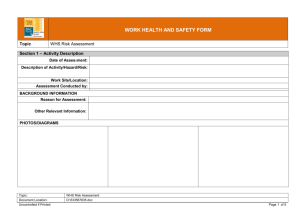

WHS Risk Management System

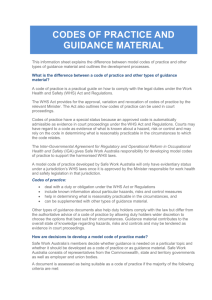

advertisement