Product Flow Model

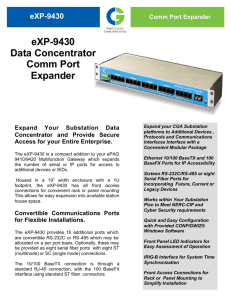

advertisement

Product Flow Model Overview May 2008 Product Flow Model 1 Flow Component Hierarchy • Model – Collection of networks. – Network – Collection of connected units. • Unit – Black box with ports. – Port – Allows flow in or out. » Node – Allows ports to connect. May 2008 Product Flow Model 2 Product Flow Model • Defines the flow behavior of something (normally larger installations). • Collection of networks. – The model is represented by one network. – The other networks represent smaller things within the model. • External ports. – Allows models to connect. May 2008 Product Flow Model 3 Product Flow Network • Represents the internal behavior of the model or a unit in another network. • Collection of connected units. • Ports expose internal nodes. Network Unit Port Node May 2008 Product Flow Model 4 Product Flow Unit • A black box with ports but internal network allows drill-down for more details. • A unit can represent: – A complex thing like a platform or separator. – A simple thing like a valve or choke. • Contextual knowledge (i.e., what does this unit represent). May 2008 Product Flow Model 5 Product Flow Port • Expected direction (inlet or outlet). • Connects to one Node – Represent a one-to-one connection. • Expected Product Flow (for validation). – For example, oil production or gas injection. May 2008 Product Flow Model 6 Node • All ports that are connected to the same node are connected to each other. Unit asserts a connection Port Node • For an actual flow diagram the graphics may ignore the node. May 2008 Product Flow Model 7 Flow Assumptions • Steady state fluid flow across nodes and ports. That is, pressure is constant across internally and externally connected ports and nodes. • Conservation of mass across a node or port. • Pressure can vary internally between ports on a unit. • Connections between models should be one-toone so that mass balance concerns are internal to each model. May 2008 Product Flow Model 8 Internal Network of a Unit • Corresponding ports have the same name (i.e., they are logically the same port). • There is no pressure change across ports or nodes. Thus, there is no pressure change between ports A2 and C1. B1 A A2 B B2 B3 B Internal Network B1 C1 C B2 B3 May 2008 Product Flow Model 9 Direction • The direction is the intended direction of flow. • A change in pressure across a unit can change the actual flow direction at a port. • In the Product Volume Report: – A positive volume represents an intended direction (i.e., a flow out of an outlet port or into an inlet port). – A negative volume represents an unintended direction (i.e., a flow into an outlet port and out of an inlet port). B3 May 2008 Product Flow Model 10 Expected Product Flow • Pairs of product kind and flow kind where: – Product = oil, gas, condensate, aqueous, oleic, vapor, water, carbon dioxide gas, etc. – Flow = production, injection, consume, import, export, gas lift, overboard, etc. May 2008 Product Flow Model 11 Properties • The Product Flow Model only defines connectivity (i.e., how things could flow). • The Product Volume Report can define: – – – – – May 2008 A period of time (e.g., day, month, YTD, etc). A type of flow (e.g., production, injection, etc). A type of product (e.g., oil, aqueous, gas, etc). A volume and other fluid properties at a port. A pressure difference across a unit. Product Flow Model 12 Summary • Flow behavior defined by Network, Unit, Port and Node (connection). • Unit can represent anything (big or small). • Steady state fluid flow across ports/nodes • Conservation of mass across ports/nodes. • Properties are assigned by the Product Volume Report. May 2008 Product Flow Model 13