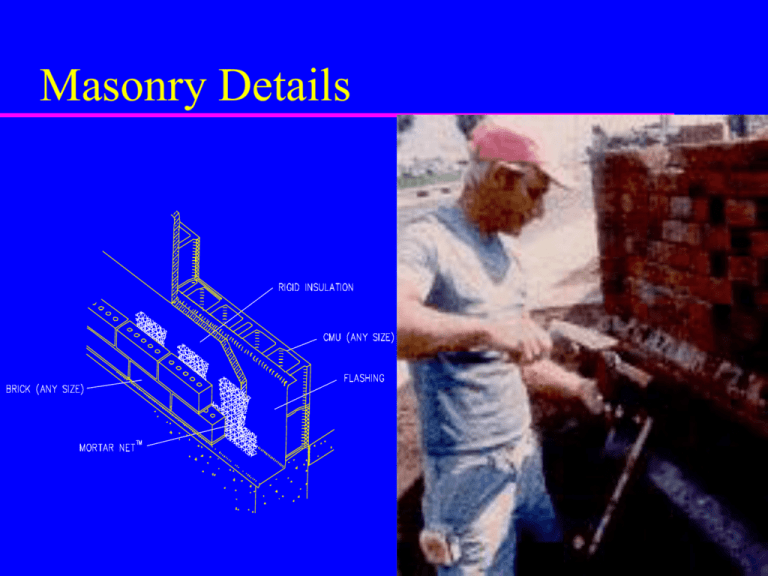

Masonry Details

advertisement

Masonry Details Masonry Categories Clay Masonry – made of burned clay, shale, fire clay or combo – shaped in plastic state – fired in kiln at high temperatures to bond mat’l Concrete – – – – Masonry made of dry portland cement, aggregates, water compacted in forms by vibration cured under controlled temperature & moisture aging necessary for maximum strength Clay Masonry Units Solid Masonry – brick (standard) » can contain holes, called cores, up to 25% of area » wide range of colors and surface textures Hollow Masonry (exceeds 25% core area) – structural clay tile (shapes of concrete block) Architectural Terra – flue liners – roof tiles – surface pavers Cotta Concrete Masonry Concrete Block – hollow – solid Special Units – decorative – split faced – faced block Why Masonry vs. Wood Fireproof Durable Long lasting Good compressive strength Low maintenance Immune to termites & rotting No corrosion Brick Sizes Net vs. Nominal – Net - actual size of brick – Nominal - brick + mortar joint Regional Size difference Mortar Joint – joint between bricks – commonly 3/8” – range 1/4” to 1/2” Brick Sizes Brick Dimensions – width x height x length Example – Nominal – Net 4x3x8 3-5/8 x 2-5/8 x 7-5/8 Brick Positions 6 possible positions – – – – – – stretcher shiner header rowlock soldier sailor Methods of Stacking Bricks Joint Terminology Mortar placed between layers of brick/block – made of sand, cement, and lime – strength of mortar bond » (High) M, S, N, O, K(Low) Each row of brick is called a wythe. Two rows of brick is termed two wythe of brick Joint terms – collar, bed, and head Joint Finishes Selected – – – – based on appearance shadow patterns water drainage surface endurance Brick Walls Cavity – space between 2 wythe of bricks – airspace – filled with grout & steel rebar Grout – sand, cement, and small aggregate – sloppy solution poured in cavity Concrete Block Block Dimensions – width x height x length Example – Nominal – Net 8 x 8 x 16 7-5/8 x 7-5/8 x 15-5/8 Concrete Block Also called Molded Concrete Units Materials – portland cement, sand, aggregates (90% by weight) and water Cores – Air spaces in concrete block – Used for reinforcement/insulation Compression strength – 700 to 1800 psi (pounds per square inch) Concrete Block Types Standard (8 x 8 x 16) nominal – Width variations » 4” » 6” » 8” » 10” » 12” Concrete Block Types Sash block also called a Jamb block Width variations – 6”, 8”, 10”, 12” Slot design – slot on end allows for attachment of metal or wood door and windows frames Concrete Block Types Lintel – U-shaped piece for use over windows & doors Width variations – 6”, 8”, 10”, 12” Concrete Block Types Bond block – notch on top to allow for horizontal reinforcing Width variations – 6”, 8”, 10”, 12” Concrete Block Types Cap or paving unit – Used to cap off the open unit at the top of a wall Problems with Masonry Efflorescence – surface discoloration – caused by water-soluble salts in cement which are sulfates of sodium – and caused by insoluble carbonates from continuous water penetration over a long period of time – occurs during high-humidity and lowtemperature conditions – high chance happening with grouted walls Construction Considerations Masonry is poor in insulation (R) value – add rigid insulation or fill with insulation Think Modular – all block and opening width dimensions are multiples of 8” – eliminates cutting – reduces costs Brick Representation in Section Simplest Cavity Detailed Which symbol used depends on office practice and/or detail scale. Block Sections don’t use B - military C-F - supported by various organizations Symbol used depends on scale of detail A - Create – – – – – – – the following details for sheet S-2: 1/S-2 2/S-2 3/S-2 4/S-2 5/S-2 6/S-2 7/S-2 HINT: Look through the class architecture folder again!!!!!!