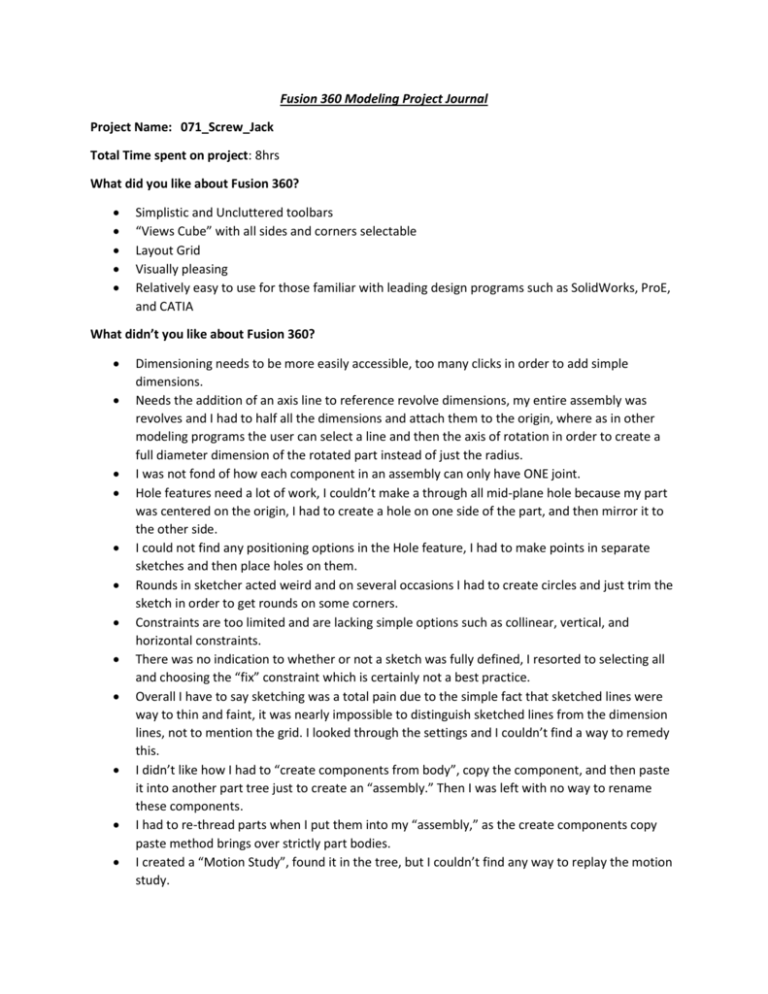

Fusion 360 Modeling Project Journal

advertisement

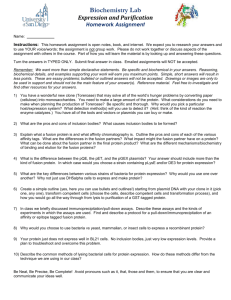

Fusion 360 Modeling Project Journal Project Name: 071_Screw_Jack Total Time spent on project: 8hrs What did you like about Fusion 360? Simplistic and Uncluttered toolbars “Views Cube” with all sides and corners selectable Layout Grid Visually pleasing Relatively easy to use for those familiar with leading design programs such as SolidWorks, ProE, and CATIA What didn’t you like about Fusion 360? Dimensioning needs to be more easily accessible, too many clicks in order to add simple dimensions. Needs the addition of an axis line to reference revolve dimensions, my entire assembly was revolves and I had to half all the dimensions and attach them to the origin, where as in other modeling programs the user can select a line and then the axis of rotation in order to create a full diameter dimension of the rotated part instead of just the radius. I was not fond of how each component in an assembly can only have ONE joint. Hole features need a lot of work, I couldn’t make a through all mid-plane hole because my part was centered on the origin, I had to create a hole on one side of the part, and then mirror it to the other side. I could not find any positioning options in the Hole feature, I had to make points in separate sketches and then place holes on them. Rounds in sketcher acted weird and on several occasions I had to create circles and just trim the sketch in order to get rounds on some corners. Constraints are too limited and are lacking simple options such as collinear, vertical, and horizontal constraints. There was no indication to whether or not a sketch was fully defined, I resorted to selecting all and choosing the “fix” constraint which is certainly not a best practice. Overall I have to say sketching was a total pain due to the simple fact that sketched lines were way to thin and faint, it was nearly impossible to distinguish sketched lines from the dimension lines, not to mention the grid. I looked through the settings and I couldn’t find a way to remedy this. I didn’t like how I had to “create components from body”, copy the component, and then paste it into another part tree just to create an “assembly.” Then I was left with no way to rename these components. I had to re-thread parts when I put them into my “assembly,” as the create components copy paste method brings over strictly part bodies. I created a “Motion Study”, found it in the tree, but I couldn’t find any way to replay the motion study. Additional Comments: For the most part, I think Fusion 360 is a good modeling program and it certainly has promise. I think it definitely needs some work though. I did everything I could to avoid using hole features as they were completely lacking in options and needed external positioning. Sketching would have been fine if it weren’t for the awful line coloring and boldness which made it difficult to distinguish sketched lines from grids from dimensions. Ultimately I just didn’t understand what the point of all the component copying and pasting was all about. Every other modeling program has an Assembly file type, where you add in finished parts and assemble them. I especially liked the overall layout of the program, instead of a plethora of tabs, toolbars, and options, Fusion 360 had one toolbar with dropdown menus that allowed me to easily find what I needed without an overwhelming amount of features.