ASHRAE Atlanta paper 5

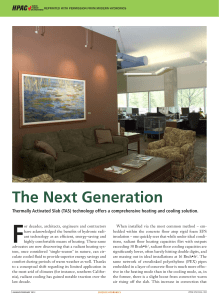

advertisement

Ceiling Radiant Cooling Panels as a Viable Distributed Parallel Sensible Cooling Technology Integrated with Dedicated Outdoor Air Systems Christopher L. Conroy, E.I.T. L. D. Astorino Companies, Pittsburgh PA Stanley A. Mumma, Ph.D., P.E. Penn State University, Dept. of Architectural Engineering Presentation Overview • • • • • • • Introduction Radiant Cooling Theory HVAC Paradigm Advantages Example Integration of Fire Suppression Conclusions and Solutions Integrating Dedicated Outdoor Air Systems with Parallel Terminal Systems Radiant Cooling Panels Fan Coil Units Unitary ACs Air Handling Units Unit Ventilators Radiant Cooling Theory • Uses both Radiation and Convection • Radiation (50-60%) » Stefan-Boltzmann Equation » qr = 0.15x10-8 · [(tp+460)4 – (ta+460)4] • Convection (40-50%) » ASHRAE S&E 1996 » qc = 0.31 · |tp- ta|0.31 · (tp- ta) Radiant Cooling Paradigm • Expensive » High first cost » Difficult or improper installation » Unavailable • Condensation!!! • Condensation!!! • Condensation!!! Radiant Cooling Panel Construction Thermally Bonded Blanketed with Insulation Aluminum or Copper Fins Copper Tubing (Serpentine or Parallel Arrangement) Cost Advantages • Long Term Savings » » » » Smaller, More Efficient Chillers Reduced Fan Energy Reduced Maintenance Cost Not paying for Over Ventilating • Other Cost Savings » Piping is not insulated » Reduced Sprinkler Piping » Testing and Balancing Made Simpler Indoor Air Quality Advantages • High comfort levels • No condensate drains or drain pans • Meets ANSI/ASHRAE Std 62-1999 • Quick response time • Individual room control at low cost Building Advantages • Architecturally Integratable » Silk screening available » Perforated face (acoustics) • Great for Retrofit or New Construction » Reduces Mechanical Space » Less Ductwork – Less vertical shaft space – Higher ceilings and/or reduced building heights • Simpler Coordination Between Trades » Integration of fire suppression » Less interferences (crossover ductwork) Example: Step 1 Defining Parameters • Open Office Plan » 1000 ft2 • Define Design Conditions » 78ºF DBT / 40% RH » 7 People (20 cfm/person) • Space Loads » » » » 7 People (Office Work) 2 W/sq ft (Lighting) 1 W/sq ft (Equipment) 4,000 Btu/h (Skin Loss) » 14,000 Btu/h (Total Sensible) » 1,435 Btu/h (Total Latent) 1000 ft2 78°F / 40% Step 2 Estimation of CRCP Capacity 25.0 20.0 15.0 25.0-30.0 10.0 20.0-25.0 15.0-20.0 5.0 10.0-15.0 (o F) DB T 72 60 58 56 54 76 52 RH ( %) 50 48 46 44 42 0.0 40 Sensible Cooling Capacity (Btuh/ft 2) 30.0 Step 3 Calculation of CRCP Capacity • Room DPT = 52°F » 78°F / 40% RH • DOAS DPT = 44°F » 1,435 Btuh Latent Load » 140 cfm @ 55°F » 3,500 Btuh Sensible Load • Panel tfi = 55°F • Panel Temp = 60°F • Qs = 29.7 Btuh/ft2 » 10,500 Btuh » 354 ft2 of panel Step 4 Selection and Layout of CRCP • 126 4x2 Ceiling Panels » ~ 1000 ft2 • 24 Light Fixtures » ~ 20% of Ceiling • 49 Ceiling Radiant Cooling Panels » 392 ft2 (40%) • 400 sq. ft. Leftover » Diffusers » Sprinklers • Qs = 26.7 Btuh/ft2 » Room RH = 43% » Increase DOAS DPT Step 5 Compare Acoustical Performance of CRCP Reverberation Time (sec) Acoustical Ceiling Vs CRCP 1.00 0.90 0.80 0.70 0.60 0.50 0.40 0.30 0.20 0.10 0.00 125 250 500 1000 Frequency (Hz) 2000 4000 T Chilled Water Loop COMPRESSION TANK CRCP’s ZONE VALVES SECONDARY PUMP (VFD) MAKE-UP PUMP Integrated Fire Suppression System ALARM VALVE FIRE FLOW SWITCH CHECK VALVE FIRE PUMP ASSEMBLY Conclusions and Solutions • Seen the Advantages • Concluded that CRCP’s can be Used Safely with No Condensation Problems • Defined a Simple Selection Process • Examined the Opportunity for Fire Suppression Integration • Break the HVAC Paradigm » More Successful Applications » Spreading the Word • Explore the Possibilities of Lowering Cost » Increase Availability » Research a way to produce custom lengths on site • Development Through the Solar Industry Questions