracy Response time Recovery time Lifetime Reliability Resolution Precision Advantages of SMR Ability to measure mass density with a resolution up to 10⁻⁴g/mL. High Precision frequency detection has enabled the suspended micro-channel resonator (SMR) to weigh single living cells, single nano-particles, and adsorbed protein layers in fluid.(I.e Weighing particles with femtogram precision.) Applications SMR is used as: Bio-molecular detector. Monitoring cells growth. Biomolecular Detection Bio-molecular Detection Since the surface area to volume ratio of the suspended micro-channel resonator (SMR) is very large, surface adsorption is an effective mechanism for biomolecular mass sensing. The exact mass of an absorbed layer can be quantified by measuring the difference in resonance frequency before, during (i.e. in real time) and after each injection. At the surface of the hollow site, biological recognition agents, can be use to absorbed the analyte. Biomolecular Detection Biomolecular Detection Biological systemsthe major selective elements They must attach themselves to one particular substrate, but not to others. They comprises of the following; Enzymes, Antibodies, Nucleic acids and, Receptors. Monitoring Cell Growth G1-synchronized cells have a negative buoyant mass (positive frequency shift). This cell passes through the channel floating on the surface of the fluid. This undergoes a circulation through the channel. The cells entering S phase at a later time point have a positive buoyant mass (negative frequency shift). This implies that the cell increases in size since it sink in the fluid.(I.e implies cell growth) Monitoring Cell Growth Monitoring Cell Growth References 1. 2. 3. 4. Beam model and three dimensional numerical simulations on suspended microchannel resonators Kuan-Rong Huang, Jeng-Shian Chang, Sheng D. Chao, and Kuang-Chong Wu Proc Natl Acad Sci U S A. 2010 January 19; 107(3): 999–1004. Published online 2009 December 23. doi: 10.1073/pnas.0901851107 PMCID: PMC2824314 Engineering, Cell Biology. Suspended microchannel resonator for improved PSA monitoring. Luke Albares, griffin, Andy guan, Dillon Achendal, Alex Shepler SUSPENDED MICROCHANNEL RESONATORS WITH INTEGRATED ELECTRONIC READOUT FOR BIOMOLECULAR AND SINGLE CELL ANALYSIS R. Chunara1, T.P. Burg2, K. Payer3, P. Dextras2, S.R. Manalis2 1Harvard-MIT Division of Health Sciences and Technology, USA 2Department of Biological Engineering, MIT, USA 3Microsystems Technology Laboratories, MIT, USA