(EM) Grid and Carbon film Preparation

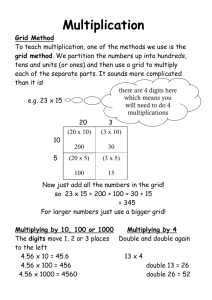

advertisement

Electron Microscopy (EM) Grid and Carbon film Preparation for Cryo-Electron Microscopy Cryo-EM tutorial July25~29, 2005 Zongli Li What I will talk about…… Some basic topics about EM grid Home-made grid preparation Grid cleaning Carbon coating and carbon film preparation Some basic topics about EM grid What is EM grid? The EM grid is a 3.05 mm diameter, thin-foil mesh, and it can be made from a number of different metals (copper, gold, nickel, molybdenum, stainless steel, tungsten, aluminum, titanium etc.), and have various spacing patterns. The diameter of grids is standard, as 3.05mm. The Thickness is variable based on the materials of the grid. The tickness range is from 10um to 25um. The mesh of the grid is defined by the number of holes within 1 inch. For example, the 200 mesh grid has 20 holes along diameter direction, 400 mesh grid has 40 holes in diameter. Since the diameter of grid is a standard length, 3.05mm, each hole size is less than 200um in 100 mesh grid, 100um in 200 mesh grid, 75um in 300 mesh grid and 50um in 400 mesh grid. The EM grid is to the TEM what the glass slide is to the light microscope. It provides a way for supporting the specimen and delivering the specimen into the TEM column for observation and data collection. Some basic topics about EM grid (Contd.) What we need to do with EM grid before we can use it? Often an electron lucent film is deposited upon the grid to aid in specimen support. The TEM techniques that are most often used to investigate macromolecular structures require films made of a thin layer of carbon which may or may not have numerous small perforations. The macromolecules are then examined while adhered to the carbon or while suspended in the holes. The grid have to be cleaned up for any dirty or chemicals left over from manufacture or process of depositing electron transparent film before putting specimen on it. Eliminate any possibility for alternating or damaging your specimen. Eliminate or reduce charging problem to get quality data Keep OLA, pole piece and column clean. Some basic concepts about EM grid (Contd.) How to chose right gridsome preliminary considerations The type of grids and films used are usually determined by the desired specimen preparation technique and sample characteristics. Copper grids are usually used because they are conductive, stable in the beam and inexpensive. But when treating the sample on the grid with some substances such as acids, bases, some salts, etc. more expensive non-reactive grids such as gold or platinum may be necessary. Both holey films and continue thin carbon films are mounted on grids with appropriate mesh value for stability in the beam at higher magnifications. Vitrified samples are best examined when suspended in the holes of a holey carbon film, while negative stained samples are examined on continuous carbon films. Some basic topics about EM grid (Contd.) Home-made grid Vs. commercially available grid (http://www.grid-tech.com/product.htm http://www.quantifoil.com/) • Manufactured holey grid Advantages: • Big time saver • Specified hole sizes/spacings Disadvantages: • Expensive • Unreliable quality • "Freshness" issue (hydrophobicity increases with age) • In house preparation Advantages: • • • • Age of grids is known Price Vary film thickness and hole size to suit specimen Availability Disadvantages: • Difficult technique • Variability • Time Home-made grid preparation* Grid with continuous thin c-film • • • Evaporate a uniform carbon layer over plastic films or freshly cleaved mica to be used as a stand alone support film Produce very thin support films (~250Å) for use in testing microscope or negative staining Evaporate a thin carbon layer over holey films for use in CryoEM grid with holey c-film • • • Provide a secondary mesh over the copper grid for the suspension of a thin film of vitrified ice forming an unsupported layer within the holes of that mesh Produce holes within that mesh that have appropriate diameters and depth (depth = film thickness) to contain the correct amount specimen solution for freezing to the appropriate ice thickness Produce a support that has the necessary surface characteristics to allow for the quick freezing of thin films of hydrated specimens *: Some pictures and materials are borrowed from web site http://bilbo.bio.purdue.edu/~baker/documentation/sample_and_prep/b2.htm for this section Home-made grid preparation --grid with continuous thin c-film (1) 1) Pre-clean copper grids. a) Copper grids should be pre-cleaned by sonicating for 10 sec. in Acetone, followed by 10 sec. sonication in ethyl alcohol. b) Allow grids to dry on filter paper in a dust-free environment before use. 2) Prepare Formvar solution. a) Add 0.12g of Formvar powder to 50 ml of ethylene dichloride and mix well on a magnetic stirrer until dissolved. b) Pour the solution into a clean Coplin jar. This solution is hygroscopic but will store well for several months if kept in the dark, tightly sealed, and refrigerated. Home-made grid preparation --grid with continuous thin c-film (2) 3) Clean a glass slide with water and detergent. a) To prevent contamination with oil from the skin do not touch the slides with bare hands (use gloves). b) Scrub the glass slide with lint-free paper, put them into the slide holder and soak in 2% RBS for at least one day. (RBS: mixtures of anionic and non-ionic surfactants, http://www.chromspec.com/Catalogue/Misc/CleaningSolutions.html) c) Rinse the slides thoroughly by running de-ionized water over the slides. d) Dry the slides by air drying but keep them dust free or dry them in an oven at relatively low temperature. After drying the slides can be stored in a slides box. 4) Coat the clean slide with Formvar. a) Dip the cleaned slide into the Formvar solution and touch edge to filter paper to drain off the excess fluid. The film will be somewhat milky when wet but it will clear as it dries. b) Dry upright in a dust-free environment (this requires 5 to 10 min. Home-made grid preparation --grid with continuous thin c-film (3) 5) Remove Formvar film from slide and add grids. a) Fill the black dish with deionized water until a meniscus is formed on top of the dish. Then drag the lucite rod across the surface of the water to remove any floating debris. b) Cut the edges of the Formvar film with an acetone-cleaned razor blade Home-made grid preparation --grid with continuous thin c-film (4) c) Thoroughly breathe over the length of the slide to loosen the film, and float the film off onto a clean water surface by slowly immersing the slide into the water at a ~25° angle. If the film is difficult to see, a bright desk lamp can be used to reflect light off the surface of the water and film. d) Place grids, shiny/bright surface down, onto good (uniform, gray color, unwrinkled, etc.) areas of the film. Home-made grid preparation --grid with continuous thin c-film (5) e) Place a small piece of clean, white office paper onto the surface of the grids and film and allow it to soak up water. The grids will show up through the paper when the paper is fully soaked. f) Pick up the paper, grids and film with forceps and place on filter paper grid side up in a covered Petri dish to dry. Home-made grid preparation --grid with continuous thin c-film (6) 6) Carbon coat film to desired thickness. 7. Remove Formvar film. a) Place the paper with grids onto a piece of filter paper saturated with ethylene dichloride in a covered Petri dish. The level of ethylene dichloride should be sufficient to completely soak the backing paper without submersing the tops of the grids. One half hour should be sufficient time to dissolve the Formvar film and not damage the carbon support. b) Remove paper with the grids and let dry in a dust-free area. Home-made grid preparation --grid with holey c-film (1) 1) Pre-clean copper grids. 2) Prepare Triafol (cellulose acetate butyrate, Fisher Scientific, https://www1.fishersci.com/Coupon?cid=1334&gid=84054) solution. a) The night before making holey grid films, prepare water and ethyl acetate solution. Take a 200 ml glass bottle which can be used with organic solvents. Add 5 mls of de-ionized water and then 40 mls of ethyl acetate, shake well and then allow the solution sit at room temperature over night. note: Do not use the solution for more than a week or two. b) The concentration of Triafol solution will depend on the size of the hole you want. We can use 0.2% Triafol solution to make the film with hole size around 2 µm. c) The Triafol is dissolved in the ethyl acetate first and then the hydrated ethyl acetate is added (1:1 in volume). Store the solution in a Coplin jar with a cover at room temperature. The solution should be on ice at lease 30 to 45 min before making holey film. Do not use the solution for more than 2 or 3 days. Home-made grid preparation --grid with holey c-film (2) 3) Clean a glass slide with water and detergent. a) To prevent contamination with oil from the skin do not touch the slides with bare hands (use gloves). b) Scrub the glass slide with lint-free paper, put them into the slide holder and soak in 2% RBS for at least one day. c) Rinse the slides thoroughly by running de-ionized water over the slides and soak them in 0.03% Amiet for at least one day. d) After the Amiet treatment, rinse the slides with de-ionized water as follows: dip the slides in a dish of de-ionized water and take them out. Change the water and dip the slides again. Change the water again and then dip the slides but when you remove them this time pull the slide holder out slowly so that there is no trace of water on the slides except near the edges. e) Dry the slides by air drying but keep them dust free or dry them in an oven at relatively low temperature. After drying the slides can be stored in a slides box. Home-made grid preparation --grid with holey c-film (3) 4) Making holey film. a) Set-up for making holey film. i. Find a small room that can be humidified without interruption. Humidify the room at least 3 hours before making the holey film. ii. Keep Triafol solution (that you prepared and put on ice) in the room. iii. Metal plates pre-cooled in refrigerator are put on ice chest and used to cool the slide below the dew-point. b) Making holey film. i. Take a clean, Amiet treated slide and place on metal plate. Do several slides, each with different time (15 seconds to 1 min). Find the time which give you best results. ii. After slide is cooled, take out and wave it in path of humidifier spray. Immediately dip it into the Triafol solution. When the slide get into the solution as far as it can, quickly pull it out and dry it by leaning it against the ice bucket with one end touching ice. iii. Check slides on phase-contrast microscope see if the results is satisfied. iv. Store good slides in slide box until ready to make holey grids. Home-made grid preparation --grid with holey c-film (4) 5) Preparing holey grid. a) Prepare 0.5% Pelex (anionic surfactant) solution. This solution can be kept in refrigerator indefinitely. b) Fill a Coplin jar with 0.5% Pelex solution and place the slide with holey film in the solution. Let slide soak for about 3 hours. Keep slides separate if more than one slide have been put into the solution. c) Take the slides out and let it air dry. d) Fill the black dish with de-ionized water until a meniscus is formed on top of the dish. Then drag the lucite rod across the surface of the water to remove any floating debris. e) Cut the edges of the slide with film with an acetone-cleaned razor blade. Float the film off onto a clean water surface by slowly immersing the slide into the water at a ~15° angle. If the film is difficult to see, a bright desk lamp can be used to reflect light off the surface of the water and film. f) Place grids, shiny/bright surface down, onto good areas of the film. g) Place a small piece of clean, white office paper onto the surface of the grids and film and allow it to soak up water. The grids will show up through the paper when the paper is fully soaked. Home-made grid preparation --grid with holey c-film (5) h) Pick up the paper, grids and film with forceps and place on filter paper grid side up in a covered Petri dish to dry. i) After drying overnight, pick grids off the paper with tweezers and put them on clean glass slide with film side up. j) Carbon coat film to desired thickness. (a thick carbon layer compared to continuous c-film). k) Remove plastic film. There are many different ways to remove plastic film, you should find the way which works best for your experiment.her l) After the plastic film removing, place the grids on another clean glass slide with the carbon side down. Carbon coat the other side and store them in clean grid box for future use. Home-made grid preparation --grid with holey c-film (method 2) (1) 1) Pre-clean copper grids. a) Copper grids should be pre-cleaned by sonicating for 10 sec. in acetone, followed by 10 sec. sonication in ethyl alcohol. b) Allow grids to dry on filter paper in a dust-free environment before use. 2) Prepare Formvar/Chloroform solution. a) Add 0.17g of Formvar powder to 50 ml of chloroform (Do not use ethylene dichloride) and mix well on a magnetic stirrer until dissolved. b) Pour the solution into a clean Coplin jar. This solution is hygroscopic but will store well for several months if kept in the dark, tightly sealed, and refrigerated. 3) Clean a glass slide with water and detergent. Home-made grid preparation --grid with holey c-film (method 2) (2) 4) Produce a suspension of glycerol droplets in the suspension. a) Add about 50 drops of a 50% glycerol/water solution to the surface of the Formvar solution. b) Place the tip of a probe sonicator onto the surface of the solution and sonicate until mixed. Sonication intensity should be great enough to cause the solution to bubble violently. This often requires no more than about 5 seconds. The solution should now appear cloudy or milky. This should produce numerous holes that are 1-2 µm in diameter and suitable for use with frozen-hydrated samples. Sonicating for longer periods of time produces smaller holes in the film; shorter times produce larger holes. Home-made grid preparation --grid with holey c-film (method 2) (3) 5) Coat the clean slide with Formvar. a) Immediately after sonicating, dip the cleaned slide into the Formvar solution and touch edge to filter paper to drain off the excess fluid. The film will be somewhat milky when wet but it will clear somewhat as it dries. b) Dry upright in a dust-free environment 6) Remove holey Formvar film from slide and add grids. (Same as before) 7) Let the film dry and perforate the pseudo holes. a) When the paper is completely dry, place the paper with the film and grids onto a piece of filter paper that is just saturated with methanol. Soak in a covered petri dish for about 40-50 minutes. This should perforate any pseudo-holes in the films. b) Let them dry completely before carbon coating. 8) Carbon coat film to desired thickness. Home-made grid preparation --grid with holey c-film (method 2) (4) 9) At this point, the grids may be examined in a light microscope with phase contrast illumination to determine the quality of the films. 10) Remove Formvar film. Grids Cleaning Why need to clean grid before use? • Good for your specimen • Good for imaging • Good for microscope Organic Solvents used for grid cleaning Two organic solvents have been used in this lab, • Acetone ((CH3)2CO ) • ethyl acetate (CH3COOC2H5 ) People in other places also use chloroform (CHCl3) and ethylene dichloride (C2H4Cl2) Caution: Ethylene dichloride, chloroform are carcinogenic, ethyl acetate and methanol are toxic. Care should be taken to avoid contact with these solvents or inhaling their vapors. Although acetone is less toxic, breathing moderate- to-high levels of acetone for short periods of time, can also cause nose, throat, lung, and eye irritation and other health problems. Diagram for cleaning gridsHome-made holey grid (1) Diagram for cleaning gridsHome-made holey grid (2) Quantifoil grid In the final stage of the production process of QUANTIFOIL® holey film, carbon is evaporated onto a plastic holey film, and the plastic is dissolved. The grids are washed with chloroform, ethyl acetate and acetone. However, not all plastic can be removed. Therefore, the final thickness of the foil is about 20 nm, although only 10 nm of carbon is evaporated onto the plastic. R1.2/1.3 quantifoil grid Diagram for cleaning gridsQuantifoil grid Acetone water water Carbon coating and carbon film preparation • Evaporate a uniform carbon layer over plastic films or freshly cleaved mica to be used as a stand alone support film • Produce very thin support films (~250Å) for use in testing EM and negative staining • Evaporate a slightly thicker carbon layer over holey films for use in CryoEM Operation of carbon evaporator EMitech K950 & K950X The evaporator has a small vacuum chamber and is very sensitive to oil contamination. To keep it oil-free the following rules are necessary: •Never work inside the chamber without gloves. •Never use solvents to clean inside the chamber. Use a brush to remove the carbon flakes from the lid, the stage, and from the walls. •Never touch anything that goes inside the chamber with bare hands. Use tweezers whenever possible. •Never use solvents or vacuum grease on the bell jar gaskets; they become sticky. We use talc powder on these gaskets to prevent stickiness. Carbon evaporator EMitech K950 EMitech K950X Procedure for operating the carbon evaporator (1) 1) Put on gloves! 2) Turn the power switch on (in back of the unit on the right side above the power cord). The "Stop" button should be lit . The unit should be at atmospheric pressure. Open the valve on the regulator of nitrogen cylinder. This will supply dry nitrogen to vent the chamber when you need to stop the evaporator. Procedure for operating the carbon evaporator (2) 3) Open the bell jar lid and check the carbon rods. The sharpened tip should be at least 3-4 mm long and make good contact with the broad tip of the other rod. If you need to clean the lid and rod holders, cover the upper surface of the jar with aluminum foil and clean the lid with a small brush. Procedure for operating the carbon evaporator (3) 4) Put your grids or mica in the slot on the stage along with a marker (A piece of filter paper works just fine). Ensure that nothing protrudes beyond the edge of the stage as the venting process can cause any such object (i.e. grids) to fly all over the chamber. Lower the lid and check to make sure that it is firmly seated and properly closed. 5) If you need to change parameters (most of the time the standard parameters are fine), push the "Enter" button and follow the instructions; otherwise push the "Start" button (Fig. 1) and wait until the unit is ready. The rotary pump should start immediately and you should hear an accelerating whine which is the turbomolecular pump. On the display is a setting that shows the actual vacuum in the chamber and the speed of the turbomolecular pump (displayed in percent of maximum speed). If the pump accelerates smoothly that is a good indication that the unit is working properly. In approximately 3 minutes the speed should reach 100%. Wait until the gauge shows that the vacuum is at the "high vacuum" level and the initial pumping cycle is complete. Currently this cycle is set at 5 minutes (changeable on the parameters page). Procedure for operating the carbon evaporator (4) 7) When the initial pumping is done the display should show "Push up arrow to outgas or down to evaporate. Stop to escape". The "Stop" button is used to escape from the previous menu or to stop the current process. Outgassing of the rods is necessary if they have not been used before, otherwise you may proceed with evaporation. In the outgas mode start with the current knob turned completely to the CCW position and slowly increase the current by rotating the knob CW. Watch the rods and continue to increase the current until the sharpened rod begins to glow. Allow the rods to glow for several seconds and then stop the outgassing by pushing the "Stop" button. Return the knob to zero (fully CCW). 8) You will then again get the message "Push up arrow to outgas or down to evaporate. Stop to escape". Enter the evaporation mode by pushing the "Down" arrow button. The stage will begin rotating. Slowly increase the current by rotating the knob CW until you are satisfied with the evaporation rate. You may want to watch the "demand" or "actual value" on the display to decide where to start the next time. Sparking rods will coat the grids much quicker than a slow, glowing evaporation but the carbon will have a much more inconsistent granularity. Procedure for operating the carbon evaporator (5) 8) When you are satisfied with the film thickness (Fig. 5) stop the evaporation by pushing the "Stop" button. If you find that the film is not dark enough, go back to evaporation mode and put more carbon onto the grids. You can repeat this as many times as you want while the carbon rods remain in contact. 9) To remove the grids (or mica) push the "Stop" button. The display will show "Slowing down turbo" followed by "venting chamber". We use a pulsed venting process to return the chamber to atmospheric pressure, meaning that air is admitted to the chamber in small bursts, to help prevent grids from flying off the stage. In about 30 seconds to 1 minute the chamber should be at atmospheric pressure. If it is not at atmosphere, press the "Stop" button again to allow more air into the chamber. Open the lid and remove the bell jar to get the grids. Replace the bell jar and close the lid. Never leave the unit under vacuum unless the turbomolecular pump is running to prevent back streaming oil vapor into the chamber. 10)Turn off the power on main unit and close the nitrogen valves. The bell jar should be cleaned when it becomes dark. If after your use the jar appears dark, please clean it as a courtesy to the next person. Procedure for operating the carbon evaporator (6) Cleaning the Bell Jar: 1) Carefully remove the bell jar by pulling it straight up and past the implosion shield. Be extremely careful when handling the bell jar because it is expensive. Remove both gaskets. 2) Soak the bell jar with soapy water for a couple of minutes then gently rub it with paper towels. When the jar is clean, rinse it with deionized water and wipe it dry with Kimwipes. 3) Apply a thin coating of Bell Bright to the inner surface of the jar. There should not be any liquid droplets on the surface. Let it dry for a couple of minutes and then replace the gaskets. Do not forget to use Bell Bright or the carbon will be nearly impossible to remove the next time it is cleaned. Carbon coating grid with holey or continuous plastic film To get holey carbon grids or grids with continuous carbon film. Put more carbon on holey carbon grid There are different reasons for putting more carbon on holey carbon grid • Increase the strength of the holey carbon grid so that the holey carbon film will not be damaged during washing • Increase the thickness of holey carbon film to meet the freezing different specimens. • Change the hydrophilicity of the grid so that one can get idea ice thickness and particle distribution. Making the stand-along thin carbon film using freshly cleaved mica Purpose • Make the continuous c-film grid for testing EM • Make the continuous c-film grid for negative staining • Make the continuous c-film grid for some special samples Procedure • Cleave mica to get the fresh, flat surface where the c-film will be made • Coating the freshly cleaved mica with fine, continuous thin c-film Put the carbon film on top of the holey carbon grid or bare grid • Cut a small piece of mica that have thin c-film on it (cut around off by 1 mm. • Float the c-film off onto the surface of water • Cut Whatman #1 filter paper to small pieces (4 mm x 4mm) • Put the grid onto the a piece of filter paper with shinny side up. Use tweezers to take the grid and filter paper together and pick up a piece of c-film from underneath. Put them on filter paper and let them dry completely in dust free environment. Store them in grid box for future use.