virtual product model

Virtual Product Development in the SME Market

Enterprise Ireland 26-Apr-2006

Agenda

•

Introduction to MSC.Software

•

Virtual Product Development (VPD)

•

MSC Product Lines

•

Case Studies

•

Conclusions

Agenda

•

Introduction to MSC.Software

•

Virtual Product Development (VPD)

•

MSC Product Lines

•

Case Studies

•

Conclusions

MSC Overview

•

Leading Global provider of

VPD software and services

•

Largest VPD Company

Worldwide

•

Trusted Advisor to Largest

Manufacturing Companies in

The World

•

42 year history in engineering process improvement

•

Broadest set of VPD tools to help you virtually test your products

Industry Experience

Aviation

Aerospace

Truck & Automotive Agriculture,

Construction

Rail

Motorcycles

Defense

Medical Device

Biomedical

Consumer

Products

Shipbuilding

Machinery,

Manufacturing

Industry Sectors

•

De facto standard in

Automotive and

Aerospace

•

Deeply embedded in the engineering processes of every major global

OEM and supplier

•

Multi-Industry

Presence

SERV

8%

Aerospace

Automotive

Heavy

Industry

RESELLERS

11%

Med,Consum,etc

2%

EDU

4%

AERO Com'l

12%

24%

29%

15%

AERO Def

12%

ELECT

7%

AUTO

29% MFG

15%

Aerospace Customers

Automotive Customers

General Industry Customers

Agenda

•

Introduction to MSC.Software

•

Virtual Product Development (VPD)

•

MSC Product Lines

•

Case Studies

•

Conclusions

Business Challenges

Intense global competition

Demanding customers

Fragmented markets

Increasing product complexity

Compressed product cycles

Price and profit pressures

Strict regulatory and liability environments

Systems integration and supply chain issues

Skyrocketing costs of testing & physical prototyping

Virtual Product Development

Functio n

Faster

Innovation

Distributed

Teams

Lower

Risk

Higher

Profits

Form Fit

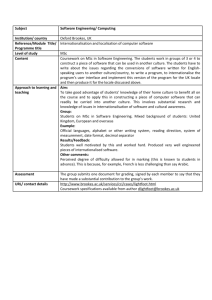

Virtual Product Development Vision

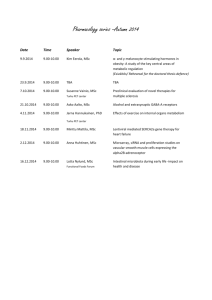

VPD Product Development Process

Concept & Specifications

Virtual Product Model

• Virtual Build: model synchronized on a regular basis and assembled in a full virtual product model

• Virtual Test: virtual product is repeatedly tested over the complete range of inter-related performance specifications

• Virtual Review: “virtual test” results shared with global design team for review and design trade-off decisions

Components & Subsystems

Virtual Product Development Process

- Test - Review Cycle

Virtual Build:

Model synchronized on a regular basis to a central Simulation Data Management portal

Incorporates components and subsystems from design team (including supply chain)

Close integration with established CAD tools and processes

Done early in the design process; done often.

Results in a detailed virtual product model that is used to perform virtual testing

Virtual Product Development Process

Build Test - Review Cycle

Virtual Test:

Duplicate your current physical testing protocol for model validation and test correlation

Enables sophisticated testing methodologies

(stochastics, robust design) based on ability to run multiple tests quickly and inexpensively

Physical testing is more strategic, less late-stage troubleshooting

Build insight to product performance, test more design variations and innovations and make better design and engineering decisions

Standard Product Tests and

Physical Test Correlation

Virtual Product Development Process

Build - Test Review Cycle

Virtual Review:

Review results and key issues from virtual tests

Component and subsystem teams can assess how their design affects overall performance

Evaluate many design alternatives and usage scenarios in rapid cycles

Use stochastic and design of experiments methodologies based on batches of tens or hundreds of simulations

Make better design trade-offs and more timely decisions

System-Level Design Review

Agenda

•

Introduction to MSC.Software

•

Virtual Product Development (VPD)

•

MSC Product Lines

•

Case Studies

•

Conclusions

MSC Product Lines

concept design test make maintain

Design level

Simulation

Solvers

Detailed

Simulation

Process Management

Enterprise PDM System

MSC Product Lines

SimDesigner CAD embedded VPD environment for designers

SimOffice

SimManager

Unified framework for integrated VPD modelling and simulation

Environment for automating and managing collaborative VPD

SimDesigner for Catia V5

Only All-In-One Simulation for V5

CAD Embedded •

The power of MSC solver technology

Nastran

Adams

Marc

•

The power of CATIA

Native Geometry

Integration

•

Data Management

Process control

PDM correlation

SimDesigner Characteristics

•

Performance

CAD Embedded Simulation

•

Fast, responsive and robust simulation within the CAD environment, improving collaboration between engineers and designers

•

Ease of Use

•

Consistent user interaction model in CAD GUI

•

Integrated model database, fully generative, improves productivity by reducing need for model preparation

•

Based on Proven Technology

• Create from components used in MSC’s products today, giving designers access to world-class simulation tools

•

Integrated in Overall VPD strategy

•

Make better design decisions and avoid rework with up-front simulation

Model preparation and results visualisation

Core Products

SimOffice Core Products

SOFY

ADAMS

Multi-body dynamics, kinematics

Patran EASY5

Control systems

Nastran Dytran

Linear statics and Dynamics

Crash, impact, drop test

Marc

Nonlinear

SimOffice Characteristics

•

Performance

Integration & Interoperability

•

Fast, responsive and robust

•

Capacity

•

Able to handle extreme model sizes

•

Scalable

•

From conceptual to detailed simulations, within an integrated environment

•

Across multiple disciplines and VPD attributes

•

Ease of Use

•

State-of-the-art user interface

•

Consistent user interaction model across all products

•

Customization and Extensibility

•

Customization, extension and process capture built in to the architecture

•

Based on Proven Technology

• Create from components used in MSC’s products today

MSC.SimManager

“The data generated by (CAE) simulation itself is useful, but the real value is the ability to move that information around and have it where and when you need it.”

Charles Foundyller

CEO, Daratech

MSC.SimManager Characteristics

Simulation Process and Data Management

•

Increase VPD Process Effectiveness

•

Synchronize simulation and design, consolidate and track models and results

•

Increase VPD Process Efficiency

•

Automation, knowledge capture and reuse, transparent data access, global communication, facilitate trade-off studies and decision making

•

Model and Knowledge Reuse

•

Consistent access and management of data, models, testing and results, data mining

•

Ease of Implementation and Compatibility

•

Leverage existing investments in software and PLM infrastructure

•

Based on Proven Technology

•

Operates with industry standard infrastructure components

World Class Simulation Technologies

The most complete and powerful range of simulation tools available:

Analyze and understand all aspects of product performance characteristics

Address the complete Product Lifecycle and Product Development process:

MSC.MasterKey Licensing System concept design test manufacture

Services Capabilities

Knowledge Capture and

Process Automation

Digital Mockup and Functional

Virtual Prototyping (Enterprise

Focus)

Product and Simulation Data

Management

(PDM/SimManager)

Funded Software Development

Industry Specific Services

Aerospace, Automotive,

Shipbuilding, Biomed,

Consumer Goods, etc….

Engineering Analysis and

Simulation Services

Software Support and

Technical Training

On-Site Consulting

On-Line Services

Agenda

•

Introduction to MSC.Software

•

Virtual Product Development (VPD)

•

MSC Product Lines

•

Case Studies

•

Conclusions

Case Study: Caterpillar

Business: Hydraulic Systems for

Mobile Equipment

Challenge: Meet increase in design requests while lowering costs and improving quality

Solution: Partnered with MSC

Services to assess, design and implement a reformulation of the design process as part of their Six-Sigma program

Value: Achieved significant improvement in overall cylinder design time

“Our new custom software environment has streamlined the cylinder design request process, reduced cylinder design time allowing us to process more requests, and automated our FEA process.”

Jason McIntyre, Black Belt, Caterpillar H&HS

Case Study: Komatsu

Business: Industrial machinery manufacturer

Challenge: Predict off-road vehicle body structure behavior on a test track

Solution: ADAMS vehicle model including NASTRAN flexible frame

Value: Predicted dynamic stress of vehicle on test track.

Rapidly evaluated effect of design changes

Case Study: GE Transportation

Business:

North American locomotive manufacturer

Challenge:

Investigate the effect of wheel back-to-back distance on locomotive stability and safety

Solution:

Parametric model built in ADAMS/Rail and run through standard suite of maneuvers

Value:

Met customer critical-to-quality requirements on locomotive design

“We have done a lot of wonderful work using ADAMS.

Jingjun Zhang

Control and Auxiliary Systems

Case Study: Leyland

Business: Truck manufacturer

Challenge: Assess ride behavior of trucks earlier in design cycle

Solution: VPD solutions from

MSC.Software

Value: Adjust truck-specific factors like cab suspension, chassis flexibility and payload to optimize ride

Case Study: Orion Bus

Business: Bus Manufacturer

Challenge: Develop a Bus in 18 months

Solution: Partner with

MSC.Software for multi-disciplinary software and services

Value: Reduced testing and time to validate vehicle for durability, safety, comfort, vehicle dynamics, and service life

Case Study: Honda Motorcycle

10

Business: Motorcycle OEM

Challenge: Optimize the straight running stability and turning performance of a motorcycle

Solution: Apply virtual tire model using MSC.ADAMS

Value: Good correlation with physical test and the ability to easily optimize tire properties

0

1.5

-10

2.0

2.5

A1(caster angle 25.7°)

A2(caster angle 23.7°)

A3(caster angle 21.7°)

Time(sec)

Stability improvement

Case Study: Sanyo

Business: General machinery manufacturer

Challenge: Reduce vibration of washing machine

Solution: Built virtual washing machine with ADAMS; used Taguchi Method to optimize performance

Value: Achieved 70% reduction of machine vibration

“ More and more What-If studies with

ADAMS virtual prototype are the key for our design optimization.”

--Mr. Takao Kinouchi, Chief Researcher,

SANYO Electric Co. Ltd

Before After

4,374 cases

Reduce

35%

60 cases

Reduce

70% few

Original

With

Simulation

With simulation +

Taguchi Method

Case Study: Grundig

Business: Consumer Electronics

Television division

Challenge: Reduce shipping damages through better packaging

Solution: FEM based deformation analysis

Value: Reduce shipping damages with robust packaging

Reduction of shipping cost with reduction of dimensional weight

Deliver products to market earlier

Case Study: Prothotics Corporation

Business: Orthotic Inserts

Challenge: Too many variables to consider. Orthotics unaided by the computer are entirely subjective

Solution: Used simulation to study kinematic and kinetic effects of an orthotic device

Value: Visualized the effects of various orthotic insert designs to find the best for each patient

“This approach has the ability to revolutionalize the way we treat lower-limb pain, disability, and rehabilitation.

We’ve already used the software to help hundreds of patients, and have plans to expand operations to clinics in other cities.” -- Brent Konantz

President, Prothotics

Biomechanics

Research Group Inc. ®

Case Study: Guidant

Business: Vascular Devices

Challenge: Confidence that soft tissue will respond safely to a device

Solution: Using simulation to understand and visualize stent / soft tissue interaction and performance

Value: Increased efficiency in stent design; accelerated innovation

“We need to model the soft tissue to increase our understanding of how the tissue responds and interacts with a device. Finite element analysis (FEA) software provides the evaluation tool to do this.”

-- Chris Feezor, Guidant

Case Study: Xtent

Business: Coronary Stents

Challenge: Accurately simulate the behavior and performance of the stent structure

Solution: simulations

MSC.Software Services ran in-depth computer of stent

Value: stress

Simulation study reveals potential problems with deflected geometry or levels

“We are very pleased with all the work that MSC.Software has performed to date. We shall definitely be back for followup simulation needs. Thanks for a job well done!”

-- Stephen Kao

Sr. R&D Engineer, Xtent

Agenda

•

Introduction to MSC.Software

•

Virtual Product Development (VPD)

•

MSC Product Lines

•

Case Studies

•

Conclusions

Conclusions

•

Manufacturers face daunting challenges today in many aspects of new product development

•

Virtual Product Development approach will significantly improve new product development processes, reduce risk, reduce costs, increased profitability and customer loyalty

•

MSC.Software is the industry leader and partner of choice for over 10,000 successful manufacturing companies

•

Proven and wide product portfolio that supports all industries and manufacturers

Contact Details

•

Ian Tasker

•

Account Manager

• ian.tasker@mscsoftware.com

•

+44 151 350 1307

•

Peter Roberts

•

Manufacturing Sales

• peter.roberts@mscsoftware.com

•

+44 151 350 1303