Powerpoint

advertisement

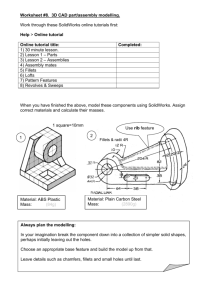

Feature-Based Modeling and Optional Advanced Modeling ENGR 1182 SolidWorks 05 Today’s Objectives Feature-Based Modeling (comprised of 2 sections as shown below) 1. Breaking it down into features Creating Construction Centerlines Construction Centerlines to Create Holes Constraining Circular Patterned Holes 2. Edge Features(3D Fillets & Chamfers) and Model Tree SW05 In-Class Activity SW05 Out-of-Class Homework Assignment Optional Advanced Modeling –Methods to Save Time ( Planes, Axes, Mirroring & Patterning, Holes, Shells, Sweep, & Loft) with HYPERLINK navigation Feature-Based Modeling • Break down into Features • Series of Steps • 1st Step: Base Feature • Adding / Subtracting Material • Edge Features • Model Tree Breaking it Down into Features ENGR 1182 SolidWorks 05 Breaking it Down into Features • Objects can be thought of in terms of features • • • • Shapes Holes Rounds Etc. • Determines design strategy Feature Modeling Example Series of Steps • Base Feature • First Extrusion or Revolve • Reduce Steps of Construction • Features • Additions or subtractions from original base feature How many different ways could we make this? Example Construction 1 We can think of the block in terms of 2 “L” shapes and then cut out the hole Example Construction 2 We can think of the block in terms of a “C” shape and then add the plank with a hole Example Construction 3 Finally, we could draw the overall shape from the top view and remove unwanted material An Important Concept Most sketches can be greatly simplified by establishing horizontal and vertical "Centerlines" and then applying constraints employing those construction centerlines. When the object exhibits symmetry, those construction centerlines are often drawn though the origin. Many sketches will be much easier to constrain if one uses horizontal and vertical construction centerlines. Typically used constraints include dimensioning, symmetry and equal. So even if you don’t initially recognize a need for vertical and horizontal construction centerlines, it is a very good practice to include them in your sketches! Using Construction Center Lines to Position Multiple Holes In the sketch mode insert a construction line of infinite length at a 45O angle through the origin Draw 4 center point circles on construction lines and make them equal Repeat procedure at a -45O angle through the origin Establish Symmetry for each pair of circles Dimension Exit sketch and perform an Extruded Cut through all A Short Cut Method to Produce Multiple Holes In the sketch mode insert a construction line of infinite length at a 45O angle through the origin Sketch a single circle on the construction line, locate and dimension the circle Note that the number 4 could have been set to any number … 2, 3, 8,etc Select Linear Sketch Pattern/ Circular Sketch Pattern Select the drawn circle Set the number of circles to 4, accept and Extrude Cut as before Breaking it Down Wrap Up Breaking it down Base Feature • Start with an extrusion (or revolve) that contains the basic shape of the object • Minimize steps by choosing an appropriate shape for the base step (what shape can be used to build off of) • Do not try to take into account every detail, add later with additional features Series of Logical Steps Homework Assignment SW05-OUT: Problem 6.4 (ss) from the text. In-Class Activity The object to the right can be created many different ways. Can you determine at least 2 different methods (starting on different planes) and create the same object? Edge Features and Model Tree ENGR 1182 SolidWorks 05 Edge Features 3D Fillets create rounded edges 3D Chamfers create slanted edges 2D Fillets vs. 3D Fillets • • 2D Fillets are only to be used in Sketches 3D Fillets are used on edges of the part (3D Fillets are extremely powerful in making realistic designs) SolidWorks Example: Piston Head How would you break this down into features? Where would you start? Where would you use the edge tools? At what point in the process? SolidWorks: Base Feature There are a couple ways to effectively model this piston head but for these slides we will start with a simple extrusion of a circle to create a cylinder SolidWorks: Extruded Cut The volume will be removed using an extruded cut offset from the bottom surface SolidWorks: Revolved Cut The piston rings will be cut out using a revolved cut SolidWorks: Review Design Is there any other way that we could have reached this point and how many steps would it have involved? Would it be easier? SolidWorks: Extruded Cut The pin hole and groove will be removed using an extruded cut SolidWorks: Chamfer The top slanted edge will be added using a chamfer SolidWorks: Fillet And finally the bottom edge of the head will be smoothed out using a Fillet (under the features menu) SolidWorks: Finished Part This finished product can now be used in an assembly with other components shown here SolidWorks: Design Tree The design tree on the left of the screen catalogs all the steps of creating this part and records the steps from top to bottom Sketches are absorbed into features but can be accessed by clicking the plus sign next to each feature SolidWorks: Part Editing The design tree can be “rolled back” by clicking and dragging the blue bar at the bottom up and the features are no longer shown New features can be added to this model in the middle of the design tree while other items are still “rolled back” SolidWorks: Altered Final Part These changes will also carry over to the assembly that contains the part When the design tree is restored then all the features return as long as changes do not interfere with previous features Feature Based Modeling Wrap Up Recognize Features of Object Start with Base Feature TOP VIEW Homework Assignment SW05-OUT: Problem 6.4 (nn) Carefully consider the use of construction centerlines in most sketches Add or Remove Material in a series of steps Features to add last: • 3D Fillets: Rounded edges • 3D Chamfers: Slanted edges Editing Features with Model Tree R3 In-Class Activity Problem 6.4 (u) Create the following shape according to the features and dimensions. • First break this object down into features (you should be able to create this in 2 sketches) • Then use 3D Fillets for the 4 rounded edges Important Takeaways Feature-based modeling is used to break down the features of a part to create the part in an efficient way. Edge features, like chamfers and fillets, are used to create different edge designs efficiently. R3 What’s Next? Due Next Class SW05 Out-of-Class HW Before next class, you will read about assembly modeling. Assemblies are collections of 3D parts that are constrained to form one engineering system. Take SolidWorks 6 Quiz on readings Optional – Advanced Modeling • Methods to Save Time • Methods to Create Shapes • • • • • • • • • Convert Entities Reference Geometry – Planes & Axes Mirroring Patterning – Linear & Circular Hole Wizard Shells Sweeps Lofts Advance Modeling Wrap Up In the SLIDE SHOW MODE this page supports HYPERLINK navigation Optional Advanced Modeling Techniques ENGR 1182 SolidWorks 05 Convert Entities (adds all lines to the sketch plane and makes them available for future operations with is very useful when more than one feature appears within a sketch) Desired Object WITHOUT Convert Entities Starting Object (1) Draw Perimeter Circle, (4) Must Trim Perimeter Circle (2) Dimensioned Center Circle and (3) Carefully Create Closed Sections for Cut (must precisely connect circle midpoints with corners as shown above) (5) Select Areas to Extrude Cut and accept Cut WITH Convert Entities Starting Object (1) Draw Perimeter Circle, (2) Dimensioned Center Circle (3) Click on Convert Entities to automatically generate shown RED Lines – No Trimming of Perimeter Circle required! (4) Select Areas to Extrude Cut and accept Cut Reference Geometry: Planes SolidWorks starts off with the 3 original planes: front, right, top To add a new plane we can reference previous planes and create offset new planes or other options RETURN TO START PAGE Reference Geometry: Axes Axes can also be created without the creation of a 2D sketch RETURN TO START PAGE Mirror Mirroring creates an reverse copy of features on the opposite side of a mirroring plane First the Mirror Plane must be chosen Mirror Once the plane has been chosen then the features to mirror are selected The new features are joined to the original model RETURN TO START PAGE Linear Patterns Once edges are selected for direction, number of instances and distance are specified in the dialog box Features can also be duplicated in linear patterns in either one or two directions. RETURN TO START PAGE Circular Patterns Once features and axes are chosen the angle and number of instances are specified Features can also be duplicated in circular patterns around an axis Also see slide 12 - Using Construction Center Lines to Position Multiple Holes RETURN TO START PAGE Holes • Mating Parts • Hole Specifications • Built-in Hole Tools • Location and Size Selected Holes using the Hole Wizard 1) Under Feature select Hole Wizard 2) Specify the type of Hole 3) Specify Hole Position 4) Add threads 1 2 3 4 RETURN TO START PAGE Shells • Removes Volume • Thin Wall Created RETURN TO START PAGE Sweep Pathways can be combined with a 2D profile, such as a circle, to create what is known as a sweep Mirror complex features to save time RETURN TO START PAGE Loft The same shape but different sizes can be used Lofting is taking two profiles on separated planes and filling the space between with material that blends the original profiles Loft Different shapes can be blended into one solid such as the hexagon is connected to the circles of different sizes Circular patterns, fillets, and appearances can also be added RETURN TO START PAGE Advanced Concepts Wrap Up Time Saving Methods Reference Geometry • Planes/Axes/Points Mirroring Linear Patterns • One or two directions OPTIONAL: SolidWorks tutorials Lofts Pattern Features Revolves and Sweeps Found under the Building Models tab of the SolidWorks tutorials Circular Patterns Advanced Shapes Sweep Loft RETURN TO START PAGE