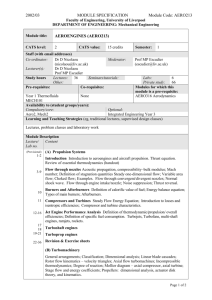

Propulsion fundament..

advertisement