DOC - Robotics Engineering CTE502

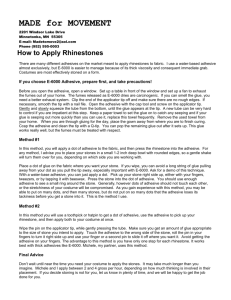

advertisement