Introduction to ExxonMobil Baton Rouge

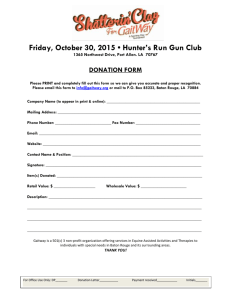

advertisement

HISTORY OF BATON ROUGE AREA COMPLEX 1909 • Refinery operations began 1927 • Exxon Research and Development Laboratories formed - Now responsible for world-wide fuels and lubes process R&D 1940 • Chemical Plant began operations 1956 • First production of hydrocarbon tackifying resins (ESCOREZ 1000 family) 1968 • Plastics Plant founded for production of low density polyethylene - EVA production began in mid 1980’s 1976 • Technology research and development center began operations 1983 • Acquired the Baton Rouge Resin Finishing Plant 1987 • First production of ESCOREZ 5000 hydrogenated tackifiers 1990 • Port Allen Lubricants Plant startup • DEXCO (DOW/Exxon joint venture) startup for production of VECTOR Styrenated Block Copolymers 1995 • Exxon Chemical acquired 100% ownership of Baton Rouge Polyolefins Plant (PAXON) for production of HDPE 1999 • Baton Rouge NGL Fractionator (Joint Venture) startup • Baton Rouge Cogeneration Project (2Q99) EXXONMOBIL BATON ROUGE AREA FACILITIES BATON ROUGE POLYOLEFINS ECA RESIN FINISHING PLANT Highly integrated Refinery/Chemical operations ECA PLASTICS PLANT N MARYLAND TANK FARM METRO AIRPORT RESIDENTIAL AREA COKE TERMINAL ENTERGY SERVICES CHEMICAL PLANT PRODUCTION GAS PLANT BATON ROUGE REFINERY & EXXONMOBIL RESEARCH AND DEVELOPMENT LABORATORIES PORT ALLEN LUBE PLANT BR FRAC/PCU ANCHORAGE CHEMICAL TERMINAL MISSISSIPPI RIVER ANCHORAGE TANK FARM STATE CAPITOL RESIDENTIAL AREA DOWNTOWN BATON ROUGE SORRENTO SALT DOME STORAGE (30 MILES) • Approximately 2400 acres • Excellent water, pipeline, rail, and highway access • Shared infrastructure • Flexibility to adapt to changing markets • Two research organizations (Refining and Chemical) Chemicals Operations include four manufacturing facilities • • • • Baton Rouge Chemical Plant Baton Rouge Polyolefins Plant Baton Rouge Plastics Plant Baton Rouge Resins Finishing Plant SITE OPERATIONS HIGHLY INTEGRATED • Significant coordination of operations - Monthly Joint Management meetings - Day-to-day operation coordination/optimization - Major mechanical workload coordination - Investment planning and general interest optimization • Many facilities and services shared - Steam, electric, and natural gas purchasing and supply - Docks - Emergency Response - Security - Business Services (accounting, stores, office services, telephone, purchasing) - Human Resources (labor relations, wage training) - Public Affairs - Law - Health Services OVERVIEW OF BATON ROUGE REFINERY • Refinery turns crude into prime products of mogas and diesel • Four basic steps make up the Refinery process - Distillation - Cracking/Conversion ( mogas, create octane) - Treating (remove impurities) - Blending • Out of these processes come molecules that can be used as Chemicals feedstock BASIC DEFINITIONS Light Ends Butane and Lighter Naphthas Generally refers to petroleum and natural gas liquid products in the 60°F - 430 °F boiling point range Middle distillates Generally includes heating oil, diesel fuel, kerosene, and jet fuel (220 °F - 750 °F boiling point range) Gas oil Petroleum distillate in the 400 °F+ boiling point range Residuum (“resid”) Heaviest oil fraction (left in Pipestill after gasoline and other distillates have been distilled off) Clean products Mogas and heating oil Also includes similar products which require more refining than heavy fuels *Mogas final boiling point approximately 430 ° F SIMPLIFIED BATON ROUGE REFINERY FLOW CRUDE SOURCE PIPELINE WATERBORNE 60% 40% PRODUCT DISPOSITION FOREIGN 52% DOMESTIC 48% PIPELINE SHIP/BARGE TANK CAR/TRUCK LPG BUTANES FUEL GAS LIGHT ENDS FRACTIONATION H2 58% 39% 3% CHEMICAL PLANT LIGHT GAS OIL REFORMATE OLEFINS NAPHTHA REFORMER MIDDLE DISTILLATES ALKYLATION CRUDE PIPE STILLS ATMOSPHERIC & VACUUM MTBE TREATING LIGHT GAS OIL FLUID CATALYTIC CRACKING UNITS HYDROCRACKER HEAVY GAS OIL FUEL PRODUCTS BLENDING MOGAS AVGAS JET FUEL DIESEL HEATING OIL LUBES LUBE/ BASE STOCKS WAXES COKER COKE BATON ROUGE OLEFINS CAT PROPYLENE REFINERY GAS CAT CRACKER COKER REFINERY GAS ETHYLENE DIL PROPYLENE OLA-1X EPLA-S C3+ TO BRRF GAS CRACKING GAS MAINTRAIN - RGR CROSSOVER LINES ECLA-W ETHANE PROPANE E/P MIX HYDROGEN ETHYLENE PURIFICATION C3- GAS OILS (0-40 kB/d) FUEL GAS EPLA-W ETHYLENE STEAM CRACKING PROPYLENE RAFFINATE / NAPHTHA (0-10 kB/d) BUTADIENE BUTADIENE EXTRACTION C4’s BELA-5 CAT C4’s ISOBUTYLENE EXTRACTION N-BUTYLENES OLA-2X BPLA ISOPRENE EXTRACTION OTHER FEEDS PENTANE, ‘BUTANE, PROPANE, E/P MIX, ETHANE ISOBUTYLENE ISOPRENE C5 / C6 DILA Cyclics C6 REFORMATE BENZENE EXTRACTION BENZENE BHLA TAR CBO CYCLOPENTADIENE DIELS-ALDER REACTOR CPLA DARLA ENB INTERMEDIATES MANUFACTURING Vinyls End Uses POLY PALA Oxy Fluids End Uses OXO/ LION PLA/ EAGLE Primary feedstock for OXO alcohols leading to vinyl plasticizers Key component of vinyl plasticizers Key component of vinyl plasticizers Flexible vinyl plasticizers Plywood adhesives, lube oil additives, mogas Latex paints, polyesters, saccharin Adhesives, lube oil additives, shampoo component Garden hose, food wraps, auto upholstery, vinyl floor tiling, shoes, fishing lures IPA MEK Neo Acids Exxate Used in pharmaceutical, coating, consumer product, and electronic chip manufacturing Component in inks, coatings, and adhesives. Processing fluid for magnetic media manufacturing Used in pharmaceutical, coating, herbicide, and adhesive manufacturing Component in coating, and industrial cleaner manufacturing Rubbing alcohol, Post-it Notes, raw material for Round Up, Kodak Film, Formula 409, Raid Insecticide Auto coatings, circuit board cleaning, Reynolds Aluminum Foil, Fuji Video Tape, Oatey Pipe Cement Antibiotics, fluorescent lamps, wood preservatives, clear coat automotive paint Aerosol carb cleaner, Goop Hand Cleaner, traffic paint, perfume POLYMERS HALOBUTYL MANUFACTURING PRODUCT FEEDSTOCKS 14 commercial and 1 market development grade produced, including butyl, chlorobutyl, bromobutyl & star-branched derivatives Molecular weight of 300,000 - 600,000 Isobutylene, isoprene from Olefins Halogens (Br2, Cl2), catalyst, and other product additives from outside suppliers Produced 302 Mlbs in 2001 END USES Inner liner of tires for automobiles and trucks (~95%) Air-tight stoppers and seals for pharmaceutical containers. (~5%) Value added properties of air retention and bonding with other types of rubber during vulcanization VISTALON MANUFACTURING 22 commercial grades and 1 development grade •Ziegler - Natta Catalyst Dynamically Vulcanized Alloys •Ethylene/Propylene Thermo-plastic elastomers 5 copolymers and 18 terpolymers Produced 200 Mlbs in 2001 •Diene: ENB or VNB Electricals Products vary in monomer content, average MW, MWD, product form •Extension Oil Oil additives Roof sheeting Hose/belts Automotive and Industrial mechanical goods (body sealing) POLYMERS ADHESION INDUSTRIES MANUFACTURING PRODUCT Catalytic and thermal polymerization with hydrogenation of thermal polymers 16 Hydrogenated and 15 Catalytic commercial grades produced, Molecular weight of 6,000-10,000 Produced 210 Mlbs in 2001 FEEDSTOCKS C5 diolefin, C9-C12 aromatic, C9 cyclic Catalyst, and other product additives from outside suppliers END USES Hot Melt Adhesives Packaging, Bookbinding, Product Assembly Pressure Sensitive Adhesives Office Tape, Packaging Tape, Pipe Wrap Tape, Masking Tape, Diaper Tabs Sealants Insulated Glass, Window and Door Caulking, Bathroom Tiles and Fixtures Miscellaneous Adhesives Tires, Textiles, Paper Sizing, Road Marking Polymer Modification BATON ROUGE COMPLEX OVERVIEW OLEFINS BRRF • Pipestills (4, 500+ kB/D) • Cat Cracking (2, 240 kB/D) • Hydrocracking (1, 30 kB/D) • Reforming (1, 72 kB/D) • Alkylation (3, 24 kB/D) • Coking (3, 120 kB/D) • LEU’s (4,120 kB/D Distillate) • Product H/F (100 kB/D) • Sulfur Recovery (3,22 MSCF AG) • Site Ethylene • Steam Cracking - Ethylene - CG Propylene • RGR - Ethylene - Dilute Propylene •PCU-CG Propylene •Butadiene • Isobutylene • n-Butylenes • Isoprene • Amylenes (>65%) • Cyclics (DCPD) • ENB (VNB) • Benzene • Comm Gr Toluene • Mixed Xylenes (4/97) • Tar Annual Capacity 2263 Mlbs 2000 Mlbs 600+ Mlbs 263 29 1500 422 295 Mlbs Mlbs Mlbs Mlbs Mlbs 26 Mlbs 43 26 102 30 137 50 Mlbs Mlbs Mgals Mgals Mgals Mgals INTERMEDIATES • MEK • IPA • Oxo Alcohols • Plasticizers POLYMERS • Resins • HCD • Vistalon • Halobutyl BRPP FWPS 10 kB/D BRPO 300 Mlbs 650 Mlbs 925 Mlbs 1000 Mlbs 290 Mlbs 150 Mlbs 200 Mlbs 300 Mlbs