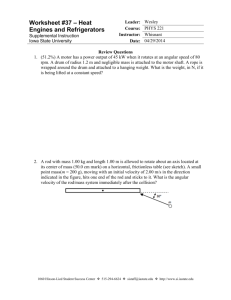

“The Statics Machine” A complex machine is being designed to

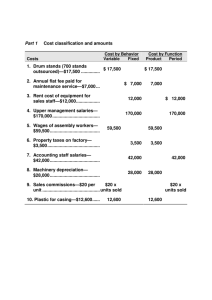

advertisement

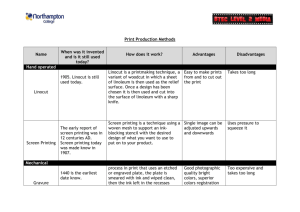

“The Statics Machine” A complex machine is being designed to punch out block P’s from a 1mm thick sheet of annealed brass (E = 100 GPa, σy = 275 MPa). A diagram of the machine, including all relevant dimensions, is shown below. The machine is powered by a water tank. As the water level rises, it eventually produces sufficient pressure to initiate motion. Specifically, the water produces a horizontal force at point m. The frame then translates that load to the punch, shown at bottom right. The frame is also connected to an inextensible cable at point k. This cable runs over a fixed drum at point u before entering the pulley system shown. The force is then transferred through a rack and pinion assembly and produces a torque at point v. The hammer is pinned to the pinion at point v and is supported by a thin rod at point w. The system is to be designed such that the thin supporting rod fails at the same water level as the punching action occurs, accentuating each punch with a satisfying drum beat as the hammer swings around to impact the drum. As the design engineer, you are asked to provide the following information: 1) What is the minimum force required to punch out the block P? Note that the total perimeter of the block P is 10cm. 2) Based on that force requirement, complete an analysis of the frame assembly to determine the forces acting at points m and k. (Assume that point q stays within the dimensions of the slot) 3) Using your result from part 2, complete shear and bending diagrams of the primary frame element, sqnm 4) Using your result from part 2, determine the height of the water at which the punch operation occurs. Note that the water tank extends 4m into the page. (Assume that the dimensions of the tank are such that the equivalent force of the water aligns with point m at the target height, thereby ensuring that the force at m is horizontal.) 5) Using your result from part 2, determine the force exerted by the rack on the pinion. Note that the drum at point u has a coefficient of friction of 0.3. Based on this force, determine the torque produced at point v. Assuming that the pin at v is a solid round bar made of A36 structure steel, what is the minimum diameter of the pin to prevent torsional failure? 6) Using your result from part 5, calculate the desired diameter of the rod at point w. Note that the rod should fail at the same load at which the punch operation occurs (namely, the loading condition calculated in part 5). Also note that the rod is a hollow circular rod (ri = 0.75*r0) made of annealed brass. 7) Note that the drum is 8 meters tall and 1 meter wide, with feet at the lower corners. Assuming that the hammer, upon release, impacts the drum with a force of 50N and strikes the drum 5 meters off the ground. Also assume that the drum weighs 150N and that the coefficient of friction between the feet and the ground is 0.25. Does the drum move? If so, does it slip or tip? 8) Assume that the water tank exerts a force at point a equal to (−0.2𝑊𝑖̂ − 0.5𝑊𝑗̂) and a force at point e equal to (−0.5𝑊𝑗̂), where W is the weight of the water in the tank. a. Calculate the volume of water when the punching operation occurs. Note that the tank is 4 meters wide, 4 meters long, and the water depth is equal to your answer from part 4. b. Using this result and the force vectors above, calculate the load in the truss elements cb,cg, gh, and hi.