Final Report Disposable Mattress Cover That Detects When the

advertisement

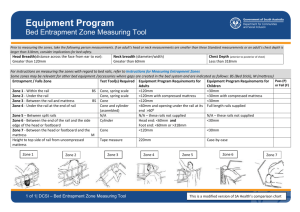

Final Report Disposable Mattress Cover That Detects When the Sheets Are Wet ECE 4884/4007 Senior Design Project Section L03, D.M.U. Team Ankit Hemani Jacob Huang Yuval Rooz Heonwoo Song Sarju Vasavada Submitted December 14, 2007 TABLE OF CONTENTS Executive Summary .......................................................................................................... ii 1. Introduction ..................................................................................................................1 1.1 1.2 1.3 Objective .............................................................................................................1 Motivation ...........................................................................................................1 Background .........................................................................................................2 2. Project Description and Goals ....................................................................................2 3. Technical Specifications ..............................................................................................3 4. Design Approach and Details 4.1 Design Approach ..................................................................................................3 4.2 Codes and Standards .............................................................................................5 4.3 Constraints, Alternatives, and Tradeoffs ..............................................................5 5. Schedule, Tasks, and Milestones.................................................................................7 6. Project Demonstration.................................................................................................8 7. Marketing and Cost Analysis ......................................................................................8 7.1 Marketing Analysis ...............................................................................................8 7.2 Cost Analysis ......................................................................................................10 8. Summary and Conclusions .......................................................................................13 9. References ...................................................................................................................14 EXECUTIVE SUMMARY A disposable mattress cover is an efficient and sustainable hospital accessory that can be used to cover hospital beds and to detect discharge of fluids through a patient’s body. Due to the high cost of hospital bed sheet washing, it is desirable for mattress covers to be replaced after each use. A cost-effective disposable mattress cover, designed with monitoring functionalities, will provide an excellent solution to maintain hygienic conditions for patients in hospitals. The disposable mattress cover, which is made up of biodegradable polyethylene material and stitched with conductive threads, will detect the presence of fluids in the bed periodically and immediately transmit an alarm whenever a change of bed sheet is required. An alarm will be also transmitted for a broken circuit on the mattress cover. This disposable mattress cover will cost $2.00 and has an excellent growth potential in the market since hospital bed demand in U.S. will increase by as much as 43% in next 25 years due to demographic shifts [2]. Our project aims to build a working prototype of a disposable mattress sheet cover that can detect urine and blood on it. After rigorous testing, this prototype can be used to manufacture a sturdier commercial product that can be implemented in hospitals and private nursing homes around the world. The targeted manufacturing cost of this product is $2.00 per sheet with the detection unit being sold separately. D.M.U. (ECE4007L03) ii DISPOSABLE MATTRESS COVER THAT DETECTS WHEN THE SHEETS ARE WET This report details the development of a mattress cover that detects wetness. It will cover the technical details, cost analysis, and the future of this product. 1. INTRODUCTION 1.1 Objective This project aims to design and build a prototype of a mattress cover that is disposable and is able to detect wetness from urine, blood, or any electrolytic fluid. The product that implements our design will be mass-produced and replaced after every use. Due to this design’s short expected use time, the target customers are hospitals, nursing homes, and bed-ridden patients who will need to change sheets regularly. These customers require frequently replaced products to have a low cost, so the target price of this mattress cover is less than $2.00. 1.2 Motivation The primary use of this product is to reduce exposure to moisture of bed-ridden patients. The CDC reports that there are 1.7 million incidents of nosocomial (hospital-acquired) infections each year [1], many of which are attributed to wet bed sheets. Bacteria are naturally more prone to damp areas, so if a mattress cover is left moist for extended periods of time, any exposed wound will have a greater risk of developing infection. The accompanying circuitry sends out a signal that, depending on the implementation, may alert any servicing personnel to replace the mattress cover. Another way this design will reduce nosocomial infections is by eliminating any contamination from previous patients. To disinfect bed sheets, it must be washed at high temperatures, a costly procedure. By using disposable mattress covers instead of reusable ones, the contamination hazard is removed. This constant disposal creates an environmental concern, D.M.U. (ECE4007L03) 1 so the design has used only bio-degradable materials. Besides the mattress cover, the mattress also absorbs fluids and may grow bacteria. To reduce this risk, a bio-degradable polyethylene 1.3 Background Many products or patent systems include the ability to detect if a material is wet. They are usually fabricated for toddlers as diapers or for hospital patients as bed sheets. Children products are used to detect urine for bed wetting training or for a diaper change reminder. The Malem Bedwetting Alarm by Bedwetting Stores has a detector in the underwear that is connected to an alarm [2]. This product is not desirable in a hospital since it is invasive. Systems for hospital patients like [3] are specifically designed to reduce the likelihood of bedsores by detecting long periods of inactivity and measuring wetness, but there are no commercial products that utilize that design. Other similar products include a wet sheet detector that uses biological materials to detect wetness by measuring the change in resistance when the sheet is wet, but are not affordable for daily replacements. The mattress cover proposed in this report builds upon these previous designs, but it will be more disposable and inexpensive to accommodate the needs of the hospital. 2. PROJECT DESCRIPTION AND GOALS The design of the mattress cover consists of conductive threads sewn onto a layer of absorbent paper manufactured covered by a thin layer of biodegradable polyethylene. The conductive pattern stitched onto the mattress cover will serve as a wetness detection sensor. The polyethylene plastic layer prevents the leakage of electrolytic fluids, reducing infections. The conductive threads will form a continuous loop, and each loop will be checked for continuity. Sew connective thread to paper using a sewing machine. Attach both paper and plastic together efficiently using adhesives. D.M.U. (ECE4007L03) 2 Design an automated assembly process to manufacture the mattress cover Detect changes in resistance due to leakage with a differential amplifier circuit Use LED to indicate wetness or broken circuit. 3. TECHNICAL SPECIFICATIONS Table 1. Technical Design Specifications Design Aspect Proposed Specification Designed Specification Voltage source 9V batteries Outlet power Threshold resistance TBD 35 kΩ Output voltage levels 0V and 5V 0V and 5V Conductive thread Silver plated nylon Stainless steel Adhesive to attach paper to plastic 3M Super 77 Spray Adhesive 3M Super 77 Spray Adhesive External connection to circuit 4 conductive traces attached binder clip fastened by electric tape Plastic clip with 4 extruding wires, connects to box by RS232 connector Weight of Mattress Cover TBD 150g Automated Process to mass produce mattress covers TBD Automated stitching machine 4. TECHNICAL DETAILS 4.1 Design Details Designing a detection circuit for the mattress sheet cover was a challenge because the circuit had to be safe, robust and at the same time cheap. In order to reduce costs we decided to implement it with comparator op-amps to compare the resistance of the threads on the mattress D.M.U. (ECE4007L03) 3 sheet cover with a known value of resistance. Once we decided to switch our thread from silver coated nylon to stainless steel, the task was easy because the resistance of the stainless steel thread is only about 100Ω/ft as compared to 1.2kΩ/ft for the stainless steel thread. Although the threshold resistances were set by measuring the dry and wet resistances of thread on the prototype, these values take into account the minor changes in thread resistance due to the manufacturing process up to a tolerance of 10%. One of the major decisions while designing the circuit was whether to use DC or AC. Since we were concerned with safety, we decided to use DC batteries as the power supply since voltage surges do not occur in a battery. Although DC current can cause ionization and thus increase resistance of the thread after it has been wet for a while, we tested this theory and found that the resistance increases up to a certain value and then stabilizes. After taking measurements of the power consumption, we found that a 9V battery would supply power for only 1-2 days. After discussing with our advisor, we decided to use an AC-DC wall adapter with an isolation transformer. The isolation transformer prevents any surges in the AC power to directly transfer into the DC output. Further, we used a 100 mA fuse to make sure that power surges in the AC supply do not enter our circuit. The output of the detection circuit needs to be connected to a computer that can monitor when the detection circuit sends a signal (for either wetness or tear in the sheet). As there may be power surges on the computer end, we used an optoisolator to isolate the output signal from the opamp outputs and thus prevent any surges from the output end getting into our circuitry. In order to make sure that our circuit uses low current (for safety and cost), we used resistances in the order of hundreds of kilo ohms. This way, the entire circuit consumes no more D.M.U. (ECE4007L03) 4 than a few milliamps and the current passing through the conductive threads at anytime is no more than 9 micro amps. Finally, the stitching of the sheet itself was done in such a way that the patient never gets into contact with the conductive threads. The prototype was built with an LED to indicate wetness or a tear in the mattress cover so that there was no need for a voltmeter to show the output signal during the demonstration. 4.2 Codes and Standards We talked to Piedmont hospital regarding any codes or standards that must be followed and they said that there were none. Yet we decided to use some components that would increase the safety our product like the fuse, isolation transformer, opto-isolator and the stitching method of the mattress cover. 4.3 Constraints, Alternatives, and Tradeoffs The major constraint for our design was cost. The mattress cover sheet must cost $2 or less to produce. Since this product is use and throw, it must be replaced several times and hence it must be cheap. So we designed a circuit that uses 3 ICs, some resistors and some capacitors. This way, we kept our costs down to the minimum while still keeping our product safe to use, which was the other constraint we had. Some of the alternatives we discussed were AC versus DC for the detection circuitry, different stitching patterns, connector design, power supply source and threshold resistances. As mentioned earlier, we decided to go with DC instead of AC along with a battery as the power source in order to make the circuit safer as well as reduce the complexity of the circuit by eliminating the need for rectifiers. As for the stitching pattern, we tried to maximize the area D.M.U. (ECE4007L03) 5 covered by using as less of the thread as possible while making sure that pattern can be easily stitched by an automated machine in order to make mass production a little easier. The connector design was a bit of a problem because we needed something that could be connected quickly to the mattress sheet cover while at the same time has a good connection. Since there were no connectors that matched our need, we had to design one on our own. The power supply was another big point of debate. A battery is safe since there are no voltage surges in it but its life is only about 2 days for the circuit that we designed. Hence, in order to reduce costs and the effort required to change the battery daily, we decided to use an AC-DC wall adapter and make the necessary changes to keep the circuit as safe as possible. Finally, the threshold resistances changed because at first, we used the silver coated nylon thread and then switched to stainless steel thread. Once we had finalized on the stainless steel thread, the thresholds were changed again to account for the tolerances due to manufacturing. D.M.U. (ECE4007L03) 6 5. SCHEDULE, TASKS, AND MILESTONES D.M.U. (ECE4007L03) 7 6. PROJECT DEMONSTRATION The final prototype for the mattress sheet cover was demonstrated during our final presentation. As we did not have a full size mattress cover, the pattern was stitched onto an actual cotton bed sheet. A volunteer from our group connected the wall adapter into a socket and its output to the detection circuit. Since the detection circuit was not connected to the sheet at this time, the LED lit up indicating an open circuit which is equivalent to a tear in the conductive thread pattern. The circuit was then connected to the mattress sheet cover and the LED switched off indicating no wetness or tear in the thread. A banana plug cable was then used to short out the conductive pattern by connecting the two loops. When this was done, the LED lit up to indicate a short circuit and when the connection was removed, the LED switched off. Finally, a glass of salty water (with a concentration of 1g/L of common salt in water) was used to simulate the effects of urine or blood on the sheet. The salty water was slowly dropped onto the center of the sheet. The LED lit up when there was a circular wet area on the sheet about 4 inches in diameter indicating that it can successfully detect ionized liquids like blood or urine. 7. MARKETING AND COST ANALYSIS 7.1 Marketing Analysis Today many hospital infections are caused by body fluids left undetected on the beds. More than 80,000 deaths happen because of these kinds of infections [4]. By using disposable mattress covers that can detect these kinds of fluids, it will be possible to reduce the number of deaths significantly. These lives motivate the development of the product for hospitals. In addition, if the product succeeds in hospitals, it would be possible to expand to nursing homes and home usage. D.M.U. (ECE4007L03) 8 As of today, there is no other disposable product that has the capability of effectively detecting body fluids. Some products that are used to detect urine of people at the age of 3-16 already exist, but they cost $70-$100. The disposable mattress cover will cost approximately $2.00 (detailed cost breakdown will be discussed in more details in the next section). For instance, the Bedwetting Store offers Malem Bedwetting Alarm, which has a detector in the underwear that is connected to an alarm [5]. This product is offered for $79.95-$84.95. In addition, The Bedwetting Store offers alternative products that are used to detect bed wetting by an external device that is laid under the bed covers. The Wet Call Bed-side Bedwetting Alarm with Pad is one of these products from the Bedwetting Store. The device is a mattress that can detect fluids and is connected to an external alarm [6]. This product costs $84.95. The products that are on the market are for home use and are meant to be used more than one time. Since it is assumed that people with bed wetting problem are going to experience repetitive bed wetting, the products offer a device that is reusable. The product proposed, on the other hand, is meant for one time use only making it attractive for hospital usage. Once body fluids are detected, the mattress needs to be replaced and a new sheet is to be put on the bed. The advantage is that the product being developed will cost approximately 1/30 of the products that are currently on the market. This will be particularly useful in hospitals, where there is a high need for cleanliness and where bed sheets are changed frequently. Now that the product is finished, there are few additional steps needed to take in order to complete the marketing process. Since some changes had to be done before the final presentation, the product was not packaged, therefore, it not in a physical stage that can be marketed. In addition, the product needs to communicate with the nurses’ station either via wireless communication or landline. Whichever is the method of communication, the box will D.M.U. (ECE4007L03) 9 need to be adjusted to talk with the local communication. Other than these modifications, the product is ready to be marketed directly to hospitals. Saying that, it is still necessary to sign mutual agreements with producers of sheets to work together to make the sheet at a price that meet the price target ($2.00) while giving revenue to all parties that are working together to produces and sell the product. 7.2 Cost Analysis This cost analysis assumes an income of $52,200 per year for Electrical Engineering students from Georgia Institute of Technology [7]. This yields $25 per hour of work. Determination of Selling Price: This estimate is based on twelve billion units sold in the first five years assuming 10% market share [8]. Assembly labor is very low since the sheets are going to be produced by an automated process. Each sheet will be tested by visual inspection only. Prices for parts are taken from company quotes. Additional cost that was not taken into account originally was the customization of each product to the local hospital. Development Costs: Fringe Benefits Item Health Insurance Fuel & Other Transportation Costs Cell Phones 401k Total Parts 10 Covers + shipment Conductive Thread 20 LN741CN Op Amps + shipment Other electric parts: AC adapter, board, box, fuse and other electrical parts Total Labor Yuval Rooz Meetings D.M.U. (ECE4007L03) Percentage 5% 5% 1% 1% 12% Price $21.70 $15.00 [9] $19.80 [10] $80.00 $175.70 Hours Price 161 $4,025.00 64 $1,600.00 10 Classes Writing Reports Product Development Web Development 32 25 30 10 $800.00 $625.00 $750.00 $250.00 Jacob Huang Meetings Classes Writing Reports Product Development 156 64 32 30 30 $3,900.00 $1,600.00 $800.00 $750.00 $750.00 Gopinath Jayaprakash Meetings Classes Writing Reports Product Development Group discussion page maintenance 156 64 32 25 30 5 $3,900.00 $1,600.00 $800.00 $625.00 $750.00 $125.00 Ankit Hemani Meetings Classes Writing Reports Product Development 151 64 32 25 30 $3,775.00 $1,600.00 $800.00 $625.00 $750.00 Heonwoo Song Meetings Classes Writing Reports Product Development 151 64 32 25 30 $3,775.00 $1,600.00 $800.00 $625.00 $750.00 Serju Vasavada Meetings Classes Writing Reports Product Development 151 64 32 25 30 $3,775.00 $1,600.00 $800.00 $625.00 $750.00 Total 926 $23,150.00 Cost and Price Calculations Fringe Benefits Overhead Sales & Marketing Expense Warranty & Support Expense D.M.U. (ECE4007L03) 12% of labor of materials, 20% labor & fringe 15% of selling price 5% of selling price 11 Development Cost (Non-recurring Cost) What it costs the company to develop the product Parts Labor Fringe Benefits, % of Labor Subtotal Overhead, % of Matl, Labor & Fringe Total $175.70 $23,150.00 $2,778.00 $26,083.45 $5,216.69 $31,300.14 Determination of Selling Price What the customer pays the company for the finished product Based on: Parts Cost Assembly Labor Testing Labor Total Labor Fringe Benefits, % of Labor Subtotal Overhead, % of Matl, Labor & Fringe Subtotal, Input Costs Sales & Marketing Expense Warranty & Support Expense Amortized Development Costs Subtotal, All Costs Profit Selling Price Total Revenue Total Profit 12,000,000,000 units $1.00 $0.05 $0.10 $0.15 $0.02 $1.17 $0.23 $1.40 $0.30 $0.10 $0.00 $1.80 $0.20 9.9% $2.00 $24,000,000,000 $2,380,768,700 It is crucial to note here that these costs were only for the initial development. Once the product is ready (packaging and communication), mass production will reduce the costs of the product significantly. It is important to note that the sheet is the only cost that matters since the detection unit is purchased only once at initial installation. Since the sheets are for disposable usage, they will be purchased in bulk. D.M.U. (ECE4007L03) 12 8. SUMMARY AND CONCLUSION The design of this project is complete. Each component, sheet, connector, and detection unit, all function as desired, though there were a few changes from the original design. The sheet was designed nearly as proposed. The only change was using stainless steel thread instead of silver thread for the conductive loop. This was due to the reduced resistance to allow for a more accurate measurement. The connector was also similar to the one proposed. An RS-232 jack was included to allow for an easy interface between the connector wires and the detection unit box. The unit was modified for increased safety. What remains to do is preparation of the design for mass-production. For the mattress cover, a full-size paper bed sheet needs to be stitched and tested. The connector currently uses an external binder clip, but the finished product will need a clip built in. The detection unit is furthest along for production. The finalized unit just needs to be enclosed. Also, depending on the implementation, an output signal may need to be installed. As of now, the prototype responds well to moderate levels of moisture. The saline solution used to simulate urine or blood triggered the detection unit and resulted in the desired effect. When the two loops were connected by dabbing the bedsheet with a moistened cloth, the output was triggered successfully. D.M.U. (ECE4007L03) 13 9. REFERENCES [1] R. Klevens, J. Edwards, C. Richards, T. Horan, R. Gaynes, D. Pollock, D. Cardo, “Estimating Health Care-Associated Infections and Deaths in U.S. Hospitals, 2002,” Public Health Reports, Center of Disease Control, vol. 122, March-April 2007. [2] Bedwetting Store, “Malem bedwetting alarm,” [online document], 2007 Sep 05, [cited 2007 Sep 16], Available HTTP: http://www.bedwettingstore.com/Bedwetting_Alarms/malem_bedwetting_alarm.htm. [3] S. E. Kanor, and R. C. Hirsc, “Personal Care Monitoring System,” U.S. patent no. 6384728, May 7, 2002. [4] B. Starfield, “Is US health really the best in the world,” The Journal of the American Medical Association, Vol. 284, no. 4, pp.483-485, 2000. [5] Bedwetting Store, “Malem bedwetting alarm,” [online document], 2007 Sep 05, [cited 2007 Sep 16], Available HTTP: http://www.bedwettingstore.com/Bedwetting_Alarms/malem_bedwetting_alarm.htm. [6] Bedwetting Store, “Wet Call Bed-side Bedwetting Alarm with Pad,” [online document], 2007 Jun 20, [cited 2007 Sep 16], Available HTTP: http://www.bedwettingstore.com/Bedwetting_Alarms/wetcall_bedwetting_alarm.htm. [7] Career Services – Georgia Institute of Technology, “Salary survey,” [online document], 2007 Sep 16, [cited 2007 Sep 16], Available HTTP: http://career.gatech.edu/students/bachelor.pdf. D.M.U. (ECE4007L03) 14 [8] MSEC, “Hospital bed sheets,” [online document], 2007 Sep 16, [cited 2007 Sep 16], Available HTTP: http://home-health-care.medical-supplies-equipmentcompany.com/PPF/page_ID/230/article.asp. [9] The Lame Lifesaver, “Stainless steel conductive thread,” [online document], 2006 Feb 04, [cited 2007 Dec 11], Available HTTP: http://members.shaw.ca/ubik/thread/thread.html. [10] RadioShack, “LM741CN Operational amplifier (8-Pin Dip),” [online document], 2007 Sep 16, [cited 2007 Sep 16], Available HTTP: https://www.google.com/accounts/ServiceLogin?service=mail&passive=true&rm=false&con tinue=http%3A%2F%2Fmail.google.com%2Fmail%3Fui%3Dhtml%26zy%3Dl&ltmpl=defa ult&ltmplcache=2&hl=en. D.M.U. (ECE4007L03) 15