Materials Science - New Technologies Research Center (NTRC)

advertisement

Remember Miller Indices?

• For directions:

– Determine coordinates

for “head” and “tail” of

the direction

– “head”-”tail”

– Clear fraction/reduce

results to lowest

integers.

– Enclose numbers in []

and a bar over negative

integers.

• For planes:

– Identify points at which

the plane intercepts the

x, y, z axis.

– Take reciprocals of

these intercepts.

– Clear fractions and do

NOT reduce to the

lowest integers.

– Enclose the numbers in

parentheses () and a bar

over negative integers.

Chapter 3 -

Special note for directions…

• For Miller Indices of directions:

– Since directions are vectors, a direction and its

negative are not identical!

• [100] ≠ [100] Same line, opposite directions!

– A direction and its multiple are identical!

• [100] is the same direction as [200] (need to reduce!)

• [111] is the same direction as [222], [333]!

– Certain groups of directions are equivalent; they have

their particular indices because of the way we

construct the coordinates.

• Family of directions: <111>=[111], [111],[111],[111],…

Chapter 3 -

Special note for planes…

• For Miller Indices of planes:

– Planes and their negatives are identical (not the case

for directions!)

• E.g. (020) = (020)

– Planes and their multiples are not identical (Again,

different from directions!) We can show this by

defining planar densities and planar packing fractions.

• E.g. (010) ≠ (020) See example!

– Each unit cell, equivalent planes have their particular

indices because of the orientation of the coordinates.

• Family of planes: {110} = (110),(110),(110),(101), (101),…

– In cubic systems, a direction that has the same

indices as a plane is perpendicular to that plane.

Chapter 3 -

Example: Calculating the Planar Density

Calculate the planar density for the (010) and (020) planes in

simple cubic polonium, which has a lattice parameter of 0.334 nm.

a0

a0

(c) 2003 Brooks/Cole Publishing /

Thomson Learning™

Chapter 3 -

SOLUTION

The total atoms on each face is one. The planar density is:

atom per face

1 atom per face

Planar density (010)

area of face

(0.334) 2

(a0)2 8.96 atoms/nm 2 8.96 1014 atoms/cm 2

However, no atoms are centered on the (020) planes.

Therefore, the planar density is zero. The (010) and (020)

planes are not equivalent!

Chapter 3 -

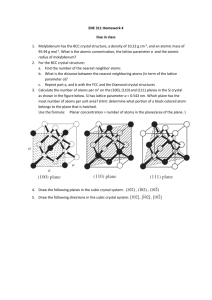

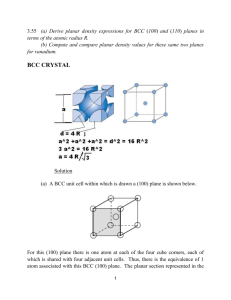

Planar Density of (100) Iron

Solution: At T < 912C iron has the BCC structure.

2D repeat unit

(100)

a

4 3

R

3

Radius of iron R = 0.1241 nm

atoms

2D repeat unit

Planar Density =

area

2D repeat unit

1

a2

=

1

4 3

R

3

atoms

atoms

19

= 1.2 x 10

2 = 12.1

2

nm

m2

Chapter 3 - 6

Planar Density of (111) Iron

There are only (3)(1/6)=1/2 atoms in the plane.

2a

h

2a

h

3

a

2

2

atoms

2D repeat unit

4 3

16 3 2

2

2area 2 ah 3 a 3

R

R

3

3

0.5

atoms =

= 7.0

2

Planar Density =

area

2D repeat unit

16 3

6

R

2

nm

0.70 x 1019

atoms

m2

Chapter 3 - 7

In-Class Exercise 1: Determine planar density

Determine the planar density for BCC lithium in the (100), (110),

and the (111) planes.

atomic radius for Li = 0.152 nm

Chapter 3 -

Solution for plane (100)

rLi 0.152nm

4r 40.152nm

a0 BCC

0.3510nm 3.510

3

3

For (100):

planar _ density

1atom

3.510 10

8

cm

2

8.115 1014 atoms / cm 2

Chapter 3 -

Solution for plane (110)

For (110):

It is important to visualize how the plane is cutting

across the unit cell – as shown in the diagram!

planar _ density

2atoms

2 3.510 10 8 cm

2

1.148 1015 atoms / cm 2

Chapter 3 -

Solution for plane (111)

For (111):

Note: Since the (111) does NOT pass through the

center of the atom in the middle of the BCC unit cell,

we do not count it!

1

1

plane _ area bh

2

2

planar _ density

2a0

3

3a0 a0 0.866a02

2

1 / 2atom

0.866 3.510 10 8 cm

2

4.686 1014 atoms / cm 2

2a0

Chapter 3 -

In-Class Exercise 2: Determine planar density

Determine the planar density for FCC nickel in the (100),

(110), and (111) planes.

atomic radius for Nickel= 0.125 nm

Remember when

visualizing the plane, only

count the atoms that the

plane passes through the

center of the atom. If the

plane does NOT pass

through the center of that

atom, we do not count it!

Chapter 3 -

Solution for plane (100)

rNi 0.125nm

4r 40.125nm

a0 FCC

0.3536nm 3.536

2

2

a0

For (100):

planar _ density

2atoms

3.536 10

8

cm

2

1.600 1015 atoms / cm 2

Chapter 3 -

Solution for plane (110)

For (110):

It is important to visualize how the plane is cutting

across the unit cell – as shown in the diagram!

planar _ density

a

2atoms

2 3.536 10 8 cm

2

1.1311015 atoms / cm 2

0

2a0

Chapter 3 -

Solution for plane (111)

For (111):

Again try to visualize the plane, count the number of

atoms in the plane:

2a0

1

1

plane _ area bh

2

2

planar _ density

2atoms

8

3

2a0 a0 0.866a02

2

0.866 3.536 10 cm

2

1.847 1015 atoms / cm 2

2a0

2a0

Chapter 3 -

Home Exercise: Determine planar density

Determine the planar density for (0001) plane

for an HCP unit cell Titanium

atomic radius for titanium is 0.145 nm

16

Chapter 3 -

Crystals as Building Blocks

• Some engineering applications require single crystals:

--diamond single

crystals for abrasives

--turbine blades(Co and Ni superalloys)

(Courtesy Martin Deakins,

GE Superabrasives,

Worthington, OH. Used with

permission.)

Fig. 8.33(c), Callister 7e.

(Fig. 8.33(c) courtesy

of Pratt and Whitney).

• Properties of crystalline materials

often related to crystal structure.

--Ex: Quartz fractures more easily

along some crystal planes than

others.

Chapter 3 - 17

Poly crystal Material

Single crystal

Grains

Chapter 3 -

Polycrystals

• Most engineering materials are polycrystals.

Anisotropic

Adapted from Fig. K,

color inset pages of

Callister 5e.

(Fig. K is courtesy of

Paul E. Danielson,

Teledyne Wah Chang

Albany)

1 mm

• Nb-Hf-W plate with an electron beam weld.

• Each "grain" is a single crystal.

• If grains are randomly oriented,

Isotropic

overall component properties are not directional.

• Grain sizes typ. range from 1 nm to 2 cm

(i.e., from a few to millions of atomic layers).

Chapter 3 - 19

Single vs Polycrystals

• Single Crystals

E (diagonal) = 273 GPa

Data from Table 3.3,

Callister 7e.

(Source of data is R.W.

Hertzberg, Deformation

and Fracture Mechanics

of Engineering

Materials, 3rd ed., John

Wiley and Sons, 1989.)

-Properties vary with

direction: anisotropic.

-Example: the modulus

of elasticity (E) in BCC iron:

• Polycrystals

-Properties may/may not

vary with direction.

-If grains are randomly

oriented: isotropic.

(Epoly iron = 210 GPa)

-If grains are textured,

anisotropic.

E (edge) = 125 GPa

200 mm

Adapted from Fig.

4.14(b), Callister 7e.

(Fig. 4.14(b) is courtesy

of L.C. Smith and C.

Brady, the National

Bureau of Standards,

Washington, DC [now

the National Institute of

Standards and

Technology,

Gaithersburg, MD].)

Chapter 3 - 20

Section 3.6 – Polymorphism

• Two or more distinct crystal structures for the same

material (allotropy/polymorphism)

iron system

titanium

liquid

, -Ti

1538ºC

-Fe

BCC

carbon

1394ºC

diamond, graphite

-Fe

FCC

912ºC

BCC

-Fe

Chapter 3 - 21

Section 3.16 - X-Ray Diffraction

• Diffraction gratings must have spacings comparable to

the wavelength of diffracted radiation.

• Can’t resolve spacings

• Spacing is the distance between parallel planes of

atoms.

Chapter 3 - 22

(c) 2003 Brooks/Cole Publishing / Thomson Learning

(a) Destructive (out of phase) xray beam gives a weak signal.

(b)Reinforcing (in phase)

interactions between x-rays

and the crystalline material.

Reinforcement occurs at

angles that satisfy Bragg’s

law.

Chapter 3 -

X-Rays to Determine Crystal Structure

• Incoming X-rays diffract from crystal planes.

extra

distance

travelled

by wave “2”

q

q

d

Measurement of

critical angle, qc,

allows computation of

planar spacing, d.

reflections must

be in phase for

a detectable signal

Adapted from Fig. 3.19,

Callister 7e.

spacing

between

planes

X-ray

intensity

(from

detector)

n

d

2 sin qc

q

qc

Chapter 3 - 24

(c) 2003 Brooks/Cole Publishing / Thomson Learning

(a) Diagram of a

diffractometer, showing

powder sample, incident

and diffracted beams.

(b) (b) The diffraction

pattern obtained from a

sample of gold powder.

Chapter 3 -

X-Ray Diffraction Pattern

z

z

Intensity (relative)

c

a

x

z

c

b

y (110)

a

x

c

b

y

a

x (211)

b

(200)

Diffraction angle 2q

Diffraction pattern for polycrystalline -iron (BCC)

Adapted from Fig. 3.20, Callister 5e.

Chapter 3 - 26

y

Bragg’s Law:

Bragg’s Law:

n 2d hkl sin q

Where q is half the angle

between the diffracted

beam and the original

beam direction

is the wavelength of X-ray

d is the interplanar spacing

Interplanar

spacing:

d

d hkl

a0

h2 k 2 l 2

Miller

Chapter 3 -

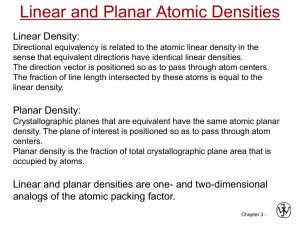

SUMMARY

• Atoms may assemble into crystalline or

amorphous structures.

• Common metallic crystal structures are FCC, BCC, and

HCP. Coordination number and atomic packing factor

are the same for both FCC and HCP crystal structures.

• We can predict the density of a material, provided we

know the atomic weight, atomic radius, and crystal

geometry (e.g., FCC, BCC, HCP).

• Crystallographic points, directions and planes are

specified in terms of indexing schemes.

Crystallographic directions and planes are related

to atomic linear densities and planar densities.

Chapter 3 - 28

SUMMARY

• Materials can be single crystals or polycrystalline.

Material properties generally vary with single crystal

orientation (i.e., they are anisotropic), but are generally

non-directional (i.e., they are isotropic) in polycrystals

with randomly oriented grains.

• Some materials can have more than one crystal

structure. This is referred to as polymorphism (or

allotropy).

• X-ray diffraction is used for crystal structure and

interplanar spacing determinations.

Chapter 3 - 29