SCM - WordPress.com

advertisement

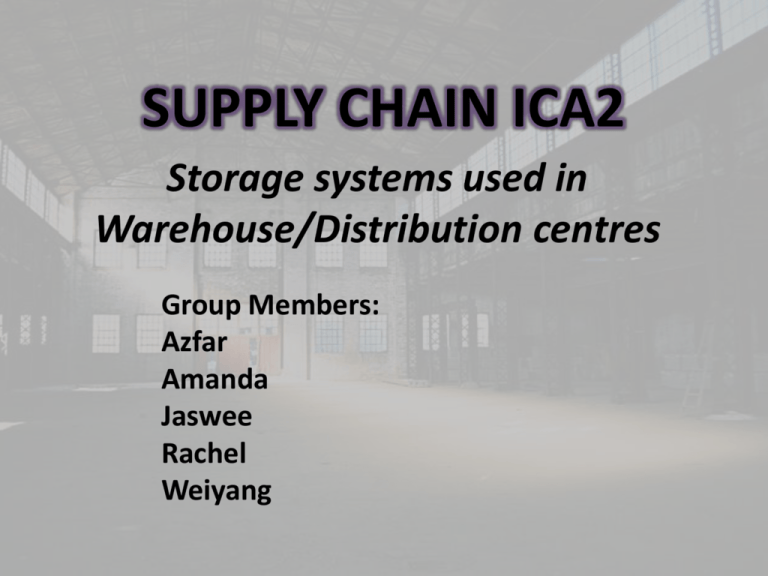

SUPPLY CHAIN ICA2 Storage systems used in Warehouse/Distribution centres Group Members: Azfar Amanda Jaswee Rachel Weiyang WAREHOUSE • Stores products at and between point of origin and point of consumption. • Provides the desired service level for customers in a cost-effective way. Distribution Centre • Building, structure or group of units used to store goods and merchandise that are to be redistributed to retailers, to wholesalers or directly to consumers. • Usually thought of as being "demand driven". Uses of Warehouses and Distribution Centre • Manufacturing Support: Hold receipts of shipments such as raw materials and automobile parts from suppliers. • Product Mixing: combination of various products that form an entire product line and are produced by different plants. Uses of Warehouses and Distribution Centre • Outbound Consolidation: Small load shipments from a number of manufacturing plants transported to the consolidation warehouse. • Break-Bulk: Receives large shipment from manufacturing plant. When these shipments arrive, they are broken down into smaller shipments. Types of Storage System in Warehouse and Distribution Centre • Block Stacking: Storing large quantities of palletized or boxed products on top of each other in stacks without racks used. • Racking: common technique, pallet racking utilizes racks so that goods can be stored in multiple levels above the ground. Types of Storage System in Warehouse and Distribution Centre • Bin-shelving: Store small parts in individual compartments adding to organization of the operation. • Mezzanine storage systems: Structural, roll formed, and rack or shelf-supported and generally made from steel, fibreglass, or aluminium. Automated Storage and Retrieval System [ASRS] • System that utilizes computers to store and recall materials by storage location. • Computer-controlled, it requires less manpower. • Expensive to install than other storage systems, plus it involves high maintenance costs relating to the ASRS operation. Warehouse Management System [WMS] • Aims to manage information transfer into an integrated process that drives warehouse operations and efficiencies. • Benefits: Helps to reduce the dependencies on direct labour practices, resulting in reduced training costs and lower error rates. Ways to store products Randomized Storage/Floating Slot Storage • Items of the same height grouping are stored together regardless of their uses, to achieve maximum storage density and the highest degree of storage flexibility. • Only works in a computer-controlled environment. • Requires lesser storage space. Dedicated Storage • Storage policy in which a warehouse located is dedicated to house a specific Stock Keeping Unit. • Stored in the same locations and efficient space is always available for all items in replenishment batches. • High space requirements and consequent low space utilization. Storage by Complementary • Placed in the same area that results in more efficient use of space and more efficient material handling. • Storing them too close together might result in order picking and shipping errors. • High cost as the layout needs to be precise. Storage by Popularity • High turnover items should be located as close as possible to the point of usage. • By storing the popular items together, items still have to be sorted into orders which require time and may also lead to error. • Helps save cost, as it helps maximises space and high turnover items can be easily accessed. Storage by Compatibility • Practically located next to each other. • Contact between certain individual harmless materials, can result in extremely hazardous reactions or product damage, when placed together • High cost, as the warehouse layout needs to be precise