Nutrient Best Management Practices for Water Quality

advertisement

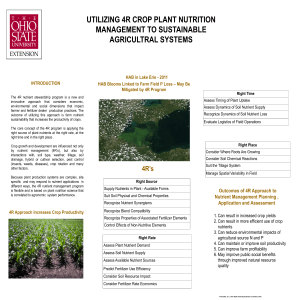

Nutrient Best Management Practices for Water Quality Protection (Focused on Small Landholders & Limited Resource Farmers) Training and Discussion Session IWC-7 October 31, 2013 Tom Simpson and Ron Korcak Water Stewardship Annapolis, Maryland, USA E-mail: toms@waterstewardshipinc.org ronk@waterstewardshipinc.org 1 Funded as part of the Global Program for Nutrient Management (GPNM) under the leadership of UNEP This project is a sub-project funded by, and part of, the overall UNEP GPNM coordination programme, led by the Global Environmental Technology Foundation 2 Excess Nitrogen and Phosphorus: 1) N and P: Stimulate algal growth, consumes O2 that degrades riverine and coastal habitats 2) Drinking water contamination (Nitrate-groundwater and phosphorus-lakes/reservoirs) Degraded underwater grasses: Impaired clarity in shallows Fish kills : Low oxygen 3 This discussion will focus on BMP systems specific to three GPNM “hot spot” areas • Chilika Lake (Lagoon), India • Kagera River Catchment (Lake Victoria Basin) • Manila Bay, The Philippines (not just Ag) • Focus: Small Landholders/Limited Resource Farmers (SL-LRF) Kagera River Catchment Farms adjacent to Chilika Lake 4 Managing Agricultural Nutrients for Water Quality: • Strong multi-disciplinary science and engineering team • Includes economist and social and policy scientists • Local input and knowledge tailored to local systems The Participatory Approach in Manila Bay Experience from SL-LRFs focused projects, suggests that an engaged, participatory approach is necessary for success with these farmers and communities. The SANREM CRSP Project in the Manila Bay area of the Philippines concluded that: “The Participatory Approach uses the premise that one does not come to the community with a solution to the problem when farmers do not know they have a problem in the first place, and that farmers are part of the solution.” 5 Most current practices and BMPs were developed for large, intensive agricultural systems but this work is focused on BMP implementation by Small Landholders/Limited Resource Farmers • Small Landholder: usually farms < 5 ha • Limited Resource Farmer: Economic limitation on purchased inputs (e.g. fertilizer), equipment and/or technology • Frequently suboptimal productivity/ yields and/or net revenues due to limited resources and size • Trying to move “SL-LRF” up the yield and income curve with reduced or minimal impacts on water quality Kagera River Basin 6 Farm and Field Scale Nutrient (and Sediment) BMPs We will discuss the 4Rs, being widely promoted for fertilizer use, as relevant to SL-LRFs but will first propose: The 4As for BMP implementation for SL and LRF • • • • Applicability Adaptability Affordability Acceptability The 4As interact with and affect each other. 7 The 4As - Applicability • Is BMP applicable to crops or animals produced, soils, climate? • Do scale, resources, technology and/or management capacity limit applicability? – If so can BMP be adapted to overcome limitations? – Is there a role for multi-SL farmer collaborative enterprises to overcome scale or technology constraints while gaining economic benefits? 8 The 4As- Adaptability • Certain practices require land retirement and are not suited to a SL farm (e.g. buffers) – Multi-SF collaborative enterprise could help, if acceptable • Must be adapted to fit within management and technology constraints • If adapted for SL-LRFs, is effectiveness of BMP different? Can we estimate the difference? • Can adaptation enhance affordability and/or acceptability (or harm it)? 9 The 4As- Affordability • For SL-LRF, cannot afford to implement BMPs with substantial cost to them, so: 1. Promote BMPs that have positive impact on income? 2. Is it cost neutral or very low cost? 3. Can it be adapted so it is income positive or low/no cost? • Could government, NGO or supply chain provide costshare or incentives to make it more affordable? • If reducing impairment to water, can a “Payment for Ecosystem Services” system be established with annual payments for providing a public service? 10 The 4As: Acceptability • Are there cultural/social/peer barriers to acceptability? • Can it be adapted to minimize land/production loss? • How can it be adapted to be more acceptable? • Can “affordability’ incentives make it acceptable? • Can it include desirable collateral benefits? 11 ~6 meter plum tree lined mini-buffer along ~7 km of degraded stream In the Western Ukraine Collateral benefits: 1) Future “flash” grazing of Cows on rope leads. 2) Plums for fruit and vodka. 12 Eight Primary BMPs • • • • • • • • Nutrient Management Ecological/Organic Production Systems Erosion Control/Conservation Tillage Grazing Management Cover Crops Manure Management Riparian Buffers Wetland Restoration/Treatment Systems - Not all BMPs will be applicable, efficient or needed on all farms/regions - Other BMPs may be equal/more important in specific cases - Apply BMPs systematically for greatest effect and to “back-up” each other 13 Applying a Systems Approach to Agricultural Nutrient Pollution Control Industrial Pollution Control Systems Approach Pollution Prevention Process Management Facility Management On-site Treatment Off-site Remediation Agricultural Nutrient Pollution Control Systems Approach Nutrient Balancing Nutrient Use Efficiency Field Management In-field Treatment Edge of Field Management Examples of Agricultural Nutrient Pollution Control System Practices Conservation Feed Riparian Nutrient Tillage Cover Crops Management Buffers Management Limit Cattle Soil P Nutrient rate Access to Wetland Precision Ag Remediation reduction Waterways Treatment 14 T Simpson, 2008 A “Nested Landscape Systems Approach" to BMPs for nutrient and sediment pollution control In the Lake Chilika Basin in India: • Begin with field level systems • Build the system throughout all aspects of the farm • Link individual farm systems together to assure multi-farm and enterprise systems approach to water quality protection • Link farms and multi-farm enterprise systems into a catchment wide system approach to achieve a water quality based goal • Consider and link broader ecological, governance, and policy systems in which the agro-environmental systems are nested. Whole farm/enterprise/catchment systems approach allows many small actions to add up to major nutrient reductions 15 Field scale: Nutrient management The 4Rs: Concept developed and promoted by the International Plant Nutrition Institute • Match nutrient supply with crop requirements and to minimize nutrient losses from fields • The 4Rs of fertilizer BMP emphasize: – the Right rate – the Right source – the Right time – the Right place Designed for intensive, high input, high yield agriculture but can be adapted to SL-LRFs The 4Rs and Small Landholders – Limited Resource Farmers • Right source may be limited to manures, legumes, sanitary wastes and inorganic materials they can access and afford • Right rate must be based on all yield constraints and will likely be below max yields due to nutrient input and other constraints • Right placement may allow SL-LRF to increase efficiency by manual placement for efficient plant use – manual placement could achieve this better than mechanized (w/training) • Right timing may allow SL-LRF to increase efficiency by applying small amounts at key times based on plant needs 17 Soil Fertility and Yield Response Principle of limiting factor (critical concept for SL-LRF): Production can be no greater than allowed by the most limiting plant growth/yield factor. – Apply balanced fertilizer levels based on limiting yield factor – Do not apply N or P for yields above those possible by other limiting factors (nutrients, soil, climate or management) – Soil testing recommendations based on realistic yield history or expectations (can this service be provided to SL-LRFs?) Barrel A: Nitrogen limited Barrel B: Potassium limited 18 Maximum profit per hectare vs. maximum ROI Maximum Profit • The last $1 of input just gives you $1.01 back - maximum profit but low use efficiency as approach max yield - high loss potential 100 90 $ Crop Response 80 70 60 50 40 30 20 10 0 5 10 15 20 25 30 35 40 45 50 55 $ Cost for Nutrients Max Return on Investment Provides the most yield return per kg of nutrient added (purchased or farm generated – high use efficiency – low loss) 19 (Adapted from Beegle, PSU) What is the right rate for SL-LRF? Recommended for Maximum Economic Yield Insurance application? 200 Grain Yield (Mg/ha) 8 SL-LRF in practice? Small return 6 150 Large return 4 2 Large N loss 100 Low-Moderate N loss 50 100 50 150 200 Fertilizer-N applied (kg/ha) Fertilizer N not recovered (kg/ha) High ROI Ecological optimum? 250 20 Graph only, adapted from US NRC, 1993 The Right Rate: Phosphorus • Use of manure as primary nutrient source usually results in soil P levels above crop needs over time • If soil P is high from past manure use, “mine” it down to soil test recommended levels w/o further P application or yield impact • Rotate manure use to build up soil P levels • Best choice is manage P at agronomic (crop need) levels based on soil test recommendations and realistic yield expectations • For many SL/LRFs, reaching agronomic P levels is challenging 21 Right Time: Nitrogen (Graph is for Northern Hemisphere temperate climate) Try to match N availability for crop to peak crop N needs Corn N uptake vs. growth stage SL-LRF applies a little at planting and 1 or 2 small applications at V-10 through tassle (at V-10 for manures) 22 Source: Soil and Water Conservation Unit, USDA The Right Place – Field Scale P Phosphorus Placement • Broadcasting - Builds up soil P levels uniformly over field - Contact with most of soil so high fixation • Banding - Maximize soil contact by incorporating - Place near roots – P does not move to roots, roots must grow to the P - Reduces amount needed for target yield • Combination often the best - Broadcast to build up the soil P - Band for better immediate efficiency - For SL-LRF, manure incorporated pre-plant in row area may be “hybrid” combination 23 (Beegle, PSU) Adapting the 4Rs: “Micro-dosing” • In Lake Victoria watershed and Chilika Lake, India – application of small amounts of fertilizer with seed at planting resulted in yield increases – could be organic or inorganic source or combination (integrated sources) • Not applying full amount at planting with small applications one to two more times at critical growth stages, incorporated near plant, can increase yield with same amount of N or P – Small land base may make this feasible – Manual/low technology application may allow mid-season applications at critical crop need periods (e.g. pre-tassle to early “milk” stages for maize) – Availability of labor for SL-LRF may help enable this 24 Nutrient Management – Take Home Message • Fundamental BAP – “Balancing the soil and the crop” • Goal is most efficient use of nutrients – follow the 4R’s but adapt them for SL-LRFs • Develop soil testing protocol & incentive program • Ecological Optimum Yield as target yield for SL-LRF (?) • Some decision support tools exist to support NM decision making SL-LRFs but unclear if water quality is considered. • “Breaking News”: On 25 Oct, IPNI announced release of computer based “Nutrient Expert” software to help small landholders in parts of rural China make nutrient application decisions to maximize yield and profit recognizing resource constraints and not requiring soil test. Water quality considerations in the tool were not discussed in press release. 25 Farm Scale: Ecological/Organic Production Systems: Manure and Legume Management Organic approaches: Manure as a fertilizer • Fertilizer NPK + Micronutrients • Added Organic Matter – – – – – Water Holding Capacity Infiltration Rate Cation Exchange Capacity Aggregate Stability Bulk Density – Improved soil quality! 26 Using manure as primary nutrient source requires long-term planning • Organic sources can improve soil quality but must carefully time and manage applications to allow organic nutrient release while minimizing loss in runoff • Long term manure application based on crop N needs will increase risks of P losses (Manure P:N ratio crop P:N needs) 27 Organic Approaches: Legumes for N inputs • Properly inoculated legumes meet their N requirement by fixing atmospheric N. • Significant N remains in residue from legume when crops are rotated. • Legumes can supply all N needed for following crop. 28 (Beegle, PSU) 3 Mean N2O Emissions residue retained resdiue retained, decreased N fertilizer wheat or corn residue removed -1 kg N ha yr -1 Cropping systems impact on N and P losses: 2 (Rotations Matter!) 1 Different cropping systems can trap residual soil nutrients and risks of nutrient loss and save nutrients for next crop 0 wheat -1 kg N ha yr -1 Grain following potatoes lowers N levels 45 40 35 30 25 20 15 10 5 0 corn/soy bean Mean NO3 Leached residue retained resdiue retained, decreased N fertilizer wheat or corn residue removed wheat (Adapted from: Delgado, J.A., R.R. Riggenbach, R.T. Sparks, M.A. Dillon, L.M. Kawanabe, and R.J. Ristau. corn corn corn/soy bean (Adapted from:Delgado, J.A., S. J. Del Grosso, and S. M. Ogle. 2010 29 Ecological/Organic Production Systems Take Home Message • Balancing N and P for expected yield makes appropriate use of manures and legumes critical in organic system • Eco-efficient agriculture adapts technologies from intensive agriculture and combines them with practices to reduce environmental impacts (including water quality) • Ecological-based adaptation (EBA) is new approach that can include water quality BMPs in an economically viable system that may provide greater revenue to SL-LRF 30 Farm and Field Scale: Erosion Control Conservation Tillage • Keep the soil covered, covered, covered! – Perennials – Cover crops – Crop residue • • • • Rotations with perennials help reduce erosion Farm on contour where scale allows Graze the most erosive lands but maintain good cover Plowing exposes soil, oxidizes organic matter and reduces soil quality; avoid or minimize 31 Whether crop residue or growing crop/grass/perennial, effect is the same 32 Conservation Agricultural Production Systems (CAPS) in the Manila Bay Catchment SL-LRF that are successful CAPS will: • • • • Maintain a year-round soil cover Minimize soil disturbance by tillage Utilize crop rotation systems “Promote conservation agriculture as a technologically-feasible, economically-viable, environmentally-sustainable, and genderresponsive production system that will contribute to food security of small farm communities in the Philippines.” CAPS can also include many of the other “Eight Priority Practices” and promote a “Systems Approach” as proposed in earlier slides. 33 Conservation Tillage & Erosion Control Take Home Message • Keep the soil covered as much as possible • Leave crop residues on soil surface • Use cover crops to keep soil covered when residue is harvested or inadequate • Include perennials in rotation and on erosive sites • Discontinue plowing and minimize soil disturbance • Create Incentive program for carbon sequestration for long-term commitment to perennials and/or residue management that increases soil organic carbon (?) 34 Field Management Practices: Cover crops: Cover crops capture residual N from prior crop to minimize leaching AND can be plowed into soil as N source for next crop or harvested for livestock feed 40 100 Sampled Dec. 1 80 30 Sufficiency Level 25 ppm 60 20 40 NO3-N (ppm) Total Accumulated N (lb/ac) Melnick Farm 2006 10 20 0 0 Sept. 8 Sept. 15 Sept. 22 Sept. 29 Oct. 6 Cover Crop Planting Date (planting dates for cool temperate climate) 35 (Herbert, UMASS) Legume cover crops • “Grow” N for next crop but not as effective at trapping residual N • Provides cover for erosion control • Non-legume and legume mixes show promise for fall trapping followed by spring N fixation – Working on mix where non-legume matures or is winter killed and releases N for next crop to supplement legume N 36 Cover Crops – Take Home Message • Reduces sediment loss & saves excess nutrients • Supports erosion control & nutrient management BMPs • Legumes provide cover but mixes may trap residual nutrients and supplement legume fixed N for next crop • Develop an incentive program and/or cost share for seed costs and establishment 37 Farm Scale: Manure management: Challenging, but critical, for SL-LRF • Small parcels close to neighbors & water resources – especially drinking water wells • May lack equipment & land for handling & recycling manure • Manure may contain wood products from bedding –could result in high C:N ratio unfavorable for subsequent crop – If high carbon, compost or let “age” 38 Solid manure storage • Keep away from drinking water wells, ponds, flood plains x • Covered facilities or stockpiles, where possible • Stack/stockpile in well-drained area for later application • Stockpile on flat area away from streams or swales 39 Composting for manure and sanitary sewage and solid waste management • Stabilizes N into slow release organic forms (~10% plant available N). Need to credit release over many years • Don’t over apply P • Compost can improve soil quality Water, CO2, Heat, Ammonia Organic matter C, N, H2O, other nutrients C:N ≈ 40:1 Organic matter O2 <C, N, <H2O, other nutrients Microorganisms C:N ≈ 15-20:1 Compost Pile 40 Covered compost bins: Raw uncovered compost can leak high nutrient loads into soil or water Turning the compost mix enhances aeration and creates stable compost faster (Manual turning, “roller bins” and “multi-stage” bins could all be used by SL-LRF) (Adapted from Westendorf, Rutgers Univ.) 41 Manure Management – Take Home Message • Optimize animal nutrition for both nitrogen and phosphorous - Incentive programs to optimize N & P in ration would provide high rate of return on investment • Proper collection/storage to maximize nutrient content is critical • Manure storage structures can be made scalable to community level • Learn from current incentive programs on manure/compost facilities • Provides nutrients for crop production (replace purchased fertilizers?) -Develop a manure nutrient testing program (?) * Can be an important part of an organic production system * Composting can be a viable option as part of manure and other biobased waste management 42 Field Scale: Pasture and Grazing Management • Restrict animal access to streams to control – Streambank erosion – Pathogen contamination – Direct inputs of nutrients • Fencing • Alternative water sources • Controlled grazing-good cover • Land loss and costs are challenges for SL-LRF • Incentives & cost-shared • are practices needed 43 Reduce direct access of animals to streams through the use of fencing, vegetated buffers, alternative water sources and off-stream shade Stop direct access to streams Alternative water sources can reduce livestock (Sciarappa and Obropta, 44 stream use by 50-90% Rutgers Univ.). Grazing Management –Take Home Message • Socio-Economic issues abound • Fencing cost • Loss of land for pasture with stream fencing • “Free range”, “commons” culture • Land degradation control and stream fencing/protection should be priorities for SL-LRF • Develop incentive and/or cost share program for fencing and alternate water sources • Deposited manure can be managed to help fertilize pasture 45 Landscape Scale: Buffers Stream buffers trap pollutants and protect stream banks 4 year old RFB 46 Dosskey, U.S. Forest Service Landscape-scale Multi-function Stream Buffer How applicable is this to SL-LRFs? Can mini-buffers be adapted for SL multi-farm collaborative and how effective will they be? Grass Forest Trap sediment and nutrients Vegetation Control erosion Function (Dosskey, U.S. Forest Service) 47 Reality for SL-LRFs is that they must “farm to the edge” and cannot afford to idle land. Either produce something of value in the buffer or develop multi-SL-LRF enterprises that allow strategic land retirement to increase buffer implementation. Photo from Kagera River Basin 48 Collateral benefit: Agro-forestry: Coupling water quality with biomass production in riparian buffers • Traditional Coppicing – sustainable understory tree “sprouts” regularly harvested – renewed interest in UK • Recent work with riparian tree plantations • rapid rotation and high biomass production for fuel, fencing, etc. Coppicing at Ast Wood Herefordshire, UK Remember the plum vodka mini-buffer? 49 Farm/Community Management: Treatment Wetlands • Requires “designed” flow/retention pattern and aerobic conditions before entering wetland (or last wetland cell) • Shallow < 0.8 m •> 4-10 day retention times Free water surface constructed wetland Risk Management Research U.S. EPA 625/R-00/008 UNEP-IETC. Eco-Sanitation Technologies Offer Natural Waste Treatment 50 1.0-2.0% of small catchment converted to wetland and 7-10 days detention is optimal but challenging Note: Curve numbers: 20=0.2%, 40=0.4%, etc. 51 Riparian Forest or Grass Buffers – Take Home Message • The first 10m of width is critical for nitrogen removal • Buffers have a low to moderate phosphorous removal efficiency • Requires conversion of arable land • Incentive programs to offset land conversion or; • Collaborative enterprise that “pools” land resources to allow buffer implementation (with incentives or other economic return) • Wetlands – “Offsite treatment” to remove nutrients and sediments • Reduces nutrient/sediment losses but requires land retirement • Could be used for stormwater & sewage treatment (pathogens?); • System of small wetlands that each treat small flow may work best 52 Observations and recommendations • Develop low cost applicable versions of the 8 priority BMPs and use in a systems approach for SL-LRFs – Standard BMPs may be hard to implement on small landholdings – May need research, demonstration and outreach to adapt “mini” versions of BMPs for SL-LRF – Based on our experience, outcome based projects will provide more consistent, implementable and transferable results • Emphasize outcome based reporting and web based information as products • External expert collaborator/advisor to help plan and implement for outcomes • If possible, adapt BMPs so SL-LRFs will adopt without subsidy or incentives (positive/neutral revenue or collateral benefits) • Cost share, incentives and payments for ecosystem services could accelerate adoption by SL-LRF 53 Applying BMP knowledge base to SL-LRFs • Science is the same but much current information developed for large scale, intensive systems and must be adapted for SL-LRFs • The 4Rs still apply but must be adapted to SL-LRFs and should be documented by field research/demonstrations – Non-nutrient factors often limit yield; limit apply nutrients to achieve realistic yield expectations – SL-LRS often farm degraded lands; increasing nutrient application without improving soil quality may not increase yields, but may increase losses • Small size of SL-LRFs limits implementation of BMPs like buffers, wetlands, contour tillage, etc. – Need economic incentives and/or to explore multi-SF-LRF collaborative enterprises to create larger management units. – Requires social and political engagement and willingness to develop such enterprises but may offer both economic and environmental benefits 54 TOP 4 SCALABLE PRACTICE FUNDING PRIORITIES • Crop nutrient management: • Nutrient management (adapted 4Rs) • Manure application management • Erosion control: • • • • Minimize soil disturbance Conservation tillage Perennials in rotation Grazing management • Cover crops: • Non-legumes (cereal grains, canola, etc.) to trap nutrients after primary crop • Legumes to “grow” Nitrogen for next crop • Legumes – non-legume mix to do both • Pasture management and stream fencing (including miniriparian buffers) 55 TOP FOUR INCENTIVE FUNDING PRIORITIES for SL-LRFs (preliminary list) • Collaborative enterprises: To share the burden of land conversions for buffers & wetlands • Novel cropping systems: On-farm demonstrations. Cost share seed and establishment cost • Mobile technologies: Crop and animal production support & information with associated water quality protection practices (apps, websites, tweets) • Feed management: On-farm demonstrations; Incentive payments based on kg N and P kept out of feed or manure Funding to adapt BMPs to facilitate SL-LRF adoption and to support/assure outcome based projects, with clear reporting expectations, may be as important as the incentives above. 56 AND REMEMBER THE 4As!!! • • • • Applicability Adaptability Affordability Acceptability 57 Acknowledgements This module was developed by Drs. Tom Simpson and Ron Korcak, Water Stewardship Inc, but it includes information compiled previously by Dr. Art Gold, Professor, University of Rhode Island Dr. Gold acknowledged the individuals below for contributing to his compilation (and we thank Dr. Gold and the scientists whose information was included above). Dr. T. Bauder, Colo. St. Univ Dr. D. Beegle, Penn. St. Univ. Dr. B. Costa Pierce, Univ. of RI Dr. H. Darby, Univ. of Vermont Dr. J. Delgado, USDA-ARS Dr. M. Dosskey, U.S. Forest Service K. Hagos, Univ. of RI G. Loomis, Univ. of RI L. Moody, 4R Nutrient Stewardship Dr. S. Oakley, Chico St. Univ. Dr. D. Osmond, N. Carolina St. Univ. Dr. B. Posadas, Miss. St. Univ. Dr. M. Risse, U. of Georgia Dr. W. Robertson, U. of Waterloo Dr. L. Schipper, U. of Waikato, NZ Dr. R. Schultz, Iowa St. Univ. Dr. R. Waskom, Colo. St. Univ. Dr. M. Westendorf, Rutgers Univ. Contact Dr. Tom Simpson at toms@waterstewardshipinc.org or by phone at +1-301-873-2268 58 59