KGCOE Dynamometer Lab Quick Start Guide

advertisement

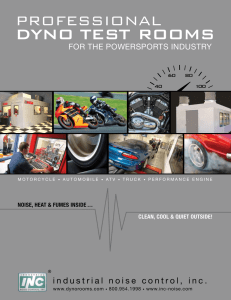

KGCOE Dynamometer Lab Quick Start Guide This quick start guide was written by the P15280 senior design team to assist any team working with the dynamometer and to provide clarification on anything that may not be up to date in the official Dyn-Loc IV user manual and quick start manual. The manufacturer’s documentation can be found at the links below. User Manual- http://www.dynesystems.com/PDFs/Dyn-LocIV_User_Manual.pdf Quick Start Guide- http://www.dynesystems.com/PDFs/Dyn-Loc-IV-QSG.pdf Overview of the environment The dynamometer system is split into two rooms, a test room and a controls room. The picture below shows the test room complete with the dynamometer and auxiliary cooling solutions. There is an access port in the wall at the right for controls and data acquisition cabling and is connected to the equipment bay in the controls room. The electric motor or engine to be tested (Device Under Test or DUT) is mounted to a rigid platform and coupled to the dynamometer input shaft with a chain and idler system. The regenerated power from the dyno is fed back into the building’s power bus. Pictured below is the controls room equipment bay. The Dyn-Loc IV controller on the top rack as well as the PC is available for use by anyone in KGCOE. Additional instrumentation shown is dedicated for Formula SAE only use. Steps to operate the Dyno without a DUT 1. Before operating the dyno, make sure the circuit breaker in the test room is ON. The picture below shows the circuit breaker labeled Dyno Motor Power in the test room. If the dyno is turned on while the breaker is OFF, you will need to reset the breaker located in the basement by switching it off for 30 seconds. (Please refer to the section below How to Reset Basement Circuit Breaker for additional information.) It is important to vacate the test room and close the door before operating the system. 2. There are two ways to operate the Dyn-Loc IV controller. To control it manually, refer to the picture and instructions below. A. (REFER TO GREEN rectangle) First, make sure the controller is set on MASTER mode by depressing the MASTER push button and observing that the switch indicator is lit. B. (REFER TO ORANGE rectangle) Set it to RPM or TORQUE mode as desired. Change the RPM/TORQUE switches to the desired speed or force and hit the ACTIVE button to use either the top or bottom switch settings. The switch should be fixed so the light comes on when it is supposed to. C. (REFER TO PURPLE rectangle) Depress the Auto Zero switch while the dyno is off for measurement accuracy. Set the LAC to the desired acceleration rate for the dyno to reach the desired RPM/TORQUE. D. (REFER TO RED) Press DYNE ON to start the dyno. 3. To control the Dyne Controller remotely, use an application program such as RealTerm. Open the program and select the port tab. Set the baud rate to 19200 and set the port to COM2. Finally click change to connect to the Dyn-Loc. To communicate with the controller select the Send tab. On the left there is a text field where the user can enter desired commands and click Send ASCII to send the command. The Dyn-Loc should reply with a “\” as an acknowledgement. Each sent command should end with carriage return and newline characters, \r\n. To test the operation of the dyno use the following commands. Procedure 1. Set controller to computer mode 2. Set controller to RPM mode 2. Set linear acceleration rate 3. Set the RPM set point 4. Turn the Dyn-Loc on 5. Get speed, torque and power data, confirm 1000RPM 6. Set RPM set point to 0 7. Turn Dyn-Loc off Command MD COMP\r\n MD RPM\r\n LAC 100\r\n SP 1000\r\n MD DON\r\n AD\r\n SP 0\r\n MD DOFF \r\n 4. At the completion of testing, turn off the dyno and the main circuit breaker (mentioned in step 1). Remove all test hardware so the system is ready for the next user. Problems and discrepancies with official Manual and Quick Start Guide. According to the manual, the set baud rate for the Dyn-Loc IV controller can be found through the different combination of switches as seen in the picture below. Since switches 1, 2 and 3 are on, the baud rate should be 256k, however this is inaccurate. The baud rate to connect with the controller is 19200. According to the manual, the H20 terminal and I.L. terminal has to be wired together for the DYNE ON light to stay on as shown in the picture below. Please note that this is NOT required for operation. How to Reset Basement Breaker 1. Obtain basement key from Rob Kraynik, Jan Maneti or any other machine shop personnel from the machine shop office. If you are new to the shop, ask for assistance before entering the basement. 2. The picture below shows the entrance to the basement, next to the entrance of the ME Machine Shop located at GLE-2430. 3. The circuit breaker is located past the locked gate shown in the picture below. 4. At the end of the basement, you will see many circuit breakers. The one you are in interested in resetting to the right labeled Dyno Master Power Switch. Refer to the picture below. As mentioned at the beginning of this guide, switch off the breaker for 30 seconds before switching it back on.