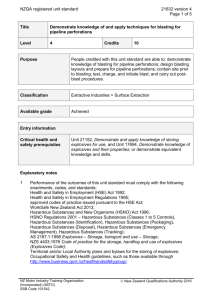

Blasting Awareness Powerpoint

advertisement

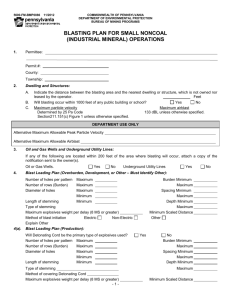

Prevent injury to people Prevent damage to property Blasting & Flyrock Awareness Recognizing the Hazards Blasting activities are carefully regulated by several governmental agencies. Legal Standards OSHA 29 CFR Part 1910 - General Industry 29 CFR Part 1926 - Construction MSHA 56.6000 - Metal & Non-Metal Mines Bureau of Alcohol, Tobacco and Firearms DOT Blaster Qualifications Knowledge and Experience Training Physical Ability Evidence of Competency Basic Blasting Terminology Blaster-in-Charge Blasting Plan Blast Area Flyrock Early-Warning Signal Final-Warning Signal All-Clear Signal Rock blasting is the controlled use of explosives to excavate or remove rock. It is a technique used most often in mining and civil engineering. Blaster-in-Charge Best Practices: • ensuring that all personnel have evacuated the blast area during shot firing; • using adequate blasting shelters for employees whose presence is required in the blast area • controlling and monitoring all entrances to the blast area; ensuring that the blast is properly designed, drilled, and loaded; and • emphasizing education and training to enhance skill levels for implementation of engineering control techniques. Weather Conditions Conduct Pre-Blast Meeting • Review of weather conditions • Communicate number of holes • Calculate bags per hole • Discuss reasons to turn off electronic devices • Review personnel location • Discuss stemming process • Discuss gas and fume releases • Remind those working alone to stay in communication w/supervisor Stemming Blasting Shelter Drilling Blast Holes Storage of Explosives Transport of Explosives An example of a firing pattern which provides separate delay time for the blastholes and gives good fragmentation as well as good breakage. Blast Area Understanding Warning Signals & Signs Two warnings are common… HOWEVER, some sites use only one signal! Early-Warning Signal Every sites warning signals are unique!! ___ minutes before shot is fired. Warns holes have been loaded with explosives and prepared. Means blast area is clear, guards have stopped traffic into area. Blast crew inspects grounds to make sure no people or equipmen is in the blast area. Final-Warning Signal ___ minutes before firing. Timing is different on each site. Radio silence is necessary. Guards will halt blast if they sight anyone in area. All-Clear Signal Blaster can't order the all-clear signal just yet. The blaster must inspect the area to see if there are any misfires. It may take minutes, hours or days to determine if there is a misfire. Stay out until the All-Clear signal sounds. Warning Signals Be alert and share information Know the blasting time, blast area and clearing procedure; and Do not enter the blast area until an “all-clear” signal is sounded. Blast Logs - Recorded Evidence The location of the blast within the permit area allows the regulator to verify the distance. Permit Area Know the location of the blast Check the distance!! 690 Feet Jones Residence North Rock blasting in northern Ontario to make way for new highway upgrades. The six exposures were taken over a span of 3 seconds. This animation is displayed over 6 seconds. Excavation crews working on sites involving blasting operations may be exposed to the hazards of undetonated charges during removal of blasted rock. Optimum Depth A B C D E Flyrock is caused by a mismatch of the distribution of the explosive energy, geomechanical strength of rock mass, and confinement. A professional baseball pitch averages 90 mph, or slightly faster. Flyrock has been clocked at 400 mph. Can you dodge that? Protect Yourself! July 2002 - West Virginia A truck driver and his supervisor were watching a blast from 1/2 mile away waiting for the "all clear" signal. A rock slammed into the front windshield and exited the rear. It somehow missed both people. No one was hurt. PPE Hard hat Safety-toed shoes Reflective vest Safety glasses Gloves Hearing protection MSHA Part 48 State of Alaska: 11 AAC 95.335. Blasting Standards (a) A person may not discharge an explosive in the following areas without first obtaining a variation under 11 AAC 95.235: (1) Type A or Type B stream riparian areas in Region I; and (2) within all riparian areas in Region II or III. (b) During blasting, an operator shall minimize the amount of flyrock materials deposited into fish-bearing waters. Authority: AS 41.17.010 AS 41.17.080 Explosives Security Reminder Inspect, verify each magazine is properly secured according to all applicable regulations, company policy, as well as manufacturers recommendations Explosives Security Reminder Report missing explosives immediately Explosives Security Reminder Ensure that any vehicle used to transport explosives is properly secured and attended. Explosives Security Reminder Verify that inventories of explosives are correct Copy is maintained in magazine with duplicate at mine office Explosives Security Reminder Verify person’s identify before allowing them to enter explosive magazines or review inventory records Explosives Misfires found during the post-blast inspection Exclude all employees from danger zone. No other work except that required to clear the misfire. Only the Blaster-in-Charge handles all the sequence of events following a misfire. Extra care must be taken, as the designed pattern HAS changed. Explosives Security Reminder Review facility’s security measures Are further measures necessary to protect explosives from theft? Explosives Security Reminder Post proper authorities phone numbers in conspicous locations Explosives Security Reminder Periodically inspect magazines for evidence of tampering or theft Explosives Security Reminder Immediately report shortages, loss or theft of any explosive material to: 1-888-ATF-BOMB Conclusion: Good communication between the driller, blaster, access control guard, and miners is the key to a safe blasting operation. Thank you for your participation. Other regulated operations • Underground transportation of explosives - 1926.903 • Use of safety fuse - 1926.907 • Use of detonating cord - 1926.908 • Underwater blasting - 1926.912 • Blasting in excavation work under compressed air - 1926.913