Impact - Sesam

advertisement

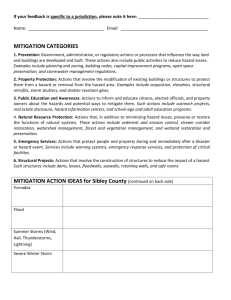

Science & Engineering Associates, Inc. IMPACT ™ Integrated Messaging and Process Analysis Control Techniques Functional and Graphical Interface Model Bringing CONTEXT to and With Hardware, Software, and the Human Element IMPACT INFLUENCING DESIGN ™ PROVING DESIGN Toolset Systems Engineering Safety Engineering Software Engineering Systems Integration System Safety Software Design • Functional Definition • Hazard Identification • Requirements Allocation • Requirements Allocation • Hazard Causal Factors • Implementation Model • Control Requirements • Hazard Mitigation • Fault Detection • System Modeling • Fault Tree Analysis • Fault Handling • Interface Analysis • Residual Risk • SW & HW Integration • Safety Reporting • User Interface Analysis Specialty Engineering Software Safety Software Test • System Integration • Safety-Critical SW • Test Rqmt Allocation • Human Factors • SW Causal Factors • Test Case Generation • Training • SW Safety Requirements • Test Acceptance Criteria • Reliability/Availability and • Hazard Mitigation • Test Readiness Report Maintainability • Integrated Logistics • Interface w/Hardware • Interface w/Human SEA Inc. Proprietary Data – Please Protect Accordingly Page One 6100 Uptown Blvd., NE, Suite 700, Albuquerque, New Mexico 87110 (505) 884-2300 IMPACT Science & Engineering Associates, Inc. ™ Integrated Messaging and Process Analysis Control Techniques Graphically Integrating Hardware, Software And Human Interaction in the Performance of System Functions SCE02068 Startup Service OSS ELE_ PWR_ U2RM PROCESS-BASED TOOL SET Action: Power to On Power On CREW SPH Crew views Power On indication Boot strap sequence ELE_ GPU_ U1 Initialize a GPU ANALYSES PLACES SOFTWARE, HARDWARE AND PERSONNEL ACTION WITHIN THE CONTEXT OF MAJOR SYSTEM FUNCTIONS Hardware Icon For all Hardware Refer to Logic Document by equipment type in IDE Package 31138: Armament *_ARM_* Resupply *_RES_* GDAS *_RES_* SP Conveyor SPH_RES_SPC Initialize SPH Perform start up BIT on GPU 2-1 ELE_ GPU_ U1 Perform BIT Sheet Connector NOTE (keyed to number) 3.1 3 OSS Initialized Ready to load applications SPH Release Main Thread for vehicle initialization to VMG SCE00850 Initialize Core Software VMG Scenario Invocation Disconnect I Scenario Iteration R Invocation Return T Scenario Terminus Initialization_Command 1. Initialize vehicle management software to coordinate system initialization 2. Coordinate initialization of core software on first GPU. Allows Hardware & Software Designers to See the “Big Picture” To CUI ELE_ GPU_ U1 Scenario Iteration or off page connector X = Sheet Number Y = Unique Number SPH 4. Upon receiving all statuses, initialize power management software: Invoke Scenario SCE08157 "Initialize VPMG Software" 5. Coordinate initialization of core software on remaining processors. ELE_ GPU_ ELE_ SAI Initialization_Command 6. Upon receiving all statuses, command all core software to configure to the AdminstrativeConfigure sub-state: Timelines & Milestones Are Met With Fewer Surprises 1 1. Verify that the PDCS subsytem is ready to accept commands. To PDS SPH Invoke Scenario SCE04895 "State Transition". 3 INVOKE X 7. Send a notification that the core software is ready to interact with the crew Can't Invoke SCE04085 here. The software to transition to Admin State has not been commanded to initialize at this point Request_PDCS_Subsystem _State 2. Command the transition into the initial power net configuration: Invoke Scenario SCE08155 "Change the Power Network Configuration" Vehicle_State_Notification Release core software applications on the GPU as directed by VMG INVOKE SCE00009 Thread Manager OSS Create core applications thread 5 5 X 4 4 X Can't Invoke SCE8155 here. PDS has not yet been commanded to initialize. 2 2 INVOKE To CUI Request threads for core software applications Can't send a message to PDS here. PDS has not yet been commanded to initialize. SCE08157 Initialize VPMG Software VMG INVOKE Testing is More a “Proving Process” Than a “Fixing Process” Shows “Actual Design” as opposed to “Perceived Design” X-Y 3. Begin monitoring health of software Reduces the Amount of Reverse Engineering to “Make It Work” Customers Have More Confidence in the Contractor as it offers Tangible Evidence of Progress Message Disconnect X Initialization_Command To PDC 3. Report the initialization status Can't notify CUI, CUI not started yet. Core software threads just now requested. Why is SCE00009 (thread manager) invoked here if OSS created and released threads above all by itself? Threads T X T CONTACT SEA, Inc. Albuquerque Division Steve Mattern or Greg Elcock (505) 884-2300 SEA Inc. Proprietary Data – Please Protect Accordingly Page Two CREW Crew turns computer power switch on 6100 Uptown Blvd., NE, Suite 700, Albuquerque, New Mexico 87110 (505) 884-2300 IMPACT Science & Engineering Associates, Inc. ™ Integrated Messaging and Process Analysis Control Techniques IMPACT Software Safety Process System Hazards Analysis The integration of the “Software Assurance” of RTCA/DO 178B and “Software Safety” of Mil-Std 882 ensures a total integration of system safety engineering, system engineering and software development methodologies for a safer system. The process as defined below produces the necessary output products to support system certification and safety requirements criteria. The Functional Hazard Analysis is a natural springboard into the safety activities required by Mil-Std 882. The most important step in the process is the in-depth analysis to identify failure modes or pathways to the identified hazards of the system. This analysis includes the identification of each hardware, software, and human interaction on the failure pathways. SOFTWARE ASSURANCE IAW RTCA/DO-178B Functional Hazard Analysis Determine Severity Ramification of Loss Of Function Allocate Software Functions to Appropriate CSCI’s CSC’s and CSU’s Determine Safety Level Definition Level A/B/C/D/E Software Design Software Requirements And Definition Review Software Safety Constraints Determine SafetyCritical Functions Identify SystemLevel Hazards Link Software Functionality to Hazard FailurePathways (Prioritize Based on DO-178B Level of Safety) Identify SubsystemLevel Hazards Software Code Preliminary Detailed Determine Software-Specific Hazard Causes Categorize Hazard (Severity & Probability) Determine Hazard Causal Factors Define Software Hazard Mitigation Define Hazard Mitigation Requirements Software Test and HW/SW Qualification and Integration Testing Define Software Safety Test Requirements (including FMET) Residual Safety Risk Assessment Produce Evidence Of Hazard Mitigation SYSTEM SAFETY ENGINEERING IAW MIL-STD-882D COTS/NDI Hardware and Software With Supporting Safety Design Test, and Certification Artifacts Software Assurance To Include Hardware & Software Functionality Software Development Engineering Software System Safety Engineering System Safety Engineering to include HW/SW/HE + Interfaces System Functional Analysis Identification of Software Safety Requirements Analysis is accomplished to determine system functionality and the ramifications of “loss of functionality”. This activity is accomplished in conjunction with systems engineering and can be used to supplement interface and integration activities. The primary purpose is to identify the Safety-Critical Functions (SCF) of the system and categorize them in accordance with DO-178B safety level criteria. The SCF’s is then tied to the software functionality to determine which CSCI’s or CSU’s will be determined to have significant safety impact. This allows functionality to be allocated to the appropriate safety levels within the software design architecture. The in-depth hazard causal analysis defines the interaction of hardware, software, and the human as contributors to potential mishaps. The results of this analysis is a more refined list of hazard mitigation requirements for hardware and software design, safety and redundant systems, fault detection, tolerance, and recovery, and procedures and training. The safety engineering team then ensures that the domain experts (designers) successfully implement the defined hazard mitigation requirements. This is accomplished through a variety of analysis, inspection, and test activities. SEA Inc. Proprietary Data – Please Protect Accordingly Page Three 6100 Uptown Blvd., NE, Suite 700, Albuquerque, New Mexico 87110 (505) 884-2300