Case Study Presentation

advertisement

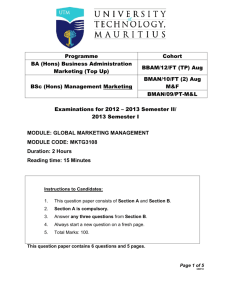

Case Study Presentation By: Lillie Collins, Daniel Mayer, Stephen Buyachek, Michael Mayer 1 of 26 What comes to mind when you hear Harley Davidson? http://www.youtube.com/watch?v=RbhmfEkj2I&feature=player_detailpage Harley Davidson has a loyal fan base that interacts via clubs, events and a museum. For their 105th anniversary, in 2008, Harley Davidson had 125,000 preregistrations for the event. Here in Vegas they offer learn-to-ride classes, motorcycle rentals and other events such as Street Vibrations Rally in Reno, Nevada. 2 of 26 “Taking the Work out of Bicycling” Founded in 1903 William Harley Arthur Davidson 3 of 26 Born to be Wild 1920, largest motorcycle manufacturer in the world with 28,000 motorcycles/year with 67 countries 1998, shipped 150,000 motorcycles up 14% from 1997 Plan 2003, increase production capacity by 100th anniversary 4 of 26 They all want a piece of the pie Honda Suzuki Yamaha Kawasaki 5 of 26 Problems Harley Davidson Was Facing? Strong Japanese competition (Honda, Yamaha, Suzuki) Capacity constraints led to decreased international market share Due to rapid expansion, quality control suffered Nearly went bankrupt in the 1980s What are some ways that Harley Davidson could recover from this? Harley Davidson created a team to improve the supply chain, focus on quality assurance, standardize systems and processes, and integrate directly with suppliers. 6 of 26 Change in the air 1995, Garry Berryman joined Brought the will to change the purchasing organization 7 of 26 8 of 26 Understanding Company Structure What is unique about Harley’s Organizational Structure? Create Demand (CDC) Produce Products Group (PPG) Provide Support (PSC) Circles of Leadership Information Technology Circle (ITC) 9 of 26 Supply Management Strategy (SMS) Garry Berryman (VP of Materials Management) led initiative Goal was to make purchasing organization a common enterprise-wide point of contact SMS intended to move the company from a sitespecific, transactional mentality to a long-term focus on supplier relationships What is your view of a Vendor vs. Supplier? Berryman felt that a supplier had a vested interest in your company while a vendor merely provided goods for sale and could care less about your success 10 of 26 Supplier Information Link (SiL’K) Forming the team Mapping “as is” Processes Stakeholder Survey Mapping “to be” (future) Processes 85% of time spent on non-strategic activities (reviewing inventory, data entry, etc.) 11 of 26 Harley Davidson’s Business Integration Model (BI) People, Processes, and Technology People Restructured from decentralized organization to a hybrid organization Processes Critical step is defining project scope Focused on managing expectations Team-led updates on project status Technology Technology decisions had to be deferred to Harley’s Architecture Integration Group (AI) 12 of 26 Supplier Selection SiL’K team held a conference where they presented to all their potential suppliers Searching for partners that could provide functionality and could adapt to their culture Why didn’t Harley want a full ERP system? They just wanted to redefine materials management department, which included purchasing, procurement, inventory, and supplier relations. 13 of 26 Supplier Selection Process October 16, 1998 RFQ (Request for quote) sent to potential software suppliers. Intent to bid had sent in by October 25, 1998 8 suppliers submitted response to RFQ and completed self evaluation checklist 5 eliminated because of architectural incompatibility, small size, ability to meet future needs, any who self rated below 90% fit 14 of 26 Functional Criteria (Quantitative Method) 100% 95% 90% Provider 1 Provider 2 85% Provider 3 80% 75% 1 2 3 4 5 1. Design and Foundation 2. Request Definition 3. Documentation 4. Receiving 5. Supply Management 6 7 8 9 10 6. Project Tracking 7. Miscellaneous 8. Interfaces 9. Training 10. Other 15 of 26 Qualitative Approach 16 of 26 What do YOU look for in a supplier? Price Integration Potential Reputation Which are most important? Track Record Financial Position Experience Ethics Support/Maintenance Completion Time Quality/Value Professionalism/Reliable Ambition/Passion/Dedication 17 of 26 Individual Opinions Braunschweig – Functionality is key “that’s what they’re going to use day to day” We can work with personality conflicts Cost is going to be added in there Jarosz – Change management and implementation “change people are going to go through is going to be ten times more difficult than software implementation” Anding – Functionality matching with strategy “most functionality to the purchasing community and to the strategy and direction that we want to move into for the future” Pues – Organization personality and support they have behind it “people like to do business with people they like” Cotteleer – Functionality “we can deal with personality conflicts for the implementation…that is not as insurmountable as implementation risk based on functionality that doesn’t exist” 18 of 26 Pros and Cons Supplier 1 Culture Functionality Cost Training/Support Supplier 2 Supplier 3 + Culture Match + Functionality + Change Mgmt. - Cost + Existing Relationship + Training Processes - Too Formal - Functionality (Web Enablement) - Training Process Self-Eval: 93.4% Self-Eval: 98.7% + Cost - Presentation Experience Self-Eval: 96.8% Which provider would you choose and why? 19 of 26 Alternatives Option 1 Choose Supplier 2 (Best Functionality) Keep SiL’K team intact for support and training Option 2 Choose Supplier 1 (Best Support) Use proven 3rd party partner for web-enablement Option 3 Continue evaluating Check references/validity Which option do you like best? Do you see any pros or cons? 20 of 26 Plan 2003 In 1996, Harley Davidson announced their ambitious “Plan 2003”. Their goal was to double manufacturing capacity to 300,000 by the year 2003, coinciding with their 100 year anniversary. Do you think they were able to exceed their goal of 300,000 motorcycles by 2003? 21 of 26 Harley Davidson’s Choice On August 9th 1999, Oracle announced Harley Davidson’s selection of Oracle Internet Procurement, a premier Oracle ebusiness solution, to streamline and support its procurement function across all domestic manufacturing sites. The need to standardize arose as a result of the prior establishment of essentially separate procurement systems at each of its domestic manufacturing sites which led to numerous separate systems, fragmentation of procurement data, and manual process integration across sites. As a result, they will be consolidating all U.S. manufacturing production and non-production related procurement across its eight domestic sites into a single automated procurement system, in order to streamline processes, reduce costs, and consolidate demand across the enterprise. 22 of 26 Harley Davidson’s Suppliers Garry Berryman optimized Harley’s supply chain by reducing their 3,000 maintenance, repair, and operating (MRO) suppliers to three primary ones. The direct suppliers that provide the parts that go into making motorcycles and accessories were consolidated from 1,000 to 350. Why did Harley reduce the number of suppliers when they just implemented a system to help manage this kind of purchasing? By reducing the number of suppliers, Harley could focus on developing a deeper relationship with these key suppliers by inviting them to get involved in product design and manufacturing processes. 23 of 26 Relationship with Suppliers From what we learned in class, what are some ways Harley Davidson could open it’s doors to suppliers and exchange data? Harley Davidson standardized their forms and procedures and required all suppliers to use EDI. As not all suppliers had the capabilities to perform EDI, Harley Davidson eventually created a web based portal called the Harley Davidson Supplier Network. Harley also utilizes bar codes and electronic trigger systems for replenishing parts so that their systems notify suppliers when they are running low on inventory. 24 of 26 H-D Supplier Network Harley Davidson picked Manugistics NetWORKS collaborative solutions to power the H-D Supplier Network. Manugistics also provides seamless integration with Oracle’s applications. Together, Manugistics and Oracle will enable Harley to leverage best-in-class supply chain optimization and enterprise resource planning (ERP). 25 of 26 Harley Davidson Supplier Network The Web Portal is designed to enable Harley Davidson and its suppliers to conduct transactions, ranging from placing purchase orders to invoicing, over the internet. Nearly 300 of Harley's 695 parts suppliers log on to applications through the supplier portal. Suppliers can view production forecasts, account status, and two-dimensional drawings of parts while also being able to submit shipment notices and receive inventory-replenishment alerts. The portal eliminates the expense of EDI and is proving even more reliable than EDI. Overall, the portal has allowed Harley to work with longtime suppliers to achieve lower costs, consistent quality, and improved delivery performance. 26 of 26