pptx - SAPICS Conference

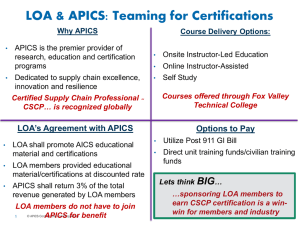

advertisement

SCOR ®: A Journey of Supply Chain Process Excellence Using SCOR to Drive Process Improvements Derinda Ehrlich VP, Corporate and Channel Services, APICS Introductions Topics • APICS and Supply Chain Council merger • What is SCOR? • Using SCOR to Drive Process Improvements • Implementing SCOR • Next steps for YOUR organization APICS merger with Supply Chain Council Leading the Industry • APICS is globally the leading association advancing supply chain and operations management. • Our research, education and certification programs elevate individual and corporate supply chain performance, innovation and resilience. • APICS Products and Services – Professional Membership – Research and Publications – Education – Certification – Events – APICS and the Supply Chain Council – officially merged August 2014 APICS Supply Chain Council (APICS SCC) • We are a global, non-profit organisation that developed and actively manages the Supply Chain Operations Reference (SCOR) model. • The SCOR® model is globally recognised as the standard framework that links supply chain process, performance, practices, people (organizations) and technology into a unified structure. • Since 1996, over 5,000 companies worldwide have used SCOR®. • APICS SCC Services – Research Projects, Corporate Advisory Board, Executive Summit – SCORmark™ Benchmark – Training is now available through APICS – Publications, Resource Library, and Case Studies – Other Value Chain Frameworks including M4SC, DCOR®, CCOR®, and PLCOR® APICS and APICS Supply Chain Council Training, certification and networking APICS Individuals Research, Benchmarking and Process Frameworks APICS Value Proposition APICS SCC Corporations, and Institutions APICS delivers a total individual and corporate value proposition. We help individuals achieve career development goals. We help corporations achieve strategic supply chain goals. What is SCOR®? A Process Framework • Process frameworks deliver the well-known concepts of business process reengineering, benchmarking, and best practices into a cross-functional framework – Process Standards: Plan, Source, Make, Deliver, Return, Enable – Performance Standards: Perfect Order Fulfillment, Cash-to-Cash Cycle Time, Cost of Goods Sold, Order Fulfillment Cycle Time, etcetera – Practices: EDI, Cross-Training, Sales & Operations Planning, … – People/Skills: Process, practices, and metrics cross-referenced with personnel skills that include experience, aptitude and training needs History of SCOR • • • • In 1996, 69 companies collaborated Described the Supply Chain in terms of a Process Framework Currently on SCOR version 11 Since 1996 more than 5000 companies used SCOR Business Process Re-engineering Performance Benchmarking Best Practices Analysis Capture the ‘as-is’ business activity and design the future ‘to-be’ state Quantify relative performance of similar supply chains and establish internal targets Identify practices and software solutions that result in significantly better performance Organizational Design Assess skills and performance needs and align staff and staffing needs to internal targets Process Reference Framework Processes Performance (metrics) Practices People (skills) SCOR® Processes Plan Deliver Source Return Return Plan Make Deliver Source Make Deliver Return Source Plan Make Return Return Deliver Source Return Return Return Enable Enable Enable Suppliers’ Supplier Supplier Your Organization Internal or External Customer Customers’ Customer Internal or External SCOR MODEL SCOR® Process Decomposition Level 1 Description Examples Comments Process Types (Scope) Plan, Source, Make, Deliver, Return and Enable Level-1 defines scope and content of a supply chain. At level-1 the basis-of-competition performance targets for a supply chain are set Process Categories (Configuration) Make-to-Stock, Maketo-Order, Engineer-toOrder Defective Products, MRO Products, Excess Products Level-2 defines the operations strategy. At level-2 the process capabilities for a supply chain are set. (Make-to-Stock, Make-to-Order) • • • • • Level-3 defines the configuration of individual processes. At level-3 the ability to execute is set. At level-3 the focus is on the right: • Processes • Inputs and Outputs • Practices • Technology capabilities • Skills of staff 2 3 Process Elements (Steps) Schedule Deliveries Receive Product Verify Product Transfer Product Authorize Payment SCOR® Metrics Attribute SCOR 11.0 Metrics Reliability RL.1.1 Perfect Order Fulfillment Responsiveness RS.1.1 Order Fulfillment Cycle Time Agility AG.1.1 Upside Supply Chain Flexibility AG.1.2 Supply Chain Upside Adaptability AG.1.3 Downside Supply Chain Adaptability AG.1.4 Overall Value At Risk (VAR) Cost CO.1.1 Total Cost to Serve Asset Management Efficiency AM.1.1 Cash-to-Cash Cycle Time AM.1.2 Return on Supply Chain Fixed Assets SCOR Quick Reference Guide SCOR QRG is a handy reference for SCOR Processes and Performance (metrics) across the main SCOR processes Product & Portfolio Management PLCOR™ Product & Process Design DCOR™ Sales & Support CCOR™ Supply Chain SCOR® Customer processes Supplier processes Other APICS SCC Frameworks Using SCOR® to Drive Process Improvements Nigel Clements, from the Deming Forum estimates that up to 70% of process improvement projec fail. 2012 WSJ by S. Chakravorty estimate 60% of Six Sigma projects fail. Typical Lean and Six Sigma Challenges Top Five Challenges with Lean/Six Sigma projects 1. Executive alignment / change management 2. Project selection (typically through brainstorming) 3. Projects aligned to functions (silos and departments) 4. Access to meaningful metrics and performance data 5. Quantifying the benefit/outcome Source: © 2003 Dan Swartwood Internal External End to End View Strategic Metric (Attribute) Strategy Perfect Order (Reliability) Consistently getting the orders right, and product meets quality requirements Order Fulfilment Cycle-Time (Responsiveness) The consistent speed of providing products/services to customers Flexibility, Adaptability & Risk (Agility) The ability to respond to upside or downside changes and overall value at risk Cost to Serve (Costs) The cost associated with managing and operating the supply chain Asset Management (Asset Management Efficiency) The effectiveness in managing the supply chain’s assets in support of fulfillment Hierarchy of SCOR Metrics Level 1 Strategic Metric Level 1 Level 2 Level 3 Level 2 Process Metrics Level 3 Diagnostic Metrics Hierarchy of SCOR Metrics Level 1 Ability to execute the strategy Level 1 Level 2 Level 3 Level 2 Explains why the strategy not achieved Level 3 Diagnose the gap Hierarchy of SCOR Metrics Level 1 Customer StrategicPerfect MetricOrder Level 1 Level 2 Level 3 Level 2 Process Metrics Orders Delivered In Full Customer Perfect Order Fulfilment Orders Delivered in Full Delivery Item Accuracy Delivery Quantity Accuracy Level 3 - Delivery Item Accuracy Diagnostic Metrics - Delivery Quantity Accuracy Competitive Requirements Competitive Requirements • Identify Customer Groups or Market Segments • Based on the expectations for that supply chain, define performance requirements for each segment – One assigned superior (S) – Two assigned advantage (A) – Two assigned parity (P) • Each unique combination of ratings defines the Supply Chain Strategy for the channel • Think of the rating as a desired state, NOT where you want to improve the most Example Competitive Requirements Retail Channel Distributor Channel Delivery Reliability S A Responsiveness A P Agility A P P A P S Total Supply Chain Management Cost Asset Management Efficiency What are YOUR targets? Determine your Competitive Requirements • Identify your largest channel • Determine where you desire to perform at best in class • Determine two attributes where you desire to be better than average • The remaining two get parity rankings Delivery Reliability Responsiveness Agility Total Supply Chain Management Cost Asset Management Discussion • Q: Where did you place your S? • Q: Where is your largest performance gap? • Q: What insight did you learn? How do you know the size of the gap? Lean and Six Sigma driven with SCOR SCOR with Lean/Six Sigma projects 1. Executive alignment and sponsorship of improvement projects • • 2. Roadmap, data and criteria Defined people (roles/responsibilities) and practices Project selection • Portfolio of improvement projects aligned to Supply Chain data and strategic direction 3. Projects often aligned to functions and silos versus end-to-end • Projects aligned to SCOR processes (end to end) Plan, Source, Make, Deliver and Return 4. Opportunities for improvement often not data driven • Standardised operational definition for performance measures • Quantified performance gaps through SCORMark™ data 5. Quantifying the benefit/outcome • Comparative data to measurable outcomes for similar Supply Chains Implementing SCOR SCOR® Implementation Roadmap Step FOCUS Major Deliverables Touch Points APICS Enabler BUILD ORGANISATION SUPPORT • Sponsor and Key Stakeholder Support • Education DEFINE THE PROJECT • Business Context Summary • Supply Chain Definition • Project Scope and Charter 3 ANALYSE PERFORMANCE • Scorecard • Metric Defect Analysis • Process Analysis BENCHMARK SCORmark® Benchmarking Orientation 4 DEVELOP THE PROJECT PORTFOLIO • Project Portfolio • Implementation Priority PORTFOLIO DEVELOPME NT Roadmap Progress Webinar IMPLEMENT A PROJECT • Development, Pilot, and Implementation of a Portfolio Project • Results SATISFACTIO N SURVEY 1 2 5 Executive Brief Orientation Webinar ORIENTATION Public SCOR-P Training In-house SCOR-P Training APICS Instructor List APICS SCC Sponsor List Top Motivations to Use SCOR® 1. 2. 3. 4. 5. 6. 7. Building a Technology Investment Roadmap In Search of Return on Investment (ROI) for Capacity Creating a Supply Chain Strategy Implementing Supply Chain Performance Improvements Improving Sales and Operations Planning Developing Organizational Talent, Support and Competence Maximising Use of Existing Technology 8. Achieving Operational Excellence 9. Due Diligence as part of a Merger or Acquisition 10. Globalising and Managing Business Processes 11. Integrating with the greater Value Chain 12. Integrating Lean, Six Sigma, and SCOR to Build a Better Project Portfolio 13. Defining and Building an Effective and Efficient Supply Chain Organization SCOR Implementation Benefits • • • • • • • Average Operating Income improvement of 3% to sales (high 4.5% - low 1.5%) Typical inventory turn improvements of 20% Delivery reliability improvement of 25% 20% improvement in flexibility 30% faster system implementations with 30% more functionality Continuous improvement portfolios refreshed at a value of 0.5% Mitigation of costs associated with risk management Shareholder Value What are your organisation's main motivations in considering the use of SCOR? Potential SCOR Implementation Role What potential role would you play in a SCOR Project? • A. Sponsoring Executive • B. Key Stakeholder • C. Evangelist –Subject Matter Expert Discussion • Q: Are you prepared? • Q: What is your approach? Continue the Conversation Learn More About SCOR® Training SCOR® Training Options APICS SCC offers training that provides in-depth understanding of the Supply Chain Reference (SCOR®) model, widely recognised as the global standard for supply chain management. – SCOR® Group Training: Cost-effective, customized group learning at your location – SCOR® Training: Thorough, effective, skills development in public classroom setting 2015 schedule - http://www.apics.org/careers-education-professionaldevelopment/events/conferences/scor-professional-training SCOR Mobile App • Official launch soon, but you can check it out now! • www.APICS.org/SCORapp • Enhanced digital version of the SCOR Quick Reference Guide • Offers an outline of the processes under the four main areas of the model – Process, Performance, Practices and People Continue the Conversation Peter Bolstorff Executive Director APICS Supply Chain Council pbolstorff@apics.org Carolyn Lawrence – For Affiliate Subscription and On Boarding Director Corporate Development APICS Supply Chain Council clawrence@apics.org Derinda Ehrlich VP Corporate and Channel Services APICS Dehrlich@apics.org Dominic Longo, CSCP – For Training Director Corporate Services APICS dlongo@apics.org Q&A Thank You!