Add title - City of Buffalo

advertisement

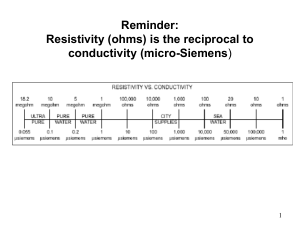

An In House – Phased Approach for Final Clarifier Rehabilitation “Providing a high level of sanitary benefits to the communities we serve.” Angel Rivera Superintendent of Mechanical Maintenance “Providing a high level of sanitary benefits to the communities we serve.” History of the Buffalo Sewer Authority When Buffalo was established as a village, all waste was disposed in adjacent bodies of water. In the 1890’s, health officials agreed that the pollution to the adjacent bodies of water was responsible for many diseases, most notably, typhoid. “Providing a high level of sanitary benefits to the communities we serve.” Slide 3 Because of persistent pollution on the Niagara River, Canada and the US entered into a treaty in 1909 to protect boundary waters. History of the Buffalo Sewer Authority “Providing a high level of sanitary benefits to the communities we serve.” Slide 4 Bird Island prior to the construction of the WWTP History of the Buffalo Sewer Authority In 1935, the New York State Department of Health mandated the City of Buffalo to stop polluting the Niagara River with waste. Because the city was in financial turmoil at the time, a new authority was created – the Buffalo Sewer Authority. By 1938, the Authority completed its system of intercepting sewers, and built its primary treatment plant on Bird Island where all city sewage was treated. This start of the art Primary Sewage Treatment Plant: Removed and incinerated all solid matter. Chlorinated all liquid matter prior to discharging into the Niagara River Slide 5 “Providing a high level of sanitary benefits to the communities we serve.” History of the Buffalo Sewer Authority “Providing a high level of sanitary benefits to the communities we serve.” Slide 6 Bird Island Primary Treatment Plant in 1938 History of the Buffalo Sewer Authority With the increasing national awareness of the need to more fully protect our water resources, the State in 1966 directed further improvement of our facilities by providing secondary treatment. With the help of federal and state grants, secondary treatment facilities were constructed and placed in service by 1981. Continual process improvements and upgrades Examples of Major Capital Improvements since 1981 Fine Bubble Diffuser and Blower Re-rating Project WWTP SCADA System New Grit Removal & Disposal System “Providing a high level of sanitary benefits to the communities we serve.” Slide 7 Sludge Dewatering Centrifuge History of the Buffalo Sewer Authority “Providing a high level of sanitary benefits to the communities we serve.” Slide 8 Bird Island Primary Treatment Plant 1980’s & 90’s Angel Rivera Superintendent of Mechanical Maintenance Supervise and coordinate all activities of the Maintenance Department at the Buffalo Sewer Authority’s Bird Island Wastewater Treatment Plant (WWTP). Responsible for the upkeep and repair of all equipment, utilities, buildings and grounds at the WWTP and eleven (11) Remote Pumping & Metering Stations. Implemented capital projects totaling over $8 million in a 6 year period, including: Installation of sludge withdrawal equipment on 16 clarifiers, $2.2 million project. Cleaning of two large (1 million gallon) anaerobic digesters, $1.7 million project. Rehabilitation of South Buffalo Pumping Station, $1.5 million project. Annual Rehabilitation of 3 WWTP Incinerators, $1.2 million in total projects. Rehabilitation of motors and impellers on three 3000/5000 HP blowers, $900,000 project. Rehabilitation of 2-550 HP RWWP and 2-1850 HP SWWP Pumps $300,000 Rehabilitation of Substation and Switchgear, $150,000 in total projects. “Providing a high level of sanitary benefits to the communities we serve.” Slide 9 Re-tubing of Natural and Digester Gas Fired Boilers, $150,000 project. Final Clarifiers What’s Their Purpose Improve Effluent Quality Provide a means for solids and floatables to separate from the forward flow and be collected Main Components Method of Settled Solids Removal Inlet Arrangements Method of Scum Removal Drive Units Slide 10 “Providing a high level of sanitary benefits to the communities we serve.” Final Clarifiers at the Bird Island WWTP- 2001 Quantity: 16 Diameter: 130 feet Depth: 12’ @ Side-Wall, 12.5’ @ Tank Center Total Average Design Flow: 180 mgd Total Peak Design Flow: 360 mgd Type Design: Riser Pipe OEM: FMC (US Filter / Siemens Water Technology) “Providing a high level of sanitary benefits to the communities we serve.” Slide 11 Approximate Age: 25 Years (Installed in 1975). Final Clarifiers at the Bird Island WWTP Slide 12 “Providing a high level of sanitary benefits to the communities we serve.” Final Clarifiers at the Bird Island WWTP Slide 13 “Providing a high level of sanitary benefits to the communities we serve.” Rise Pipe Pier Supported Type Clarifier Diameters larger than 30 feet Slide 14 “Providing a high level of sanitary benefits to the communities we serve.” Riser Pipe Clarifier Sludge Withdrawal Flow Slide 15 “Providing a high level of sanitary benefits to the communities we serve.” Riser Pipe Clarifier Sludge Control Box Riser Pipe Control Slide 16 “Providing a high level of sanitary benefits to the communities we serve.” Final Clarifiers at the Bird Island WWTP Slide 17 “Providing a high level of sanitary benefits to the communities we serve.” Existing Peripheral Feed & Overflow Influent Flow Sludge Box Effluent Wastewater Flow “Providing a high level of sanitary benefits to the communities we serve.” Slide 18 Sludge to Center Drain Existing Peripheral Feed & Overflow Influent Flow Effluent Flow Slide 19 “Providing a high level of sanitary benefits to the communities we serve.” Final Clarifiers at the Bird Island WWTP 1998 Field Evaluation of Secondary Clarifiers By John Esler, P.E. Conclusion: Moderate short circuiting up to a flow of 11 mgd High sludge blankets and direct short circuiting at higher flows At all flow rates, high degree of rotational stirring, creating instability at the tank periphery and retarding the inward current Recommendations: Reduce rotational rate. Reconfigure sludge pipes to lay horizontal on collector frame. Replace variable sized return sludge tubes. “Providing a high level of sanitary benefits to the communities we serve.” Slide 20 Control individual sludge tube flow in center RAS box with new control valves (“twist turn orifice terminals”). Final Clarifiers at the Bird Island WWTP Drive Unit 24 minutes per revolution Pipes Create Wall Effect Mass Rotation Sludge Box Flow Control One of five pipes plugged At least 20% floor not picked up Slide 21 “Providing a high level of sanitary benefits to the communities we serve.” Final Clarifier Rehabilitation December 2001 December 2001 Final Clarifiers 7B & 8B Out of Service Due to Drive Failures and Structural Misalignment. The Structural Integrity of Truss Arms, Center Cage and Center Pier on both units are in question. Treatment Plant Maintenance unable to repair units utilizing available parts, supplies and equipment. US Filter (FMC) brought on site to inspect the condition of the remaining 14 tanks. Drives on 7 of the remaining 14 tanks in determined to be “marginal” condition (Replacement gap setting >0.375”). Slide 22 “Providing a high level of sanitary benefits to the communities we serve.” Final Clarifier Rehabilitation December 2001 Slide 23 “Providing a high level of sanitary benefits to the communities we serve.” Final Clarifier Rehabilitation December 2001 Slide 24 “Providing a high level of sanitary benefits to the communities we serve.” Final Clarifier Rehabilitation December 2001 Slide 25 “Providing a high level of sanitary benefits to the communities we serve.” Final Clarifier Rehabilitation Repair of Final Clarifiers 7B & 8B – Choices? Replace existing drive unit. Inspect and repair all failed structural components. High Cost repair with no improvement in performance. No guarantee that remaining components will not fail in the near future. Reliability of remaining Final Clarifiers unknown. Continual high maintenance cost for existing Final Clarifiers Constant withdrawal tube plugging Repairing damaged to collector piping, boots, wipers and supports. Long draining and cleaning time. Slide 26 “Providing a high level of sanitary benefits to the communities we serve.” Proposed Repairs to Final Clarifiers 7B & 8B Use crane to remove bridge & Railing Separate arms from center cage. Inspect and repair structural damage. Use crane to remove and replace Center Drive Unit Inspect and repair: Center Pier, Sludge Box and Center Cage. Repair or replace all damaged piping, boots, wiper blades, piping support. Slide 27 “Providing a high level of sanitary benefits to the communities we serve.” Proposed Repairs to Final Clarifiers 7B & 8B Re-attach and rebalance arms. Adjust and level rotating plane. Slide 28 “Providing a high level of sanitary benefits to the communities we serve.” Final Clarifier Rehabilitation December 2001 - Meet with US Filter rep to discuss purchase of new Sludge Withdrawal Equipment. Presented with a proposal for two new Tow-Bro Header Sludge Withdrawal mechanisms, including: Unitube sludge removal headers and supports H40Ht Drive Unit w/ Reducer, Motor and Overload Drive Platform Center Pier Skimmer Assembly Associated Bolts and Anchors “Providing a high level of sanitary benefits to the communities we serve.” Slide 29 Structural Steel Hot Dip Galvanized Tow-bro Clarifier Design Slide 30 “Providing a high level of sanitary benefits to the communities we serve.” Tow-bro History and Development Tow-bro developed in 1920’s by Darwin Townsend and James Brower. Envirex, as Rex Chain Belt, installed the first Tow-Bro in 1929. Refinements to design resulted in Unitube header developed in 1955 by Envirex To date over 2500 Tow-Bro clarifiers installed. Slide 31 “Providing a high level of sanitary benefits to the communities we serve.” Tow-Bro Header Peripheral Feed & Overflow Slide 32 “Providing a high level of sanitary benefits to the communities we serve.” Tow-Bro Header Drive Unit 33.3 minutes per revolution Unitube Header with 23 Withdrawal Points 21” x 21” Manifold Inlet Approximate 2’ Horizontal Profile Slide 33 “Providing a high level of sanitary benefits to the communities we serve.” Exiting Riser Pipe Final Clarifiers Drive Unit 24 minutes per revolution Sludge Box Largest Inlet Pipe 8” Only 5 Withdrawal Pipes, Horizontal Pipe Arrangement Approximate 5’ Horizontal Profile “Providing a high level of sanitary benefits to the communities we serve.” Slide 34 Sludge to Center Drain Existing Peripheral Feed & Overflow Influent Flow Effluent Flow Slide 35 “Providing a high level of sanitary benefits to the communities we serve.” Existing Peripheral Feed & Overflow Influent Effluent Flow Flow Sludge Box “Providing a high level of sanitary benefits to the communities we serve.” Slide 36 Sludge to Center Drain Tow Bro H-drive Slide 37 “Providing a high level of sanitary benefits to the communities we serve.” Tow-Bro Strip Liner Drive Unit Slide 38 “Providing a high level of sanitary benefits to the communities we serve.” Riser-pipe Ball Race Bearing Felt Bearing Race Cover 4 pt. Ball Bearing “Providing a high level of sanitary benefits to the communities we serve.” Slide 39 Oil Bath Circular Clarifier Drive Units Bearing Arrangements Strip Liner Riser-Pipe Ball Race Bearing (4-Point) “Providing a high level of sanitary benefits to the communities we serve.” Slide 40 Tow-Bro H-Drive Bearing 4 Pt. Contact Tow-Bro H-Drive Bearing Arrangements Strip Liner Split Gear Field Inspection of bearing 38 to 42 Rc Can be rebuilt, in-place, in the field Low Cost, quick delivery Keeps working after failure Slide 41 “Providing a high level of sanitary benefits to the communities we serve.” Tow-Bro H-Drive Replaceable Strip Liner Replaceable Strip Liner Main Gear Slide 42 “Providing a high level of sanitary benefits to the communities we serve.” Tow-Bro H-Drive Replaceable Strip Liner • Main Gear Split for On Site Disassembly Slide 43 “Providing a high level of sanitary benefits to the communities we serve.” Riser-Pipe Ball Race Bearing 4 Point Contact Higher Hardness Higher Loads Factory Repair Only Requires Crane and Lifting of Bridge Locks up with Failure Slide 44 “Providing a high level of sanitary benefits to the communities we serve.” Circular Clarifier Drive Units Main Bearing Failures Condensate, water, produces oxidation, rust High carbon content of the balls, races oxidize very quickly Oxidation leads to surface pits Surface pits lead to stress risers Stress risers lead to critical shearing stress Broken balls Slide 45 “Providing a high level of sanitary benefits to the communities we serve.” Circular Clarifier Drive Units Main Bearing Arrangements Oil Lubricated “Water Lubricated” Slide 46 “Providing a high level of sanitary benefits to the communities we serve.” Passive Automatic Condensate Drain System The Drive is Equipped with piping that allows any Condensate that would otherwise accumulate in the main Drive Housing to drain out. The difference in Specify Gravity between water and lubricating oil used in drive is the principle upon the system functions. Note: Successful operation of the system depends upon the sequence of filling the drive housing initially and every time periodic maintenance is performed. “Providing a high level of sanitary benefits to the communities we serve.” Slide 47 Note: Heat Trace required for operation during periods of below freezing temperature. Passive Automatic Condensate Drain System Slide 48 “Providing a high level of sanitary benefits to the communities we serve.” Main Tank Skimmer Assembly Scum Blade Length From Center to Side of Tank Slide 49 “Providing a high level of sanitary benefits to the communities we serve.” Main Tank Skimmer Assembly Slide 50 “Providing a high level of sanitary benefits to the communities we serve.” Tow-Bro Benefits for Final Clarifiers 7B & 8 B New drive, collector, and structural components. Reduced rotational rate, less stirring of the FC tank. Lower header profile. Increased number of withdrawal points, reducing the effect of plugging. Removal of Sludge Box Passive Automatic Condensate Drain System “Providing a high level of sanitary benefits to the communities we serve.” Slide 51 Downside - Real World Performance at BSA Unknown? Final Clarifier Rehabilitation – December 2001 Final Clarifiers 7B and 8B Out of Service and Cleaned by Maintenance for Repairs by 12/4/01. Maintenance begins initial repairs to both tanks. Discovers structural damage to drive unit, truss arms, center cage and sludge box. Contact US Filter for preliminary budgeting information regarding the replacement Drive Units. Request on-site inspection and evaluation of remaining 14 FC tanks. US Filter on site on 12/10/01 for tank inspection. US Filter submits proposal for Tow-Bro equipment Slide 52 “Providing a high level of sanitary benefits to the communities we serve.” Final Clarifier Rehabilitation – Dec 2001 to Jan 2001 Maintenance Department reviews and evaluates proposed equipment. Contacts references and validates past performance claims. Maintenance Department works with Process Department to determine design flows. Maintenance Department presents findings to BSA management (General Manager, Financial Officer, Plant Manager). BSA management agrees with finding and BSA Board is polled for approval. January 9, 2002 - BSA Board Approvals purchase of Tow-Bro Headers for a not to exceed price of $195,000.00 Slide 53 “Providing a high level of sanitary benefits to the communities we serve.” Final Clarifier Rehabilitation – Jan 2001 to Feb 2001 Maintenance Department develops final purchase specifications. January 4, 2002 – Maintenance submits purchase specs for design of new Tow-Bro system. January 25, 2002 – Maintenance Department reviews and approves arrangement plan and elevations for 2 new Tow-Bro Sludge Collectors January 29, 2002 – US Filter releases the design for fabrication. February 5, 2002 – Meet with Mechanical Maintenance Contractor Quackenbush (Q Co.) to review installation requirements for 2 new Tow-Bro Sludge Collectors Slide 54 “Providing a high level of sanitary benefits to the communities we serve.” Final Clarifier Rehabilitation – Feb 2001 to March 2001 February 18 2002 – Q. Co. submits proposal for Tow-Bro installation under the terms of the existing Maintenance Contract. Proposal reviewed by maintenance and submitted to BSA Management for approval. Approximate cost for installation of Tow-Bro equipment on both tanks $70,000. February 27, 2002 – BSA Board approves Q. Co, proposal for a not to exceed cost of $70,000. March 4, 2002 – US Filter begins shipping Tow-Bro components “Providing a high level of sanitary benefits to the communities we serve.” Slide 55 March 18, 2002 – Q. Co mobilizes on-site and begin receiving major Tow-Bro components (Trusses, Headers, Drive Unit) Final Clarifier Rehabilitation – March 2001 to July 2001 March 22, 2002 – Last major Tow-Bro components ships from US Filter fabrication shop. March 22, 2002 to May 24, 2002 – Q. Co proceeds with installation of Tow-Bro equipment in Tanks 7B & 8B. Maintenance Department supervises and inspects all work by contractor. May 27, 2002 – US Filter and Maintenance Department complete the start-up and testing of completed units. Both units on-line by first week in June. June 2002 to July 2002 – Both units in service with Plant Operations. July 24, 2002 – Performance Testing by CPE Services begins. Slide 56 “Providing a high level of sanitary benefits to the communities we serve.” Final Clarifier Rehabilitation – Construction Photos Slide 57 “Providing a high level of sanitary benefits to the communities we serve.” Final Clarifier Rehabilitation – Construction Photos Slide 58 “Providing a high level of sanitary benefits to the communities we serve.” Final Clarifier Rehabilitation – Construction Photos Slide 59 “Providing a high level of sanitary benefits to the communities we serve.” Final Clarifier Rehabilitation – Construction Photos Slide 60 “Providing a high level of sanitary benefits to the communities we serve.” Final Clarifier Rehabilitation – Construction Photos Slide 61 “Providing a high level of sanitary benefits to the communities we serve.” Final Clarifier Rehabilitation – Construction Photos Slide 62 “Providing a high level of sanitary benefits to the communities we serve.” Field Verification Study - Goals July 2002, CPE Service Inc. (John Elser, P.E.) hired to Study performance of new Tow-Bro verse existing Riser-Pipe Field investigation designed to a accomplish the following: Develop flow curves and determine detention times Determine location and intensity of major currents using velocity profile test and full-depth solids profiles. Determine Theoretical solids loading capacity of each clarifier using solids flux / state point analysis Characterize the relative performance of the two clarifiers. Slide 63 “Providing a high level of sanitary benefits to the communities we serve.” Field Verification Study – Conclusions Tow-Bro clarifier develop the inward flow pattern that is desirable for peripheral feed / peripheral overflow clarifier. Tow-Bro clarifier maintained a lower blanket further assisting the inward flow pattern. Tow Bro better controlled sludge blanket as flow rates varied. Tow-Bro was able to operate at significantly higher flow rate that the existing Rise-Pipe. Two-Bro able to maintain a more concentrated return activated sludge flow that existing Rise-Pipe. Slide 64 “Providing a high level of sanitary benefits to the communities we serve.” Phased Approach for Final Clarifier Rehabilitation Based on documented performance of the new Tow-Bro system the BSA’s management developed a phased approach to rehabilitating the remaining 14 final clarifiers. A preliminary plan calling for the rehabilitation of the remaining clarifiers at a rate of four clarifiers per year was submitted as part of the BSA’s Annual Capital Improvement Plan. Equipment purchase and installation funded annually based on savings and rollover of operating funds from previous budget years. Tow-Bro equipment purchased by Maintenance directly from the manufacture US Filter as funding became available. All purchase specification developed by Maintenance Department without the use of outside consultants Slide 65 “Providing a high level of sanitary benefits to the communities we serve.” Phased Approach for Final Clarifier Rehabilitation Installation contract developed by and bid annually by the BSA Maintenance and Engineering Departments. Contract installation requirements developed by Maintenance Department without use of outside consultants. All contract equipment, supplies and labor inspected directly by Maintenance Department. Rehabilitation of tanks based on severity of existing tank conditions (i.e. Worst Tanks First). Installation contract revised annually, prior to bidding, to address problems encountered in previous years contract (i.e. Change Orders, Contract Clarifications, Etc) Slide 66 “Providing a high level of sanitary benefits to the communities we serve.” Phased Approach for Final Clarifier Rehabilitation Start Year Final Clarifiers Purchase Cost 2002 7B, 8B Installation Cost Total Project Cost Per Unit Cost $195,000 $74,463 $269,463 $134,731 2003 3A,4A,4B,6B 1 $334,688 $142,320 $477,008 $119,252 2004 2A,7A,8A,1B 1 $334,688 3 $151,200 $485,888 $121,472 2005 1A,5A,2B,5B 2 $387,834 3 $151,800 $539,634 $134,909 2006 6A,1B 2 $194,000 4 $261,790 $455,790 $227,895 Cost to Date $1,446,210 $781,572 $2,227,782 $139,236 “Providing a high level of sanitary benefits to the communities we serve.” Slide 67 Footnotes: 1. Equipment price held for 2 years at $83,667 per FC. 2. Price increase to $97,000 per FC due to escalating Steel Price. 3. Installation Completed without Change Orders. 4. First project to include Weir Wall Rehabilitation Phased Approach for Final Clarifier Rehabilitation Installation Contract revision include the following activities: Material Disposal Electrical Connections Floor leveling and concrete breakouts Scum trough piping. Weir Plate Adjustment Weir Plate Pipe Support Replacement Sandblasting and Painting of all Metal Surfaces in Final Effluent Tank. Slide 68 “Providing a high level of sanitary benefits to the communities we serve.” Phased Approach for Final Clarifier Rehabilitation – Photos “Providing a high level of sanitary benefits to the communities we serve.” Slide 69 Upper Weir Wall Supports Phased Approach for Final Clarifier Rehabilitation – Photos “Providing a high level of sanitary benefits to the communities we serve.” Slide 70 Lower Weir Wall Supports (under skirt) Phased Approach for Final Clarifier Rehabilitation – Photos “Providing a high level of sanitary benefits to the communities we serve.” Slide 71 Rehabilitated Upper Weir Wall Supports Phased Approach for Final Clarifier Rehabilitation – Photos “Providing a high level of sanitary benefits to the communities we serve.” Slide 72 Rehabilitated Weir Wall Phased Approach for Final Clarifier Rehabilitation – Photos “Providing a high level of sanitary benefits to the communities we serve.” Slide 73 Rehabilitated Lower Weir Wall Supports (under skirt) Phased Approach for Final Clarifier Rehabilitation Next Phase – Weir and Tank Rehabilitation. Activities that may be included are the following: Weir Plate Adjustment Weir Plate Pipe Supports – both above and bellow Weir Skirt Sandblasting and painting of all metal surfaces. Final Clarifier Floor Coating (re-lining). Repositioning of Inlet Channel flow holes Raising of inlet channel wall to increase peak influent flow Continue rehabilitation rate of 4 tanks per year. “Providing a high level of sanitary benefits to the communities we serve.” Slide 74 Completion of all final tanks project to be completed by 2010 Special Thanks to the following: James Skrabacz – Maintenance Department Roberta Gaiek P.E., Jane Ork – Process Department Sal LoTempio (Ret.), James Keller – WWTP Superintendent Frank DiMascio P.E., Joe Baudo (Ret.), Jim Eagan – BSA Engineering David Comerford – BSA General Manager Herbert Bellamy - Buffalo Sewer Authority Board Chairman US Filter / Siemens Water Technology “Providing a high level of sanitary benefits to the communities we serve.” Angel Rivera Superintendent of Mechanical Maintenance Thank you very much for your attention. Buffalo Sewer Authority 90 West Ferry St. Buffalo, NY 14213-1799 Office: (716) 883-1820 ext 217 Fax: (716) 883-4922 E-Mail: arivera@sa.ci.buffalo.ny.us “Providing a high level of sanitary benefits to the communities we serve.”