UNDERGROUND INJECTION CONTROL (UIC) DAVID DILLON

advertisement

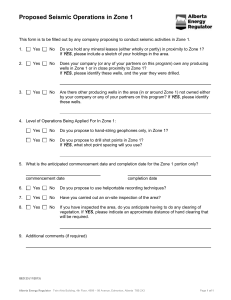

COLORADO OIL AND GAS CONSERVATION COMMISSION CLASS II UNDERGROUND INJECTION CONTROL RULES AND REGULATIONS Garfield County Energy Advisory Board Thursday, October 7, 2010 David Andrews, P.E., P.G. Western Colorado Engineering Supervisor FEDERAL UNDERGROUND INJECTION CONTROL (UIC) REGULATIONS • 40 CFR 144 – Underground Injection Control Program • 40 CFR 145 – State UIC Program Requirements • 40 CFR 146 – Underground Injection Control Program: Criteria and Standards • 40 CFR 147 – State, Tribal, and EPA-Administered Underground Injection Control Programs – Subpart G - Colorado UIC WELL CLASSES • All underground injection wells are regulated by the U.S. EPA – Class I: wells used to inject hazardous waste or industrial waste below an Underground Source of Drinking Water (USDW) – Class II: wells used to dispose of exempt oil or gas waste fluids or wells used for enhanced oil recovery – Class III: wells used for solution mining – Class IV: wells used to inject hazardous waste or industrial waste above a USDW (banned except for those which are part of an EPA or state approved CERCLA or RCRA project) – Class V: all others or wells used to inject nonhazardous fluid into a USDW – Proposed Class VI: wells used for underground injection of carbon dioxide for sequestration STATE PRIMACY • U.S. EPA often delegates regulation of UIC wells to individual states (primacy) • U.S. EPA delegated primacy to COGCC for Class II UIC wells on April 2, 1984 • U.S. EPA sometimes delegates primacy for other classes of wells to individual states (e.g., Wyoming has primacy over some Class V wells) COLORADO STATISTICS • COGCC currently regulates more than 800 Class II UIC wells in Colorado. • Approximately three-quarters of these wells are enhanced recovery wells COLORADO REGULATIONS • Rule 325 defines notice requirements for Class II UIC wells: – Written notice to surface owners and mineral owners is required within ¼ mile of the injection well. The notification distance increases to ½ mile for any mineral owners that produce oil or gas from the injection zone. – Single-well permits are typically submitted for Class II disposal wells, but COGCC’s rules accommodate applications for multiple well units, which are often necessary for enhanced recovery operations. – COGCC publishes disposal well notices in a local newspaper announcing a 30-day public comment period. COLORADO REGULATIONS • Rule 325 requires submittal of downhole construction methods, surface facility information, and a list of Class II waste sources: – Packer, tubing, casing, and cement design details which demonstrate how the operator will maintain mechanical integrity of the well and ensure that injected fluids will be confined to the injection formation. – A surface facility diagram showing all pipelines and tanks associated with the injection system. – A list of all sources of Class II fluids to be injected, by lease and well. – Anticipated injection rates and pressures. Casing and Cement Design (Conductor) Casing and Cement Design (Surface) Casing and Cement Design (Production) COLORADO REGULATIONS • Rule 325 requires a successful Mechanical Integrity Test (MIT) prior to approval of a UIC application, and Rule 326.a. defines MIT requirements for UIC wells. – 5-year MIT’s (pressure tests) on the tubing-casing annulus or monthly pressure monitoring events are performed to determine whether significant leaks are present in the packer, tubing, or casing. – Tracer surveys, cement bond logs, and/or temperature surveys are also required to determine whether there are significant vertical fluid movements above or below the injection formation. Injected fluids must be confined to the injection formation. – If a UIC well lacks mechanical integrity, the operator must immediately cease injection. Injection cannot resume until the well is repaired and pressure tested. COLORADO REGULATIONS • Rule 324B defines requirements for aquifer exemptions – Water quality test data is required from the disposal formation. – If total dissolved solids (TDS) is greater than 3,000 milligrams per liter (mg/l) and less than 10,000 mg/l, then an aquifer exemption is required in addition to a UIC permit application. – COGCC publishes notices of aquifer exemption requests in a local newspaper for a 30-day public comment period. – The notice is also forwarded to U.S. EPA for their review. COLORADO REGULATIONS • Aquifer exemptions are granted for formations that are not currently used as a source of drinking water and meet one of the following criteria: – The formation contains commercially producible minerals or hydrocarbons; – The formation is so deep that recovery of water for drinking water purposes is economically or technologically impractical; or, – The formation is so contaminated that it would be economically or technologically impractical to render the water fit for human consumption. • Aquifer exemptions are not approved for formations with TDS equal to or less than 3,000 mg/l TDS. UIC PERMIT APPLICATION REVIEW • COGCC local engineering staff reviews Form 2 (Application for Permit to Drill, Deepen, Re-Enter, or Recomplete). • Form 2 review is intended to verify that casing and cement design is adequate to ensure that groundwater aquifers, hydrocarbon production zones, and the injection formations are isolated from each other to prevent cross-migration of fluids between each zone. UIC PERMIT APPLICATION REVIEW • COGCC’s UIC Engineering Supervisor reviews Form 4 (optional, Sundry Notice request to perform injectivity test), Form 31 (Underground Injection Formation Permit Application), Form 33 (Injection Well Permit Application), Form 21 (Mechanical Integrity Test), and Form 26 (Source of Produced Water for Disposal). • Form 4 review defines testing limits (duration and volume) to ensure that the injectivity test approval does not authorize continuous injection. UIC PERMIT APPLICATION REVIEW • During the Form 31, Form 33, and Form 26 review, COGCC evaluates well construction details and injection formation water sample results. COGCC submits a request to the Division of Water Resources for their opinion regarding the well construction and its ability to protect groundwater resources. • COGCC reviews well construction details for all oil and gas and water wells within ¼ mile of the proposed injection well. If necessary to ensure protection of groundwater aquifers and hydrocarbon zones, remedial work on offset wells may be required by COGCC. UIC PERMIT APPLICATION REVIEW • COGCC reviews all mineral and surface owner notifications and the surface owner agreement or the BLM Sundry Notice which authorizes surface use of the facility for injection of Class II waste. • COGCC evaluates the technical merit of all protests and public hearing requests. COGCC hearings may be scheduled for any protests that demonstrate that the proposed injection well has the potential to cause injury to mineral or groundwater resources. STANDARD CONDITIONS OF APPROVAL • All UIC permits are approved with the following stipulations: – COGCC requires financial assurance for plugging and well reclamation. Additional financial assurance is required for surface facilities at commercial injection sites. – COGCC assigns a maximum allowable pressure for continuous injection, which is set below formation fracturing pressure. – COGCC assigns a maximum allowable injection volume for disposal wells, which is calculated to hold the pore volume within a radius of influence of ¼ mile. There are no volume restrictions for enhanced recovery wells. – Operators must monitor and report injected water volumes on a monthly basis, and water samples are required periodically to monitor any significant TDS changes in the injected fluids. UIC ENFORCEMENT • All UIC wells (disposal wells and enhanced recovery wells) are inspected annually. Injection pressures and annular pressures are checked for anomalies and recorded. Pressure anomalies may indicate that a leak has developed and the packer, tubing, or casing lacks mechanical integrity. • MIT’s are performed on all UIC wells every five years. Failed MIT’s are an indicator that a packer, tubing, or casing leak may be present. • Notices of Alleged Violation are issued for any UIC wells that lack mechanical integrity. Operators are required to shut-in these wells until repairs are made or the wells are plugged and abandoned. CLASS II WASTE EXEPTIONS ARE DEPENDENT ON THE FLUID SOURCE, NOT ITS CHEMISTRY • Class II waste includes waste materials that are intrinsically derived from primary field operations associated with the exploration, development, or production of crude oil and natural gas. • “Because the RCRA exempt status of an oilfield waste is based on the relationship of the waste to E&P operations, and not on the chemical nature of the waste, it is possible for an exempt waste and a nonexempt hazardous waste to be chemically very similar.” CLASS II EXEMPT E&P WASTES • • • • Drilling fluids Rig wash Produced water Spent well completion, treatment, and stimulation fluids • Accumulations and deposits in tanks and pipelines used to store or transport Class II exempt wastes. • Gas plant dehydration and sweetening wastes NON-EXEMPT WASTES • • • • • Unused fracturing fluids or acids Painting wastes Waste solvents Refinery wastes Used equipment lubricating oils and hydraulic fluids • Sanitary wastes • Pesticide wastes • Radioactive tracer wastes Questions Denise M. Onyskiw, P.E. Colorado Oil and Gas Conservation Commission 303-894-2100 ext. 5145 Denise.Onyskiw@state.co.us